our mining machinery

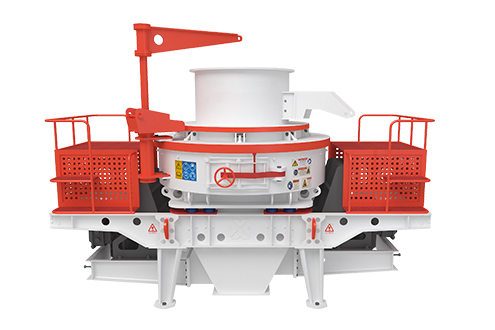

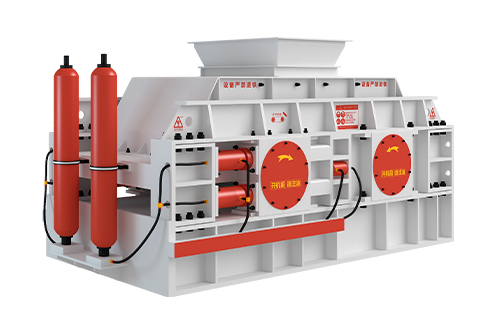

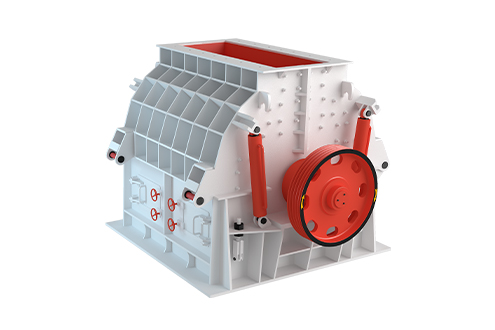

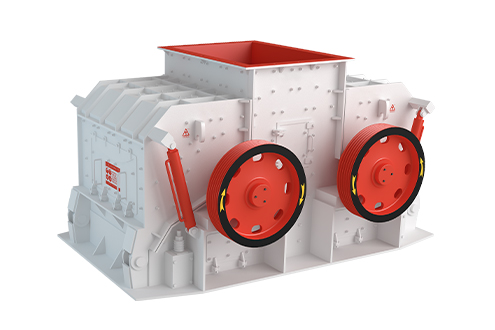

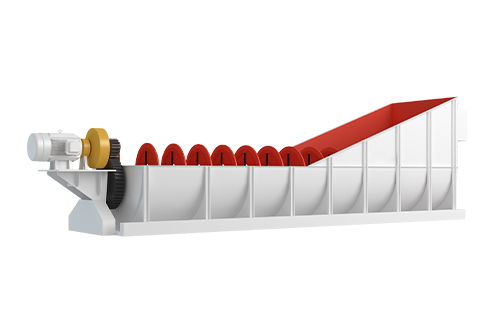

Sand Crusher

Sand crushers, also known as sand making machines, are used to produce high-quality manufactured sand from hard rock, pebbles, or waste concrete. These machines are essential for addressing the shortage of natural river sand and ensuring consistent particle shape and gradation. Vertical shaft impact crushers, sand making rod mills, and fine crushers are commonly used in this category. Sand crushers are widely applied in modern construction materials, especially in concrete, asphalt, dry mortar, and prefabricated building materials. They offer advantages such as better particle shape, high output, low operational cost, and environmental compliance. These machines are indispensable in high-rise buildings, expressways, hydropower projects, and commercial concrete plants.