Working Principle

Working Principle

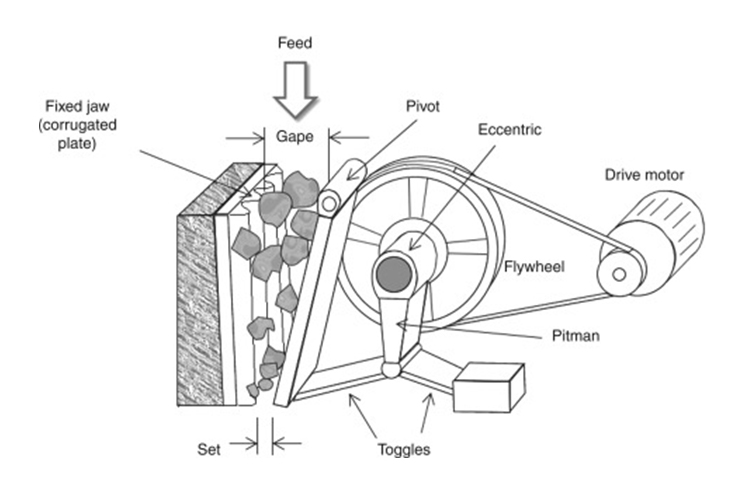

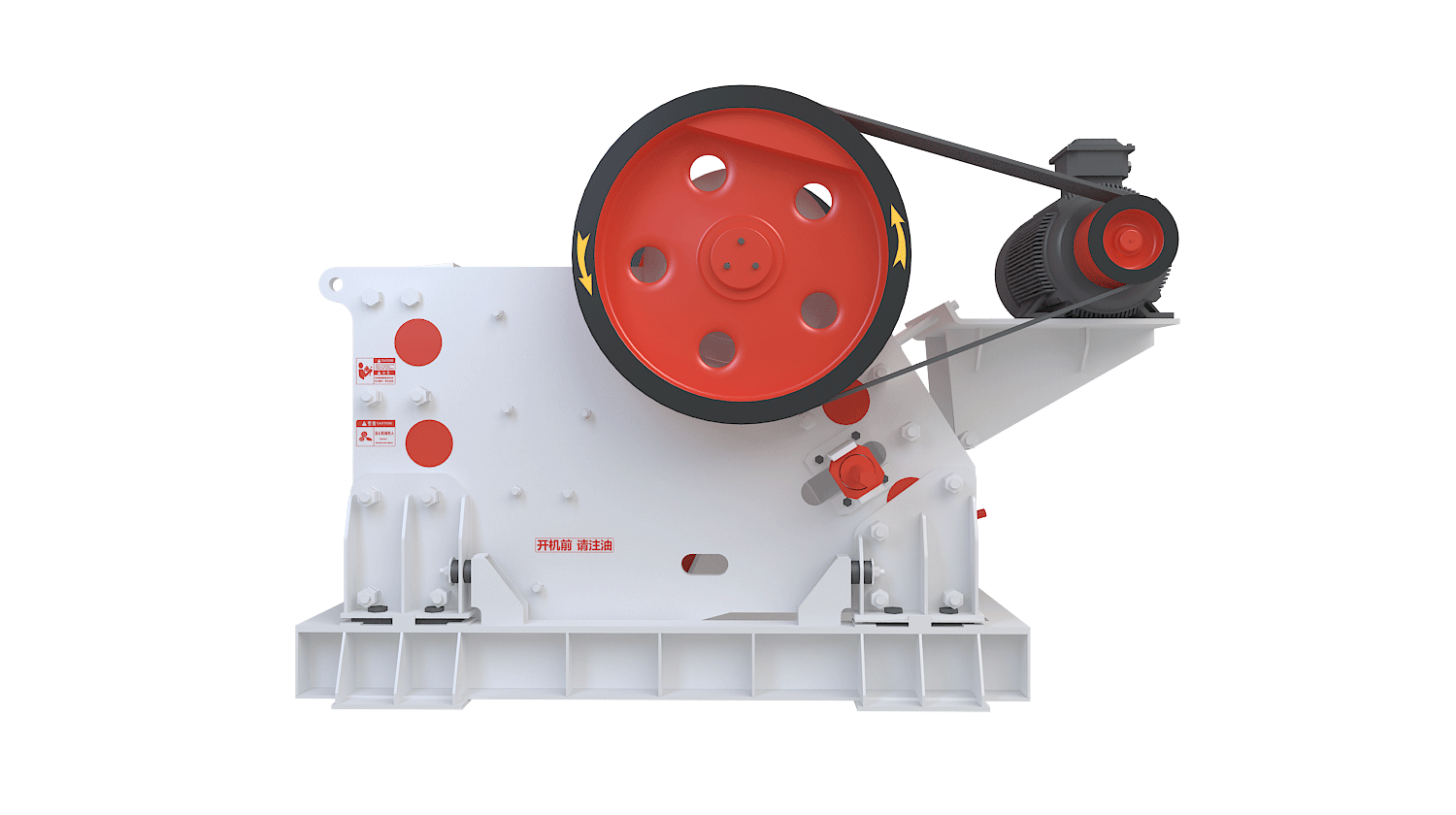

