Introduction

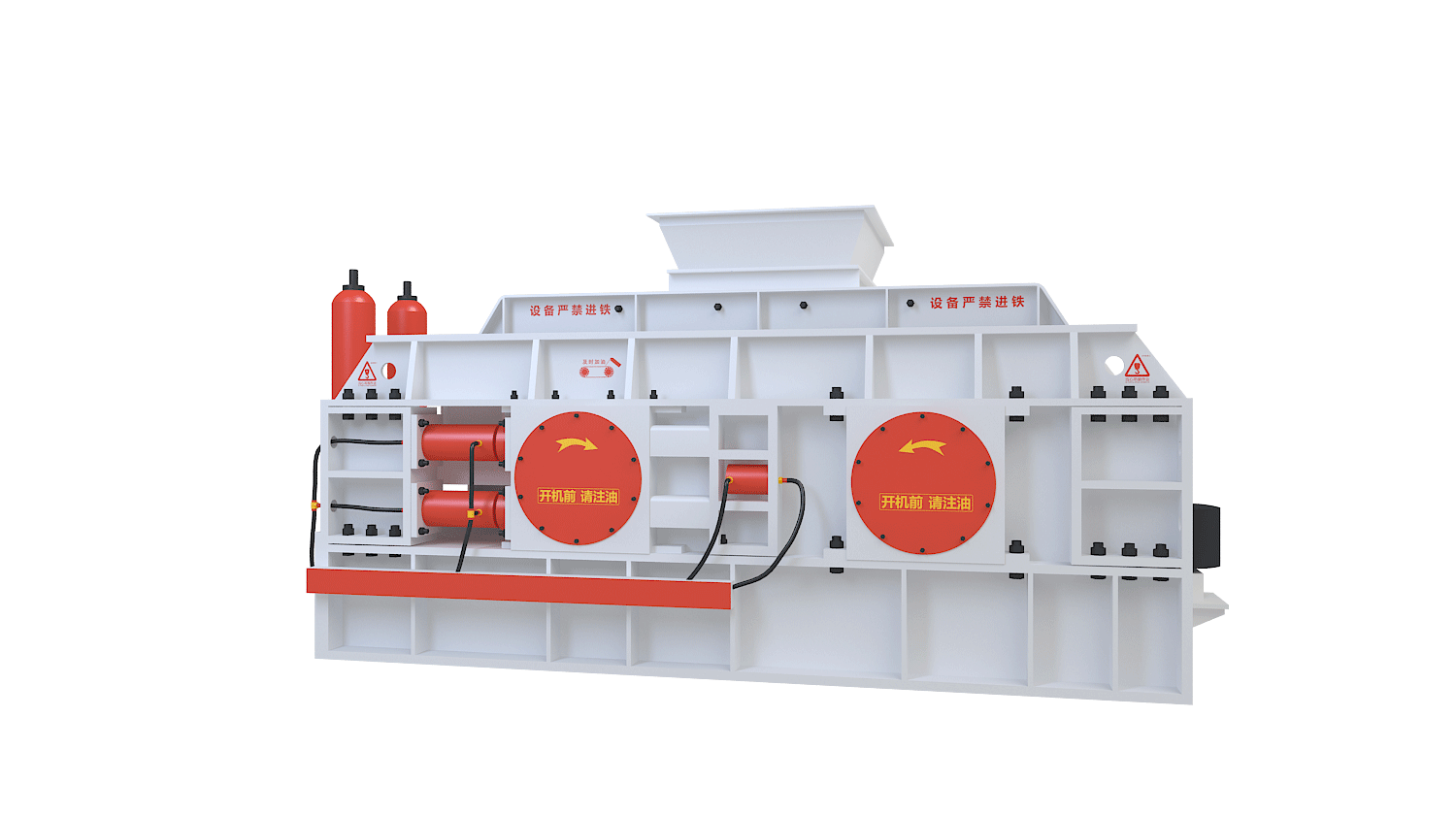

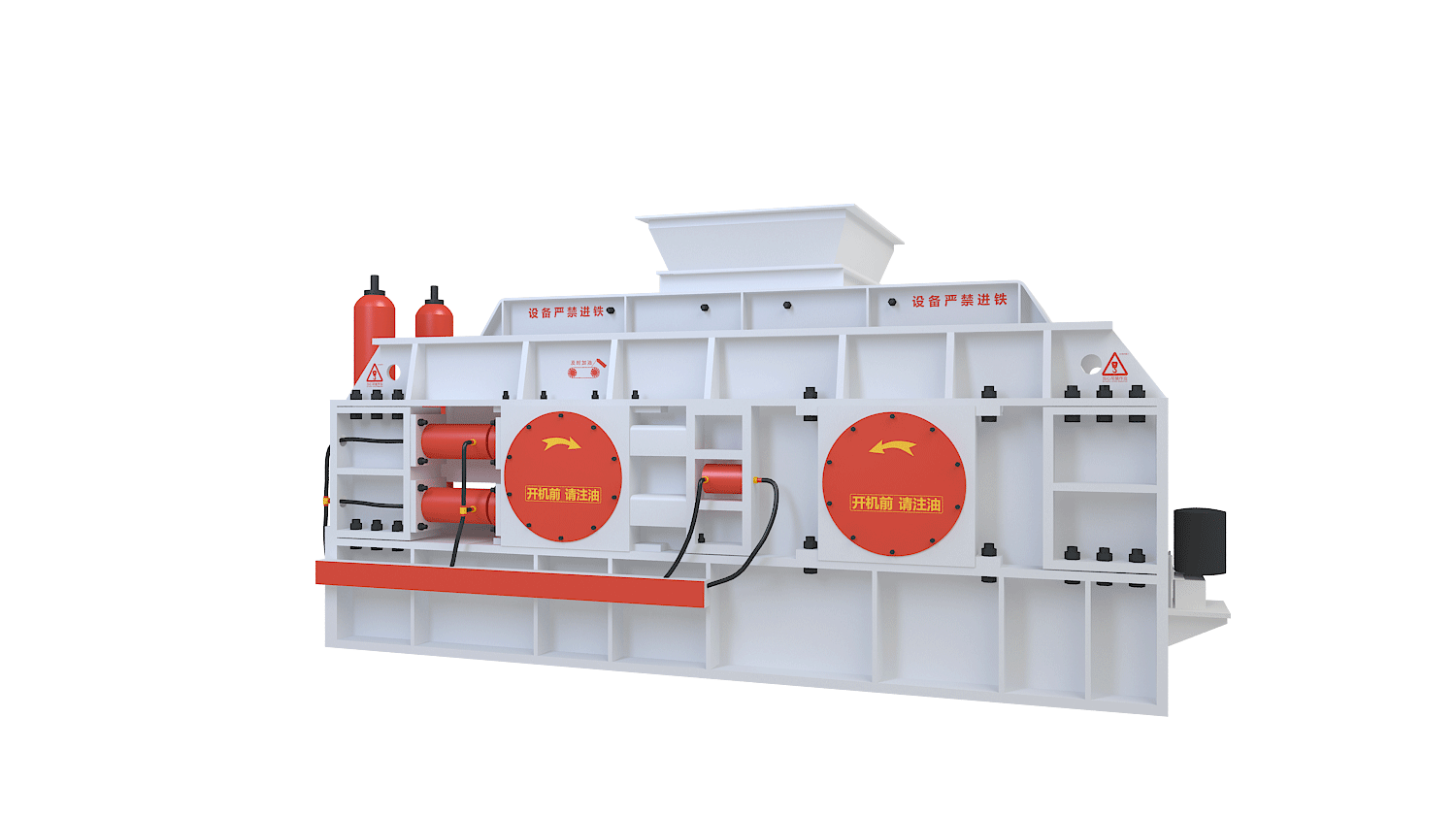

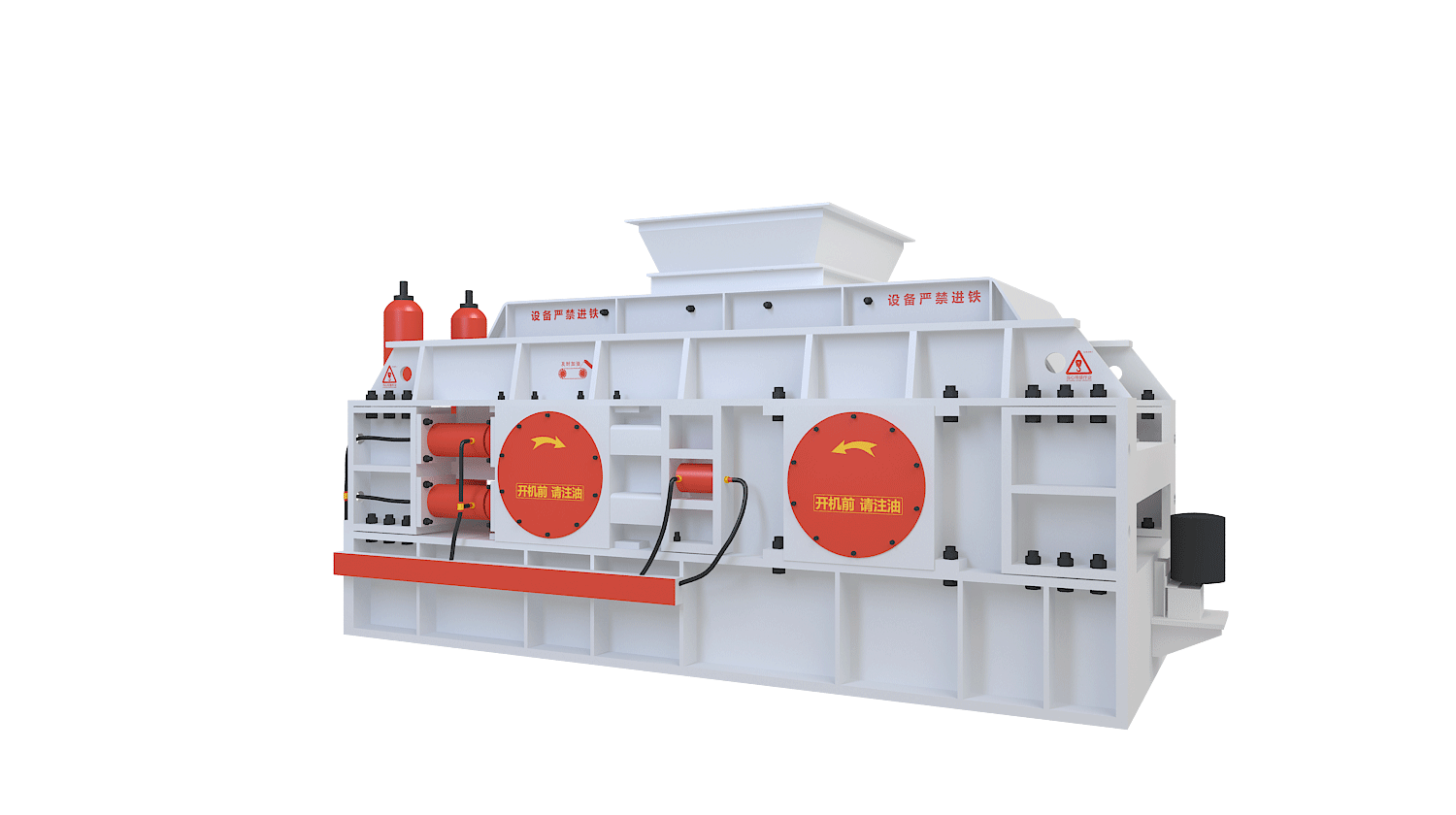

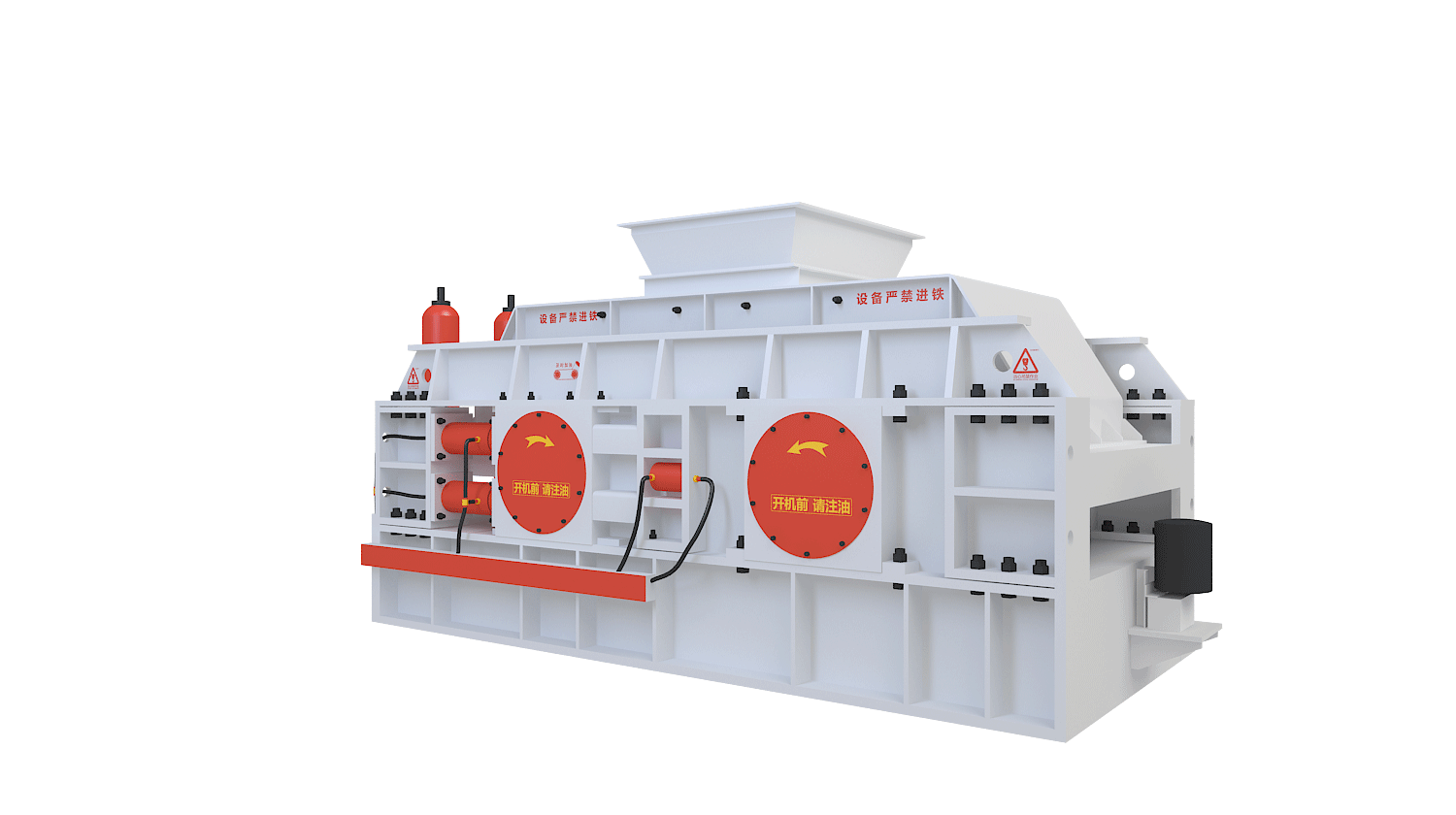

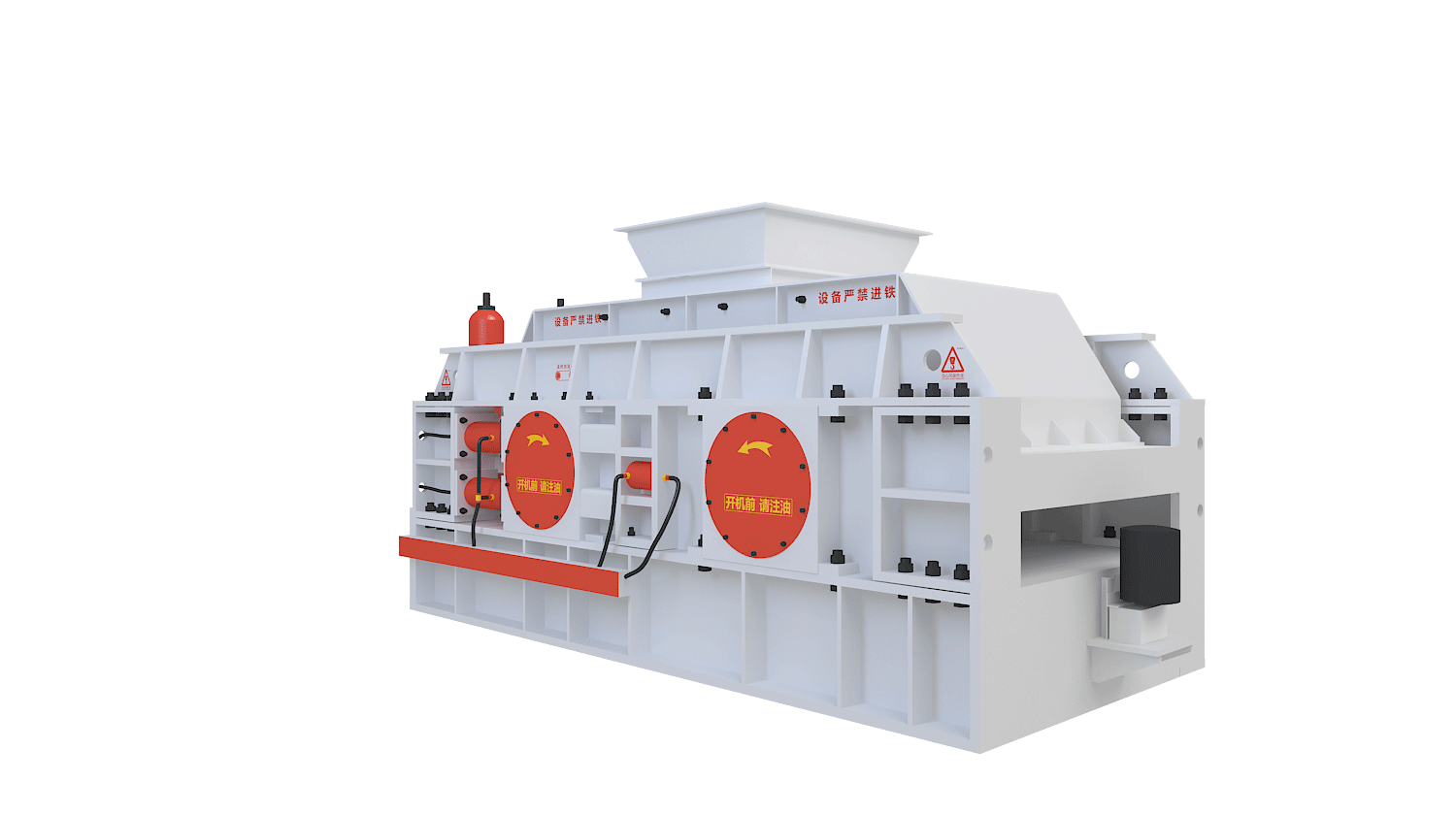

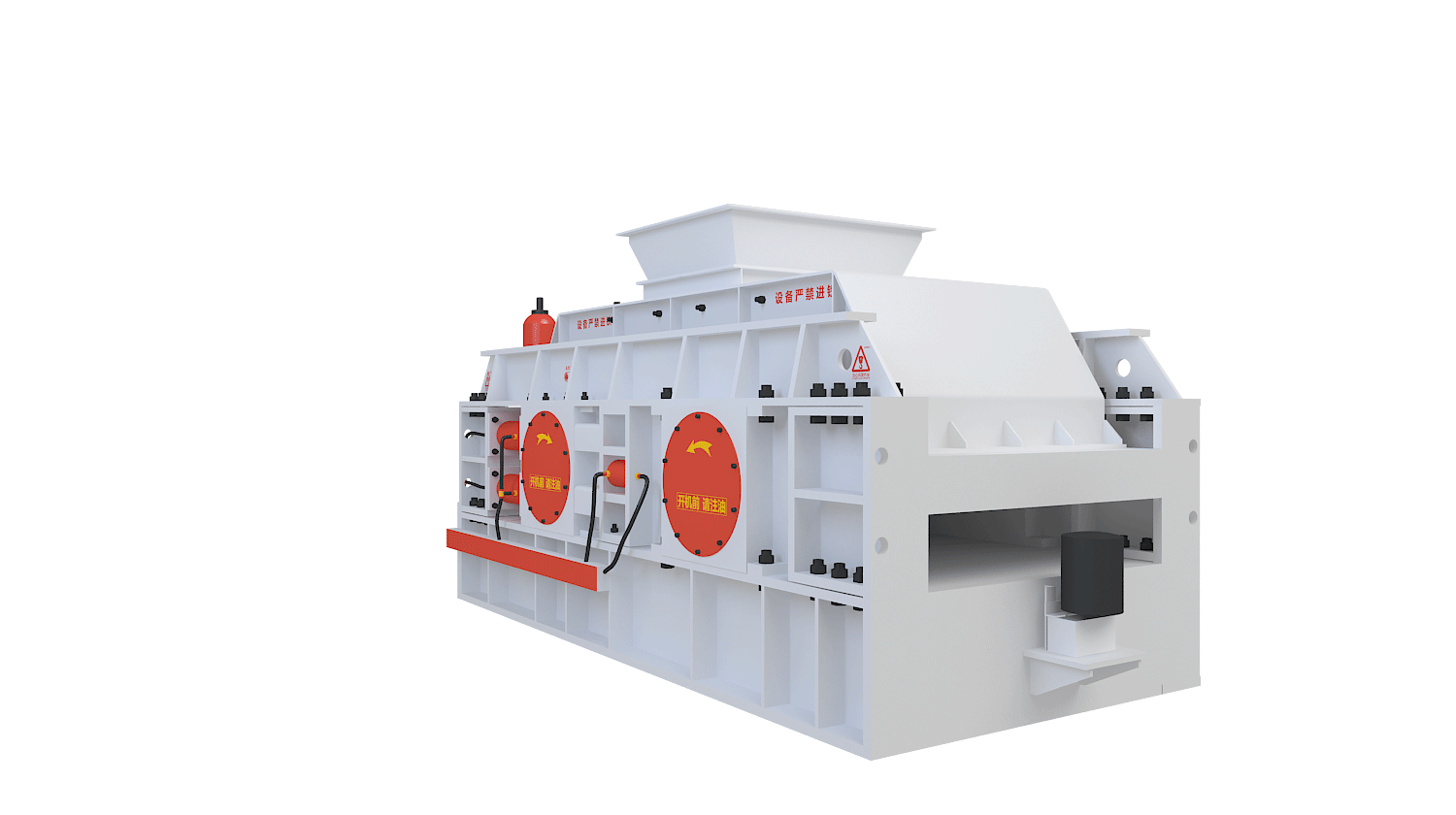

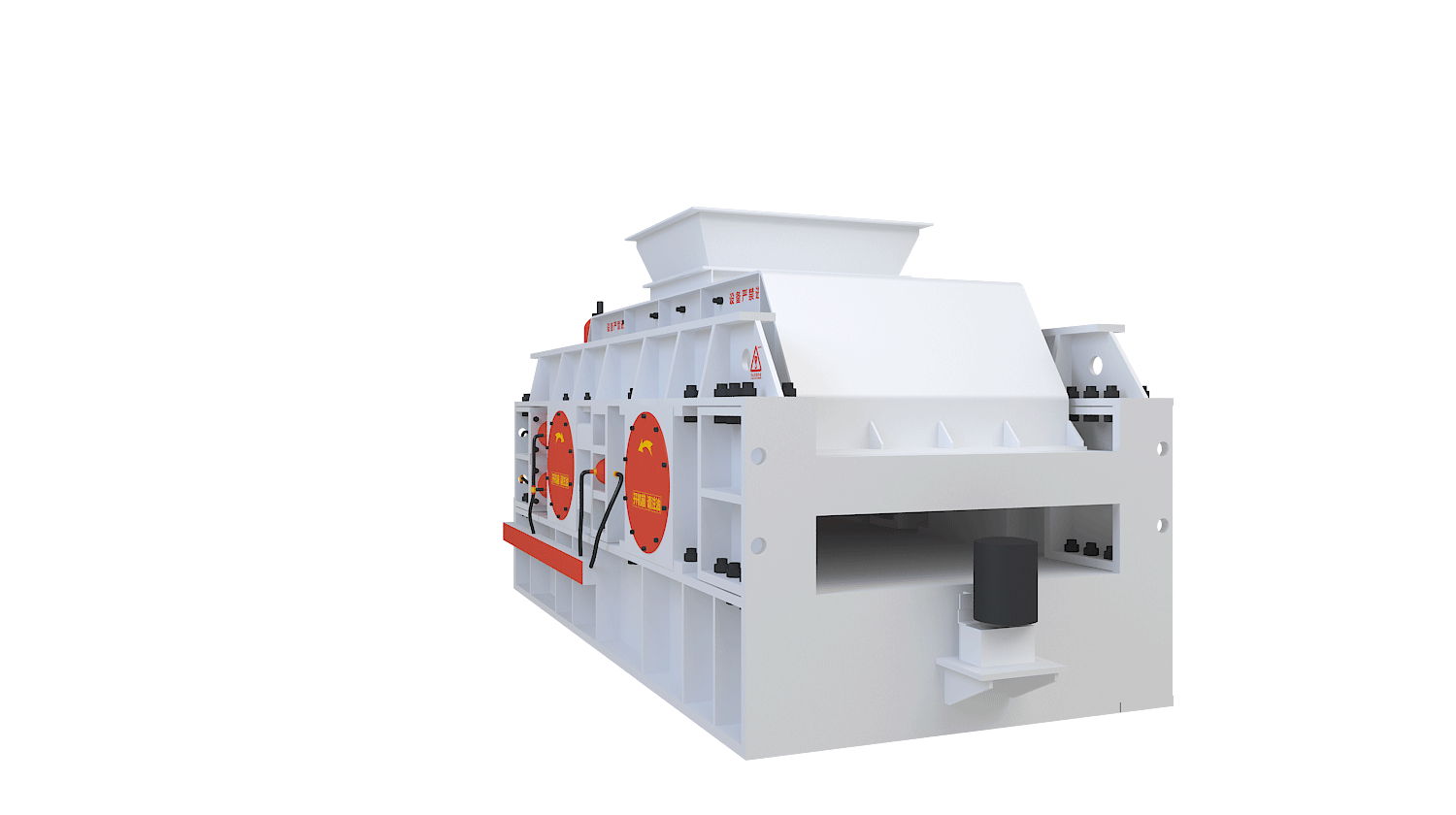

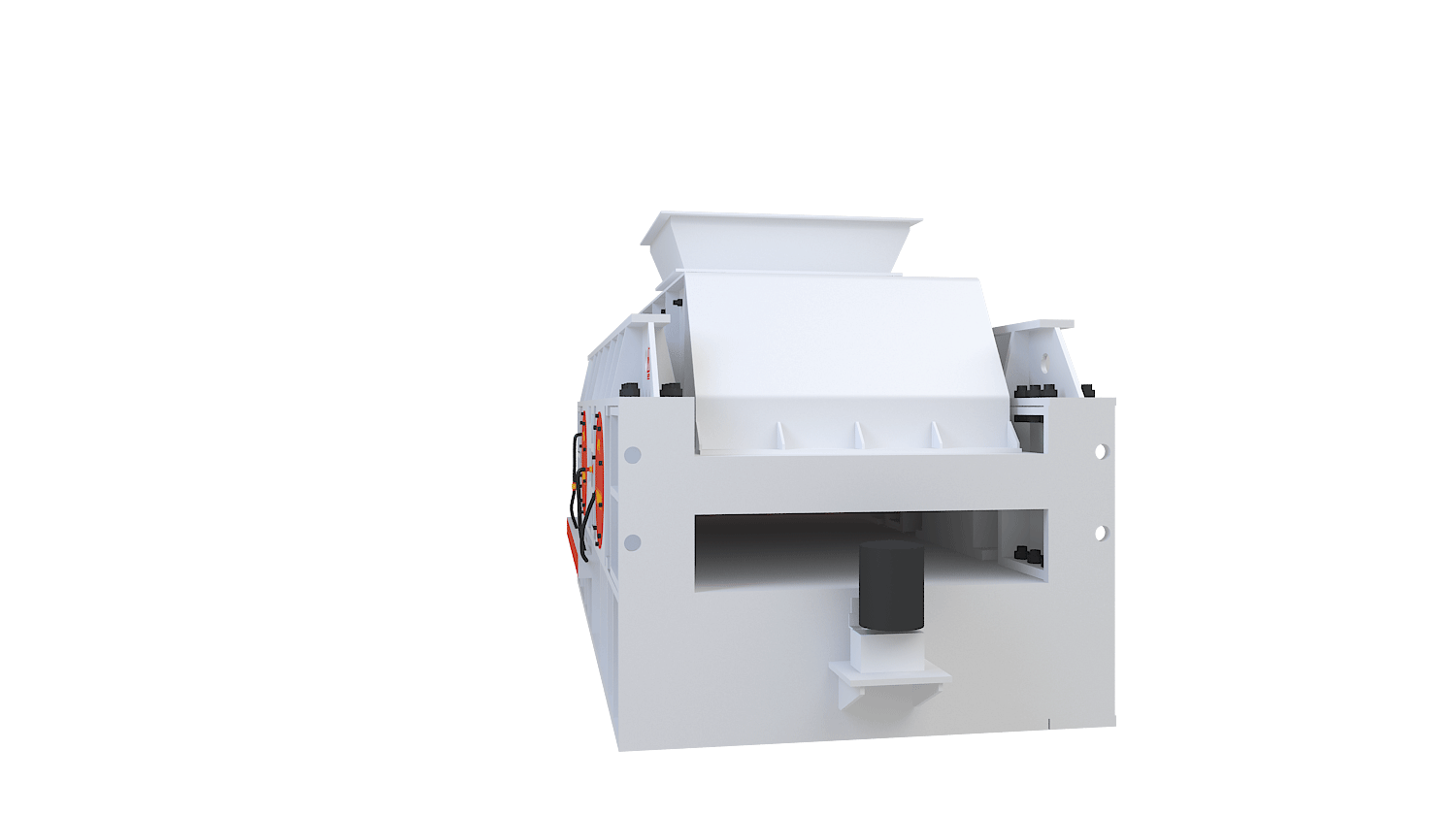

