| Model | Power (kw) |

Capacity (t/h) |

Notes |

| XL920-8m | 11 | 40-60 | ZQ400 Reducer |

| 2XL920-8m | 11*2 | 90-120 | ZQ400 Reducer |

| XL1120-8m | 18.5 | 60-80 | ZQ400 Reducer |

| 2XL1120-8m | 18.5*2 | 180-260 | ZQ400 Reducer |

| XL1500-8m | 18.5 | 100-120 | ZQ400 Reducer |

| XL1500-9m | 22 | 100-120 | ZQ400 Reducer |

| 2XL1500-8m | 22*2 | 240-300 | ZQ400 Reducer |

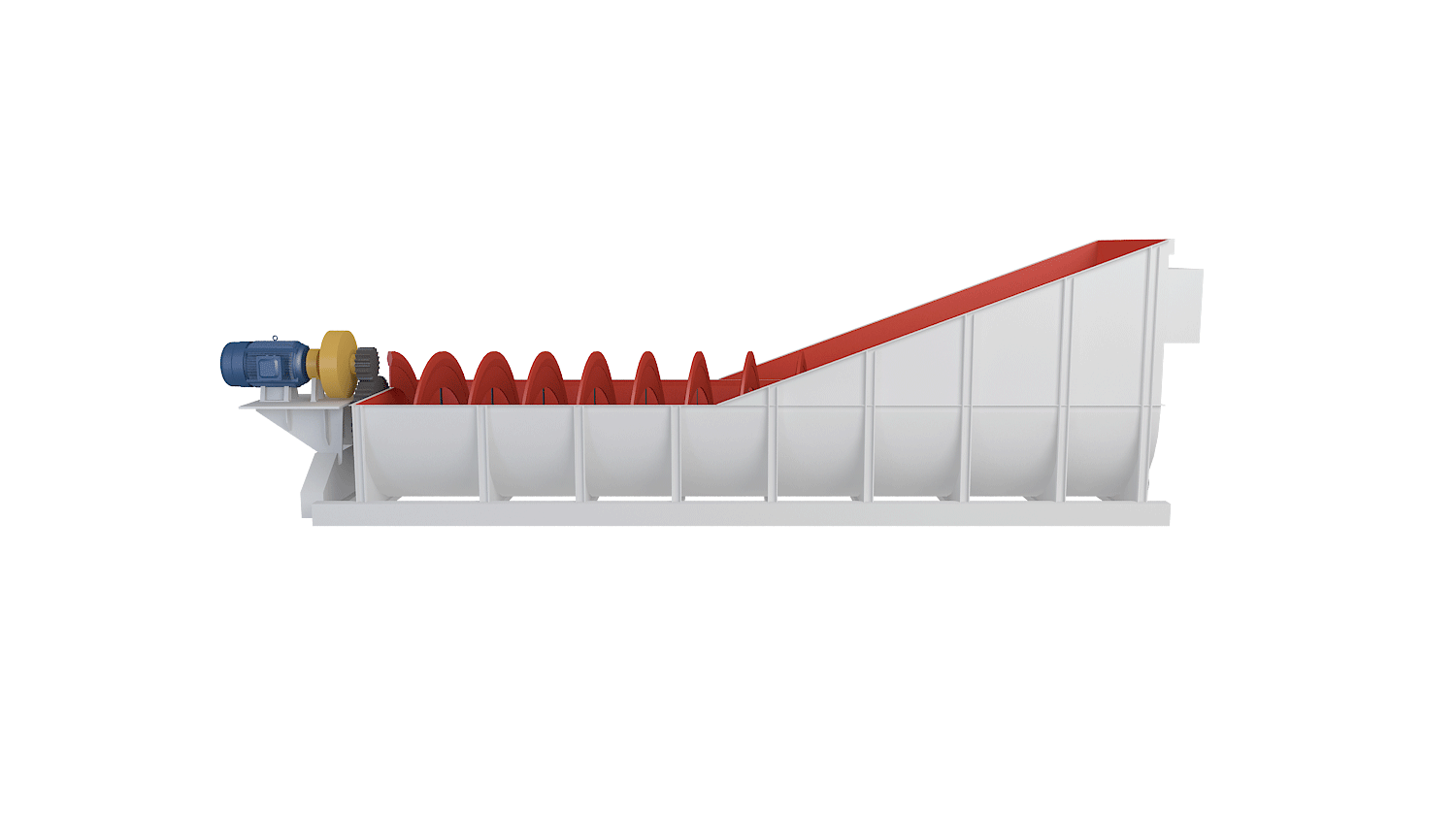

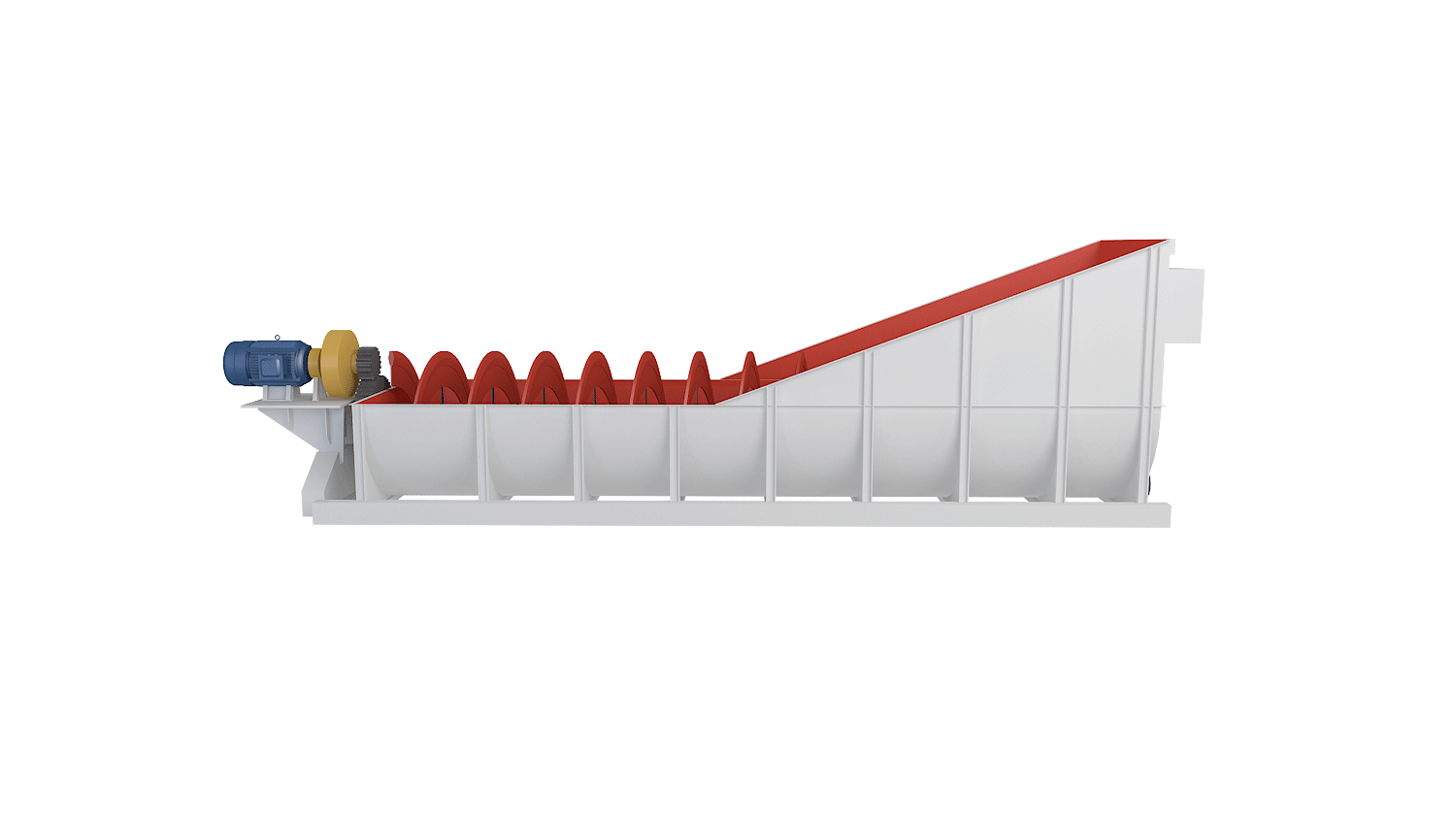

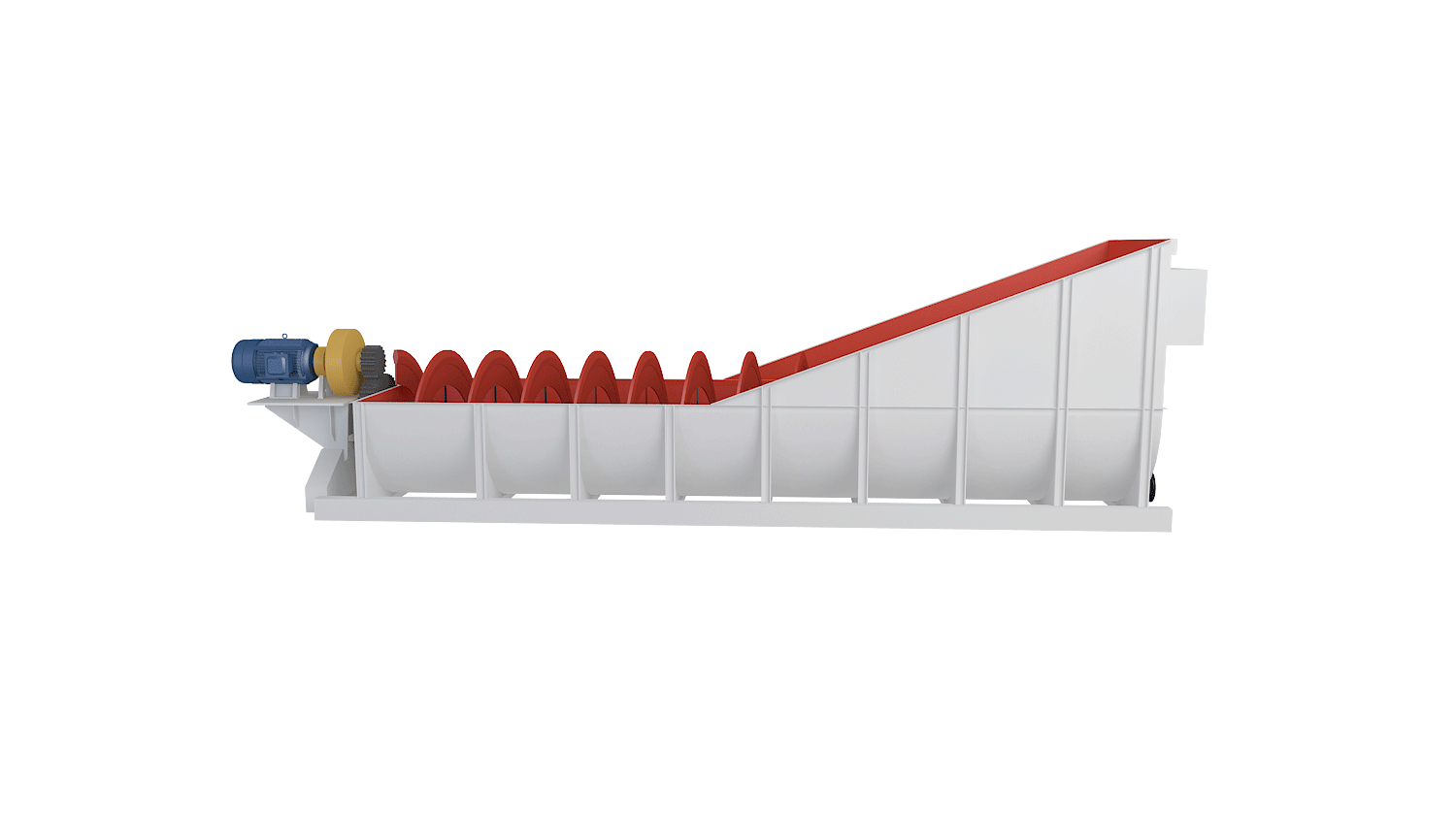

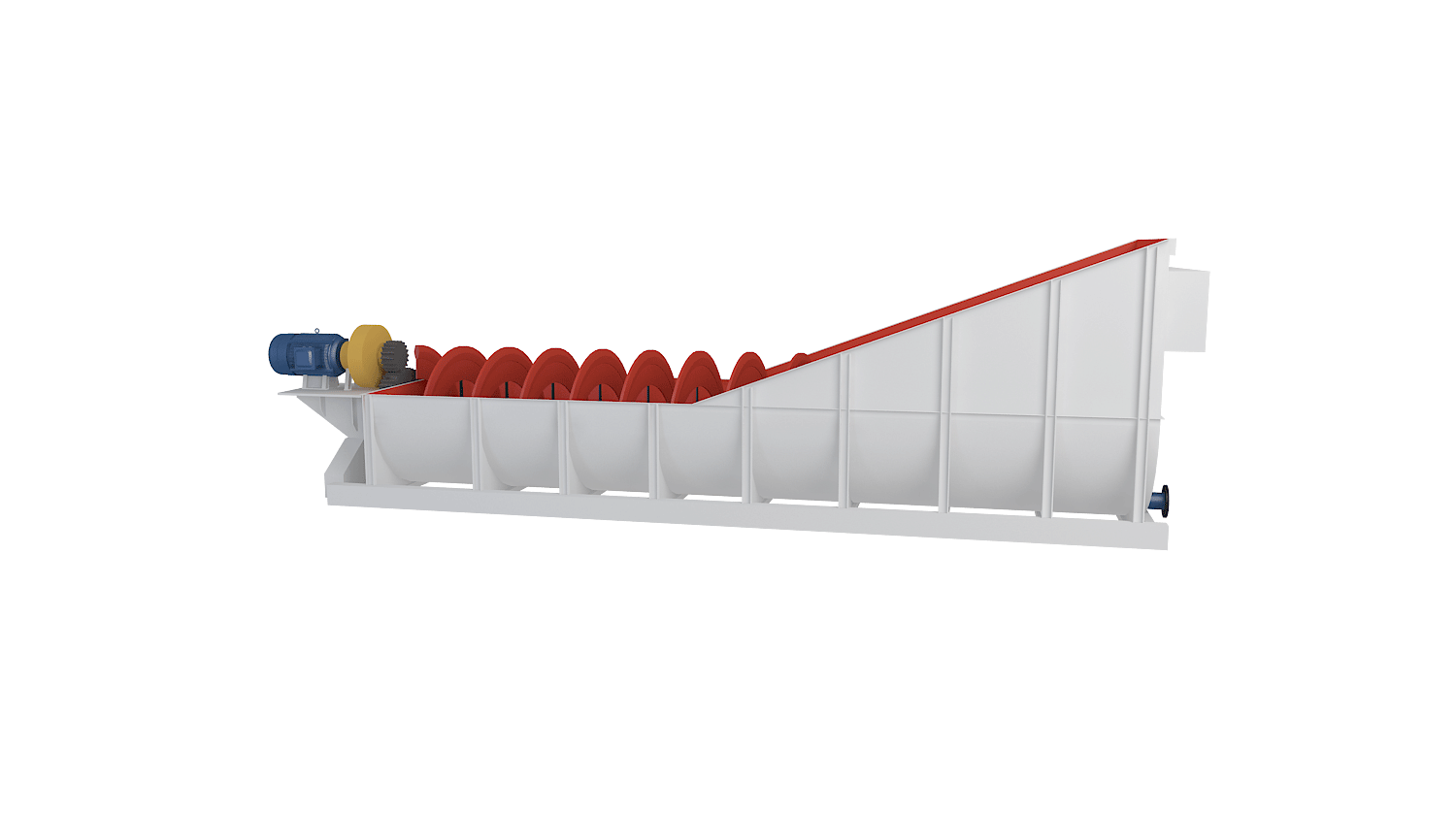

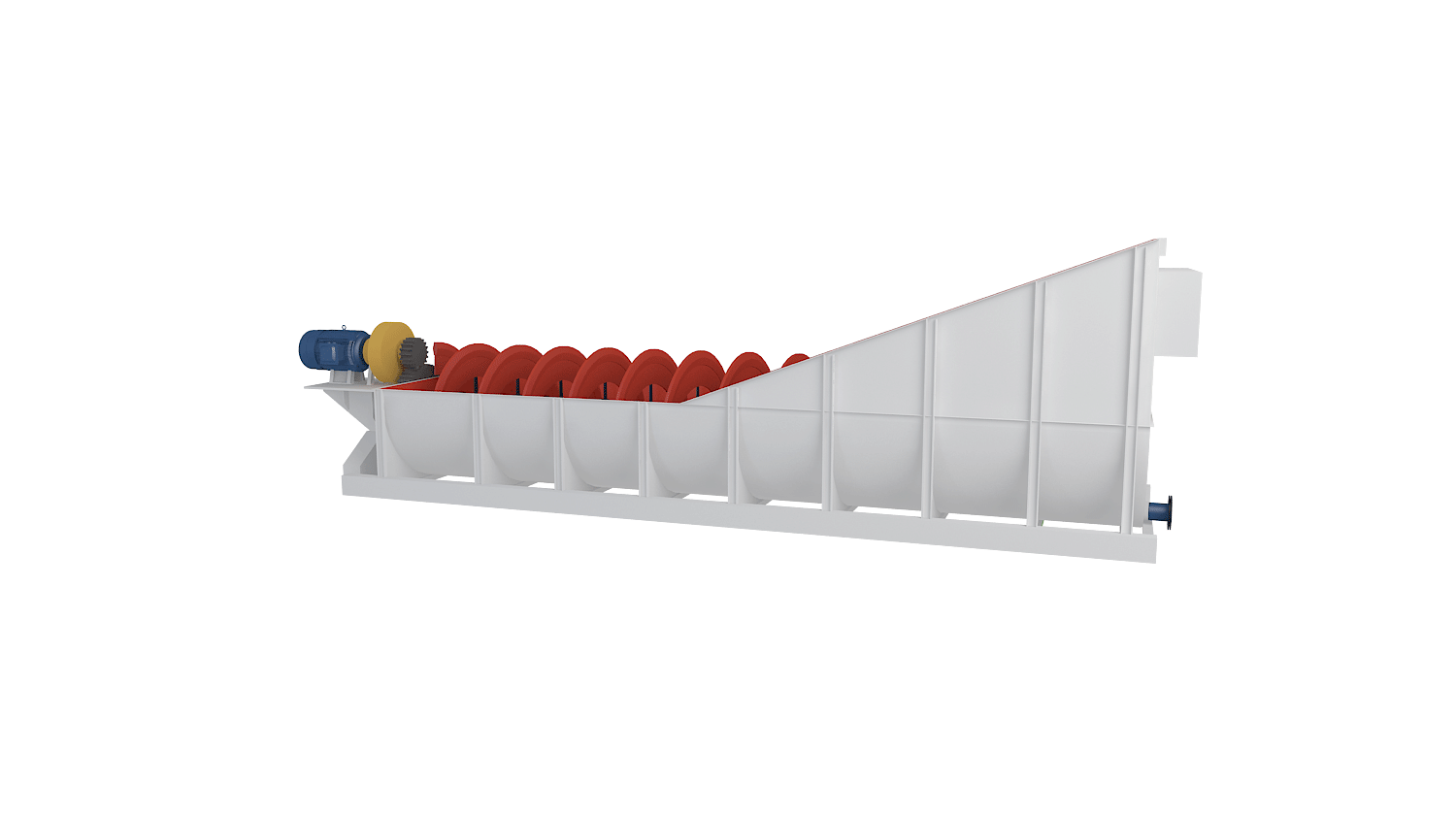