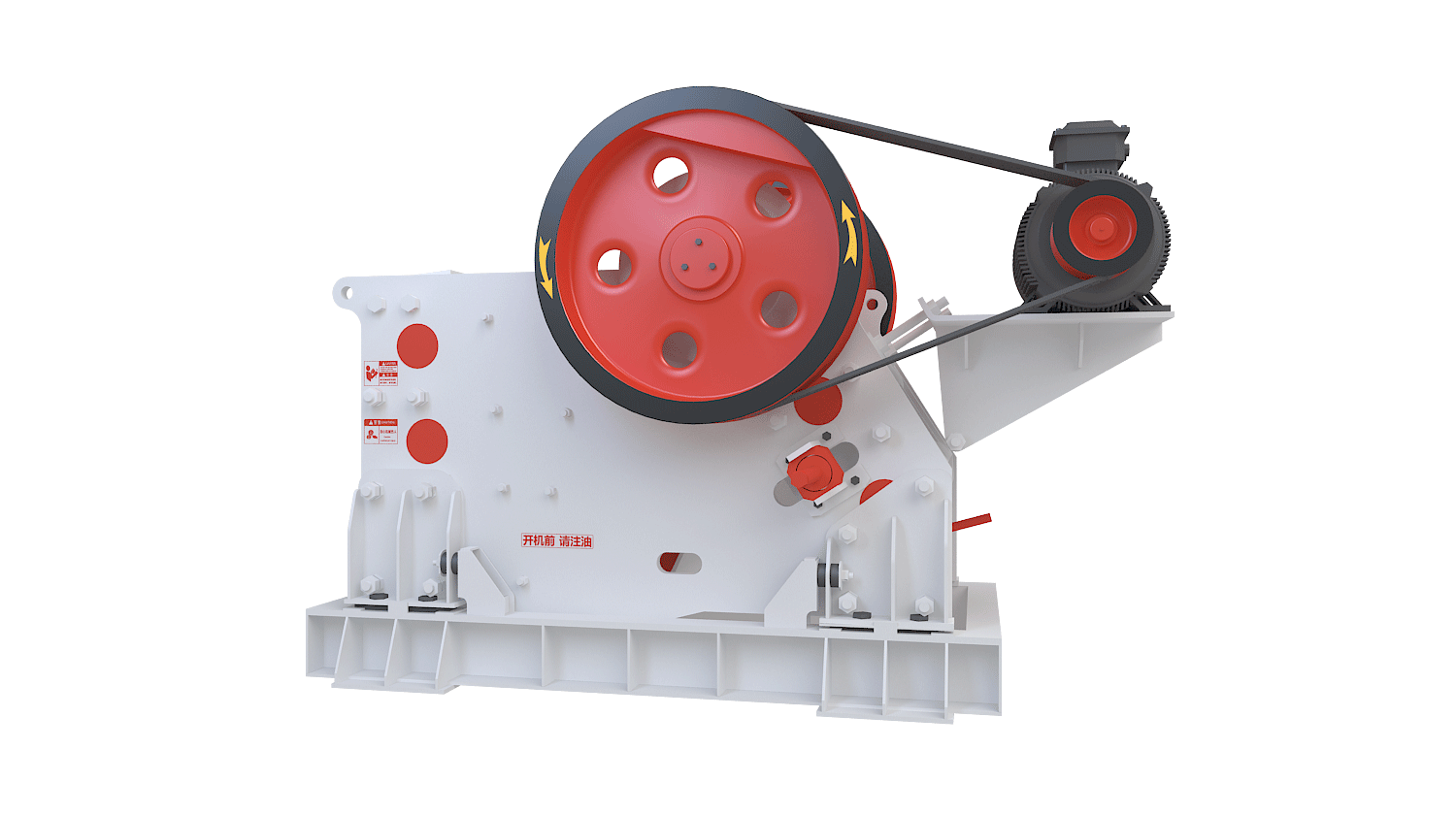