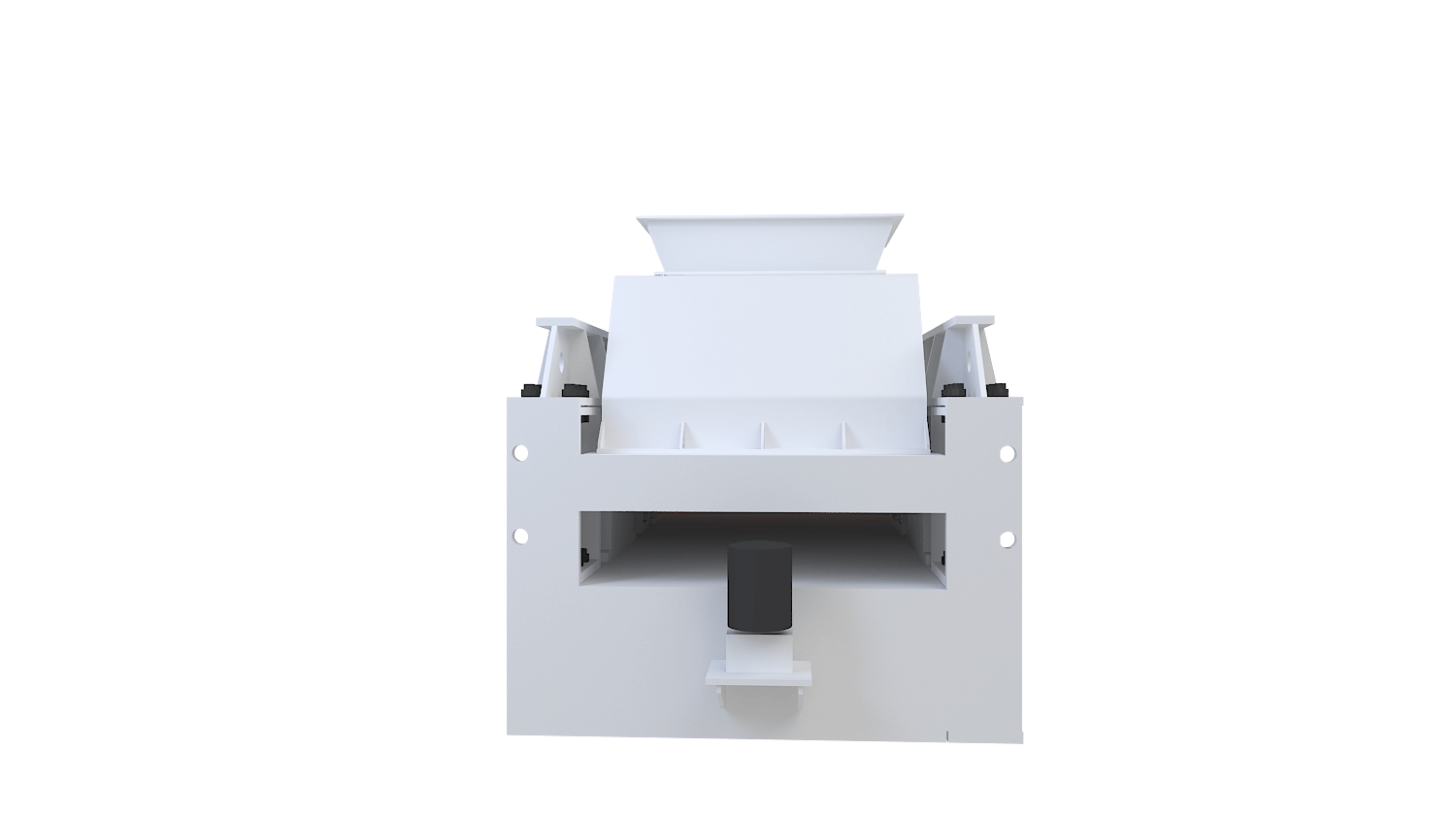

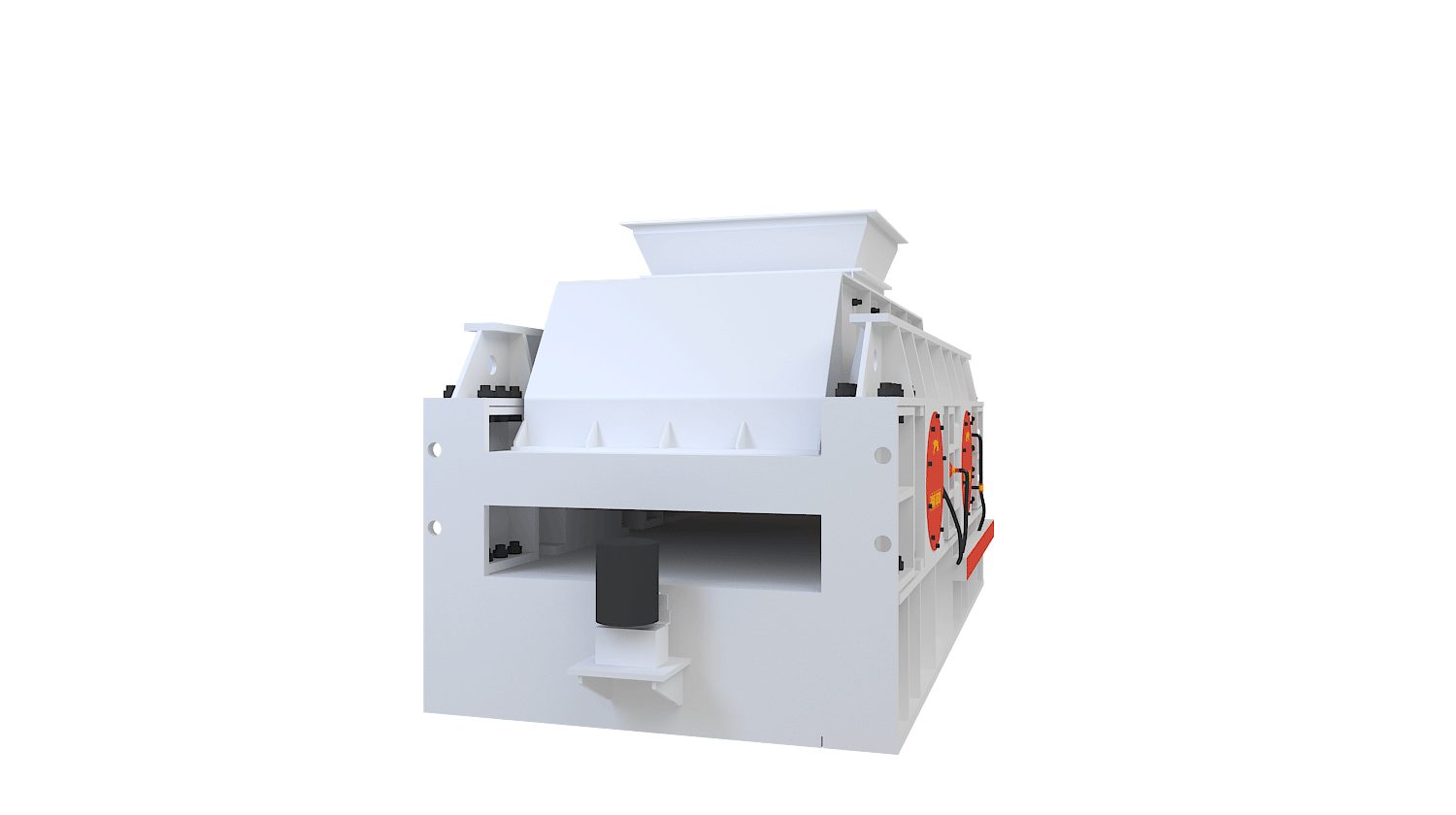

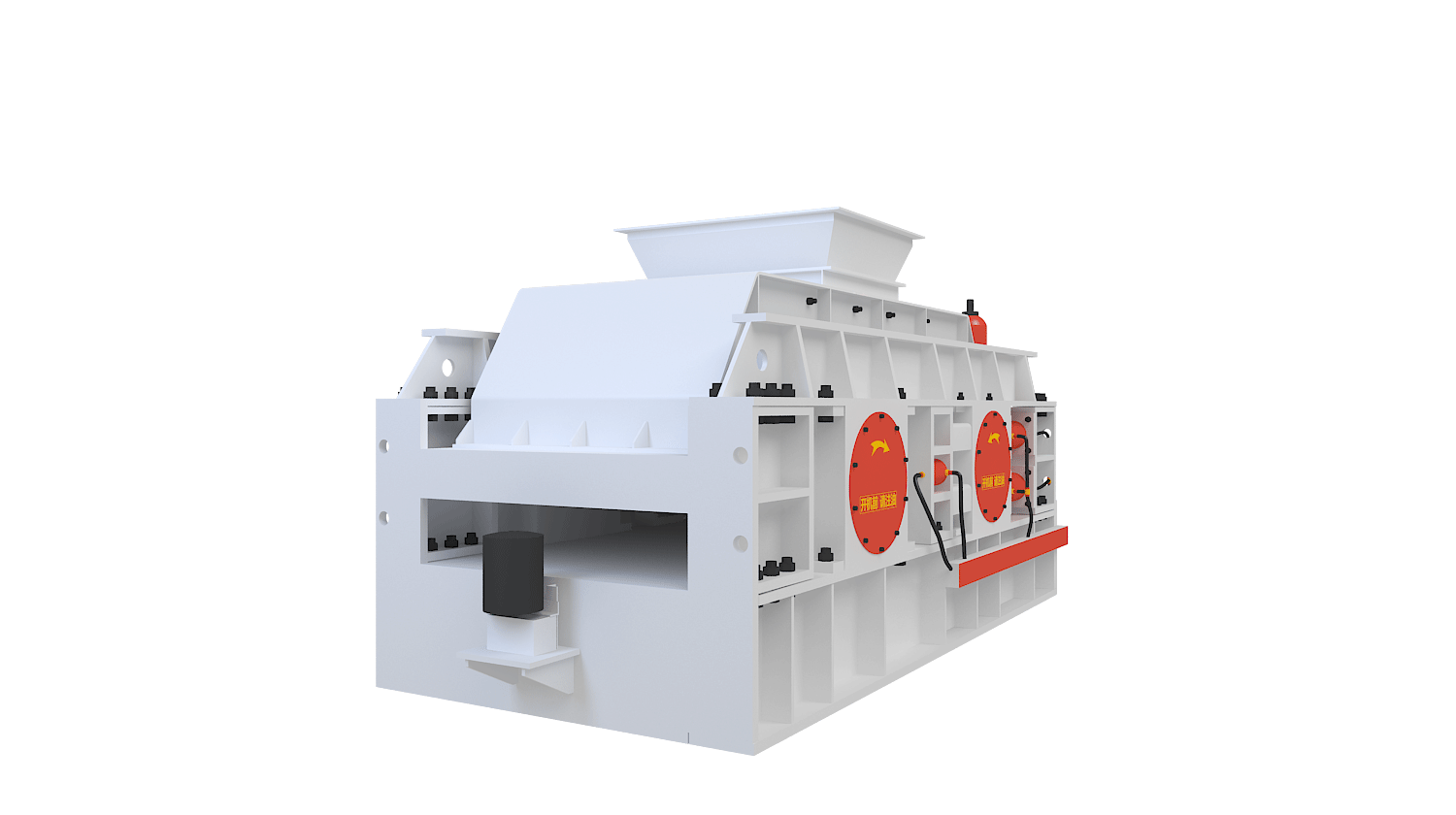

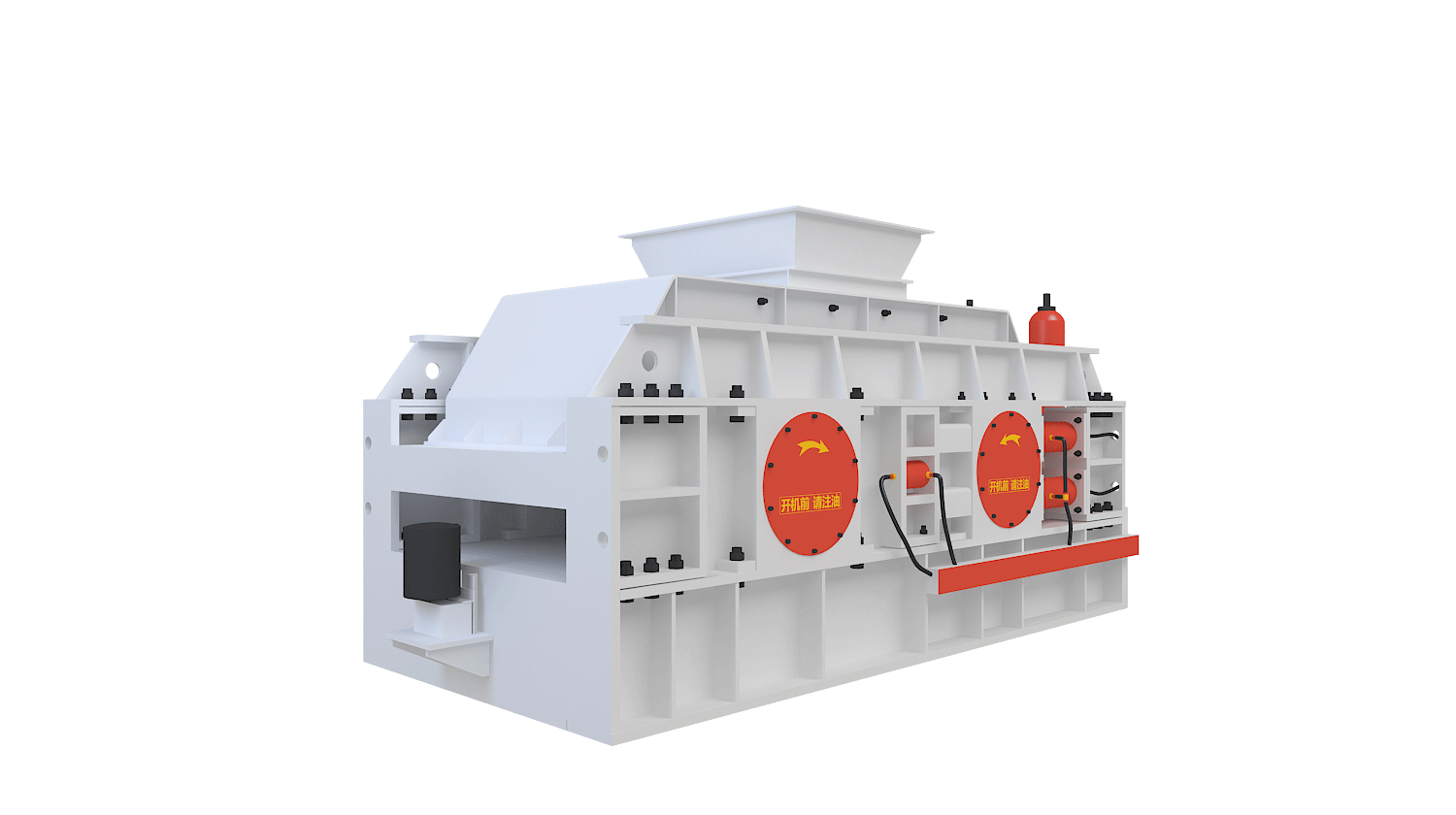

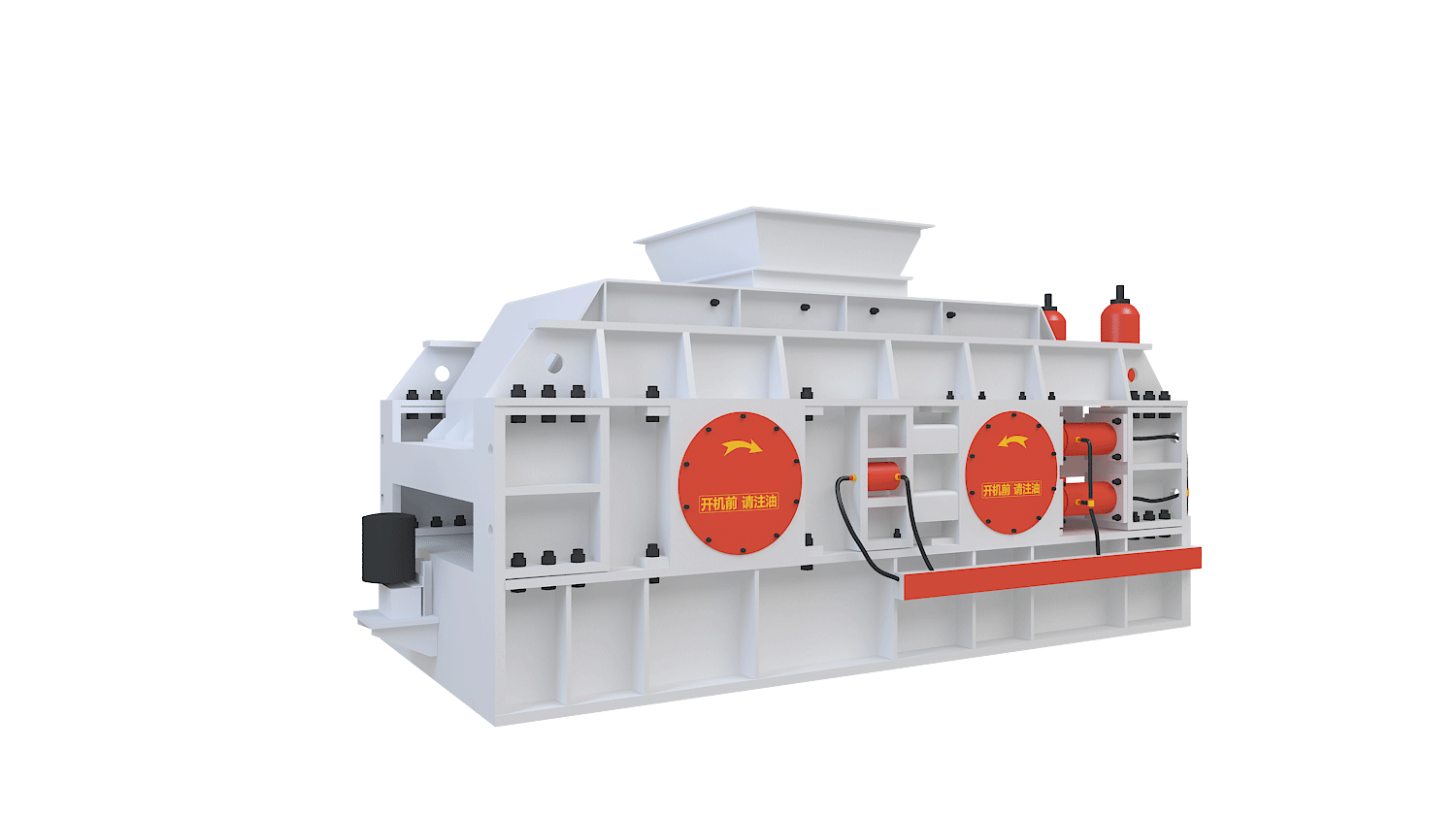

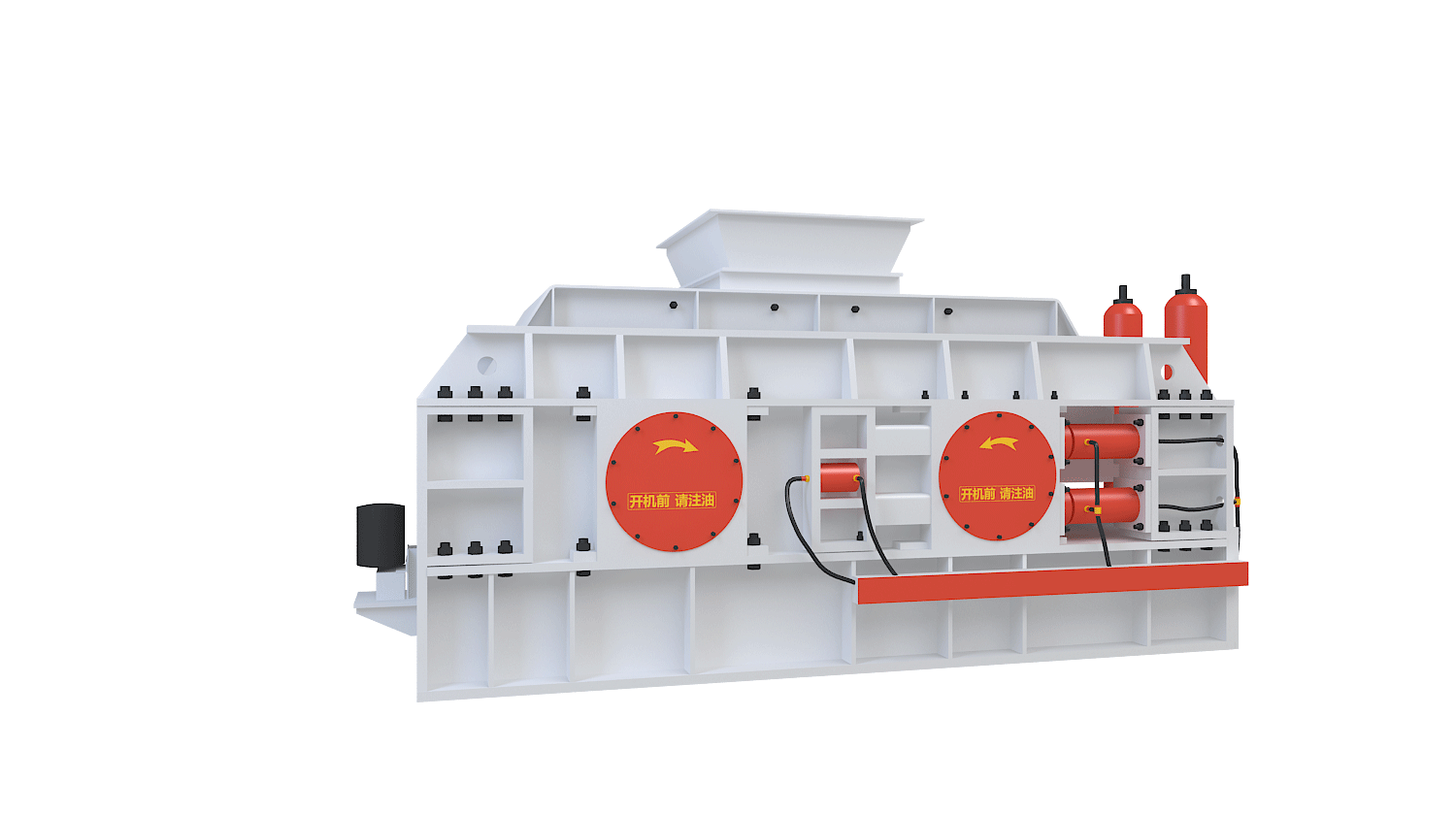

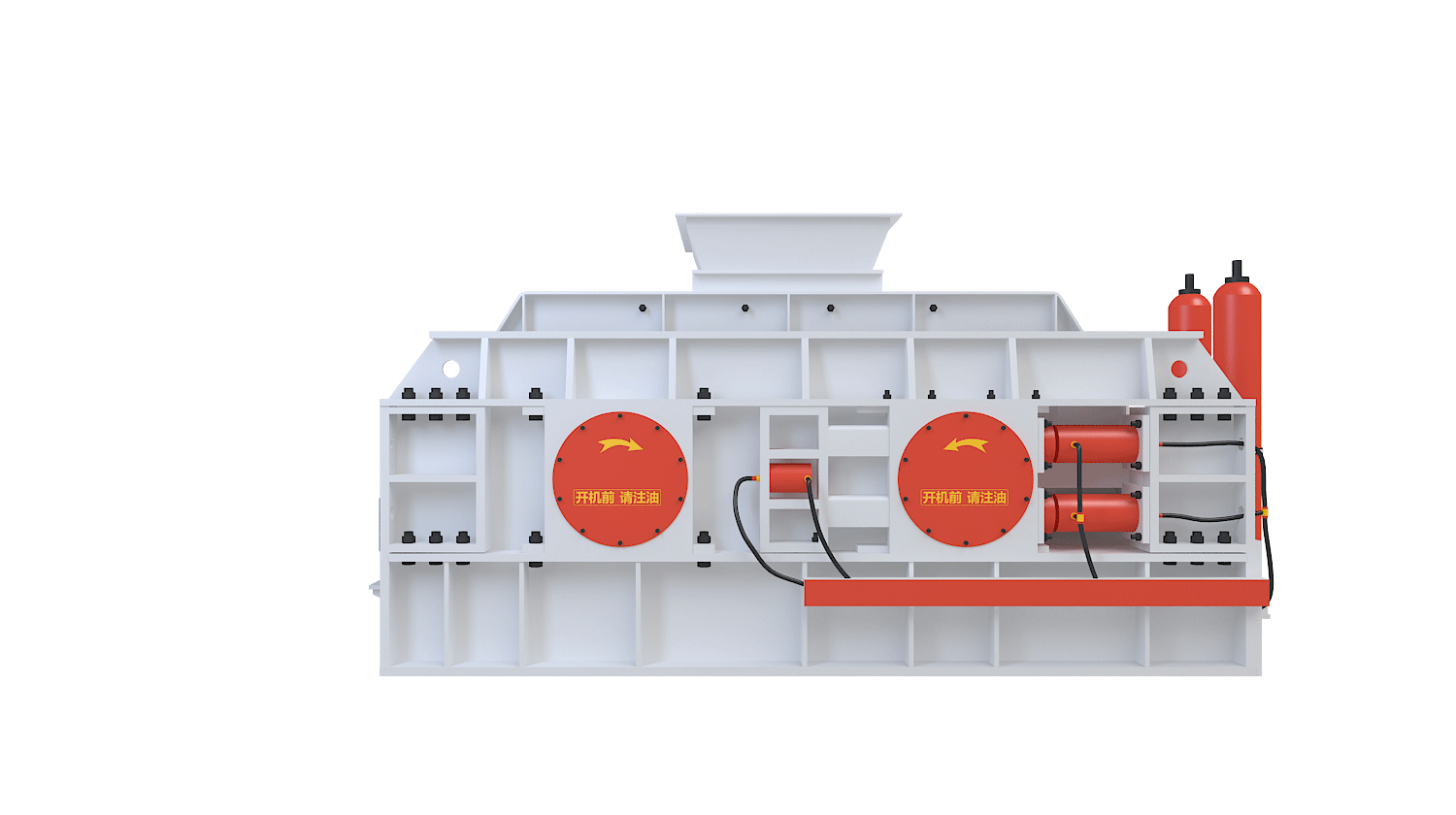

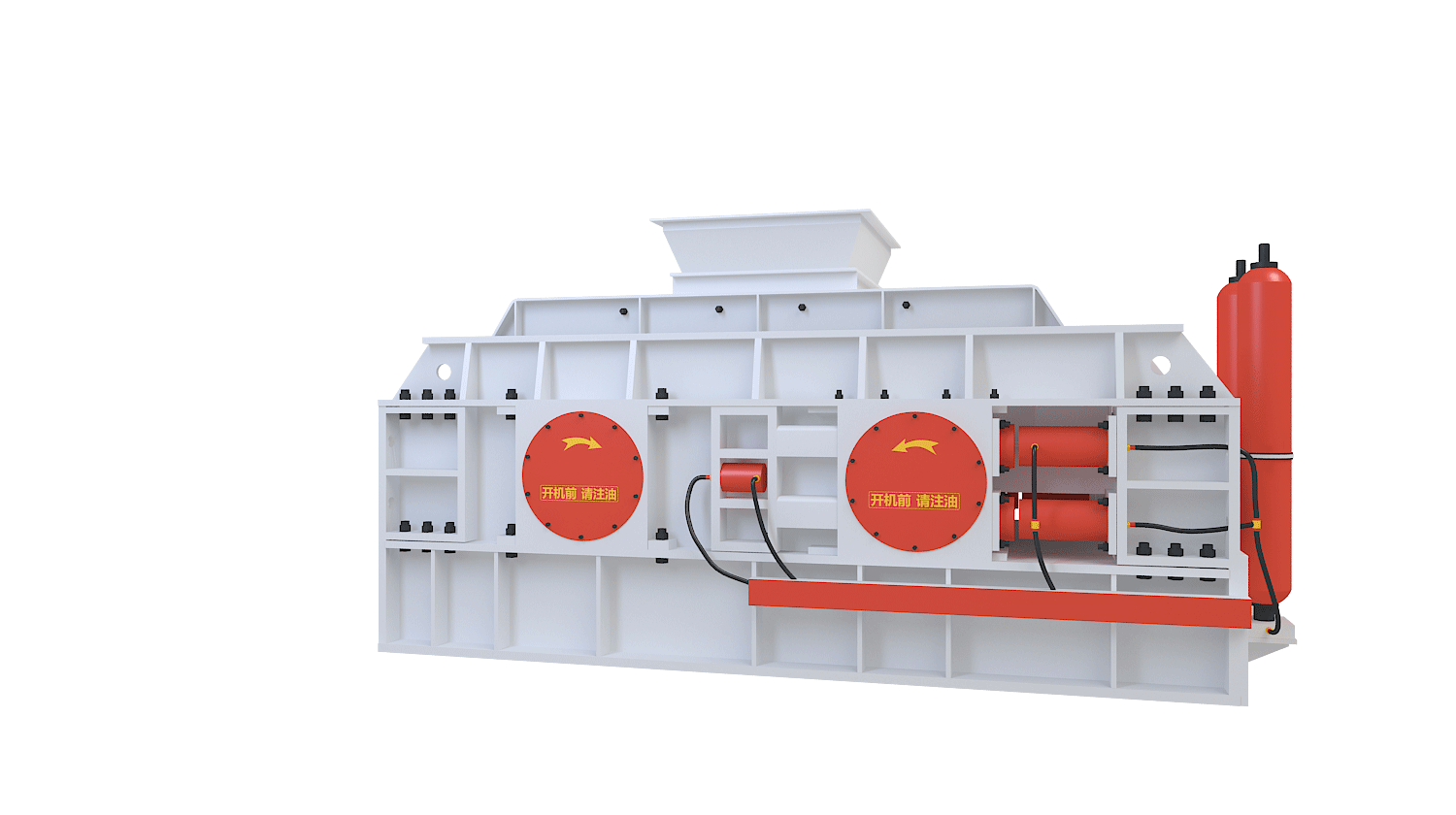

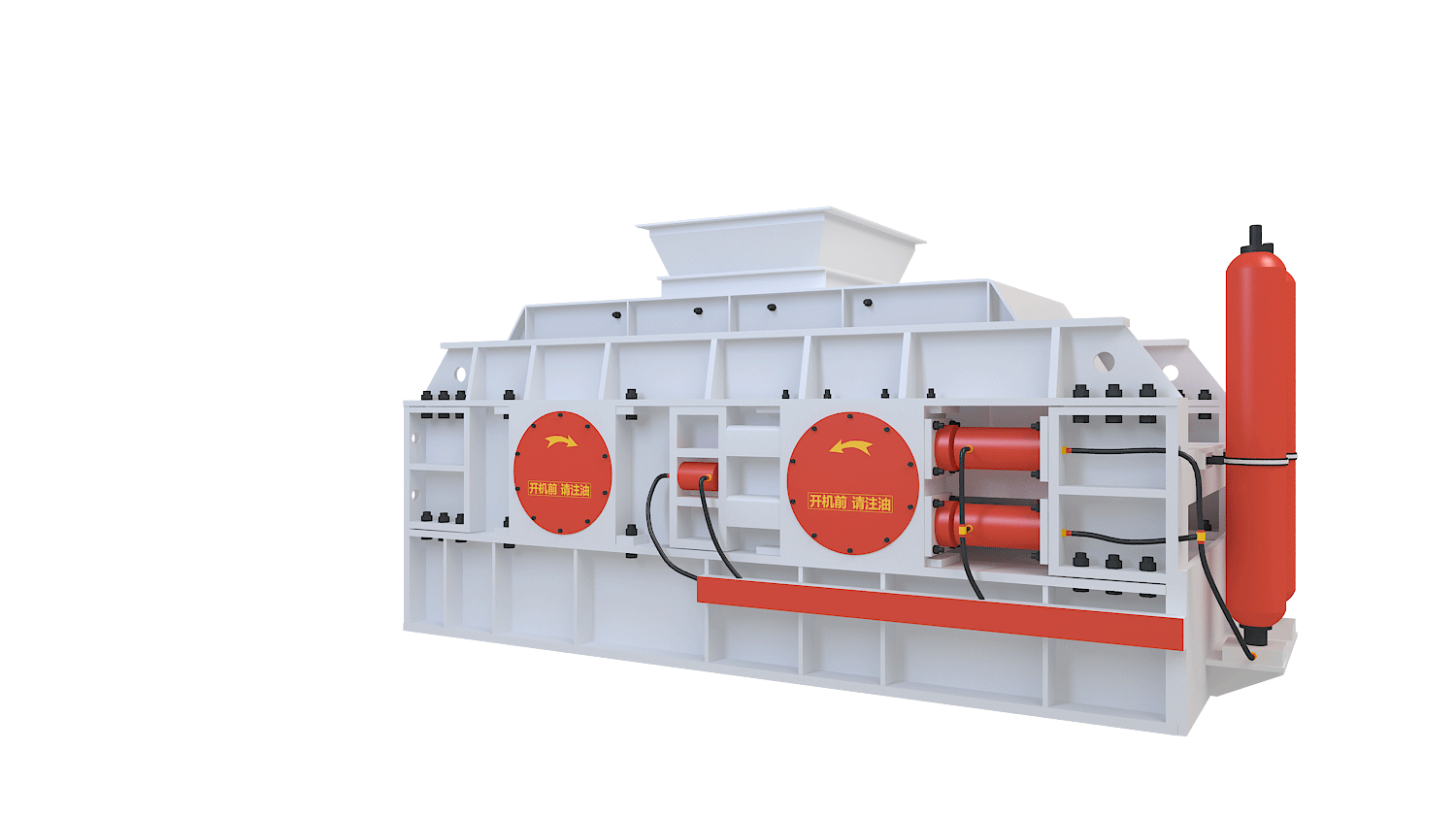