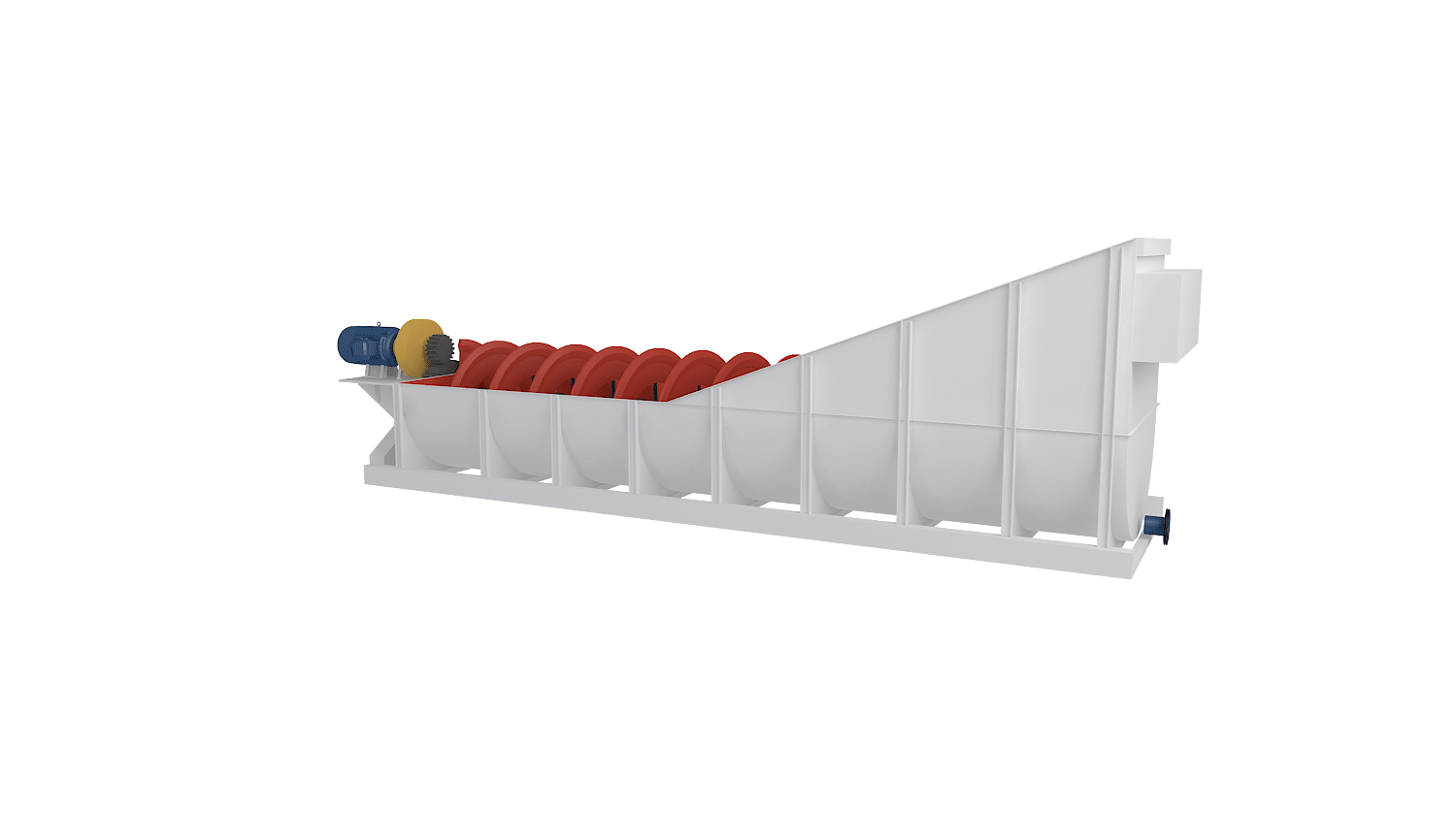

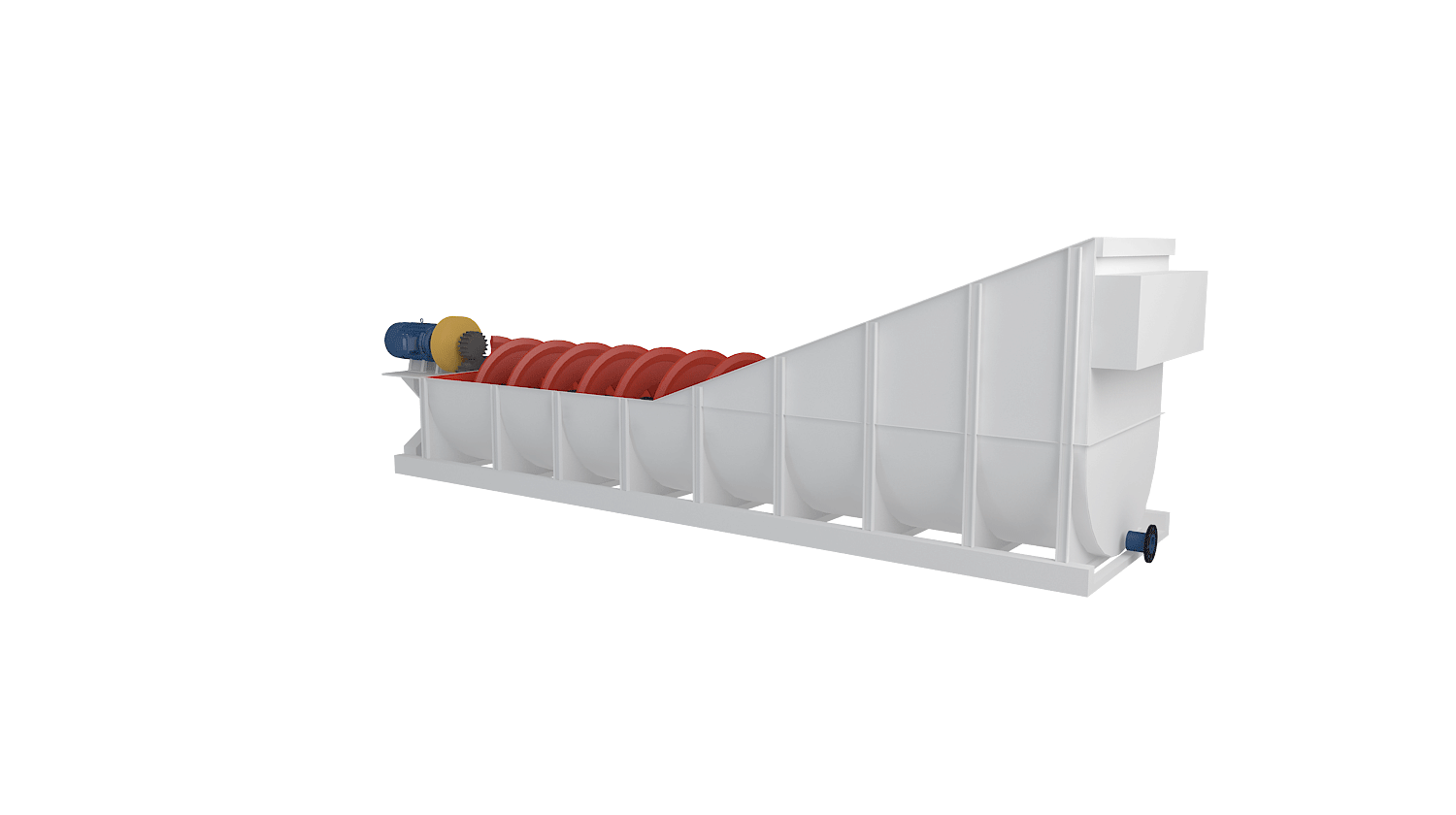

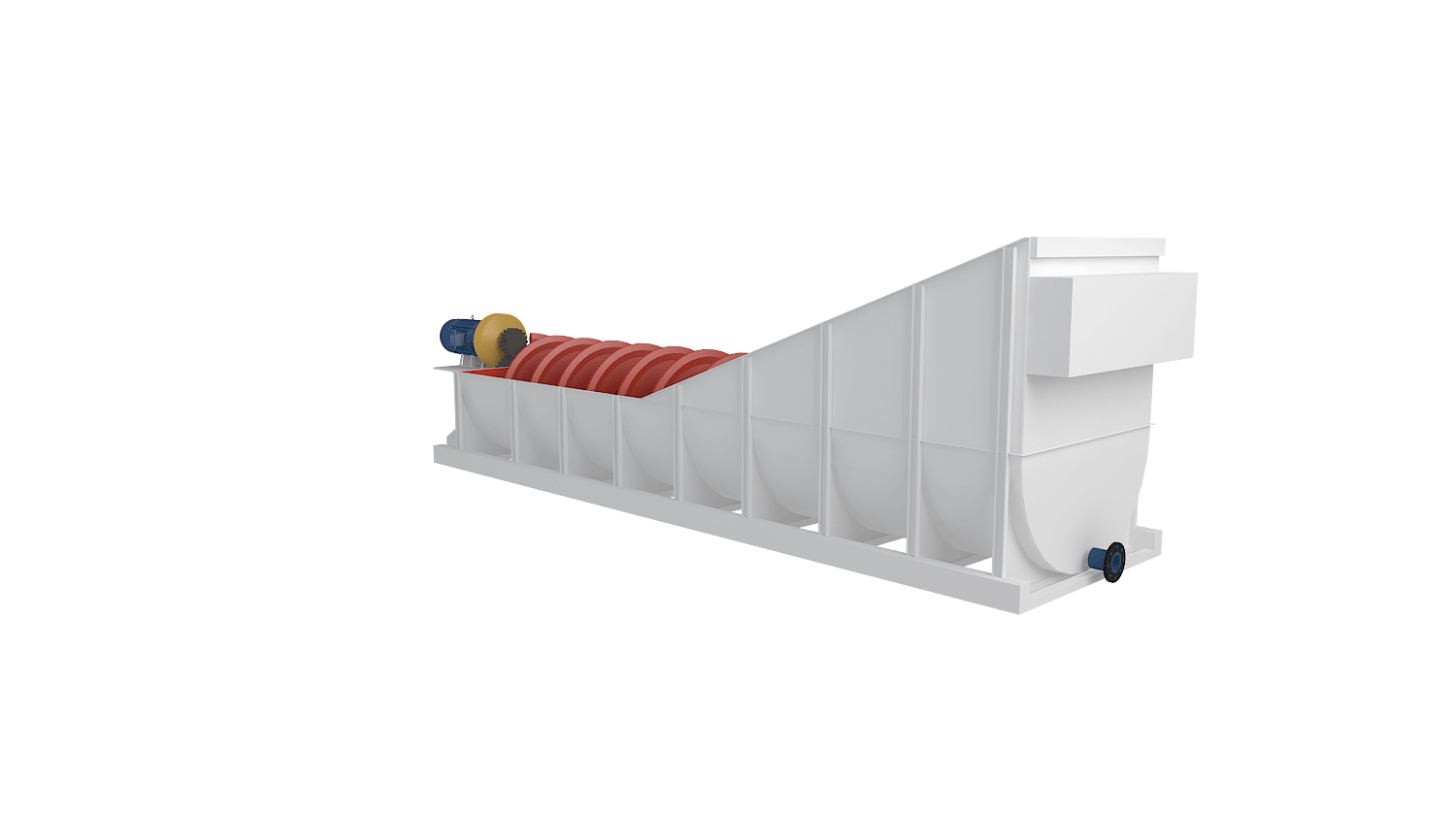

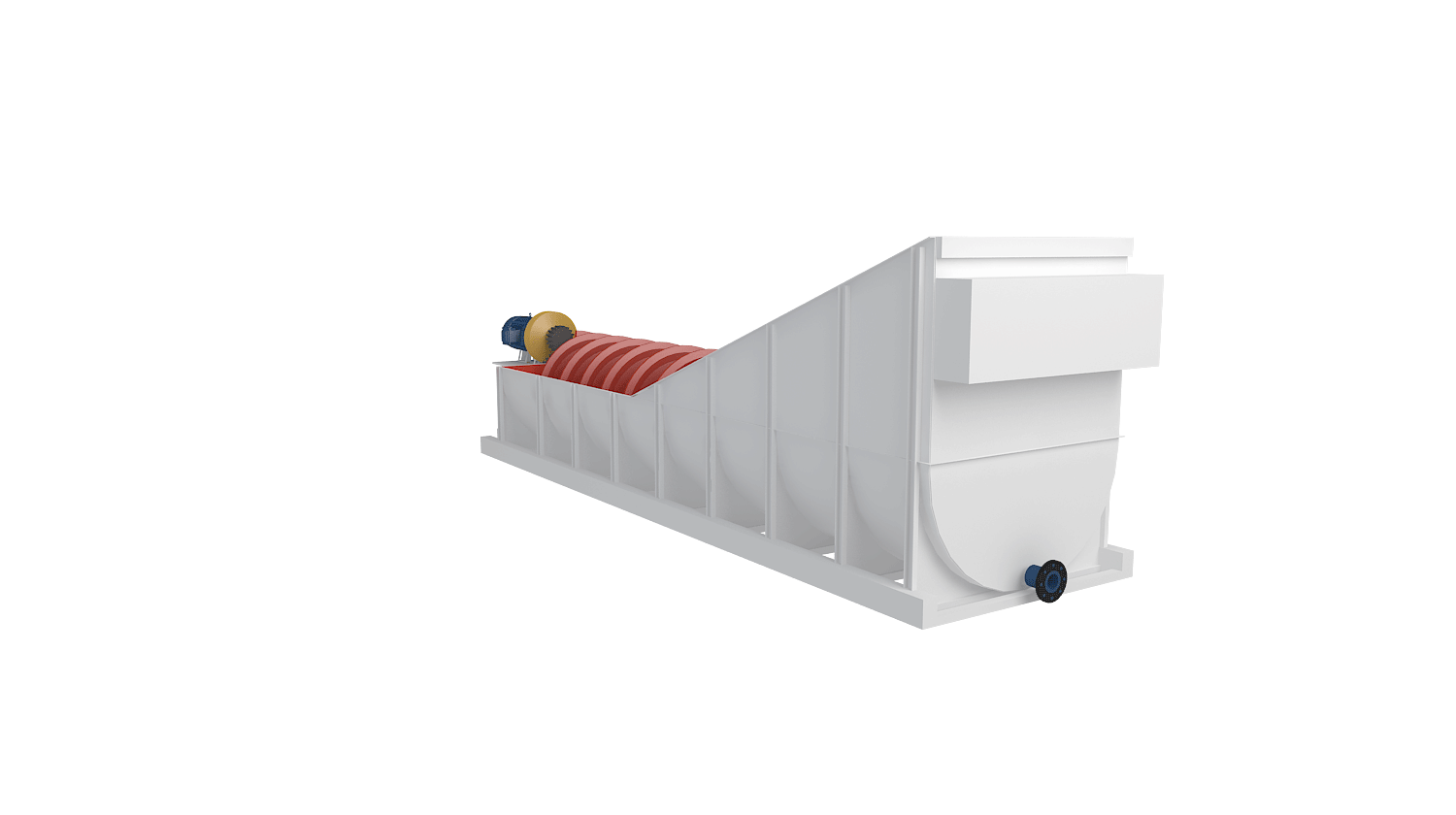

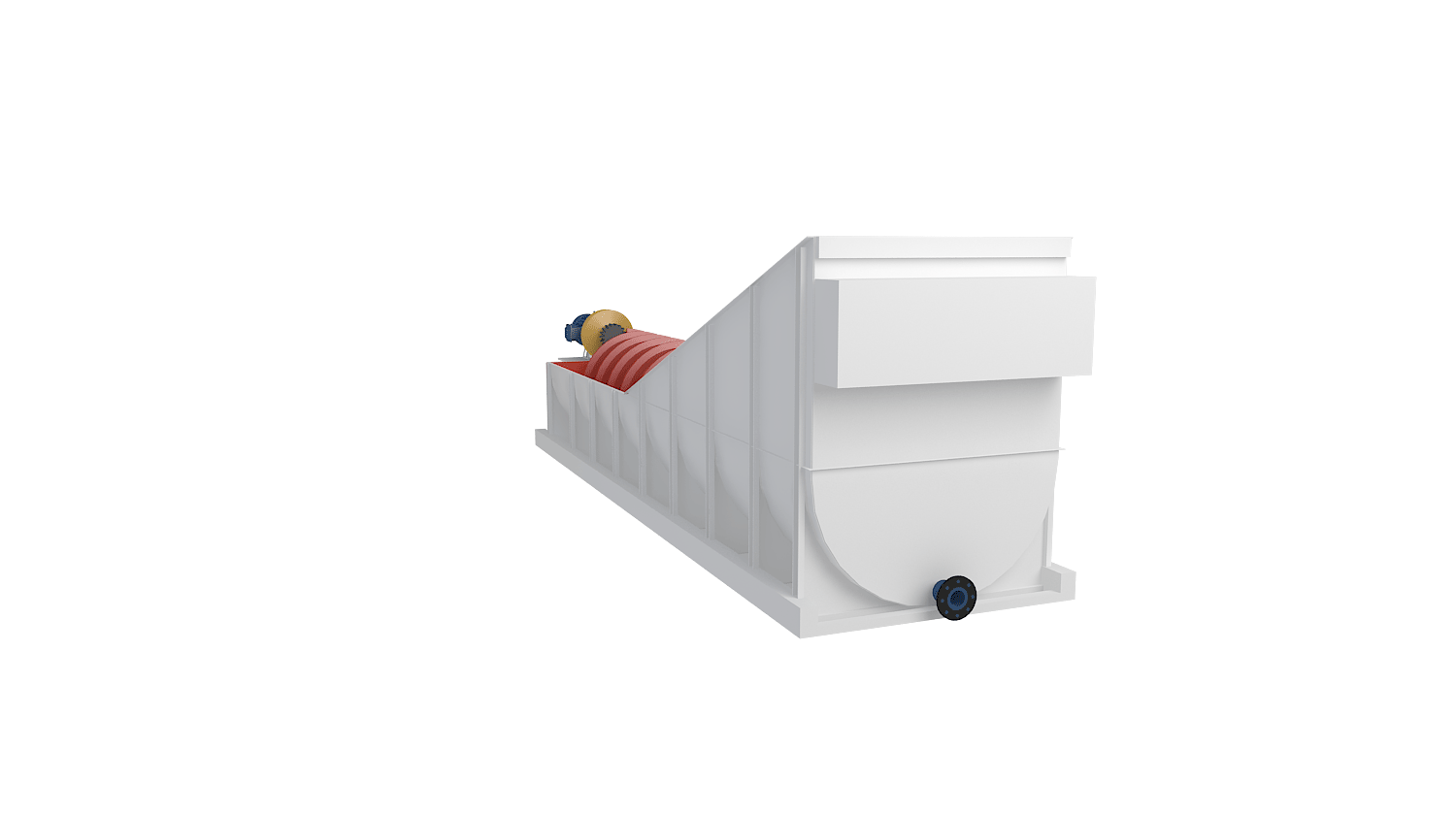

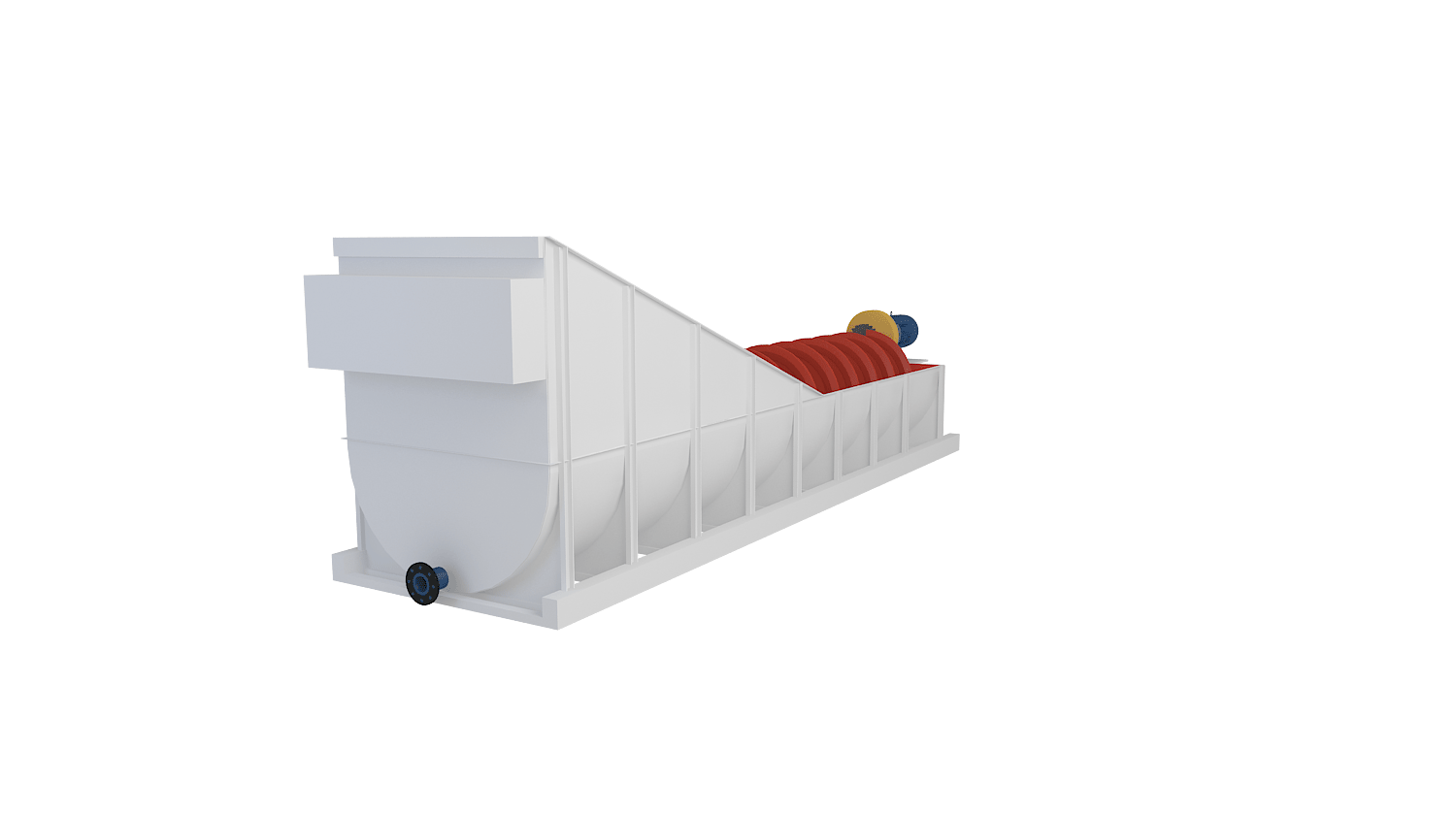

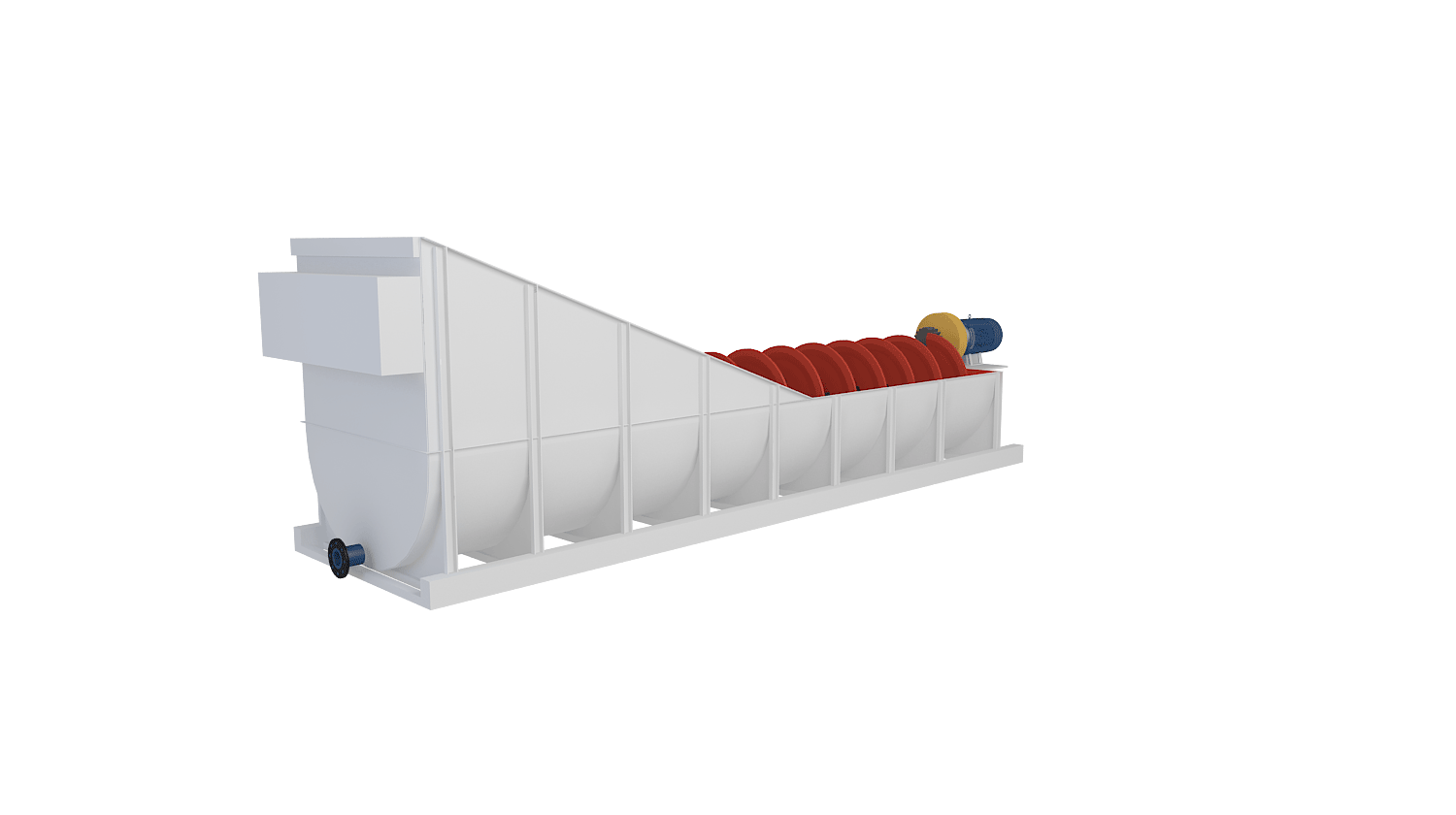

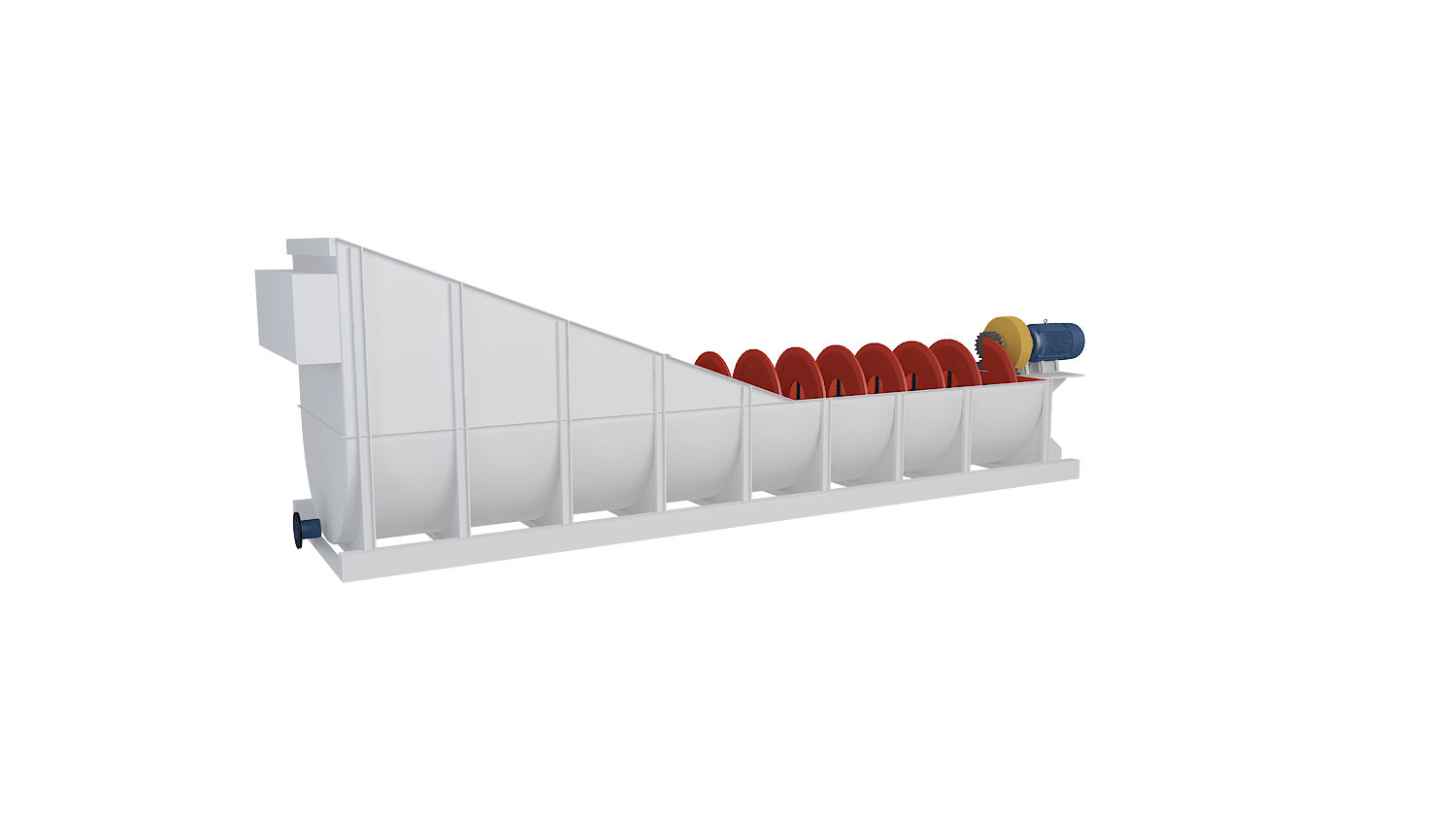