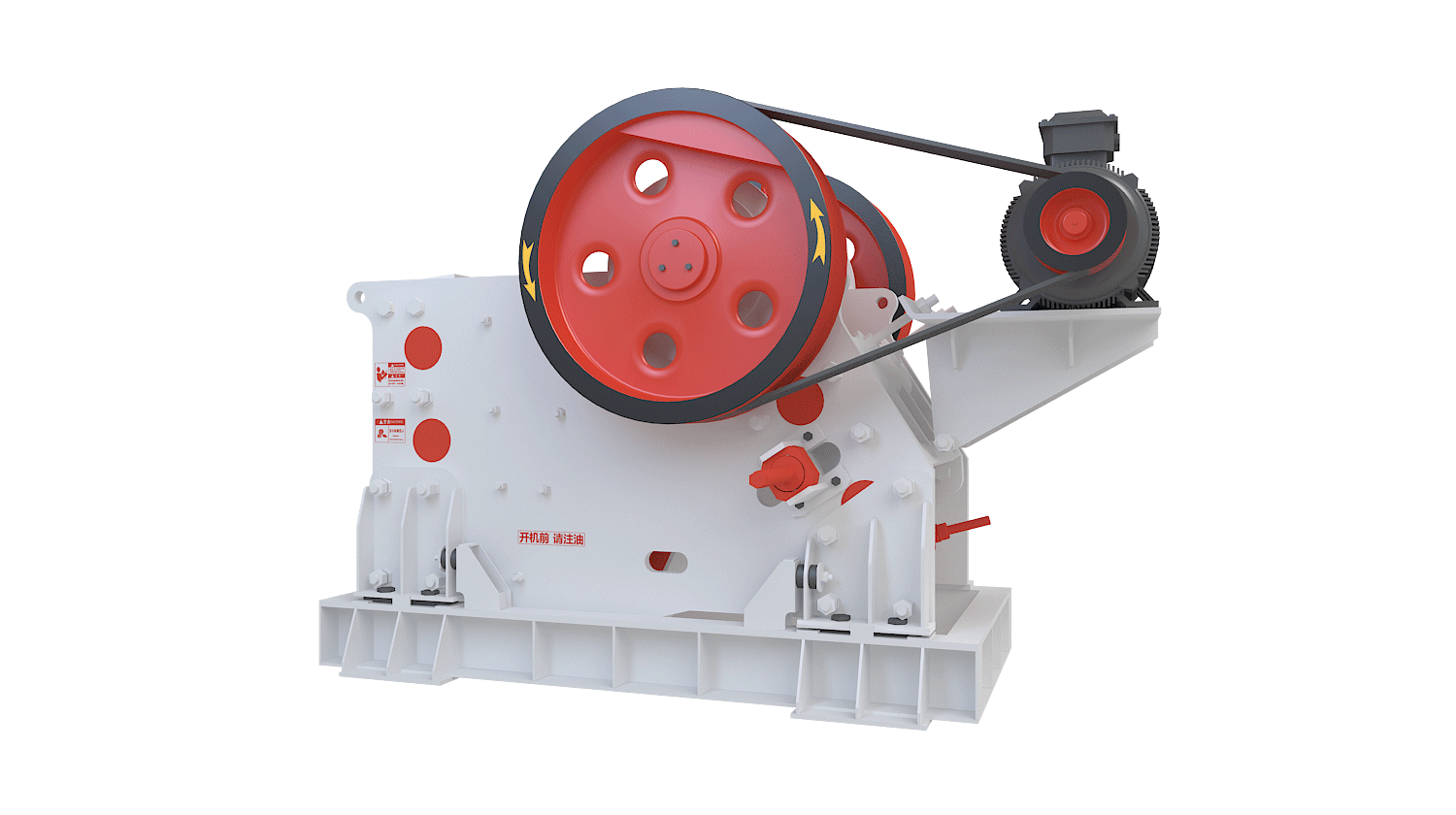