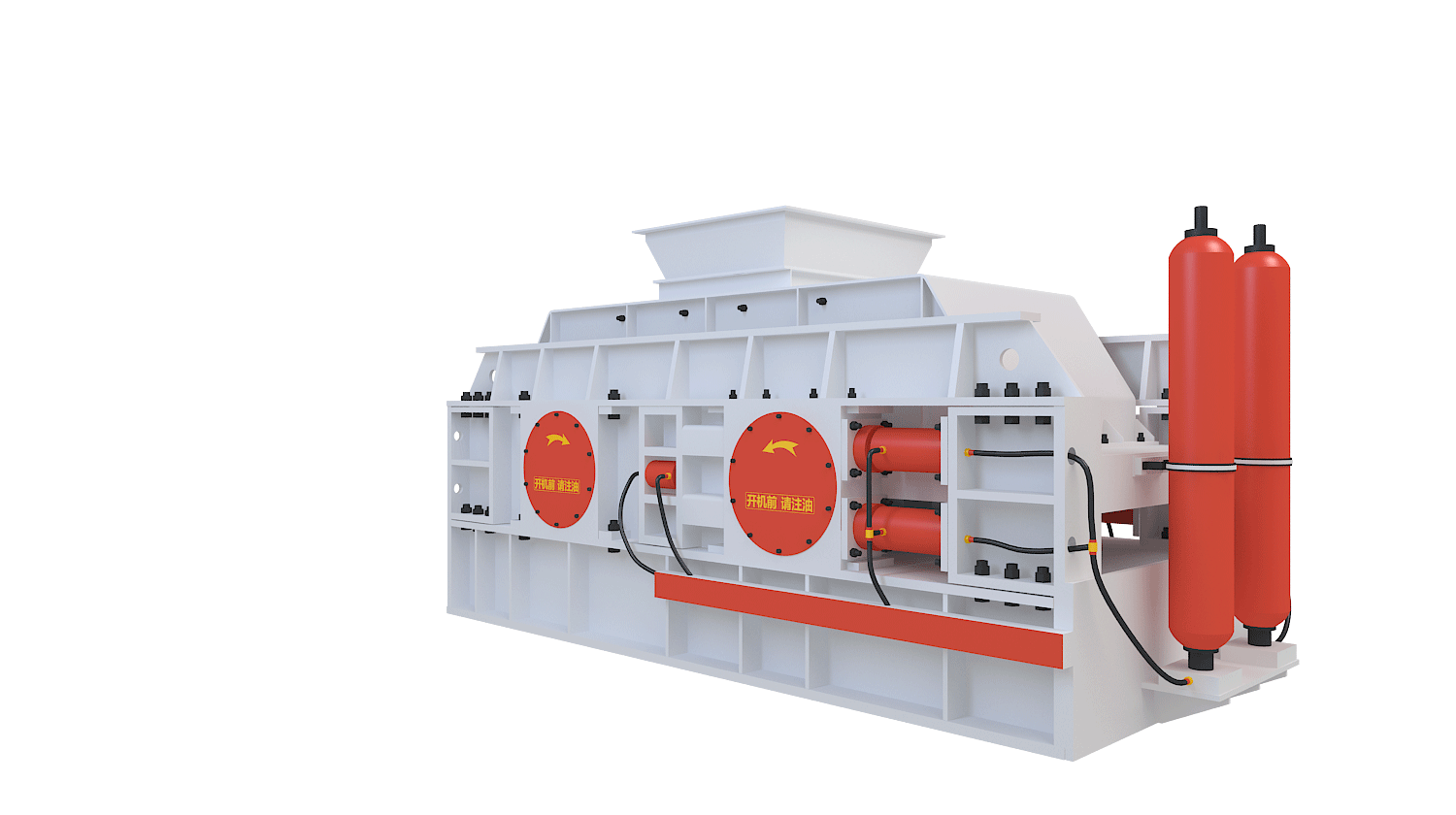

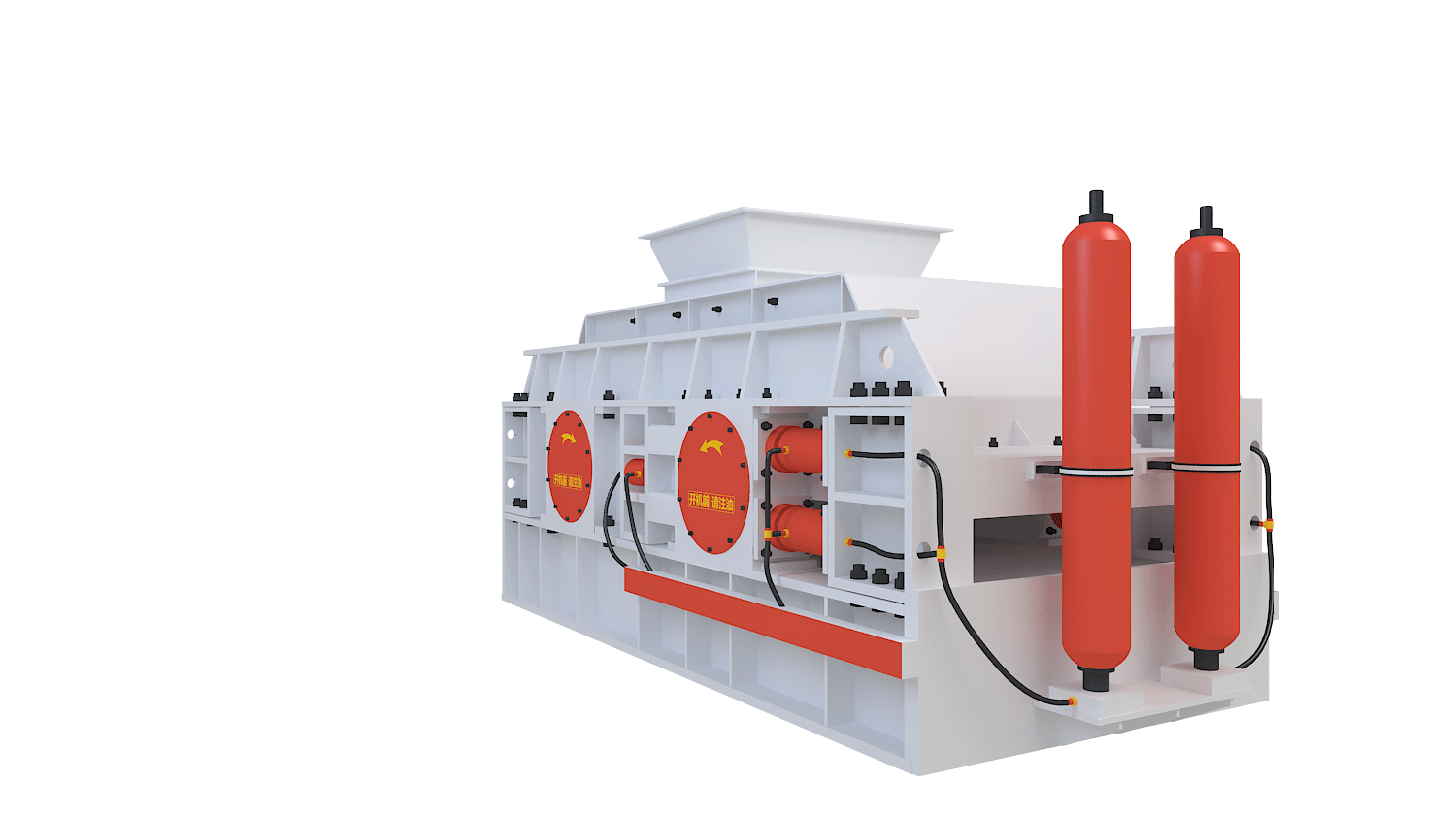

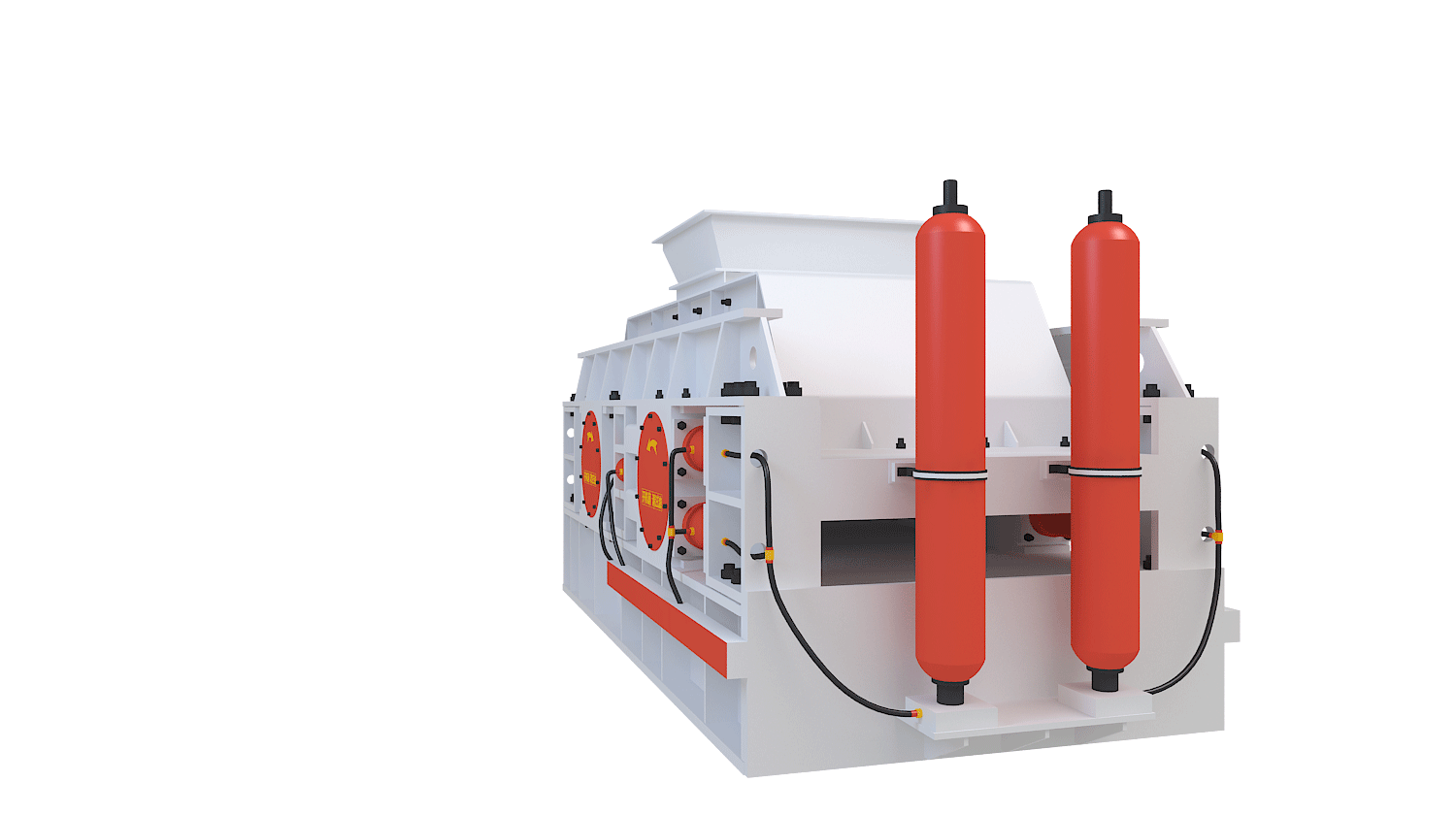

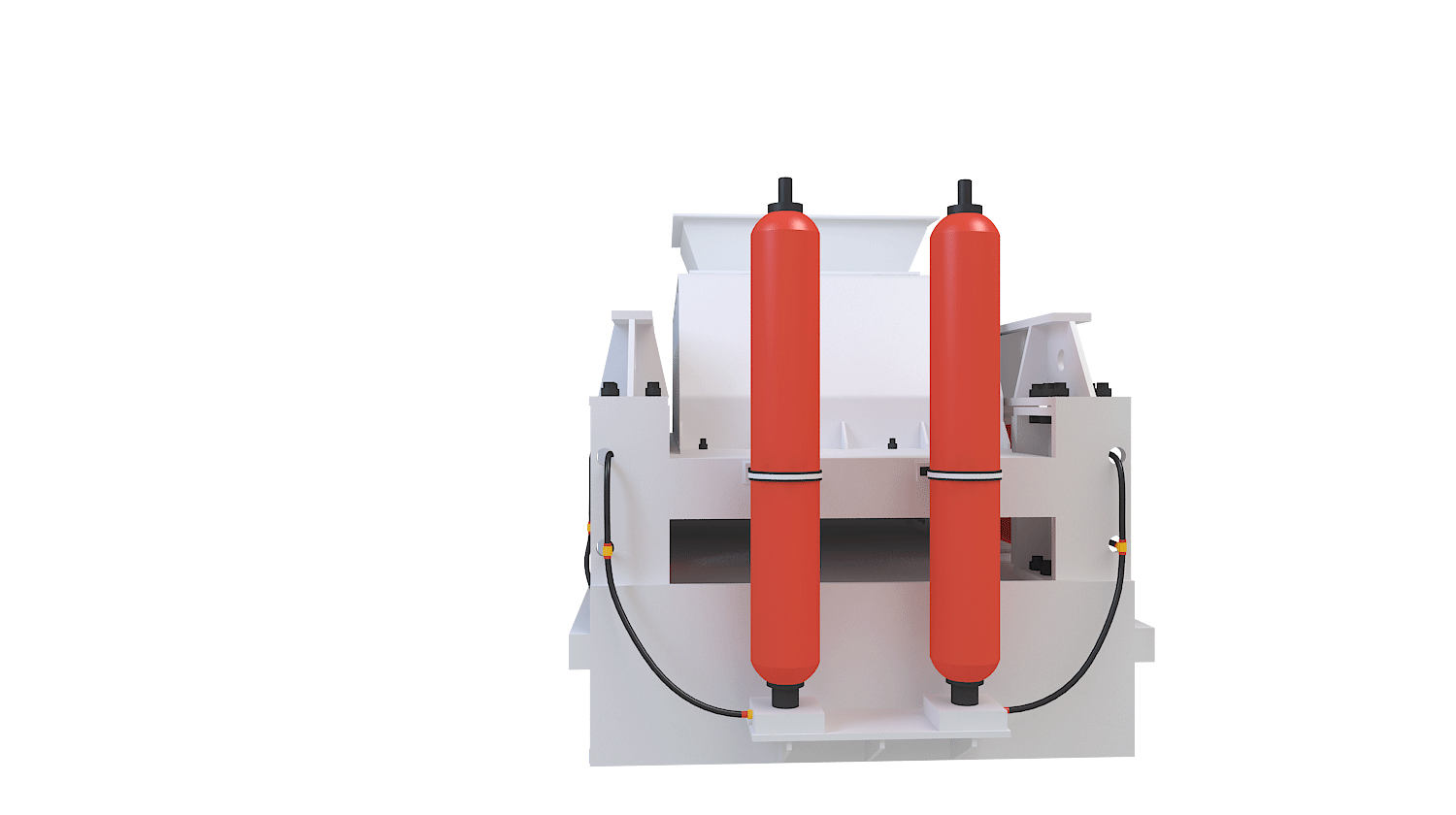

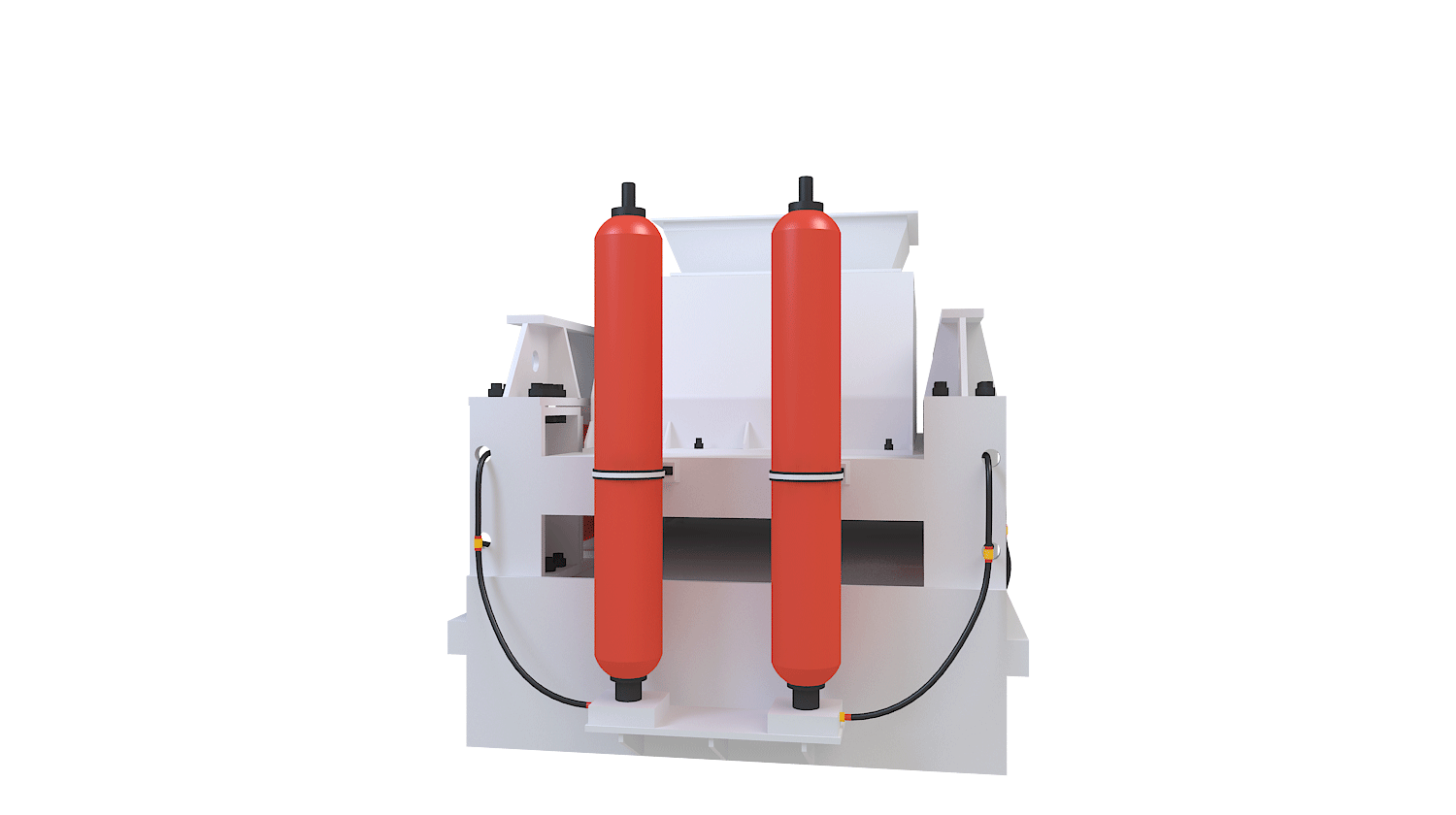

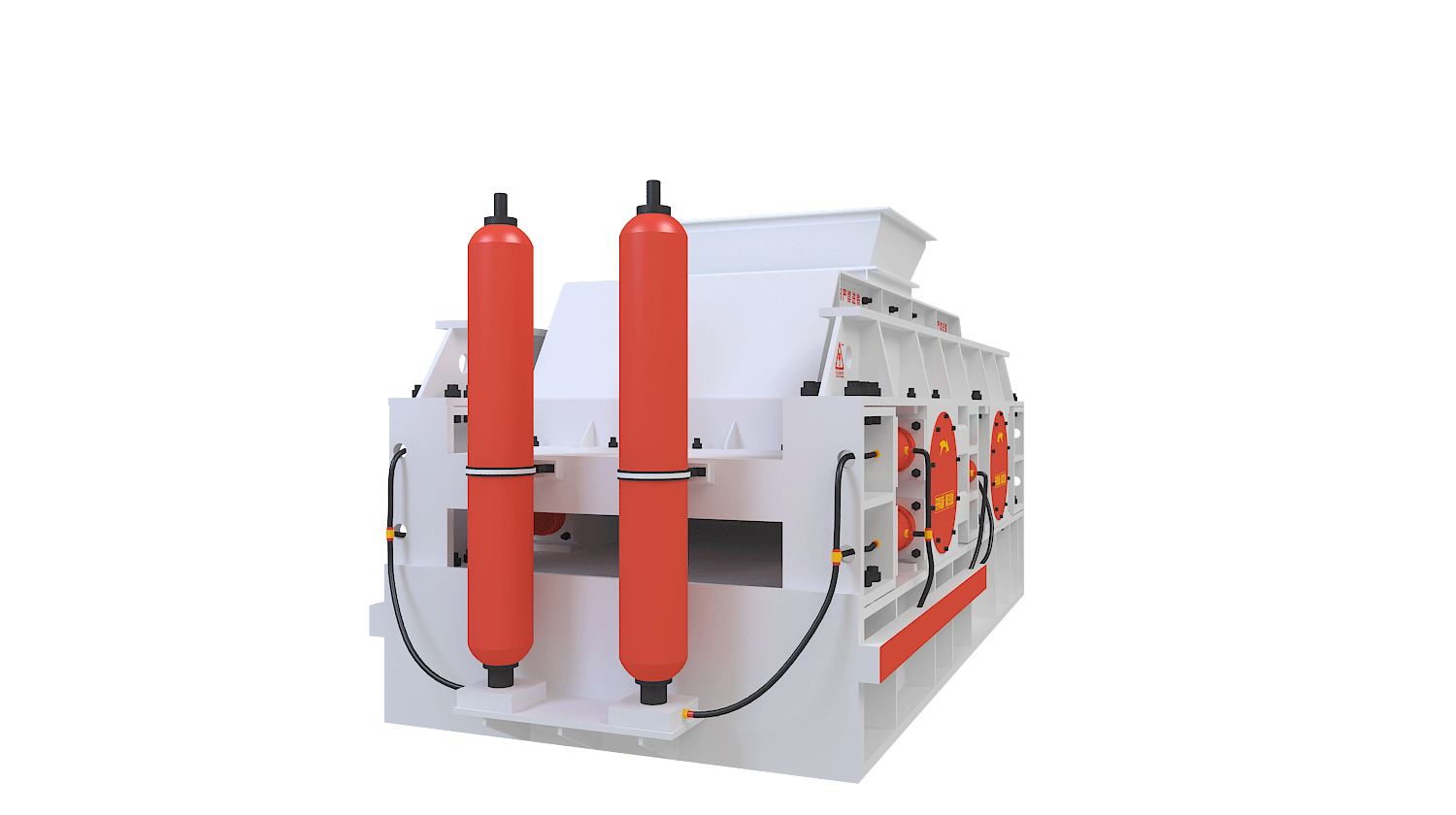

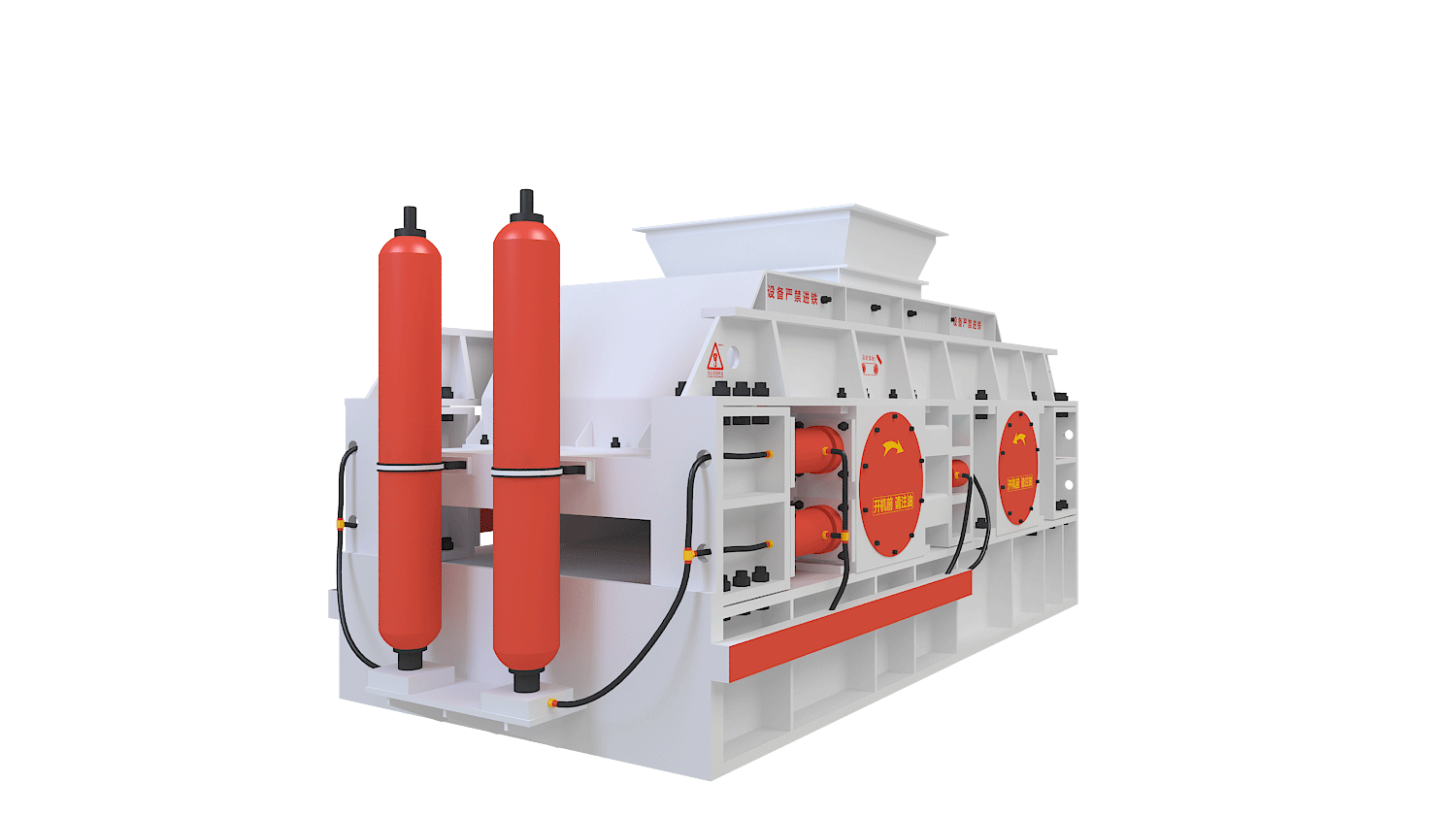

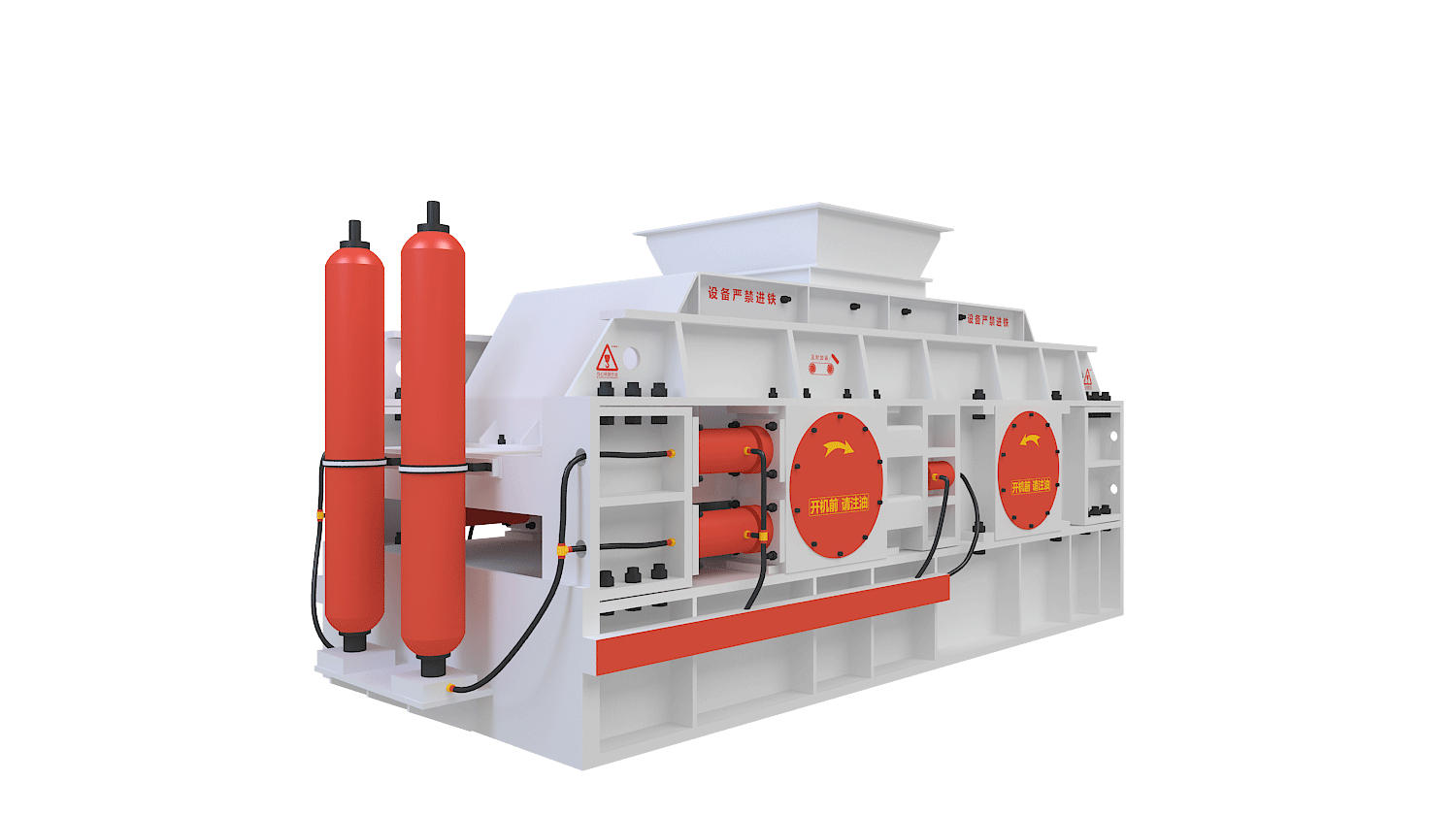

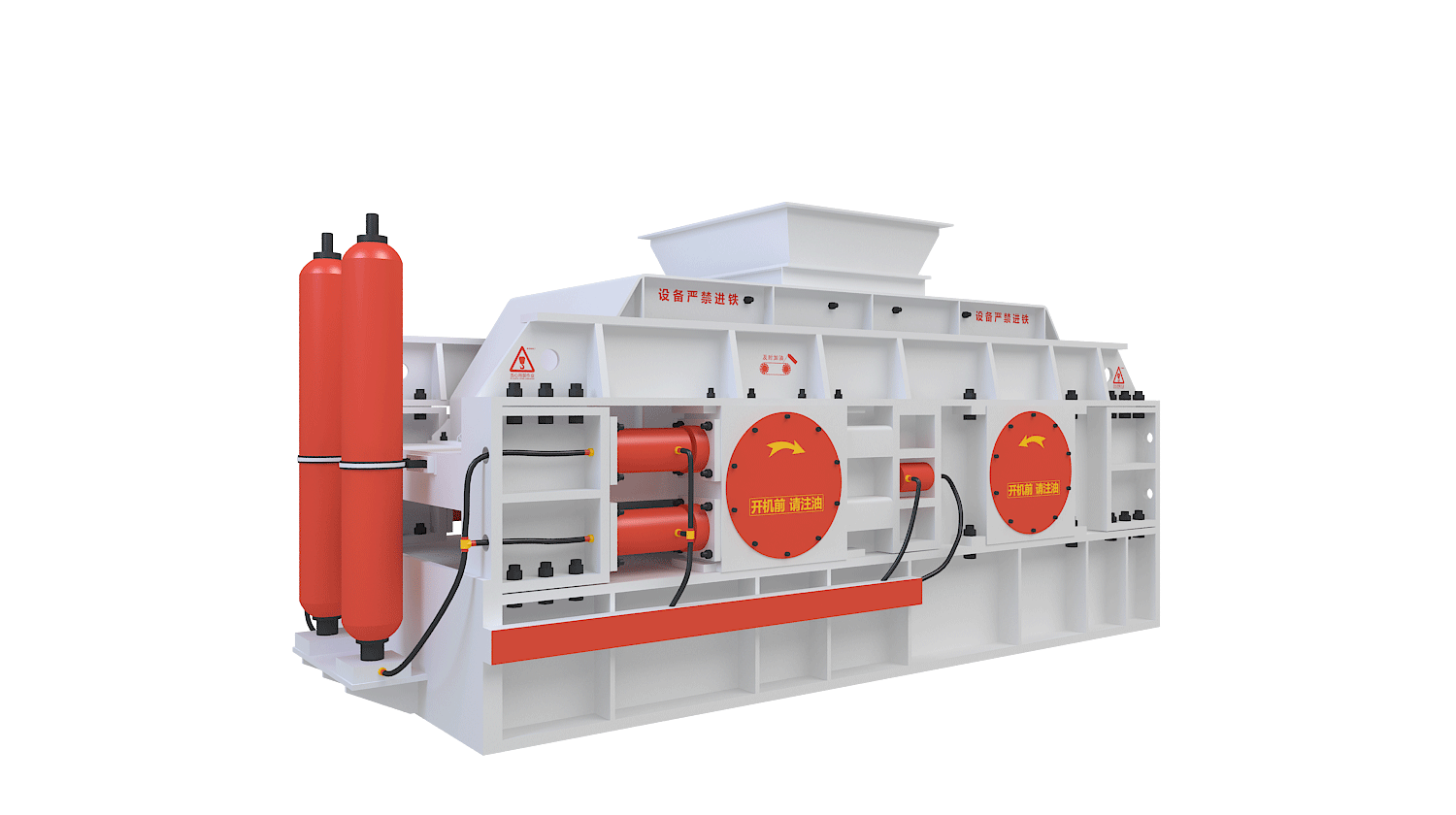