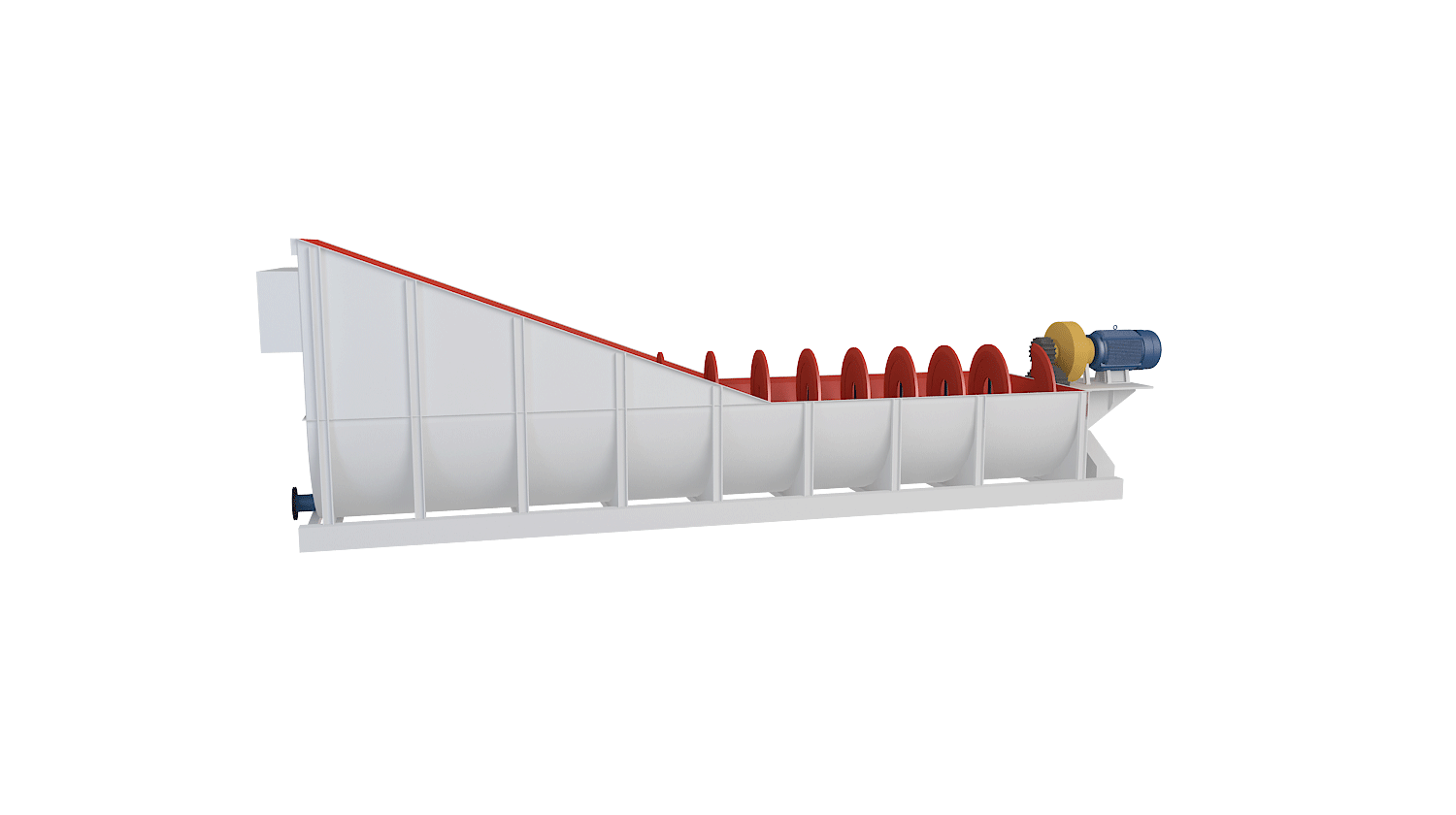

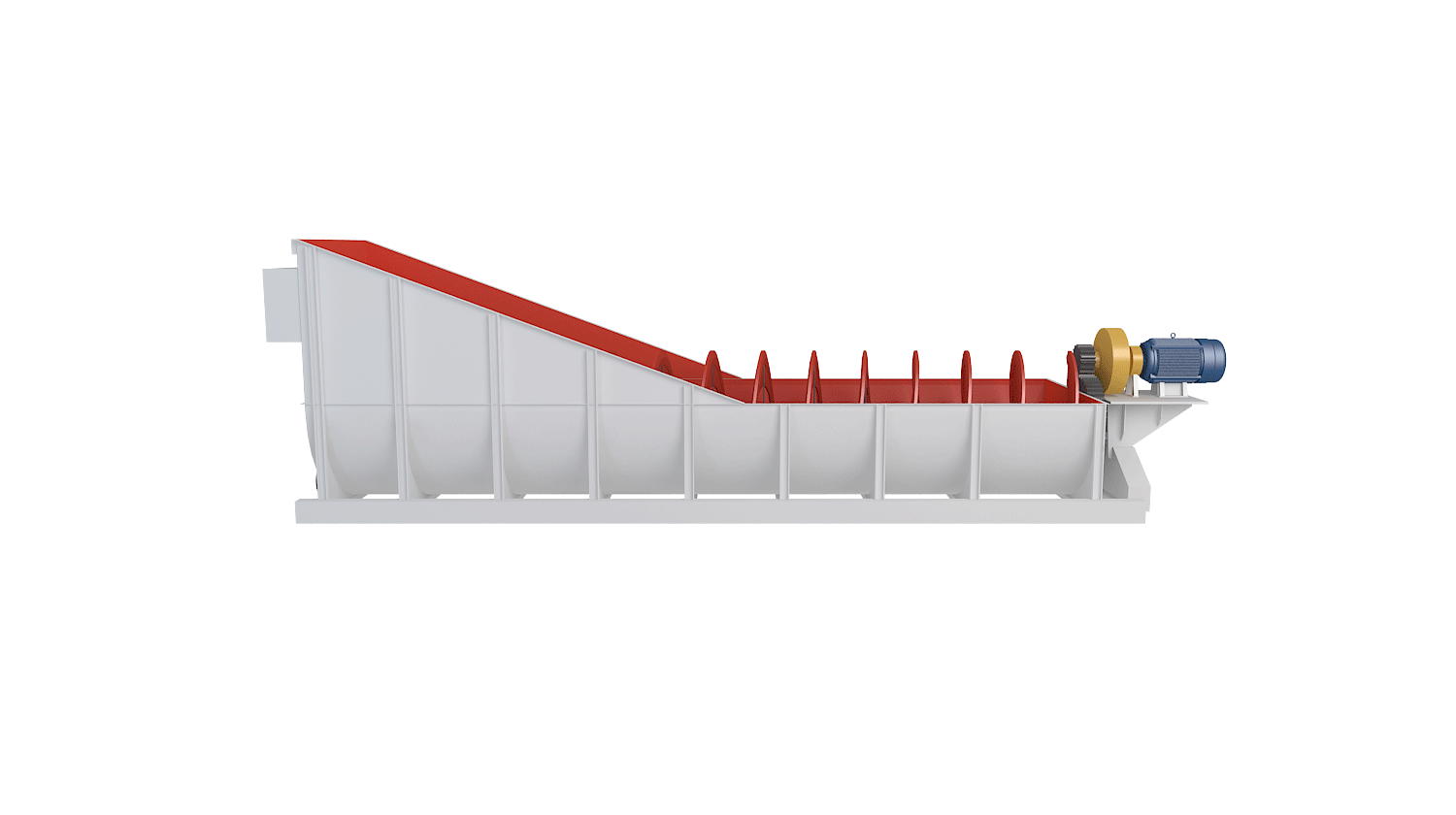

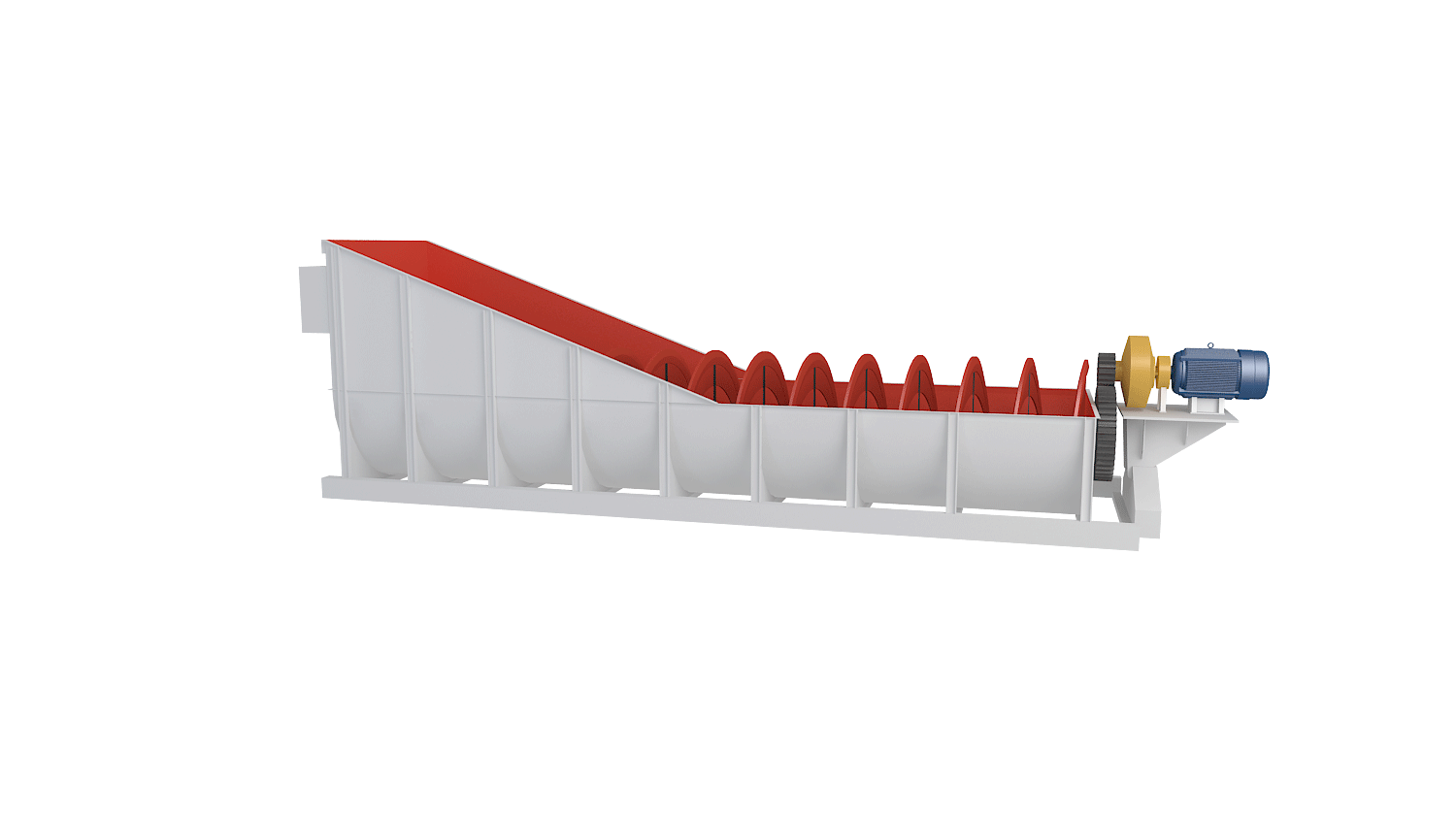

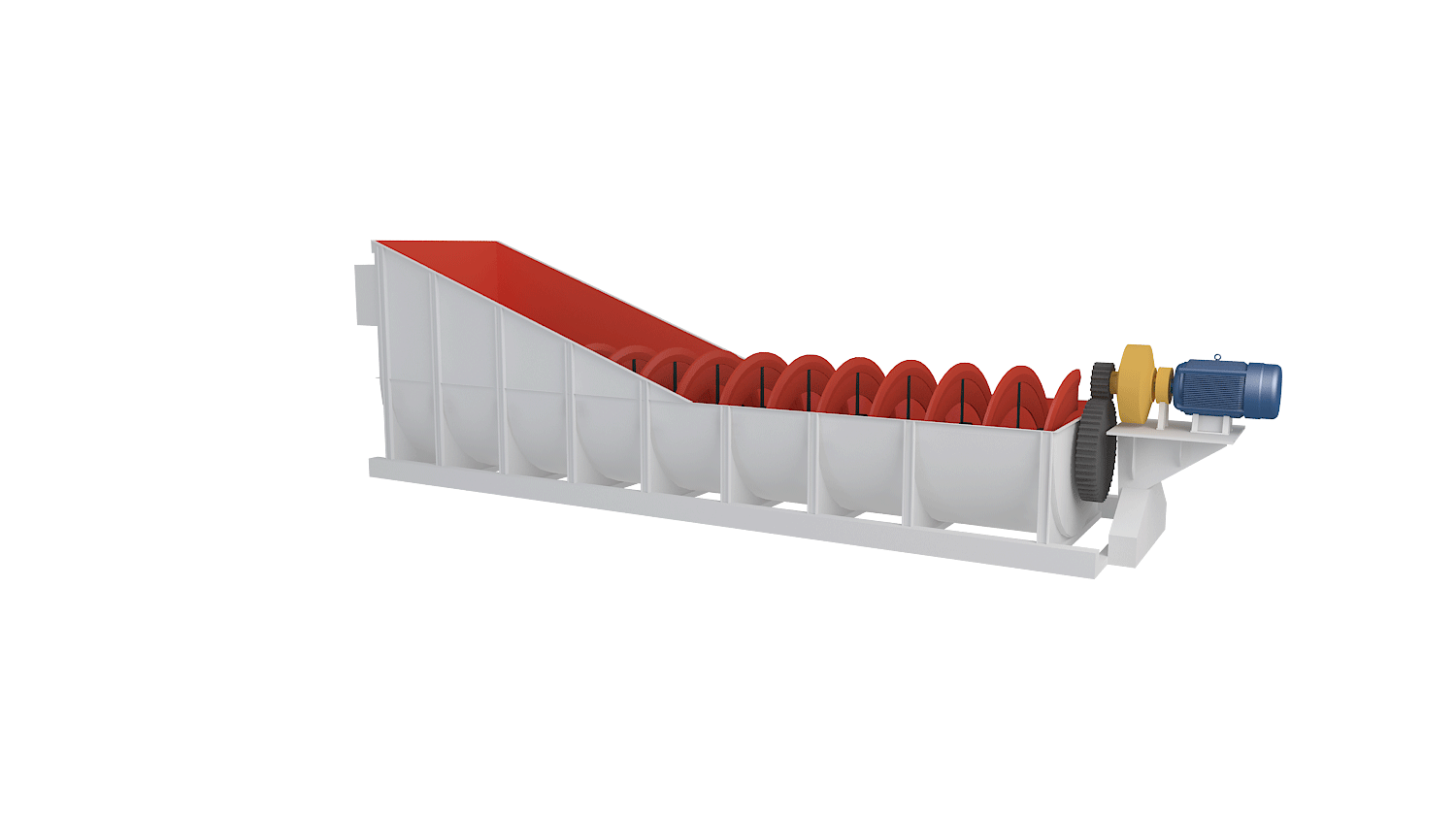

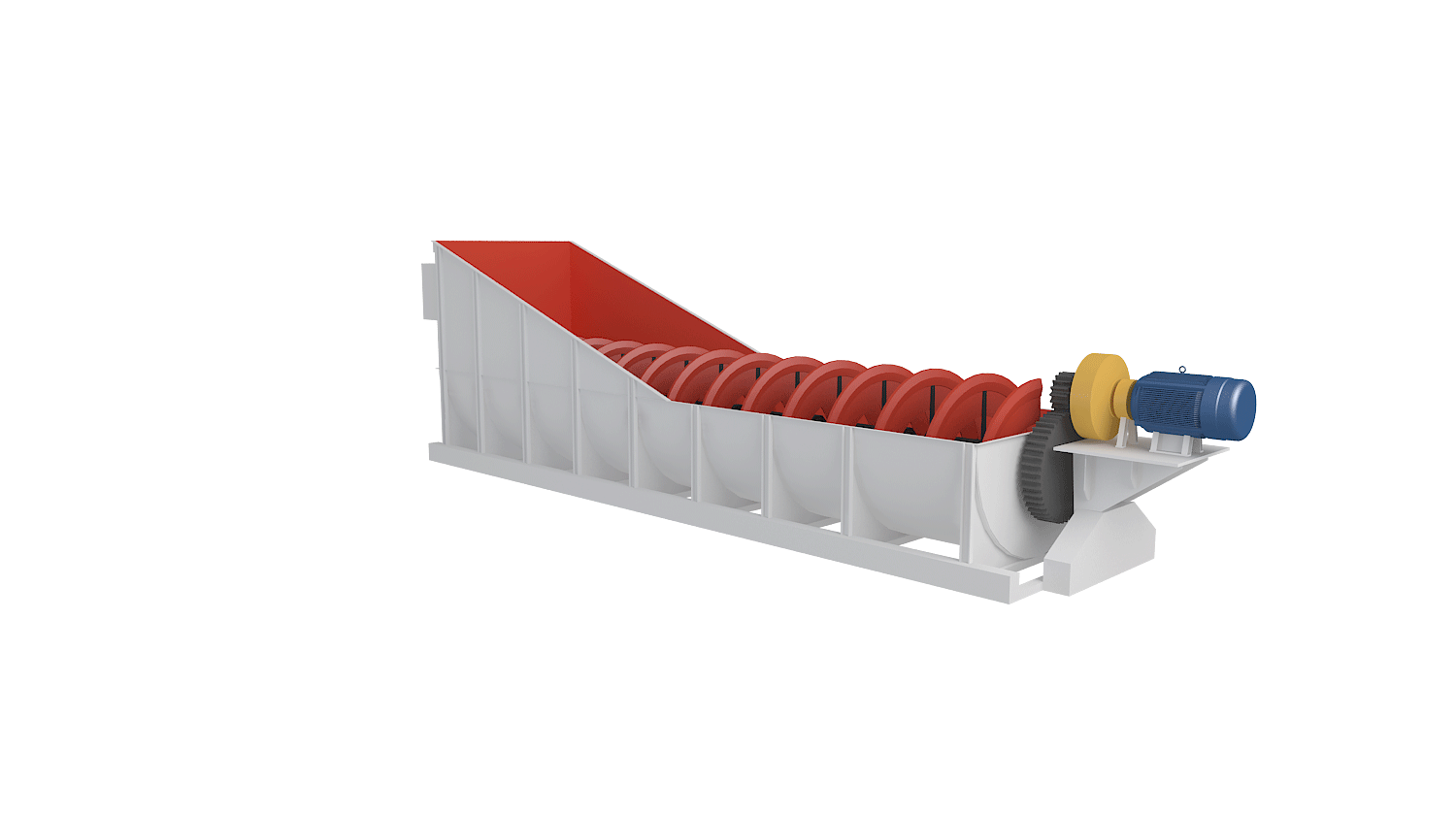

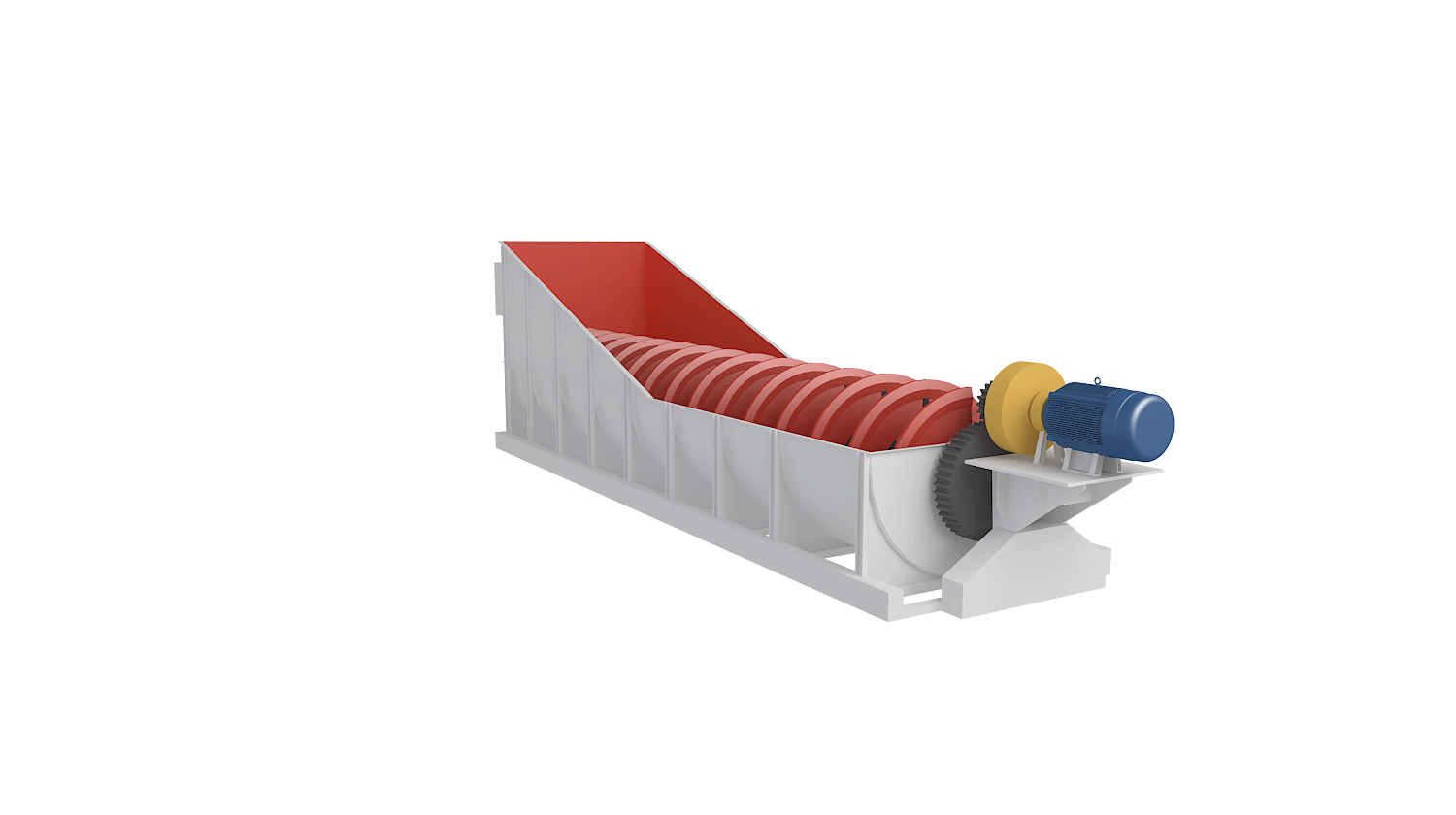

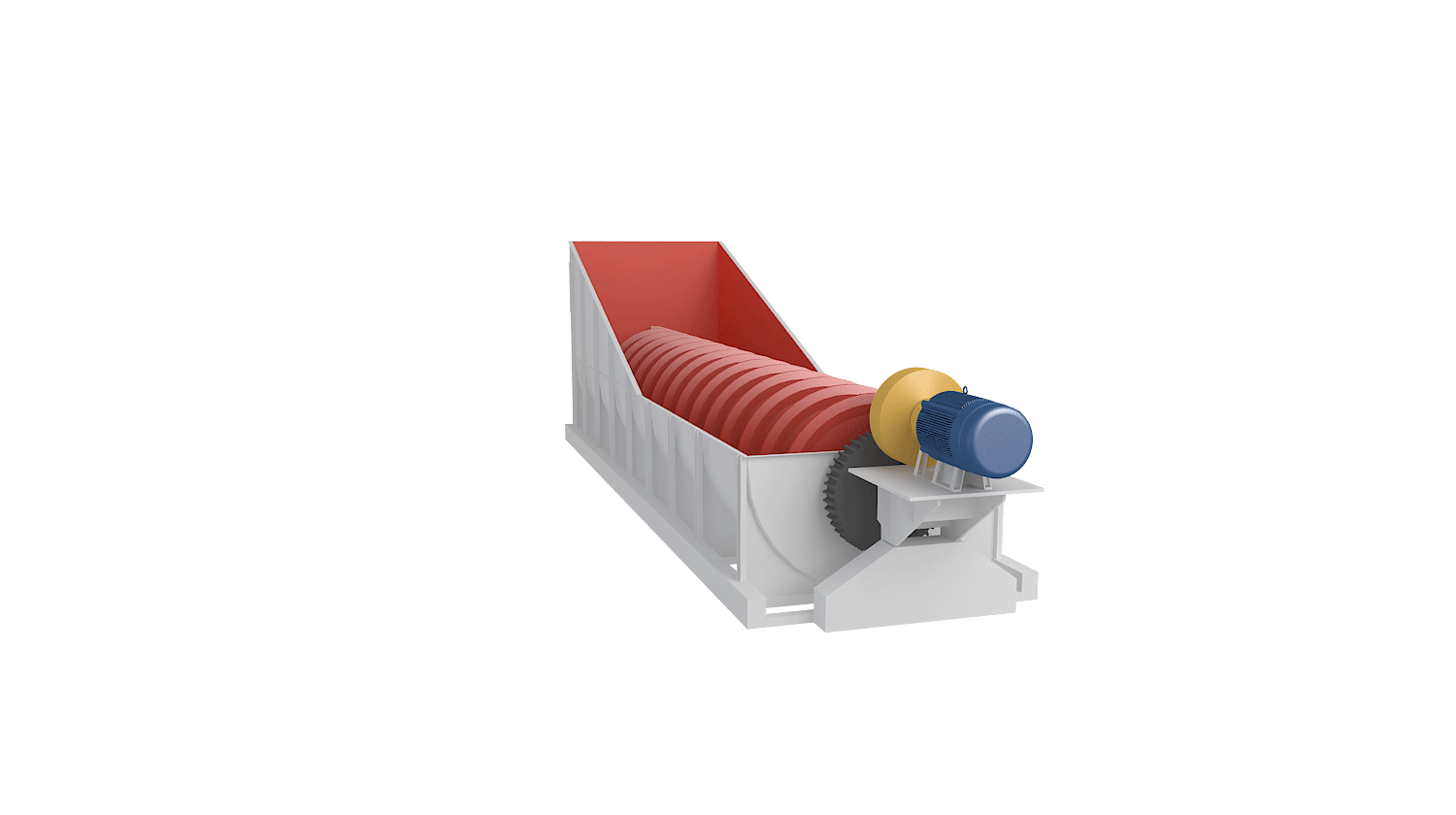