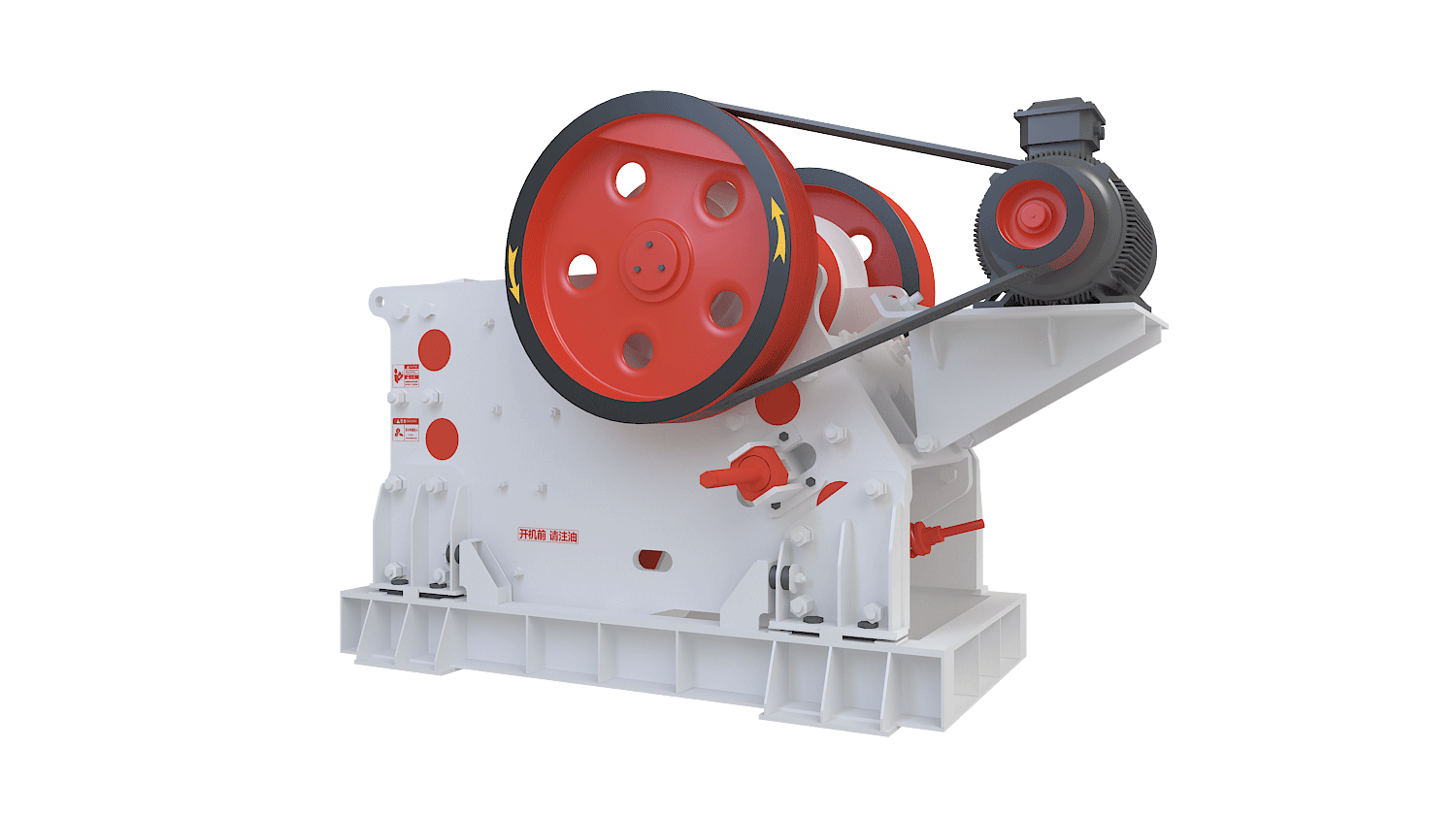

