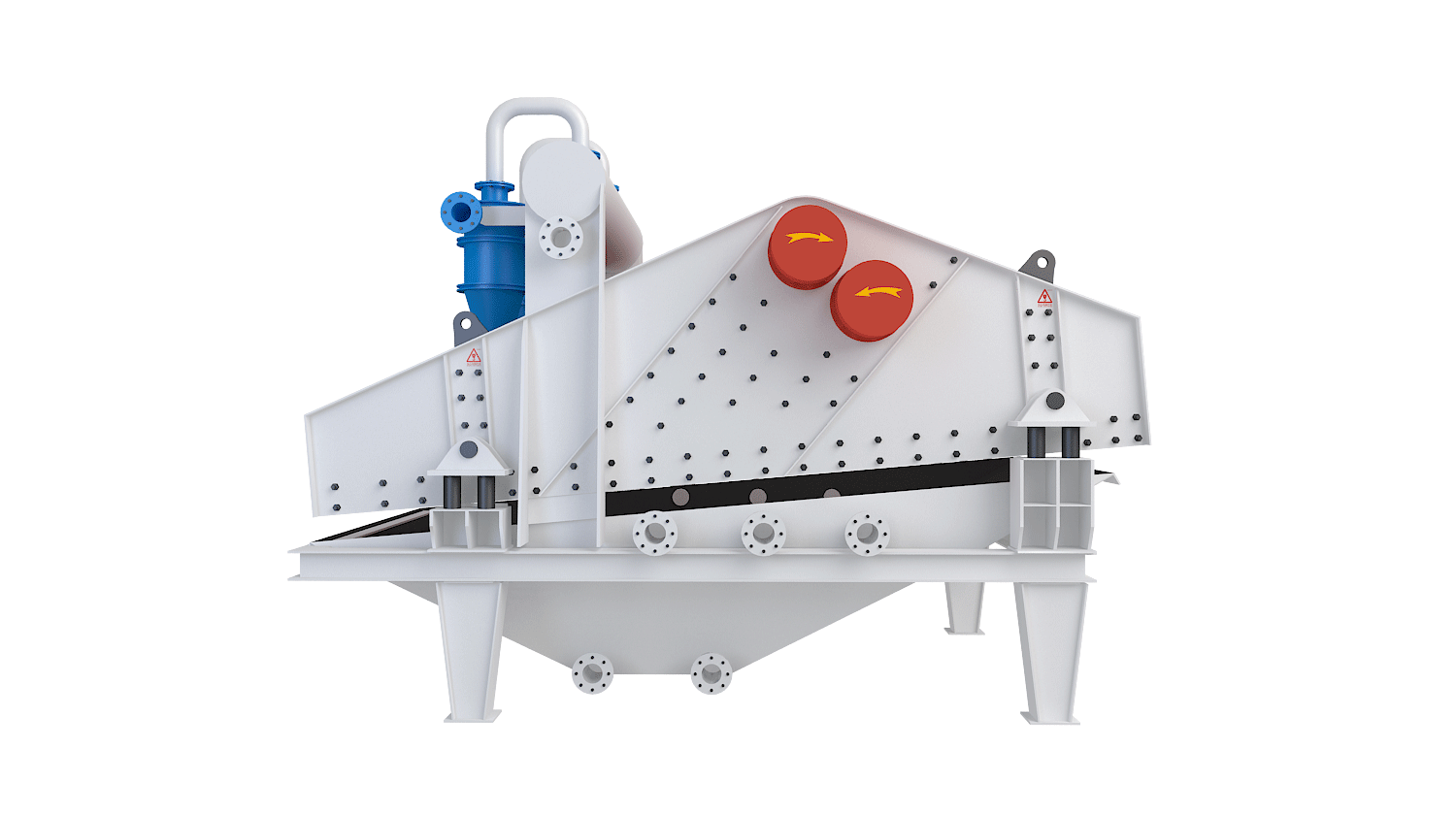

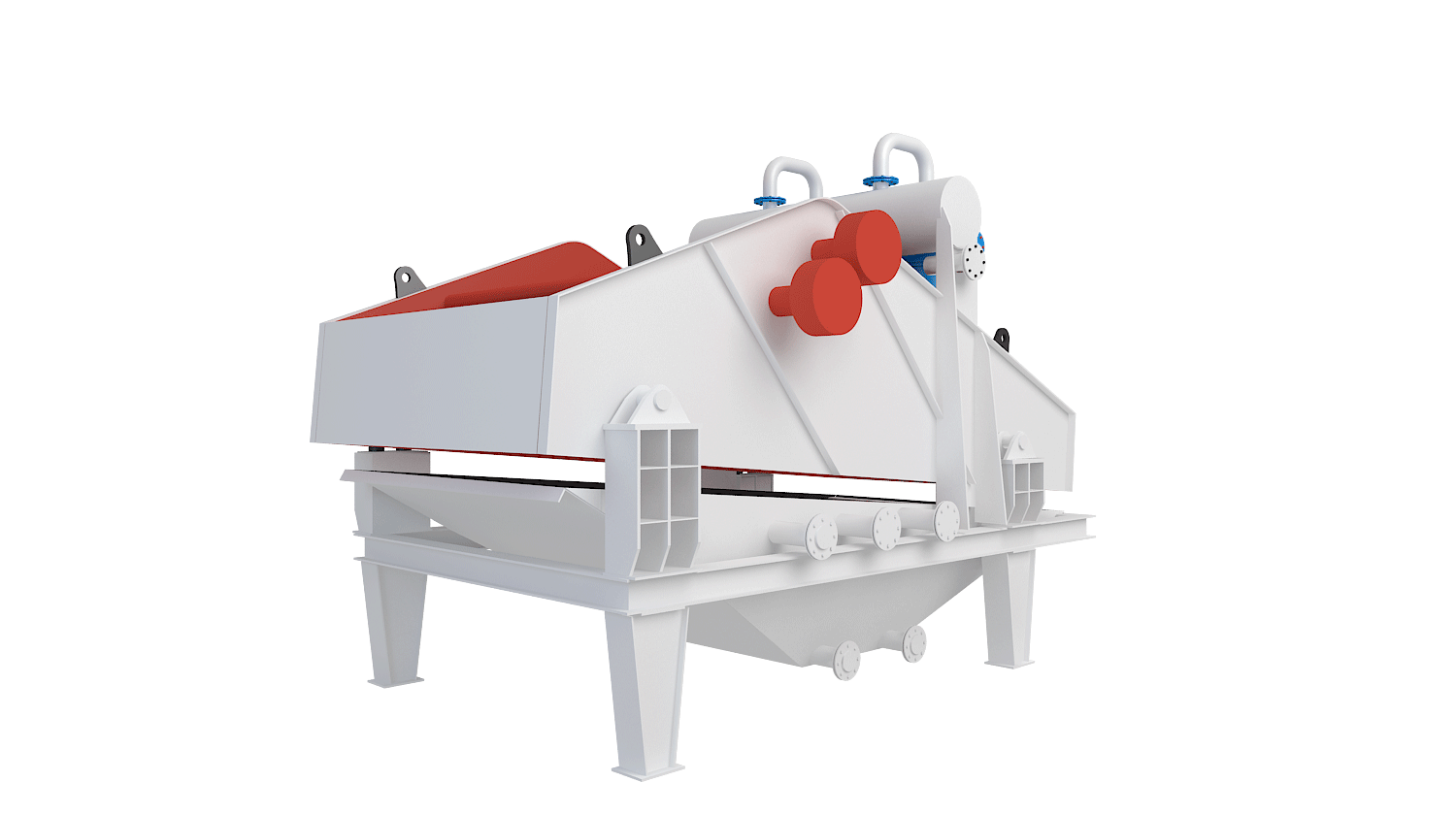

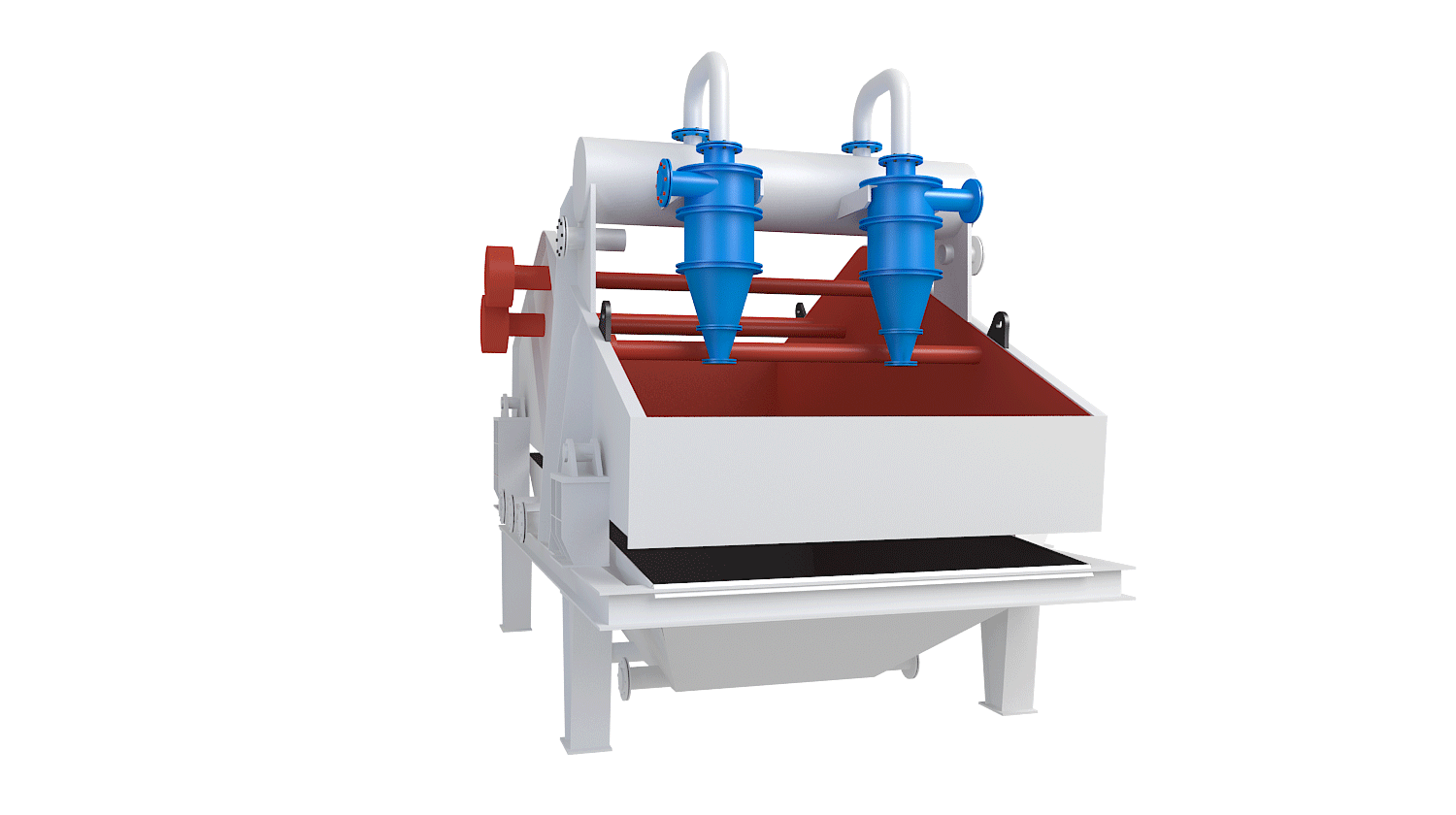

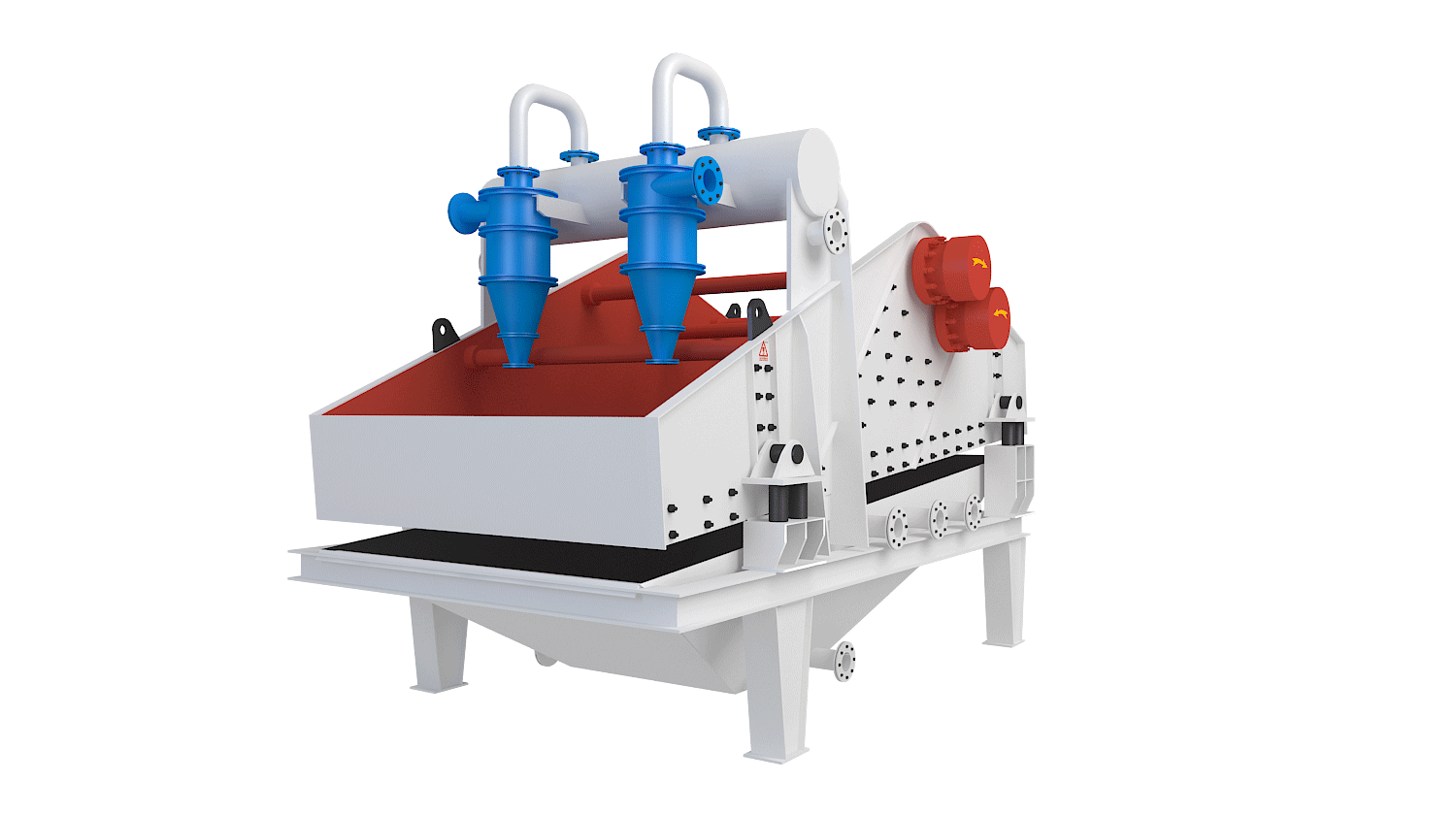