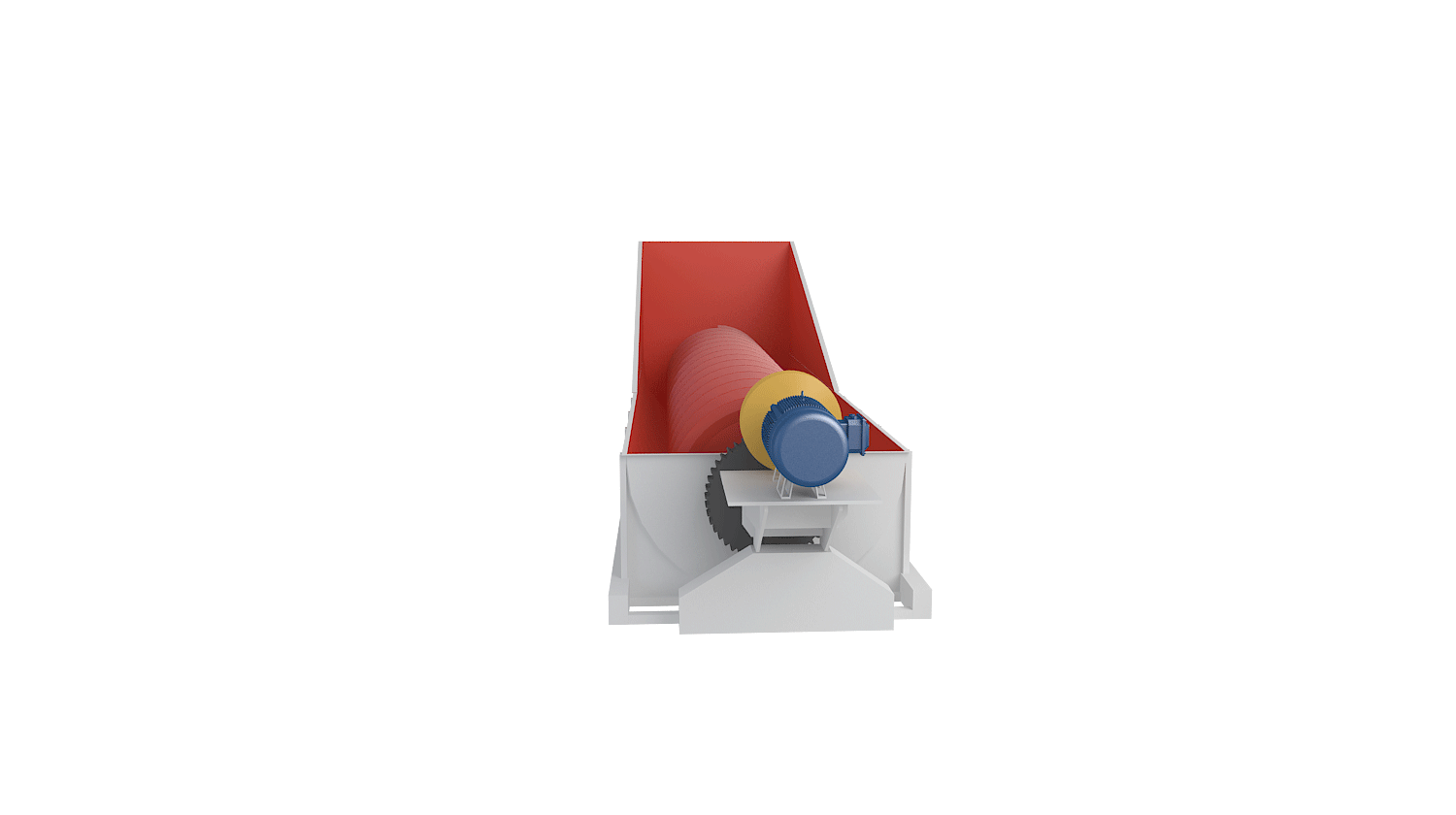

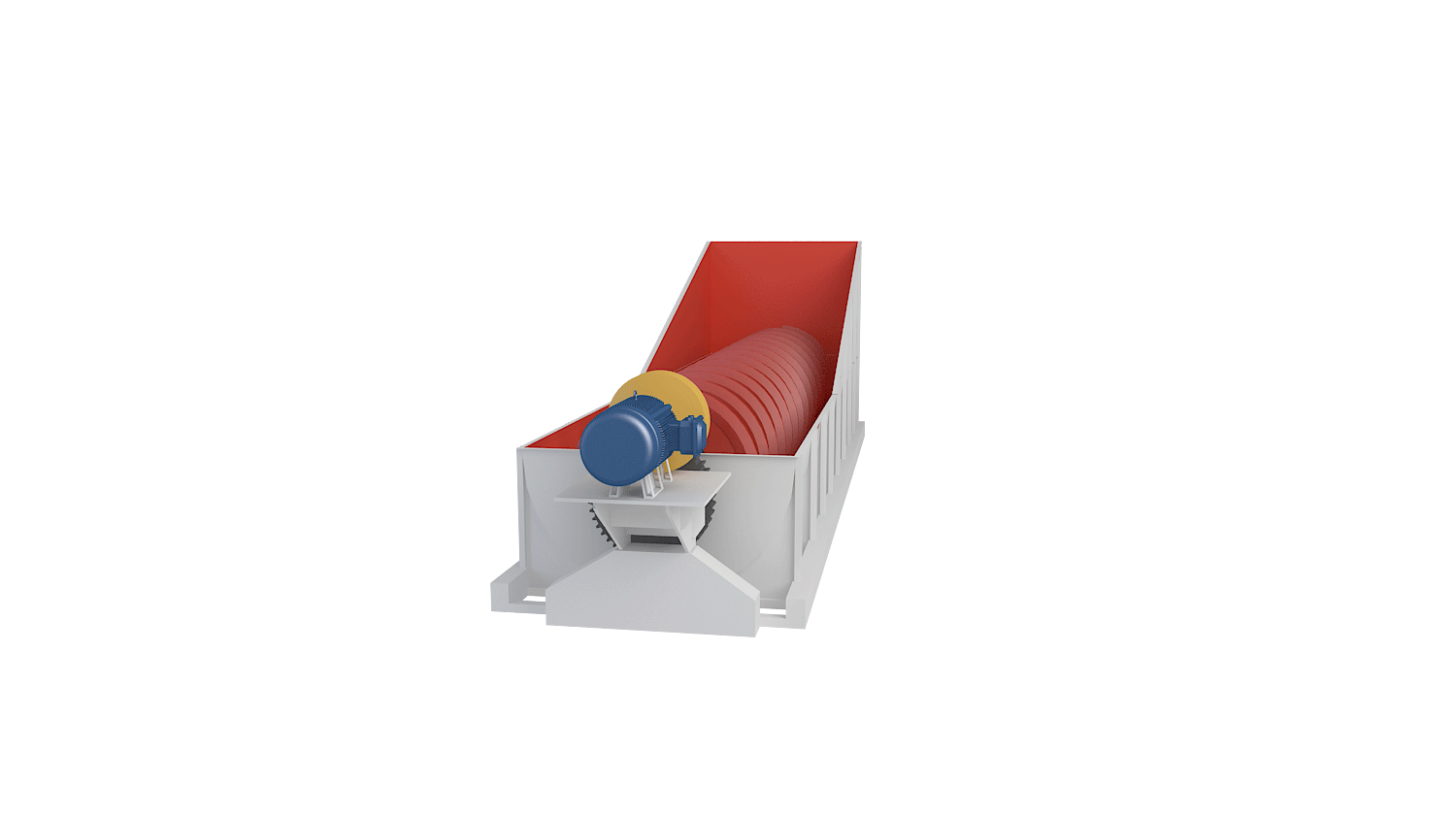

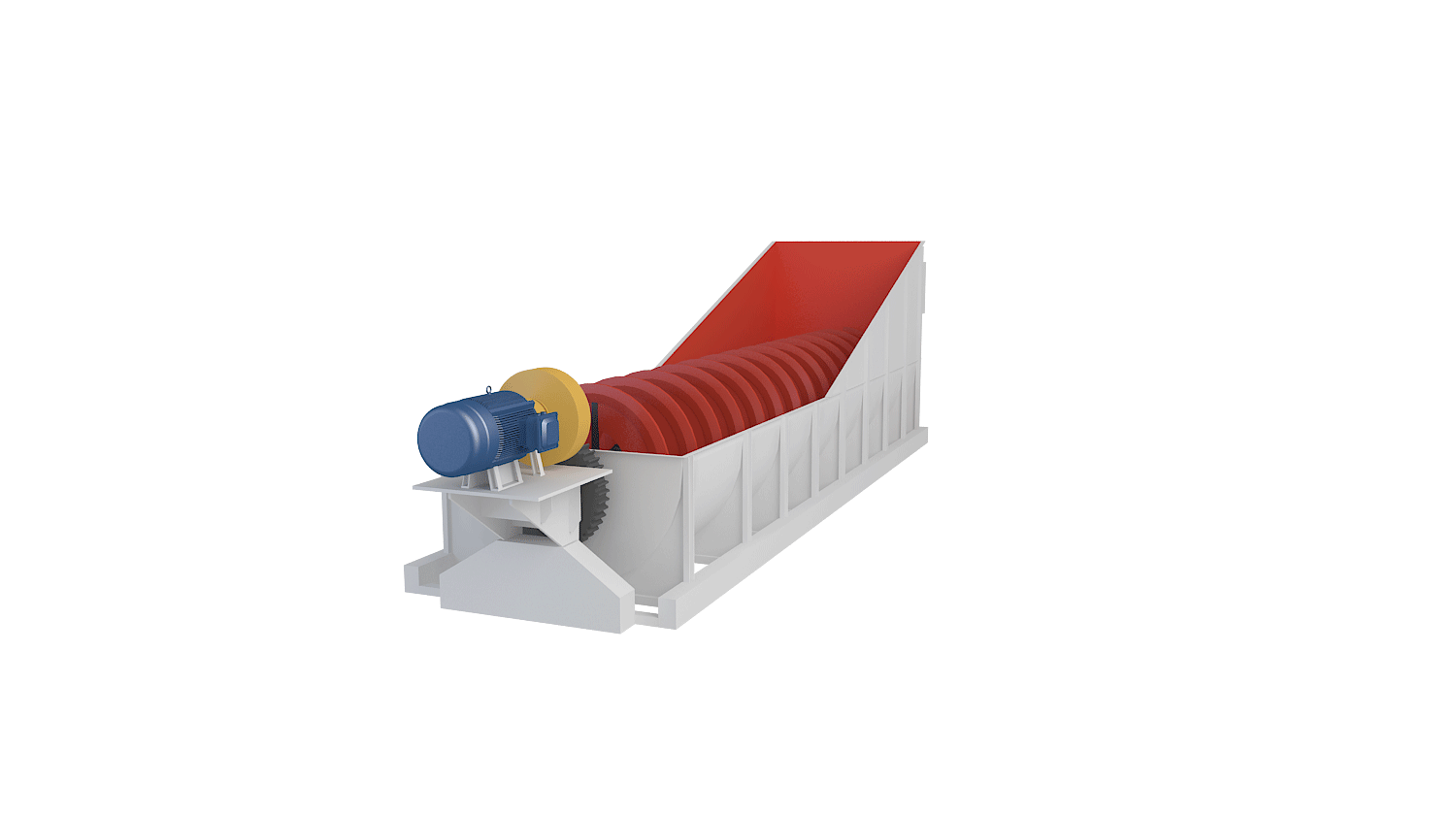

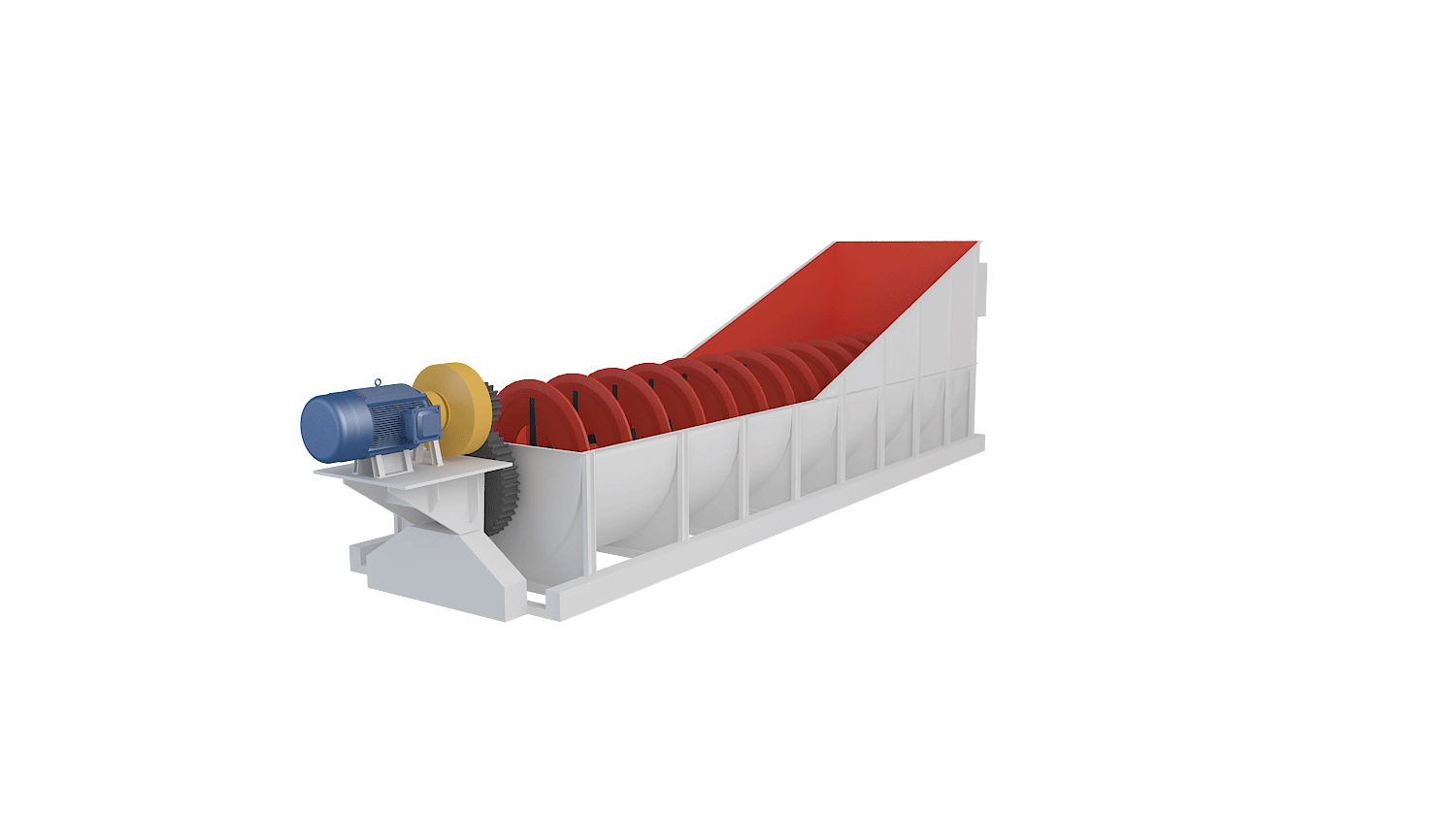

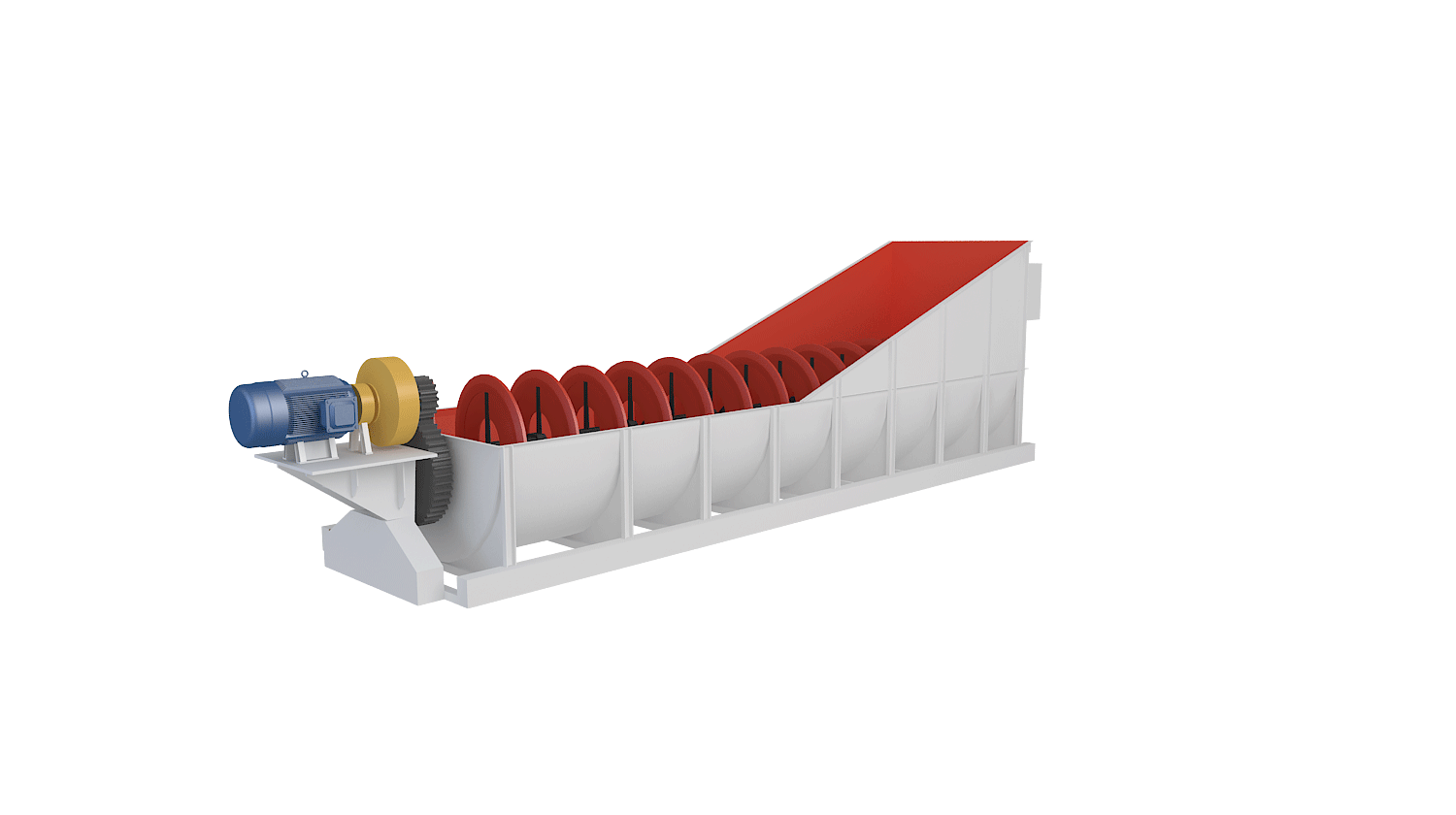

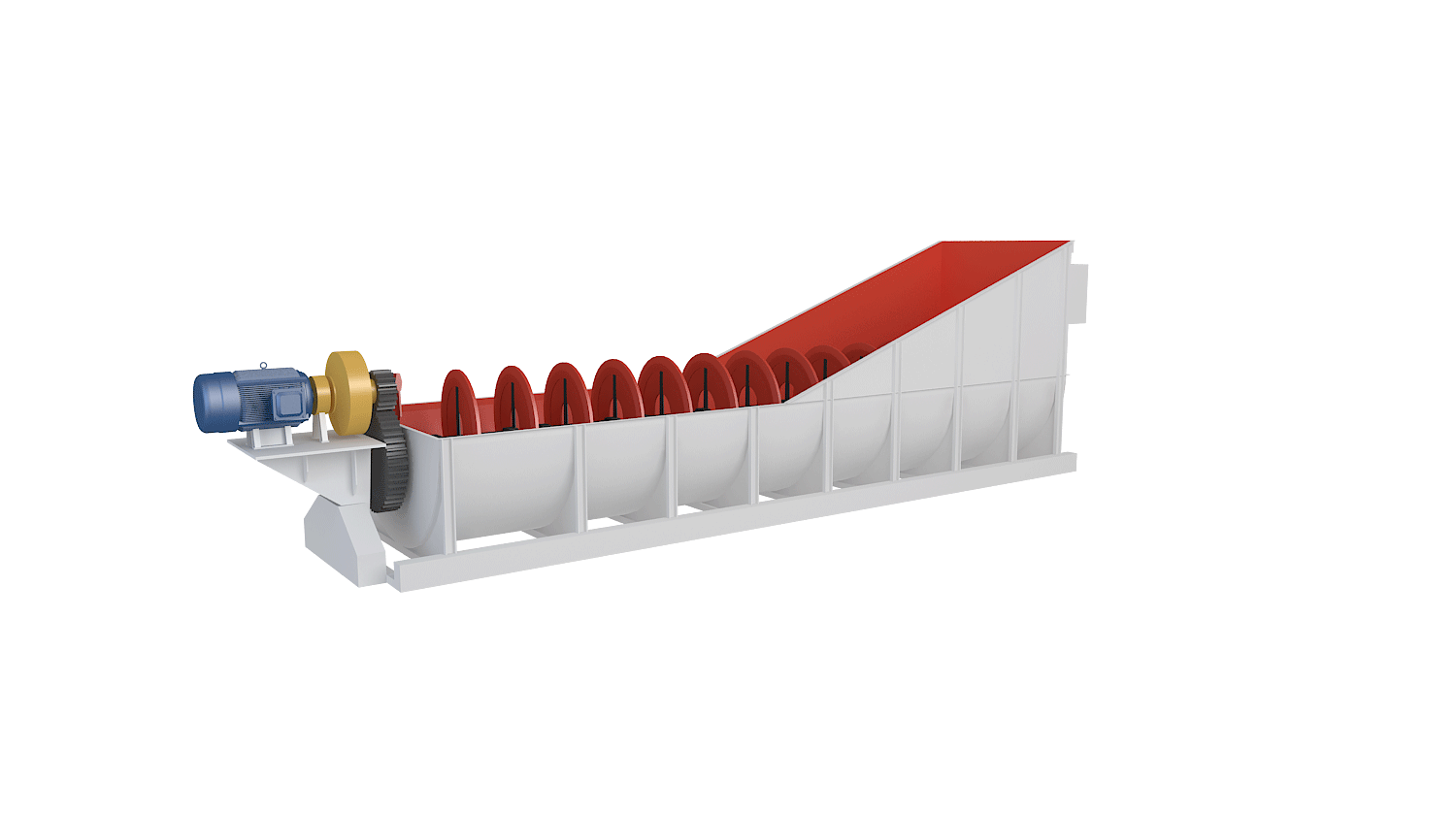

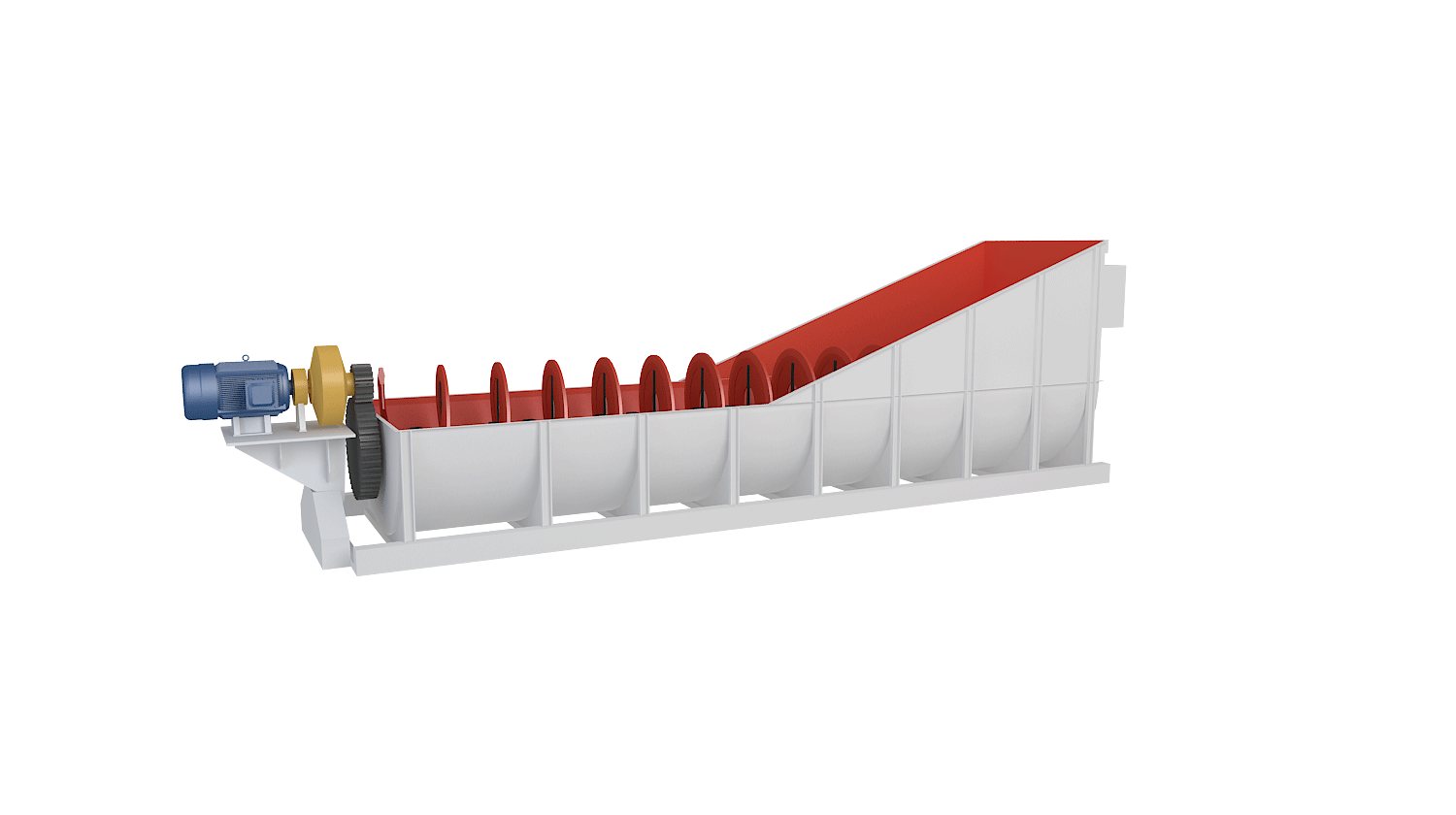