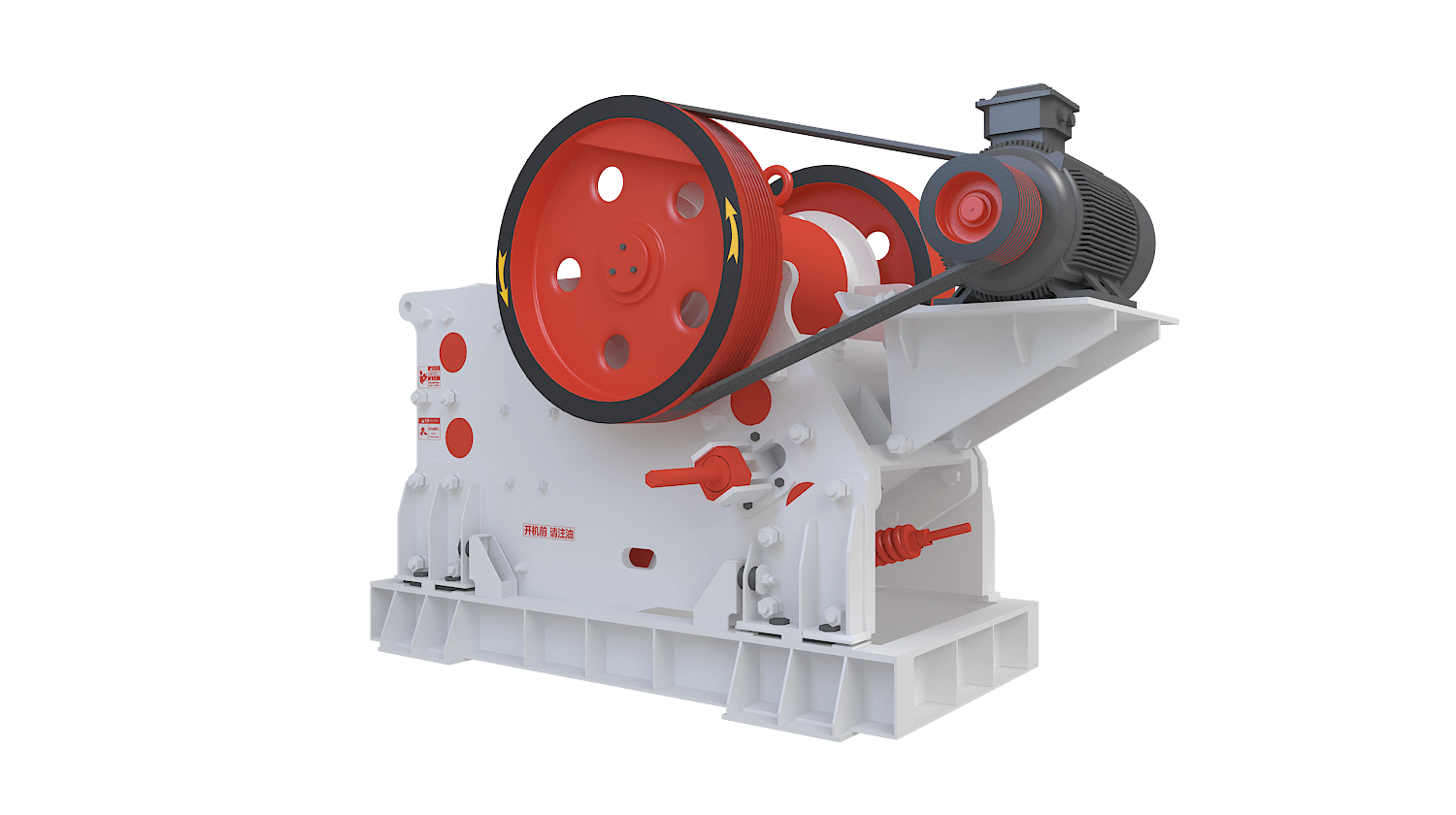

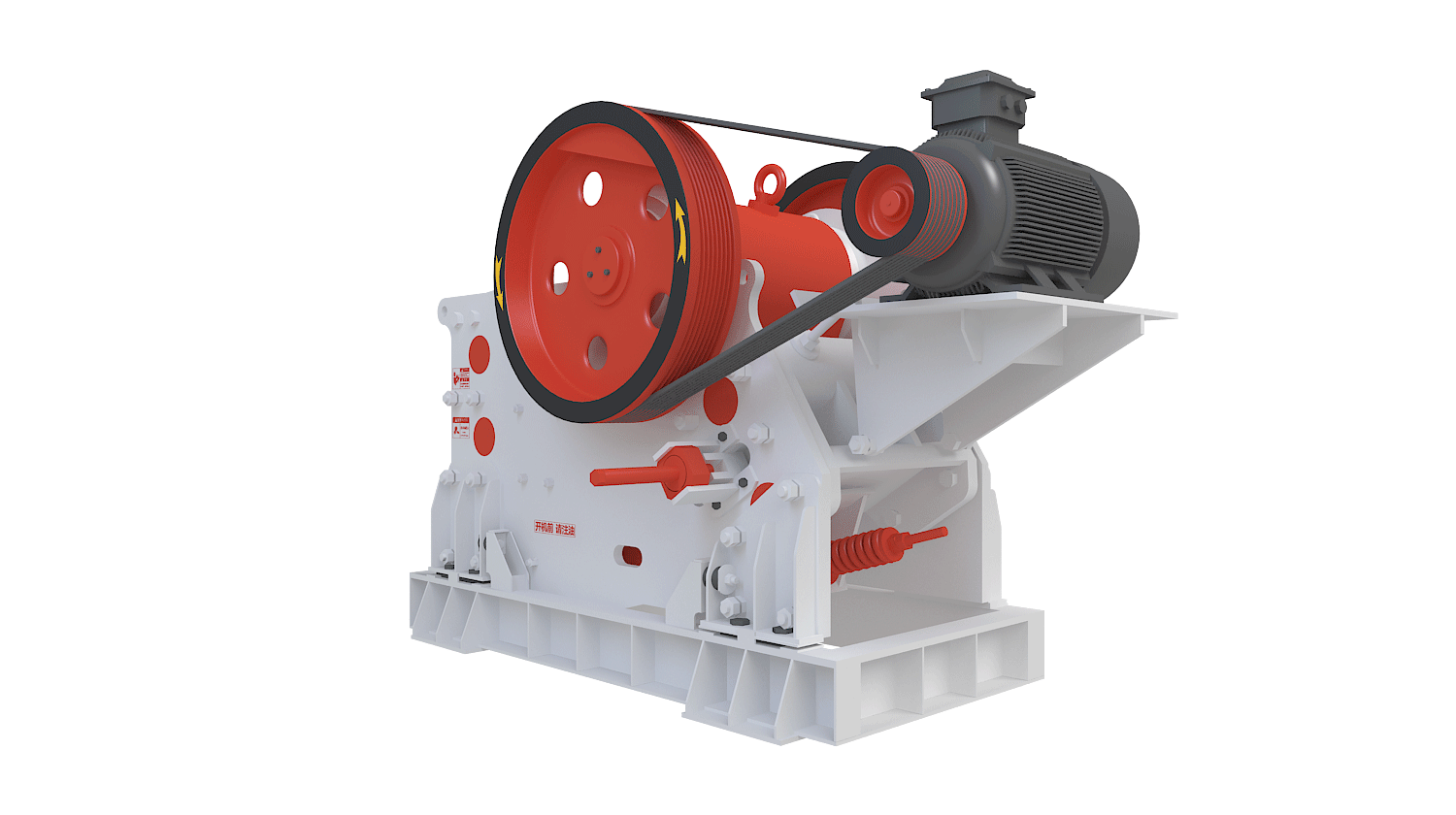