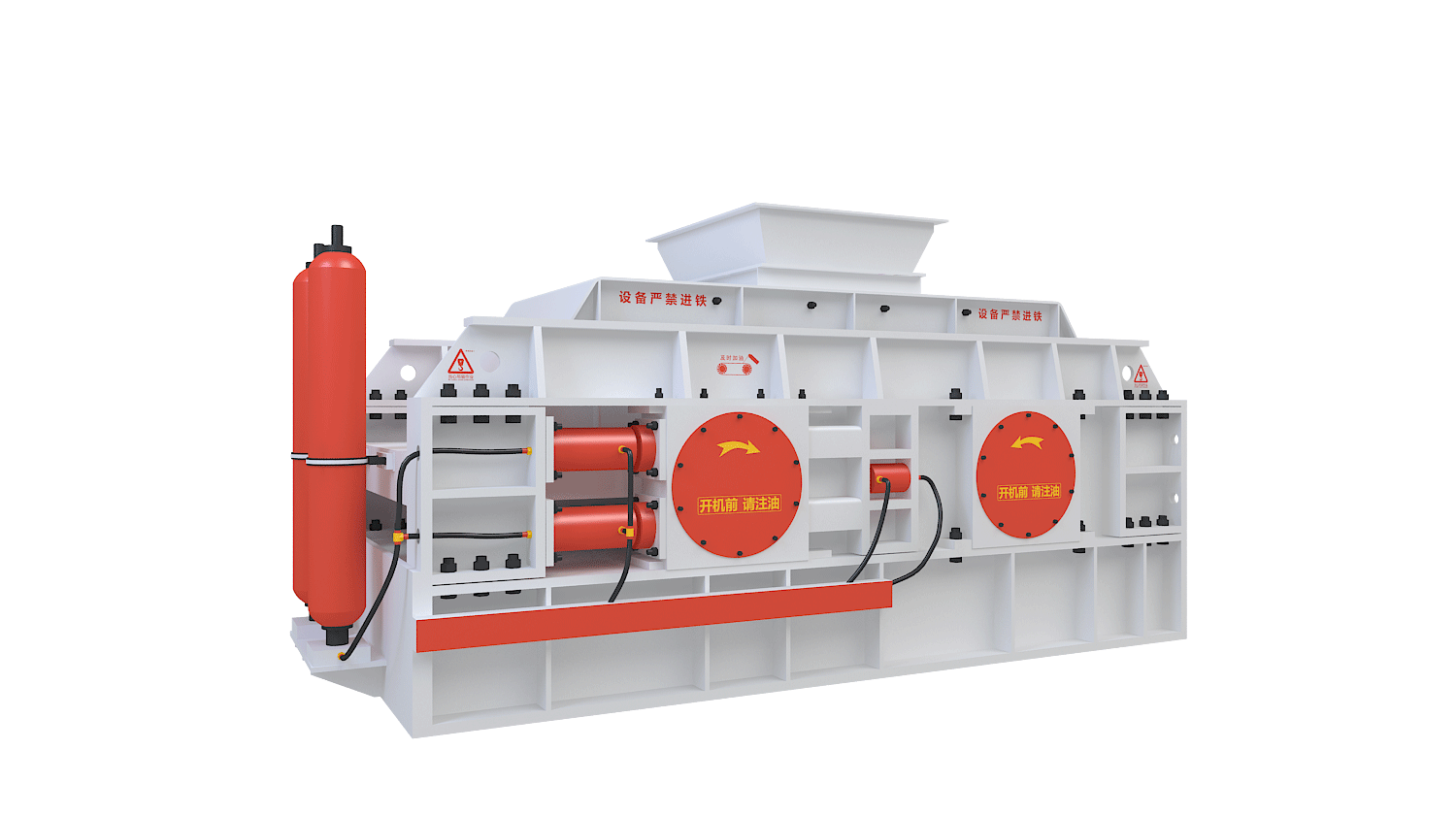

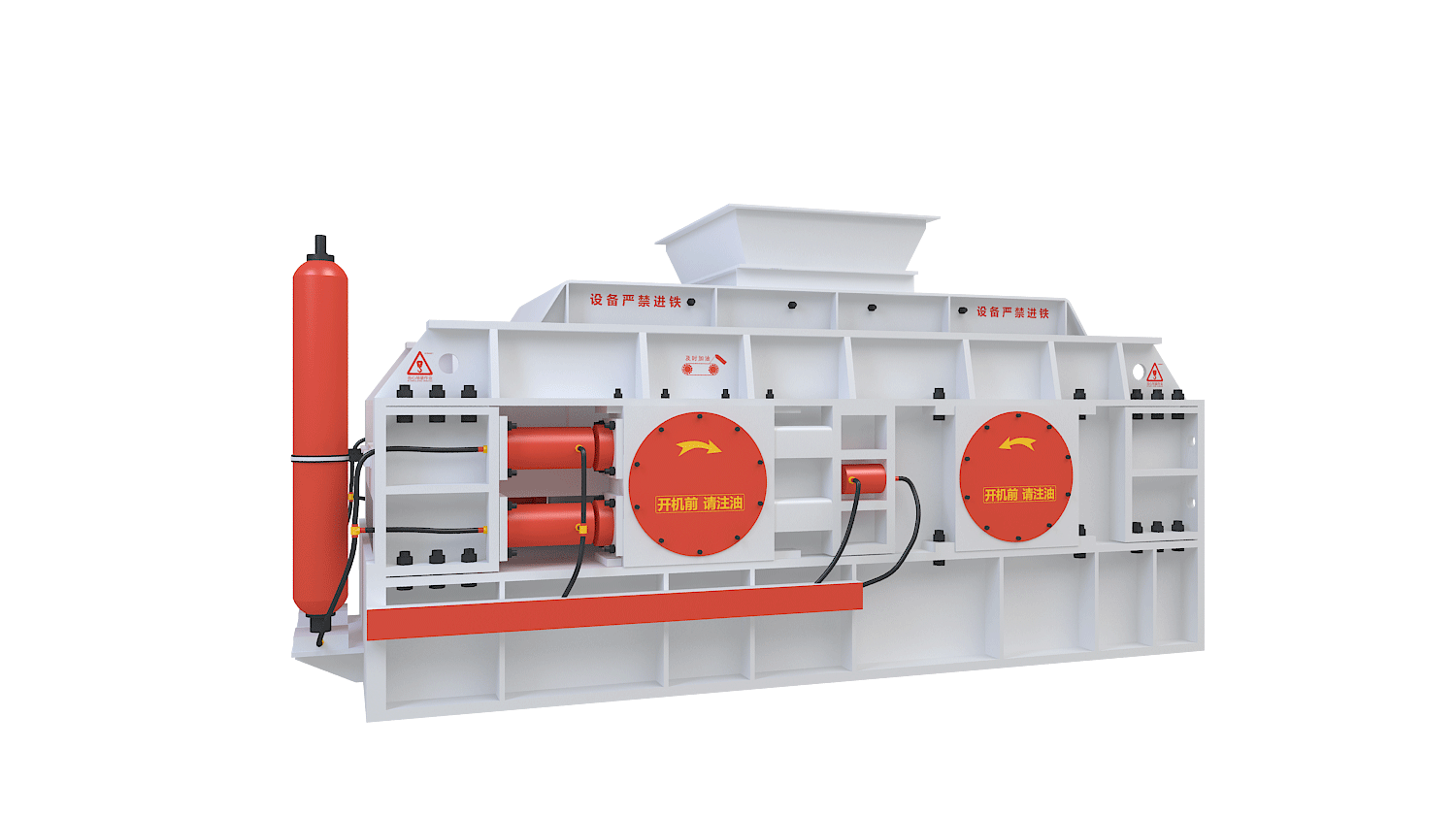

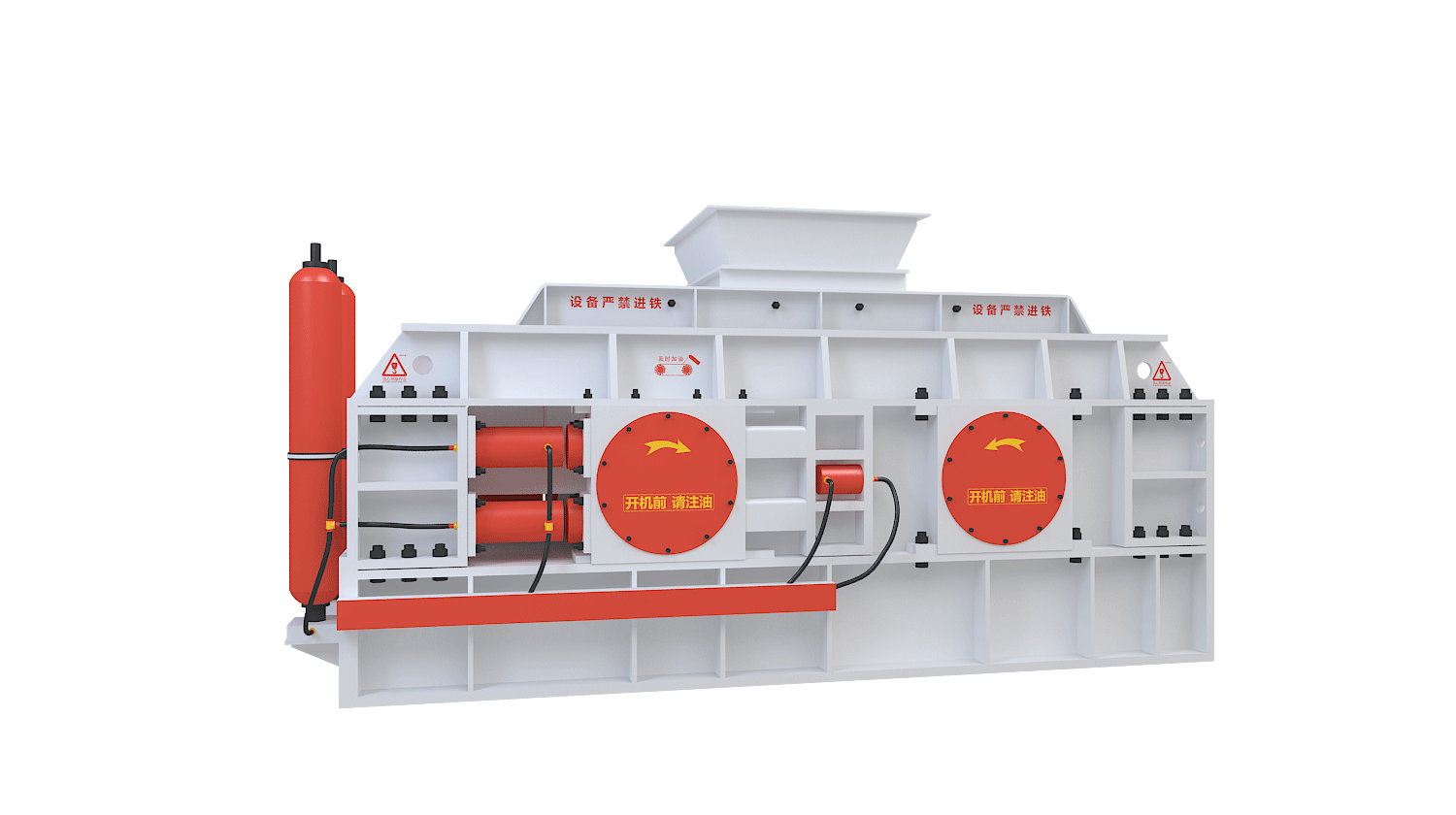

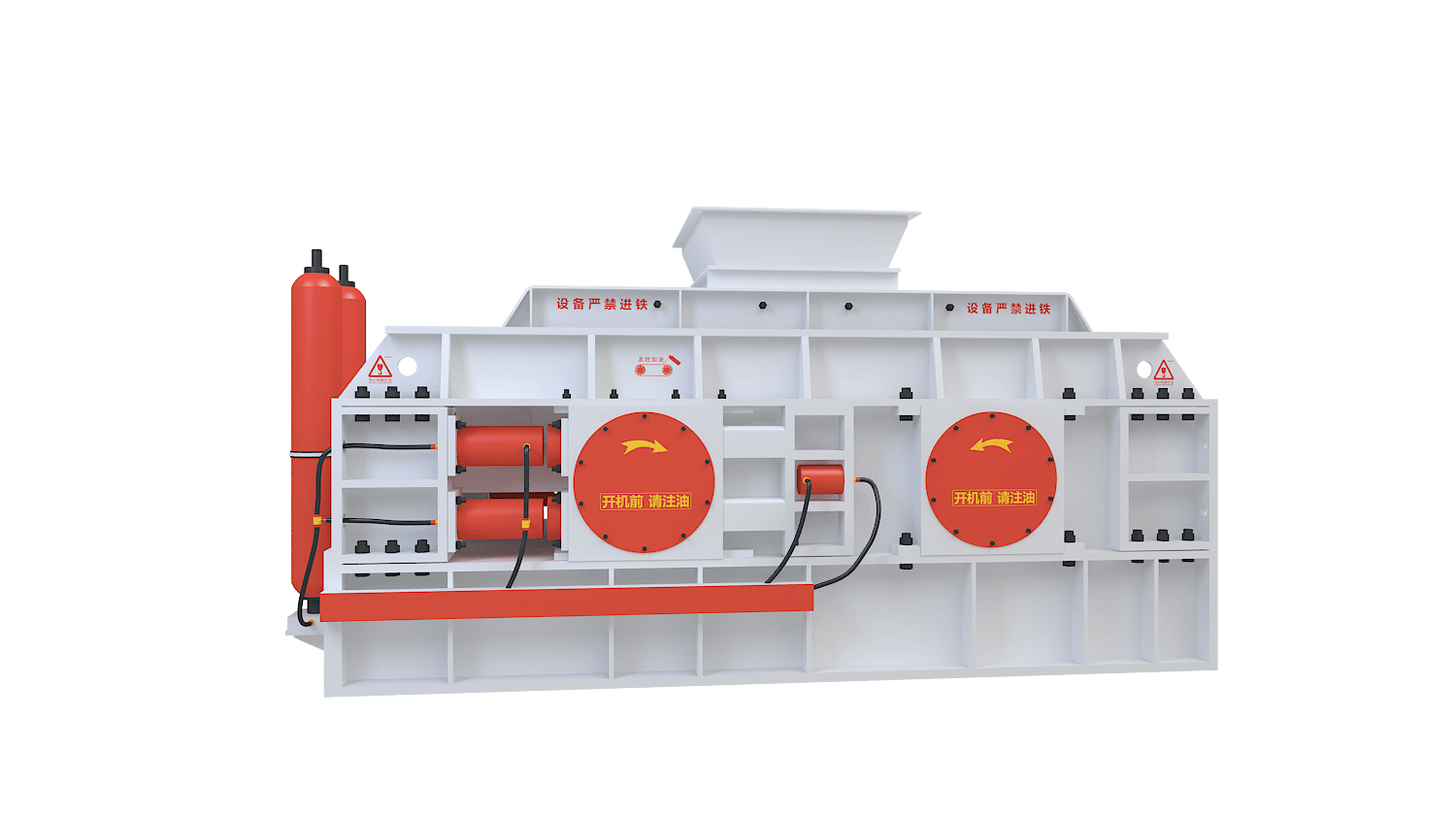

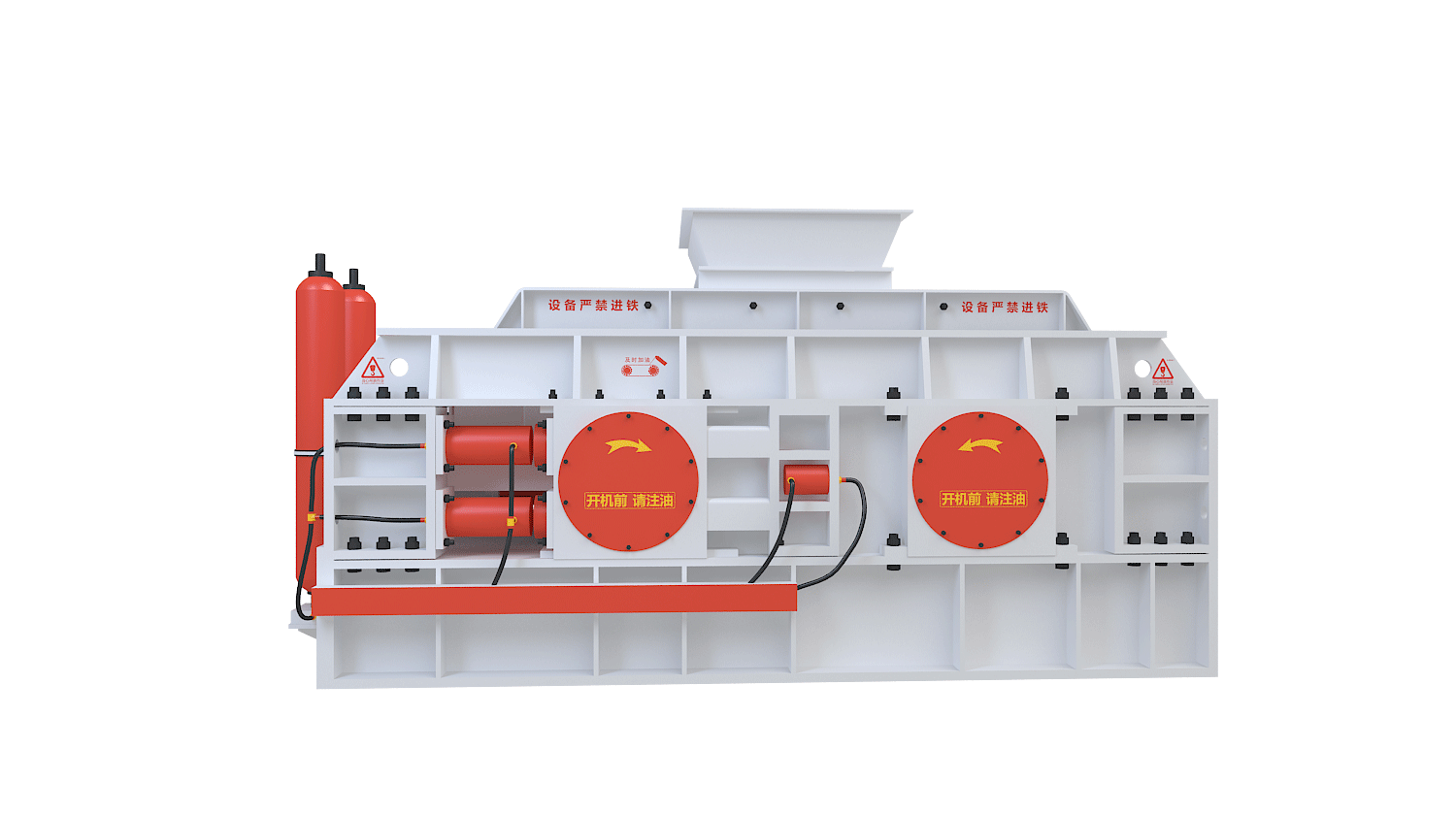

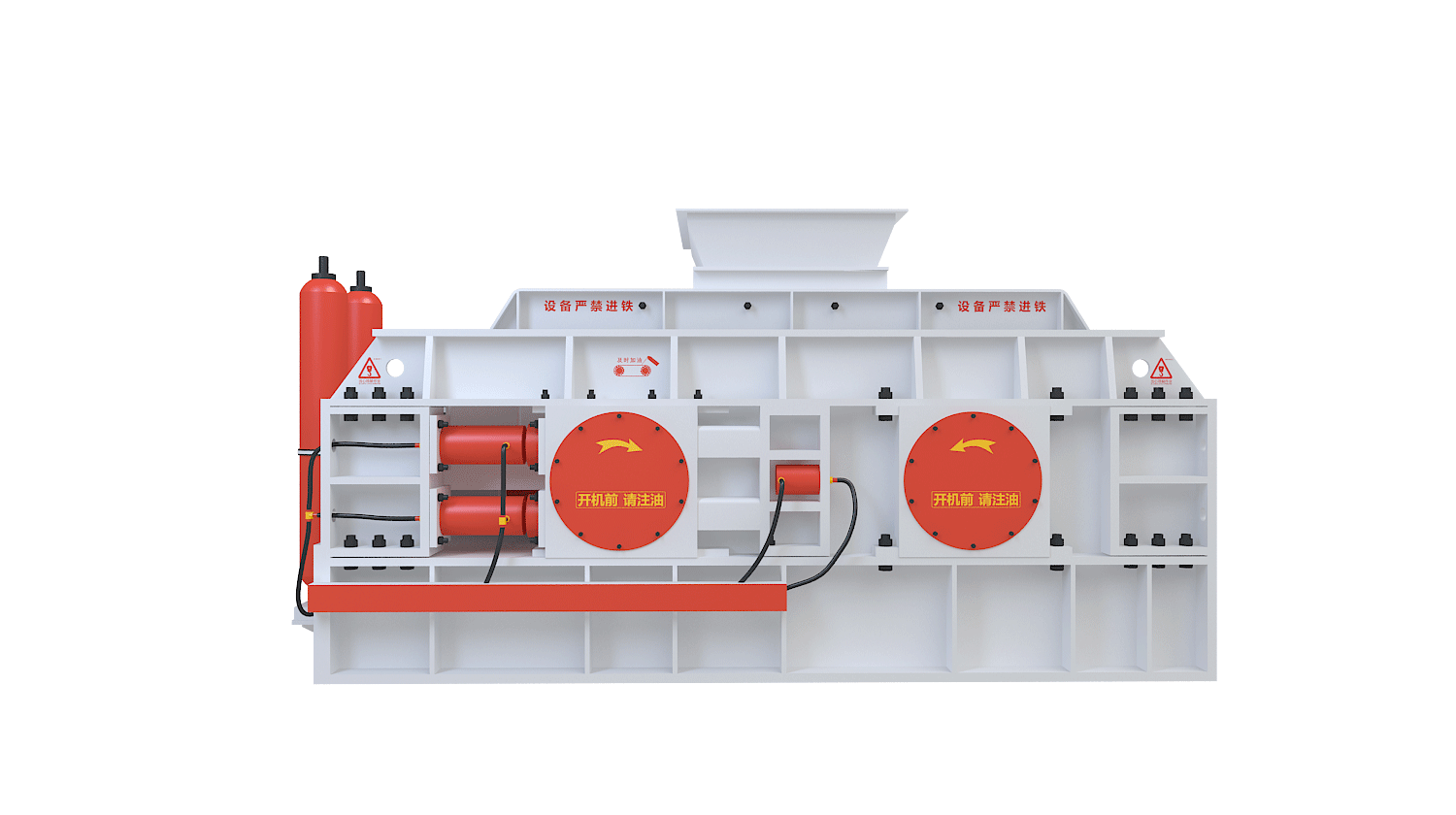

Roller Sand Making Machine

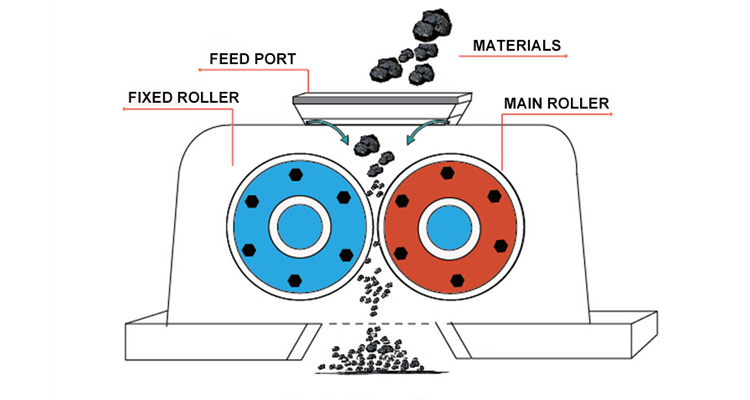

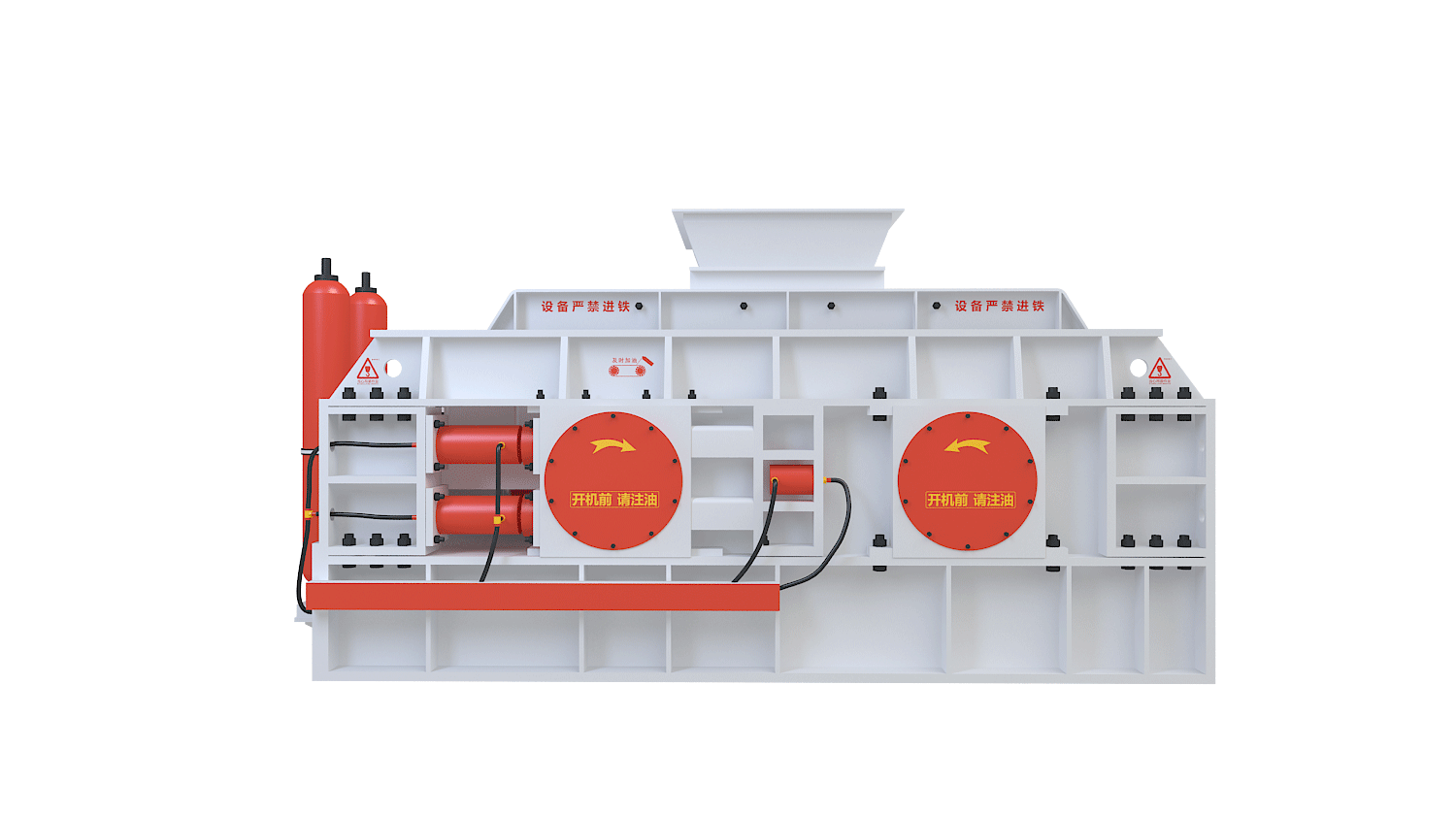