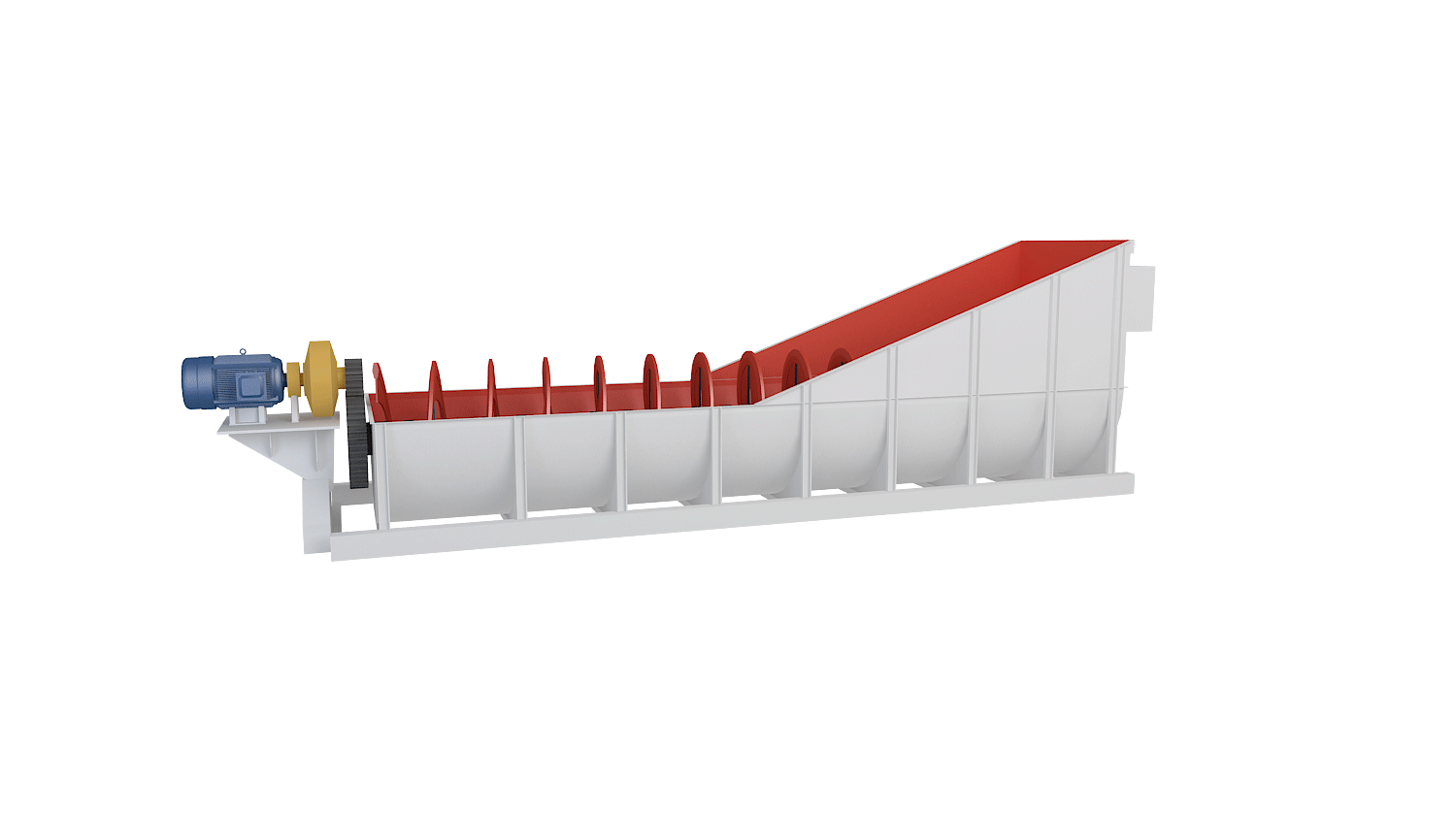

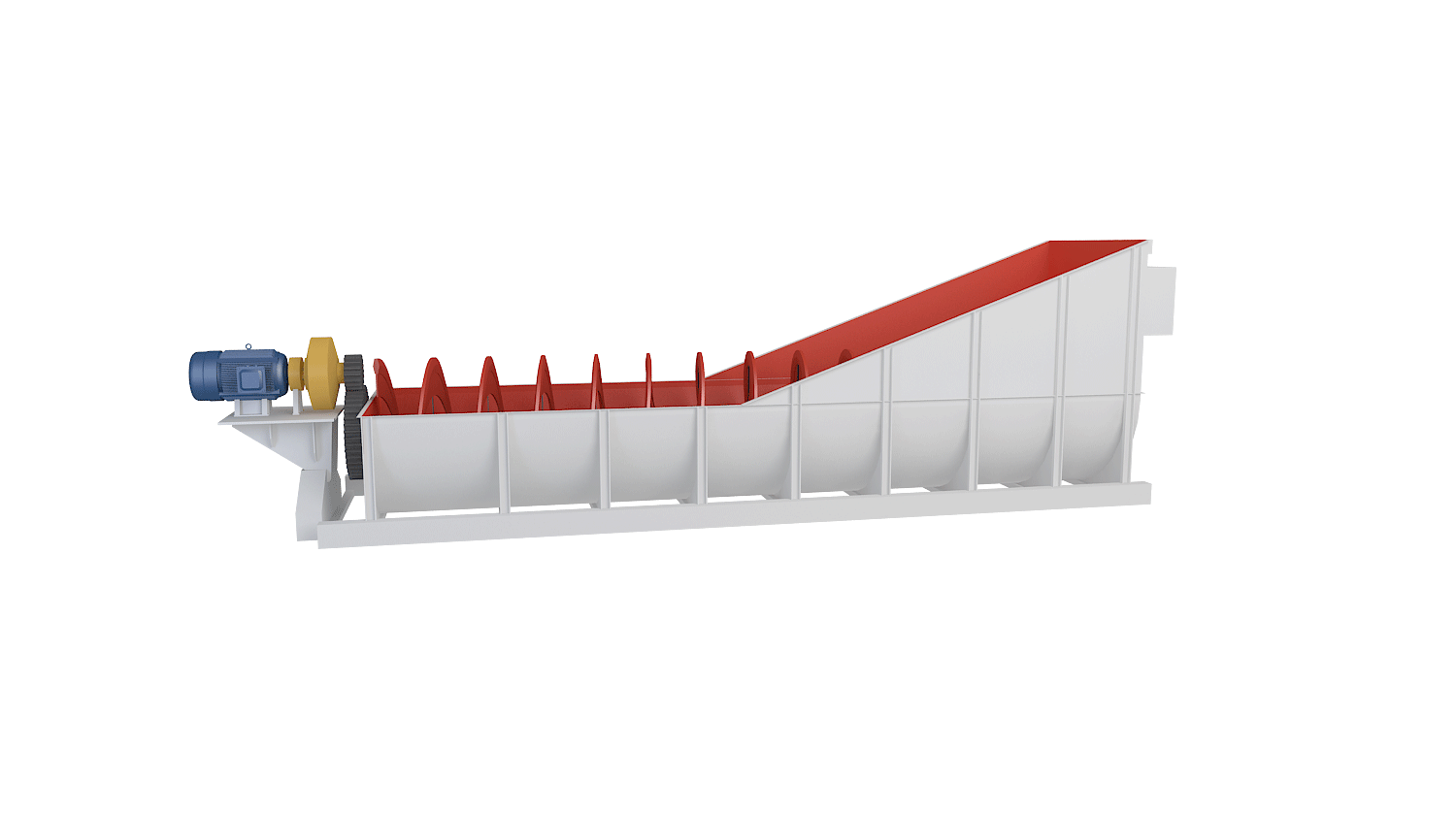

Sand material mixed with water enters a cleaning tank from feeding inlet. Inside tank, spiral shaft driven by motor rotates continuously. As spiral blades turn, they stir sand in water, allowing lighter impurities like clay, silt, and dust to be suspended and carried away through overflow outlet at top of tank.

Meanwhile, clean sand settles to bottom and is gradually pushed upward along inclined spiral shaft by rotating blades. As sand moves up, excess water drains off through perforated plates or weep holes. Final cleaned and dewatered sand is discharged from outlet at upper end of spiral washer.

This continuous and gentle cleaning process ensures sand is thoroughly washed with minimal loss of fine particles, making it suitable for high-quality concrete, construction aggregate, and other demanding applications.