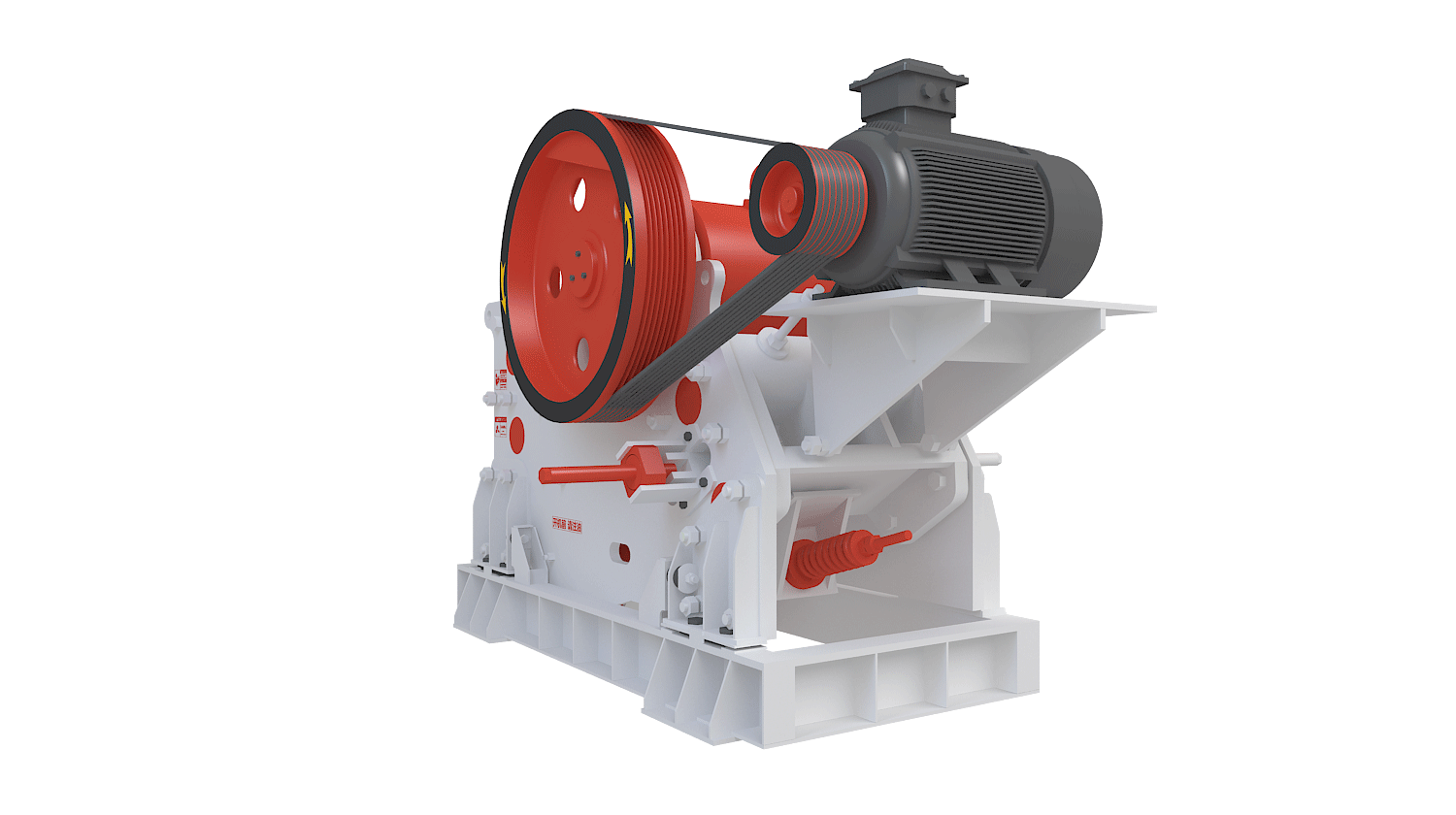