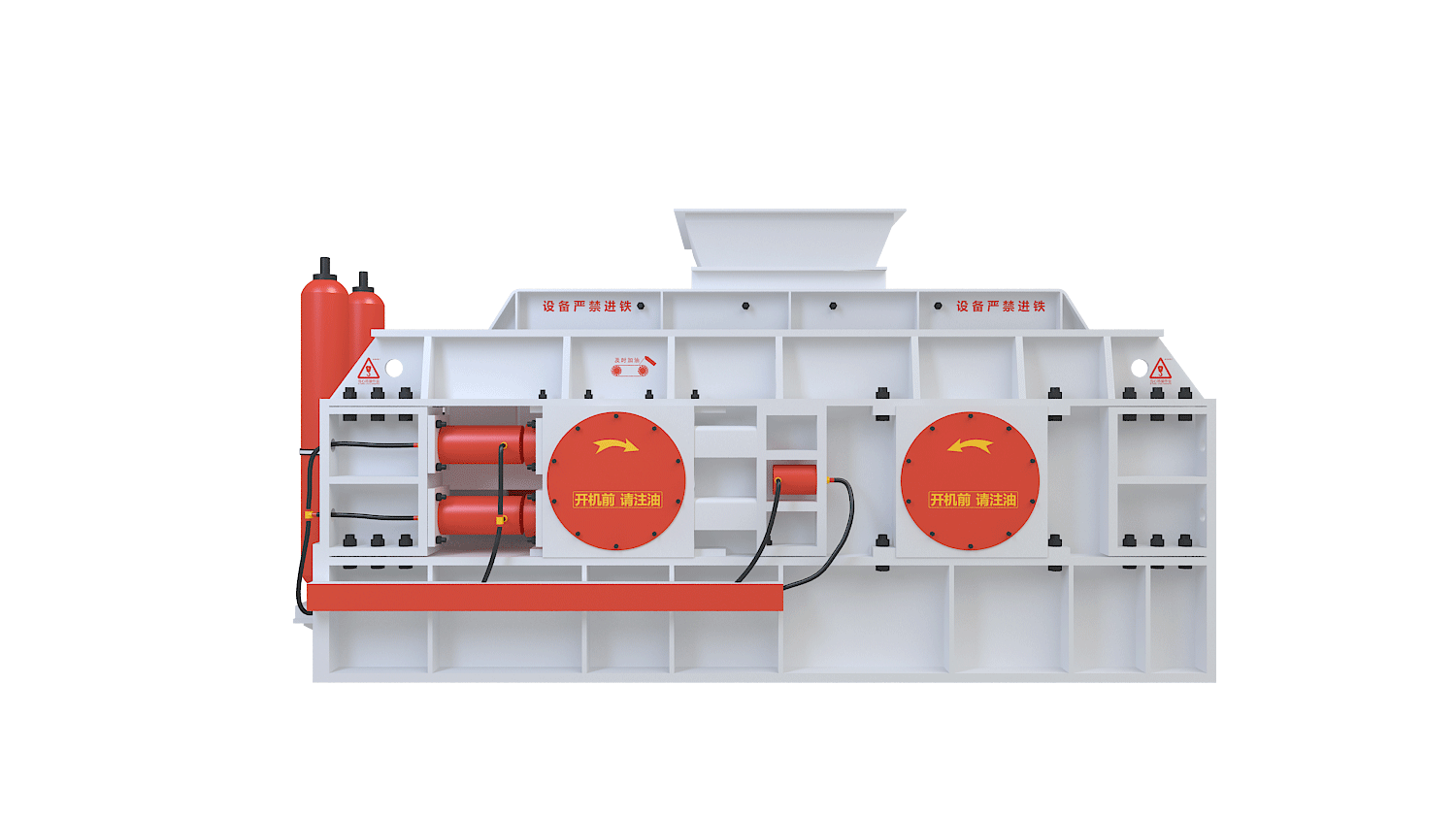

Roller Sand Making Machine is a robust and efficient sand crushing solution engineered for the production of high-quality construction aggregates. Designed with two precisely aligned rollers rotating in opposite directions, it effectively crushes medium-hard materials such as limestone, river pebbles, granite, and basalt into