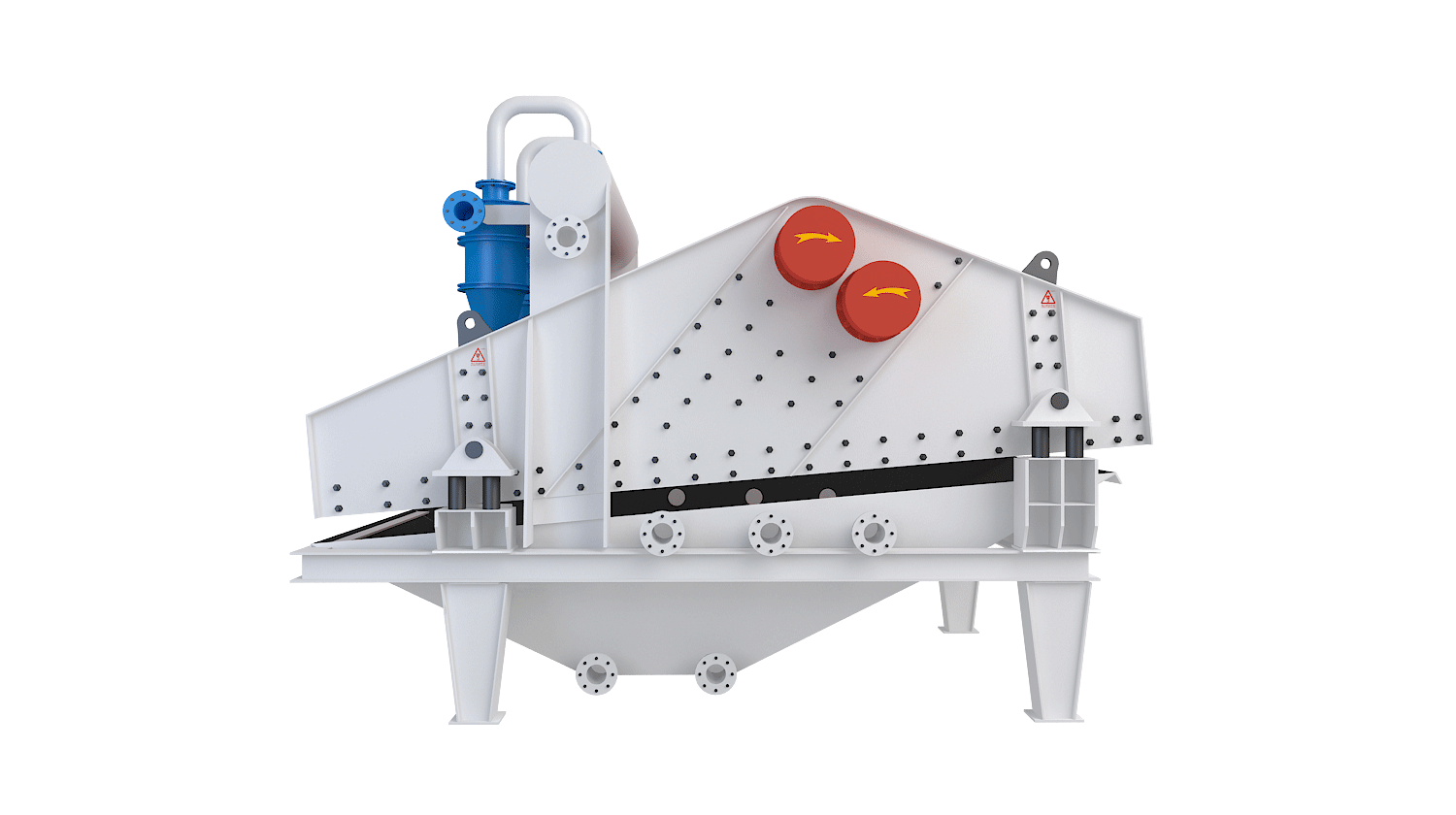

| Model | Width×Length (mm) |

Screening machine power (kw) |

Cyclone specifications | Capacity (t/h) |

Water consumption (m³/h) |

Slurry pump power (kw) |

Total power (kw) |

Weight (kg) |

Overall size length×width×height (mm) |

| KLZ 1224-35 | 1200×2400 | 2.2*2 | 350 | 50-80 | 80-120 | 18.5 | 23 | 2376 | 3000×1800×2773 |

| KLZ 1530-65 | 1500×3000 | 3*2 | 300*2 | 80-100 | 120-180 | 15*2 | 36 | 3745 | 3500×2100×3200 |

| KLZ 1840-75 | 1800×4000 | 5.5*2 | 350*2 | 100-140 | 160-240 | 18.5*2 | 48 | 5350 | 4500×2400×3300 |

| KLZ 2050-100 | 2000×5000 | 11*2 | 250*4 | 120-160 | 200-280 | 18.5*2 | 59 | 6736 | 5500×2600×3520 |

| KLZ 2250-100 | 2250×5000 | 11*2 | 250*4 | 150-220 | 200-280 | 22*2 | 66 | 7850 | 5500×2800×3600 |