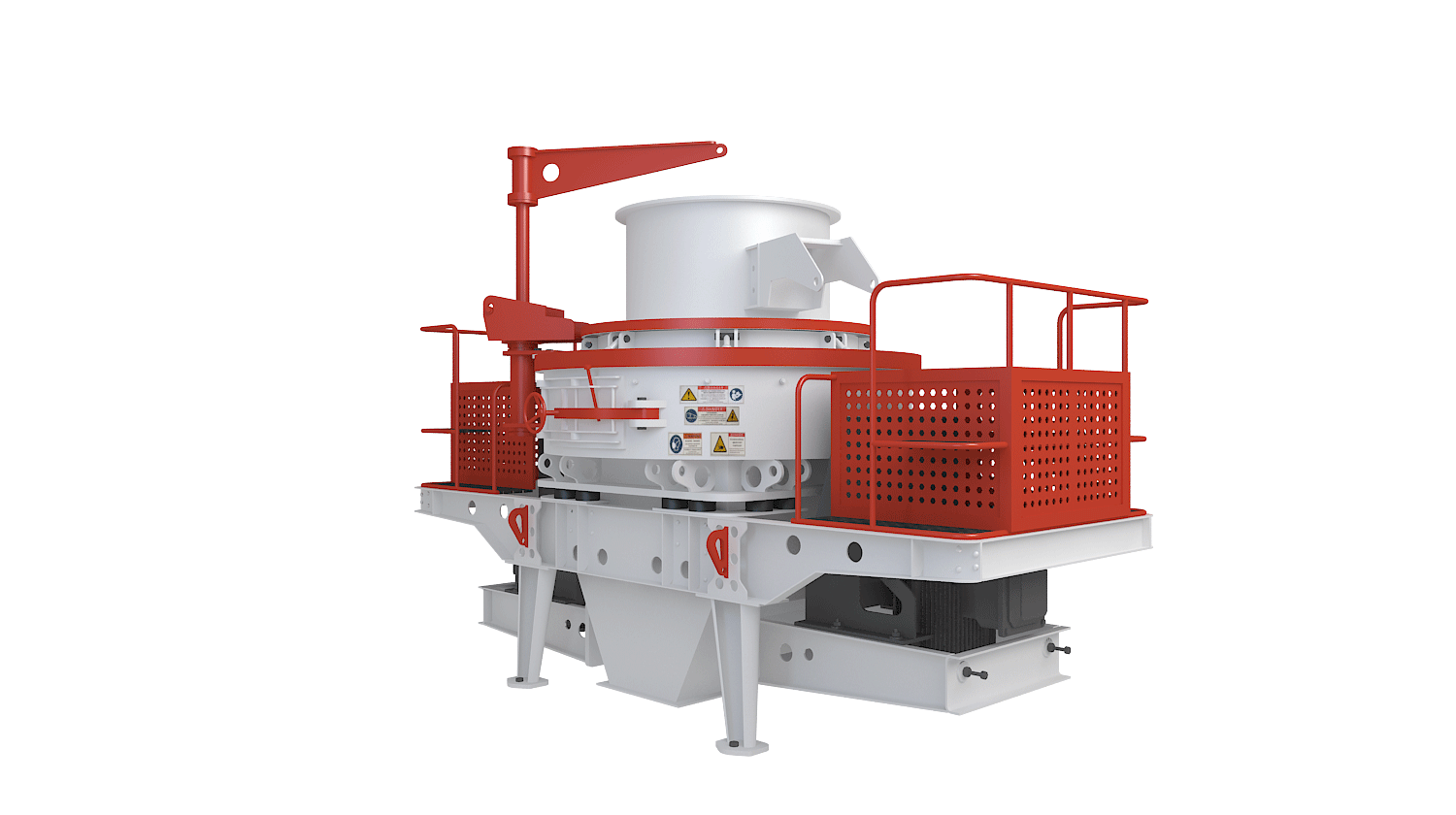

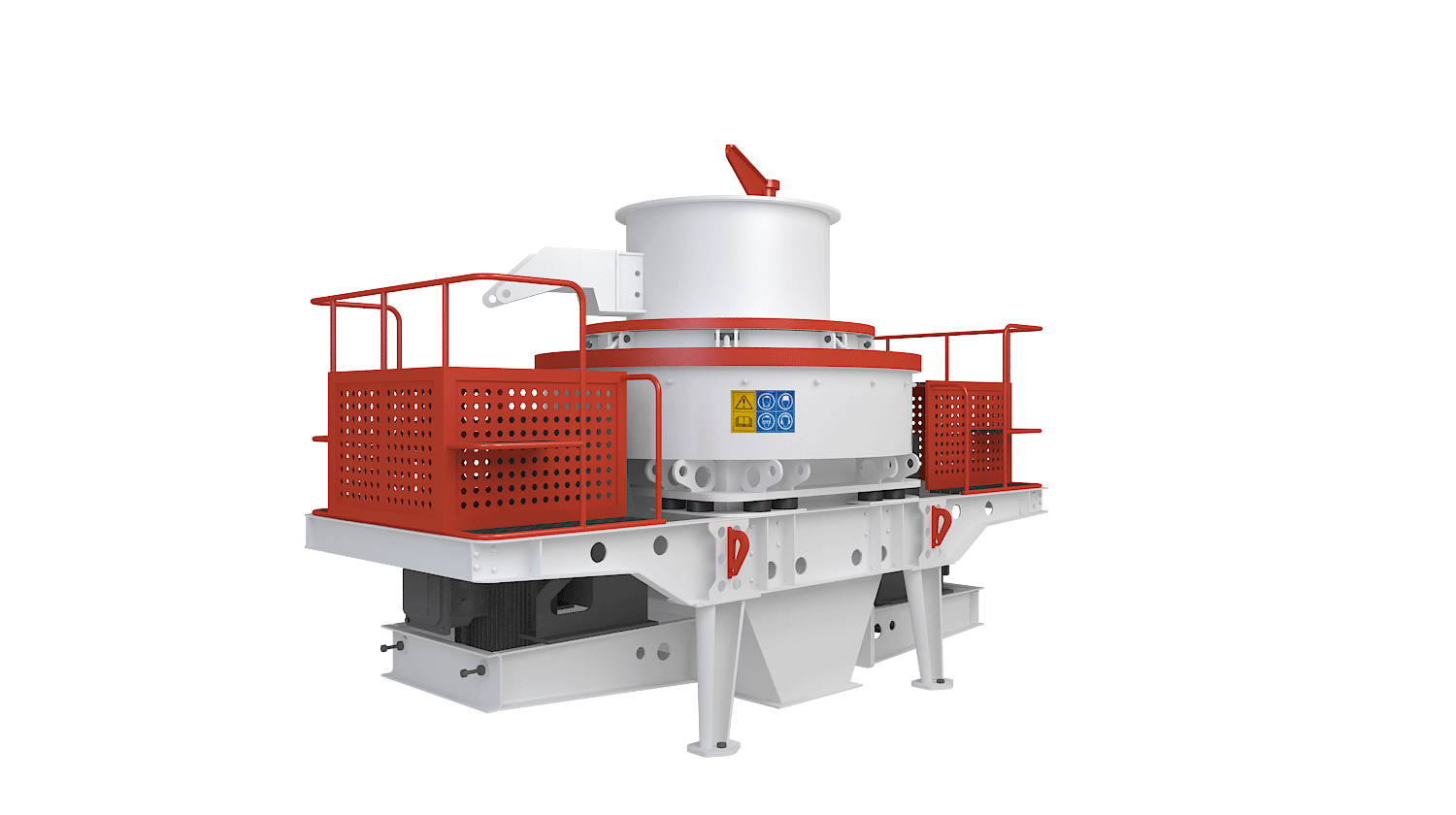

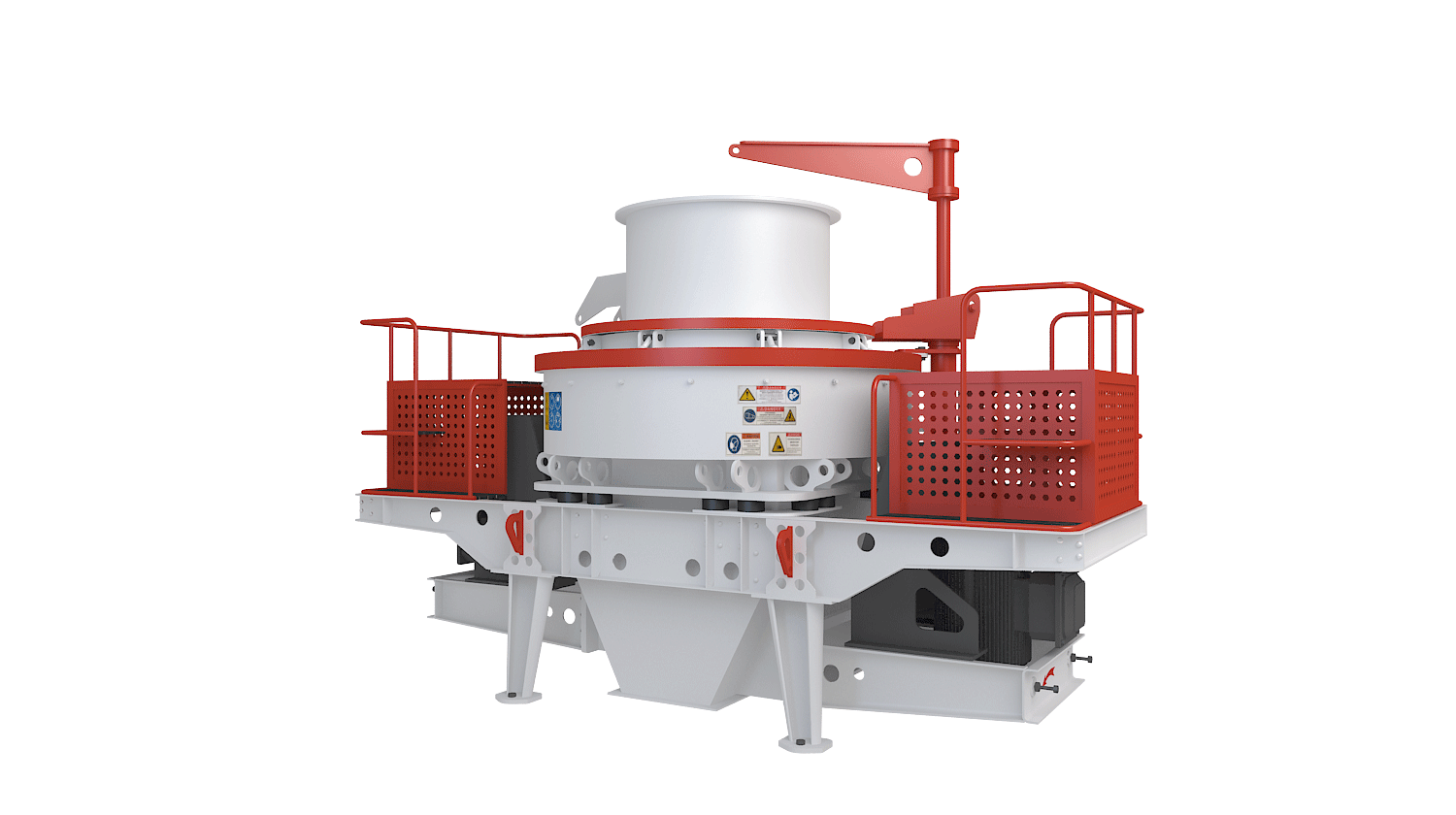

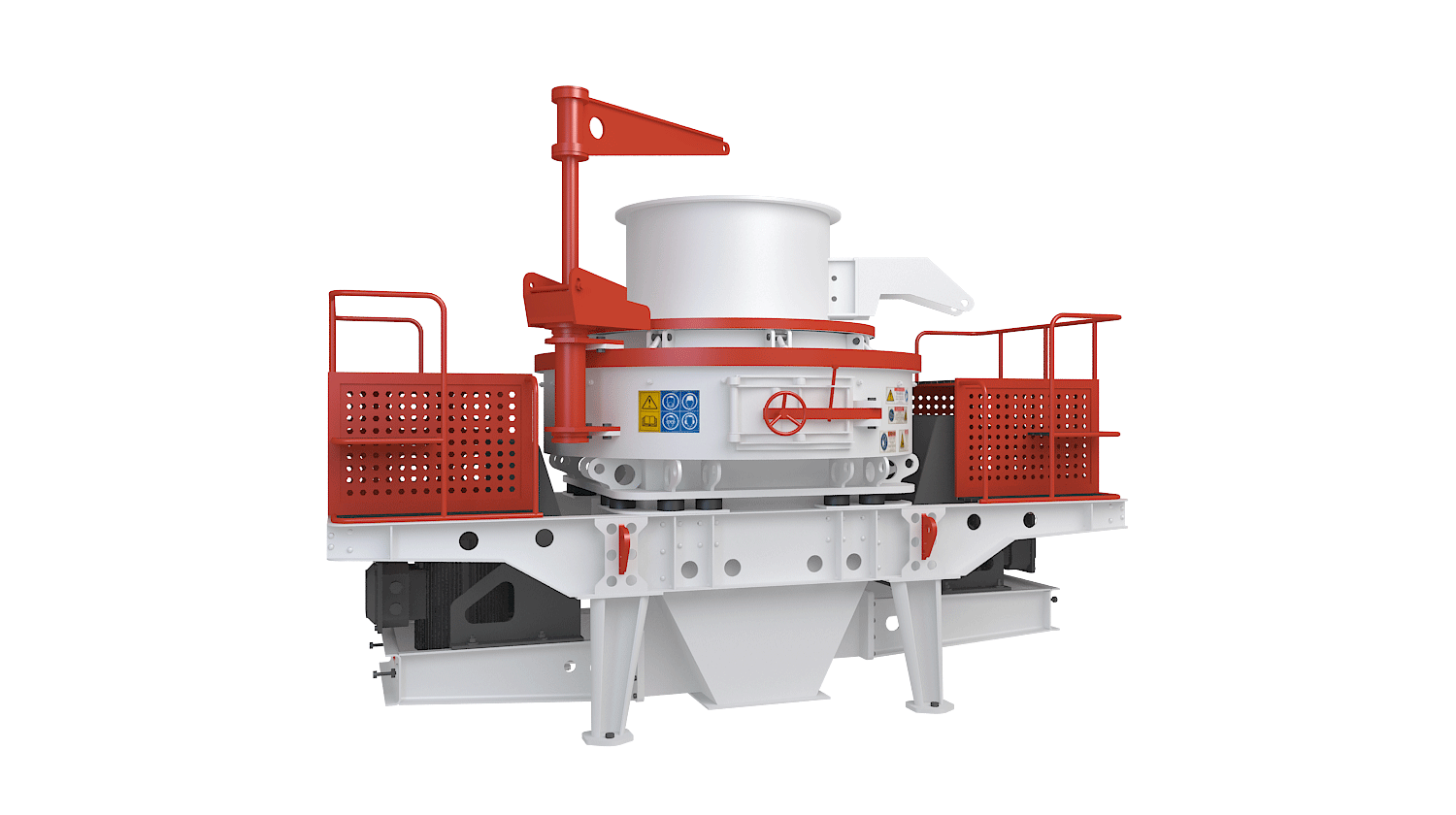

| Model | Capacity (t/h) |

The best feed size (mm) |

Rotating speed (r/min) |

Dual motor power (kw) |

Overall size (leng×width×height) (mm) |

Weight (t) |