well-graded, cube-shaped particles. The unique interlocking roller design minimizes over-crushing and maximizes output of fine, uniform sand, meeting the stringent requirements of modern construction and infrastructure projects.

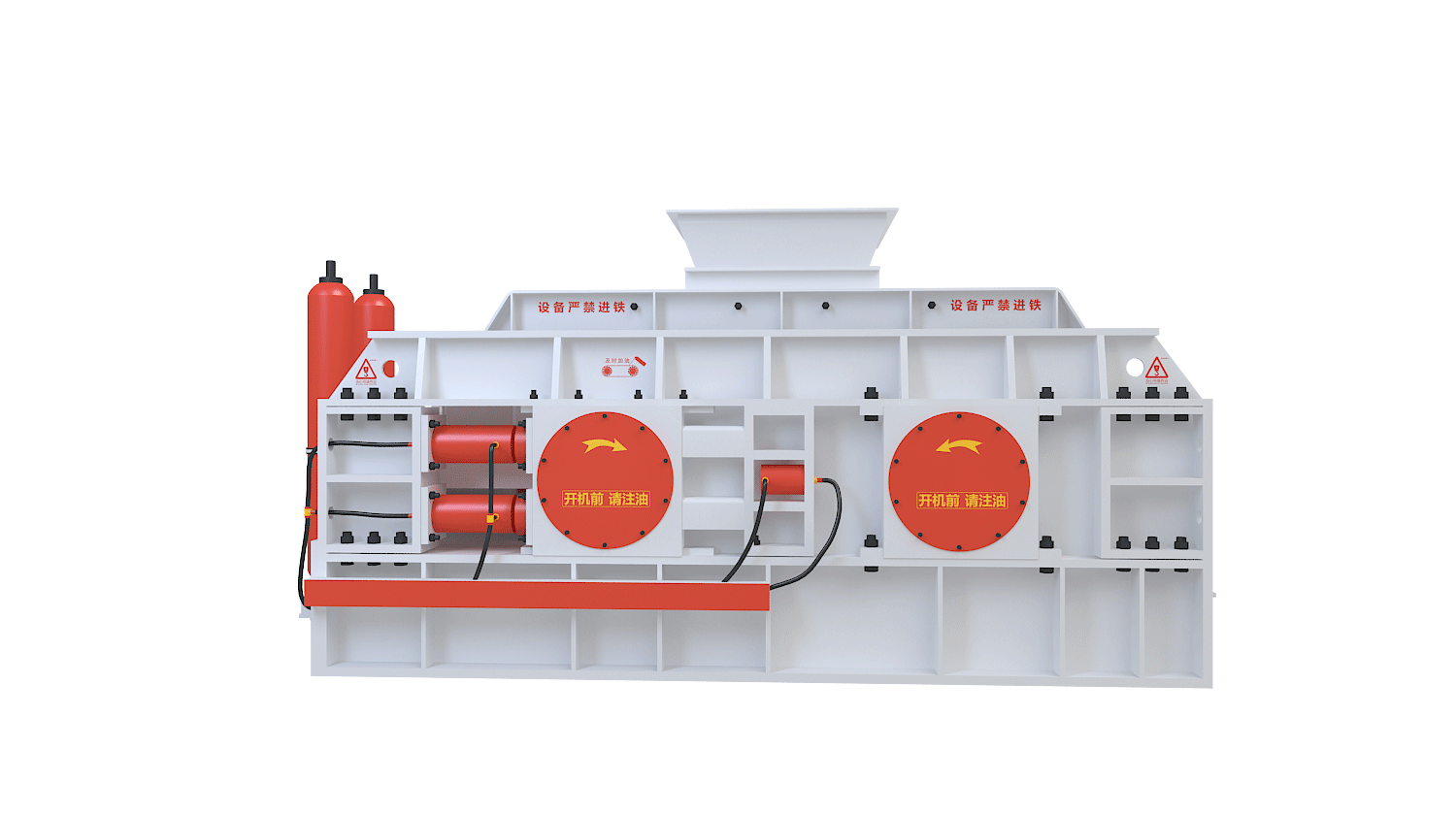

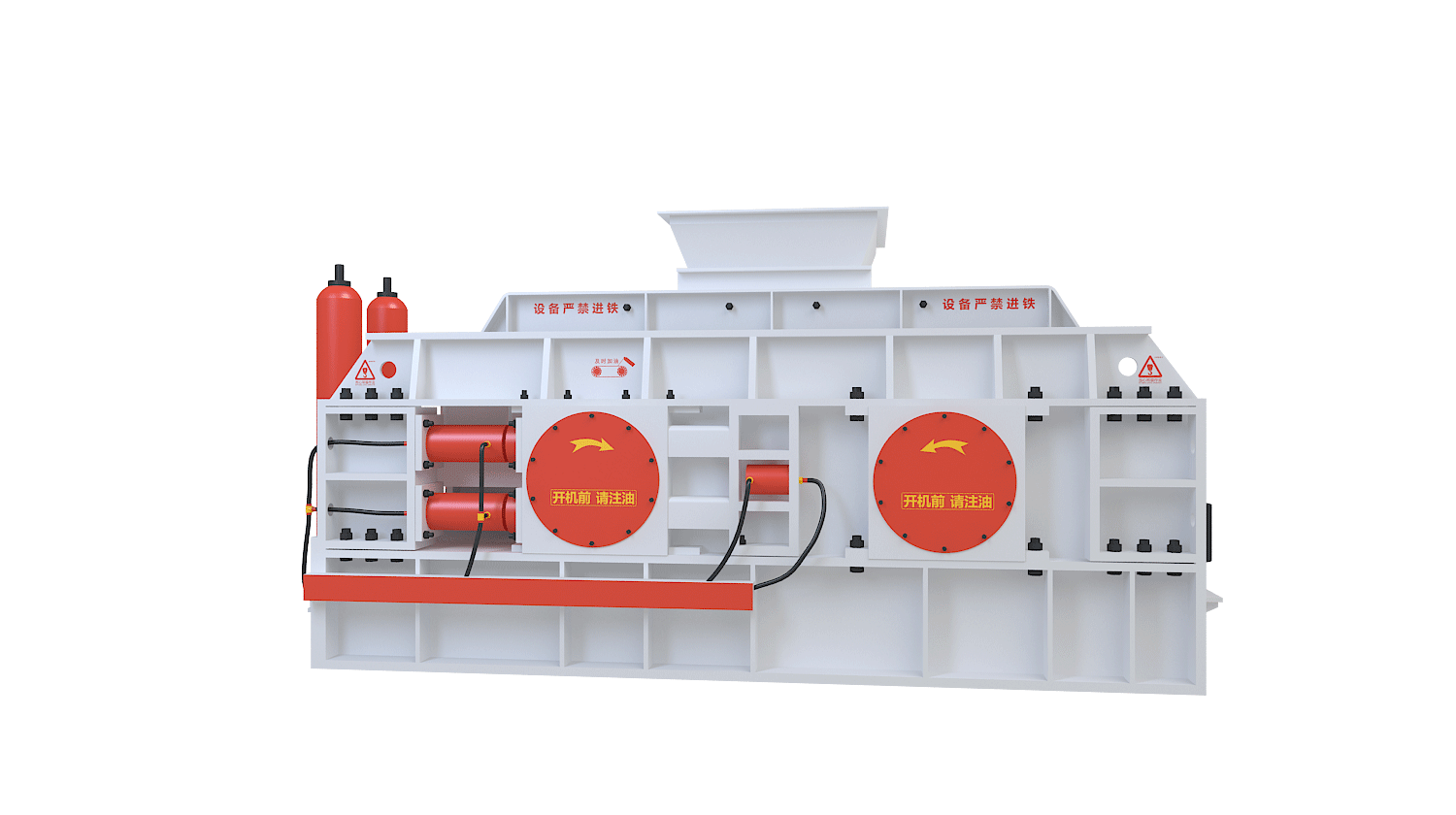

Featuring a compact structure and a fully enclosed crushing chamber, the machine ensures low dust generation and reduced noise emissions, making it suitable for environmentally conscious operations. Hydraulic pressure adjustment allows for precise control of the output size, while optional automatic lubrication and overload protection systems help extend equipment lifespan and reduce downtime. With low energy consumption and minimal wear on components, the Roller Sand Making Machine is ideal for sand plants, quarry operations, and concrete mixing stations seeking high-efficiency, stable performance, and long-term durability.

Whether used as a standalone unit or integrated into a full sand production line, it consistently delivers excellent results in various material conditions.