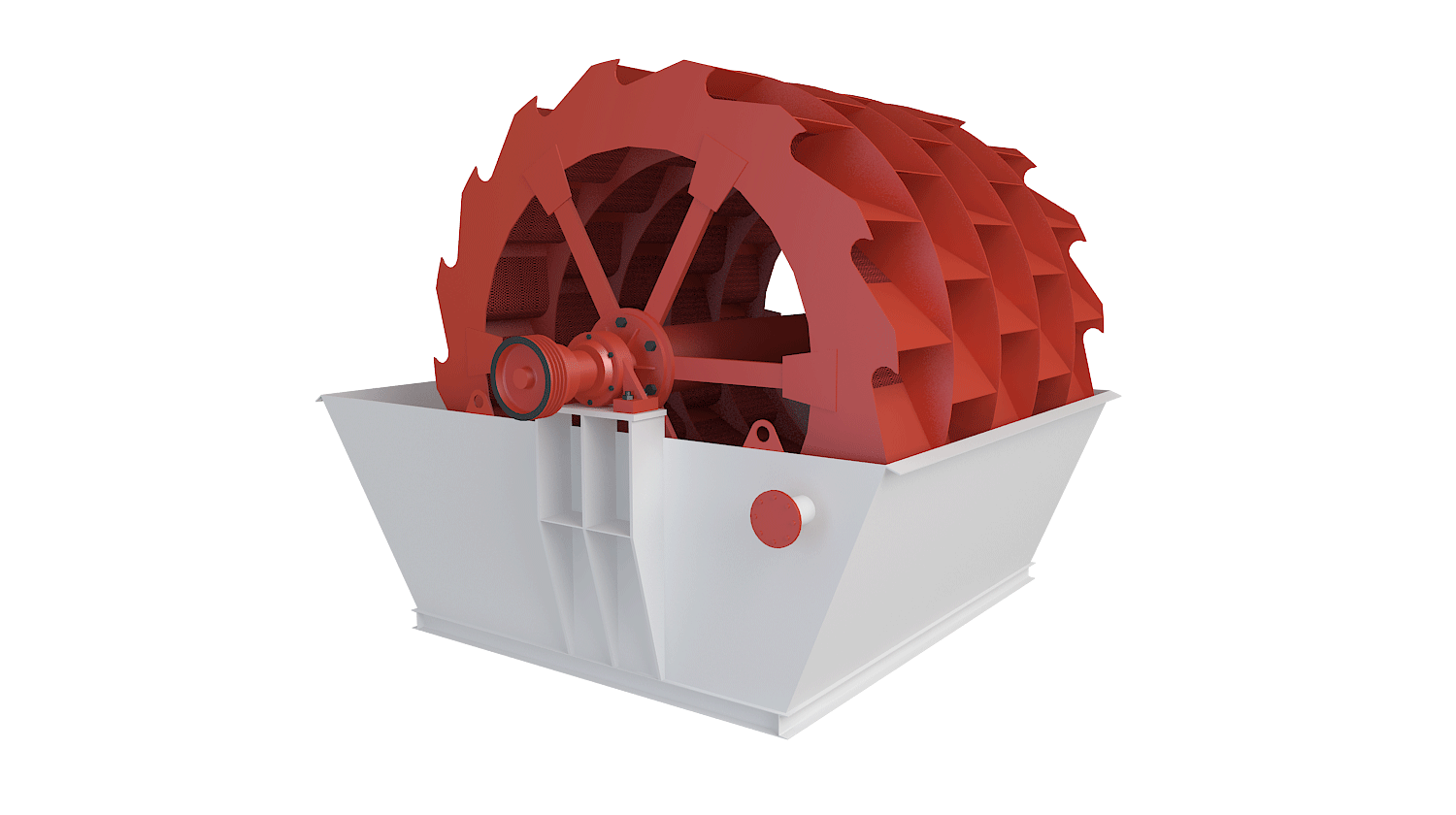

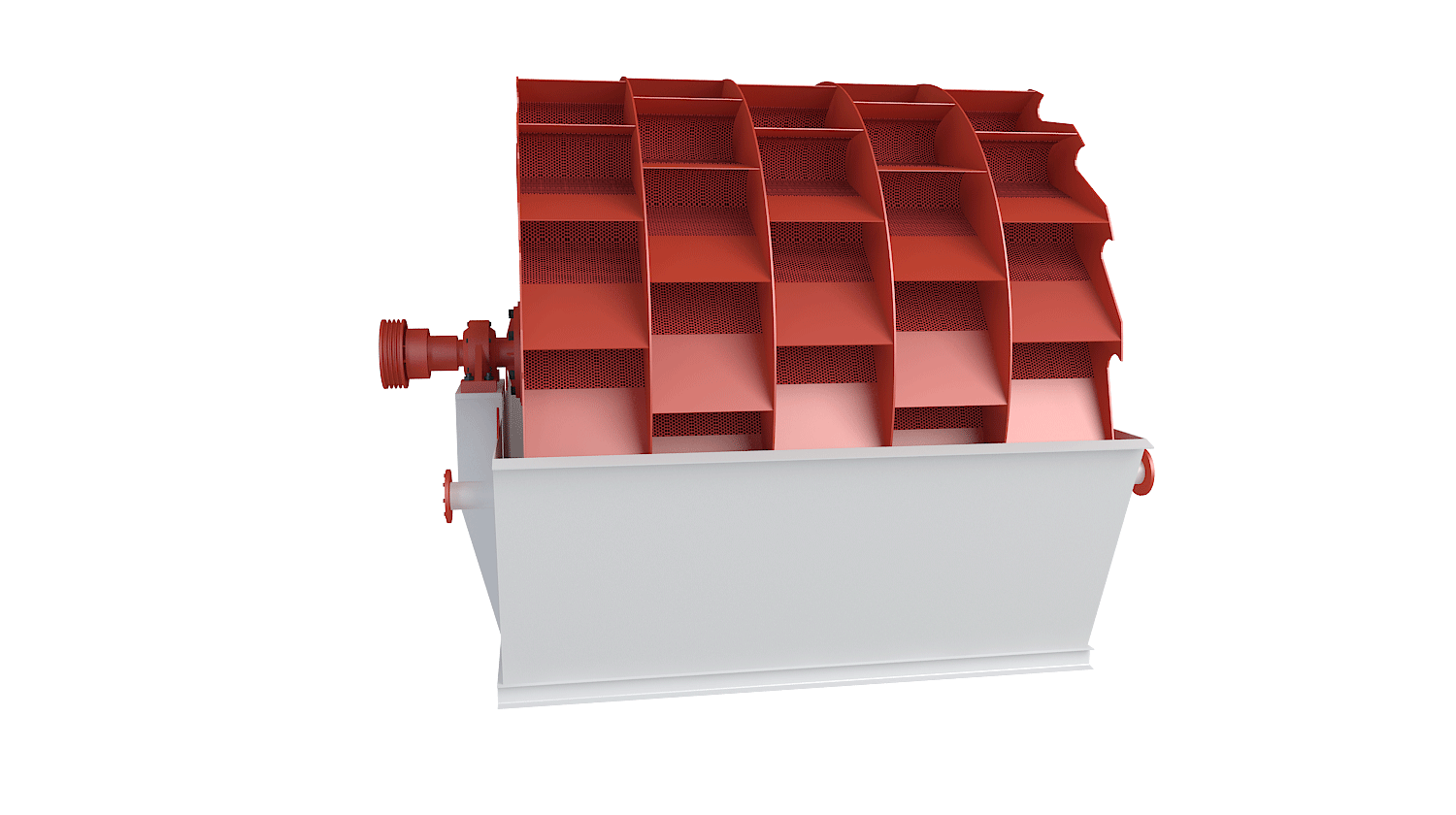

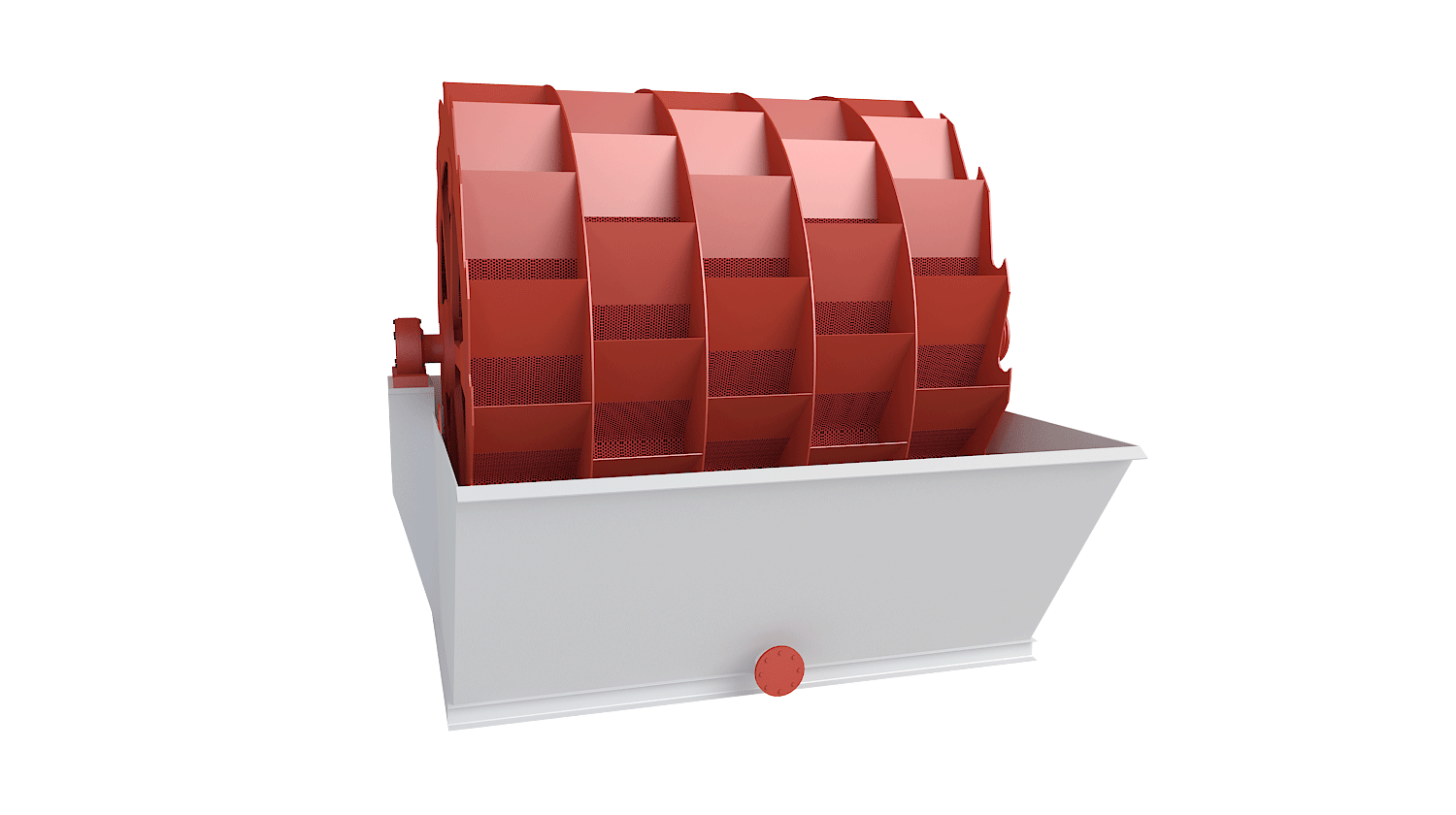

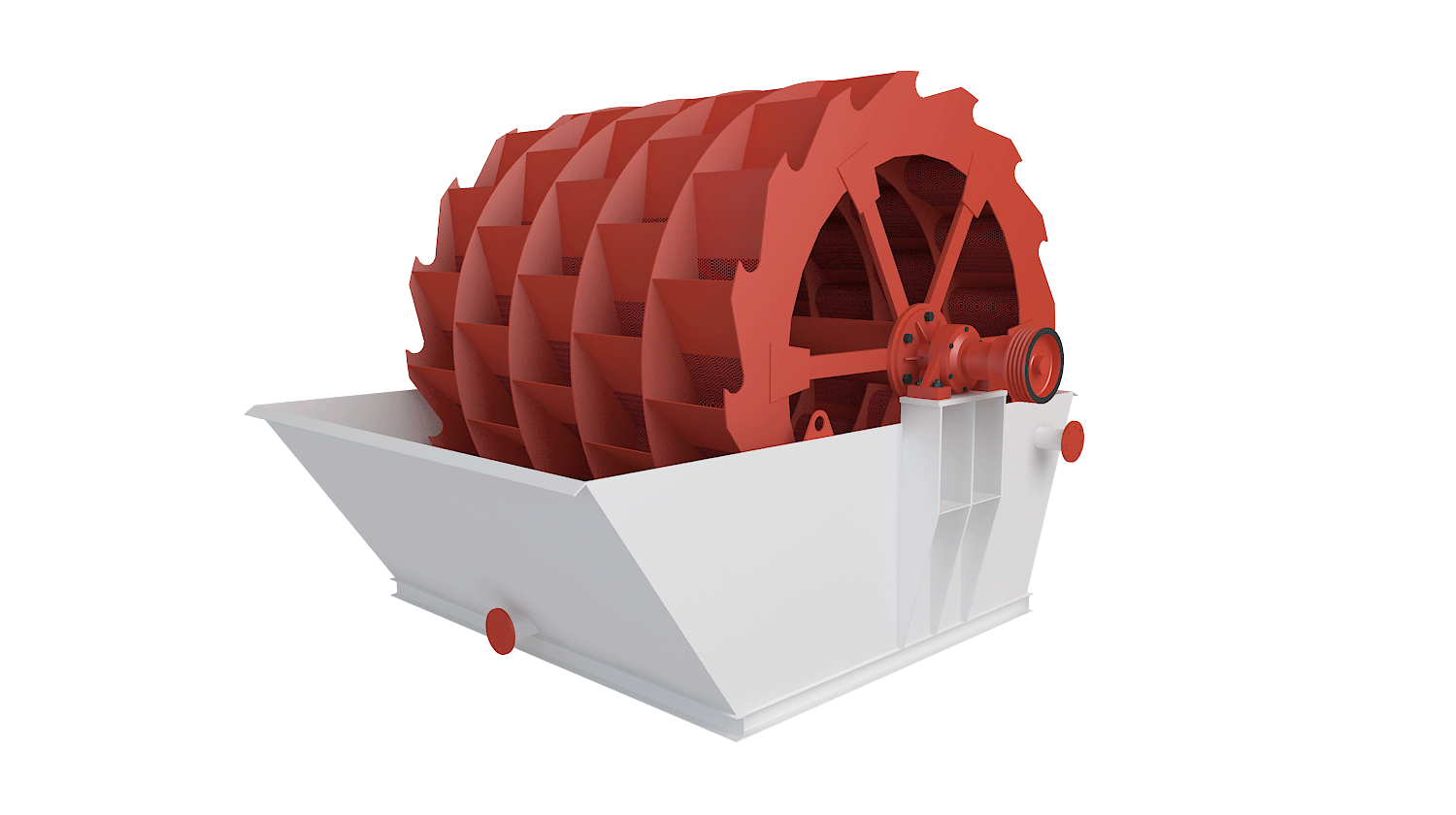

| Model | Impeller specification outer diameter×width |

Impeller speed (r/min) |

Maximum feed size (mm) |

Capacity (t/h) |

Motor Power (kw) |

Overall size length×width×height (mm) |

| KLZ-XS2610 | Φ2600×1000 | 1.95 | ≤10 | 20-50 | 5.5 | 3255×1982×2690 |

| KLZ-XS2816 | Φ2800×1600 | 1.95 | ≤10 | 30-60 | 11 | 3540×3000×2880 |

| KLZ-XS3016 | Φ3000×1600 | 1.95 | ≤10 | 50-120 | 15 | 3845×3000×3080 |

| KLZ-XS3220 | Φ3200×2000 | 1.95 | ≤10 | 70-160 | 15 | 4100×3560×3300 |

| KLZ-XS3230 | Φ3200×3000 | 1.95 | ≤10 | 180-220 | 18.5 | 4100×3560×3300 |

| KLZ-XS3620 | Φ3600×2000 | 1.95 | ≤10 | 100-180 | 18.5 | 4600×3560×3700 |