Vibration sensor | Lubrication hydraulic station | |||||

| Feed atcenter&sides | Full center feed | Soft material | Hard material | Double oil pump motor power | Safety protection | Overall size (mm) |

Fuel tank heating power | ||||||

| VSI7615 | 150-280 | 70-140 | 35 | 30 | 1700-1900 | 150 | 4100×2330×2300 | 12.1 | Detection range: 0.1-20mm/s Continuousty adjustable |

2×0.25kw | Dual oil pumps ensure reliable lubrication; Auto shutdown on low pressure or no flow; Water-cooled system; Motor preheating for winter start |

765×885×1160 | 4kw |

| VSI8522 | 240-380 | 120-200 | 40 | 35 | 1530-1700 | 220 | 4140×2600×2700 | 14.8 | |||||

| VSI9532 | 350-540 | 180-280 | 45 | 40 | 1380-1660 | 320 | 4800×2571×2893 | 18.6 | |||||

| VSI1145 | 500-640 | 250-360 | 50 | 45 | 1200-1390 | 440 | 5450×2850×3335 | 21.5 | |||||

| VSI1150 | 413-442 | 344-368 | 55 | 45 | 1000-1300 | 500 | 5500×2750×3950 | 23 | 0.75kw | ||||

| VSI1263 | 545-583 | 454-486 | 60 | 50 | 900-1200 | 630 | 5750×2980×3410 | 24.5 | |||||