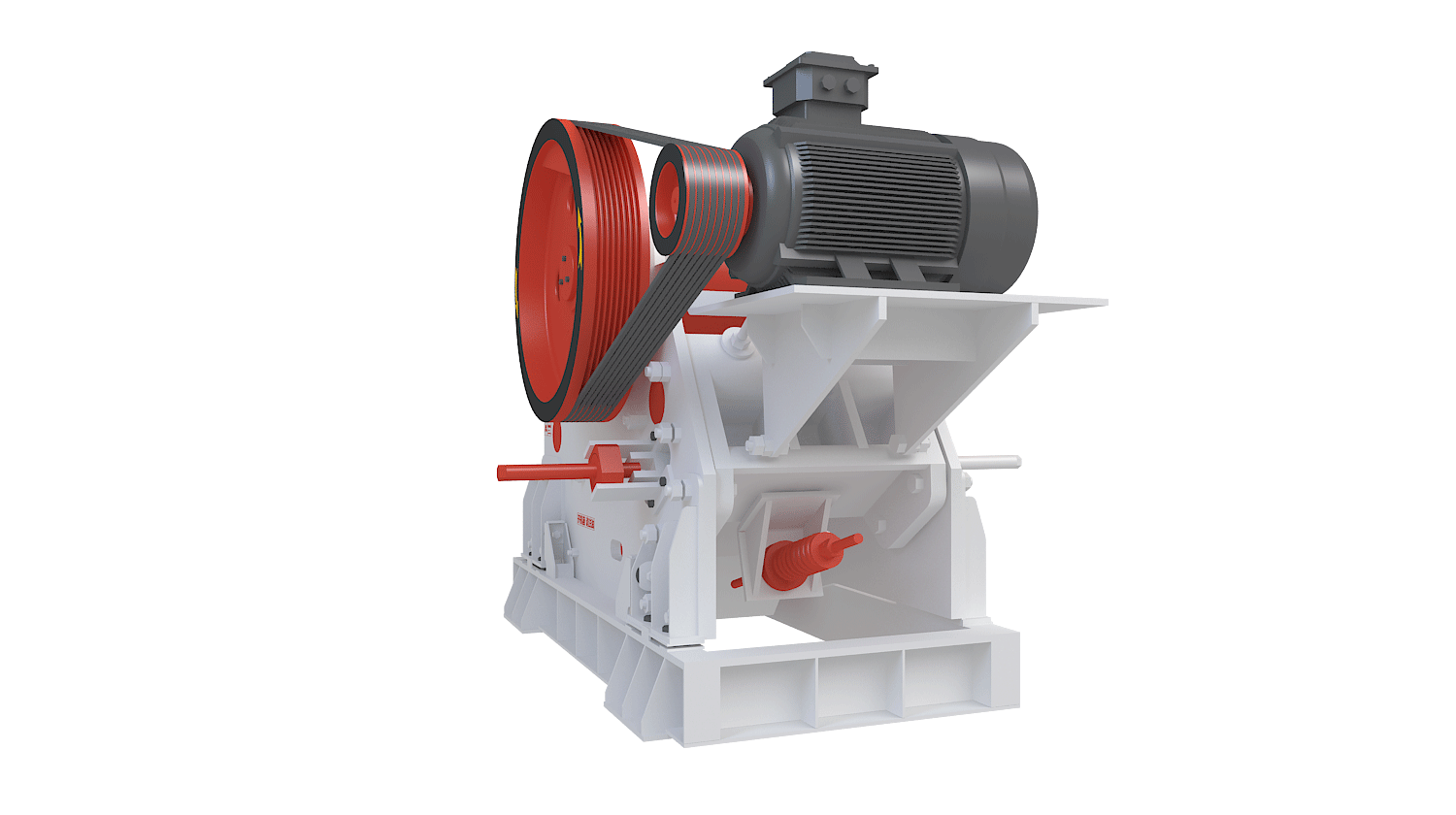

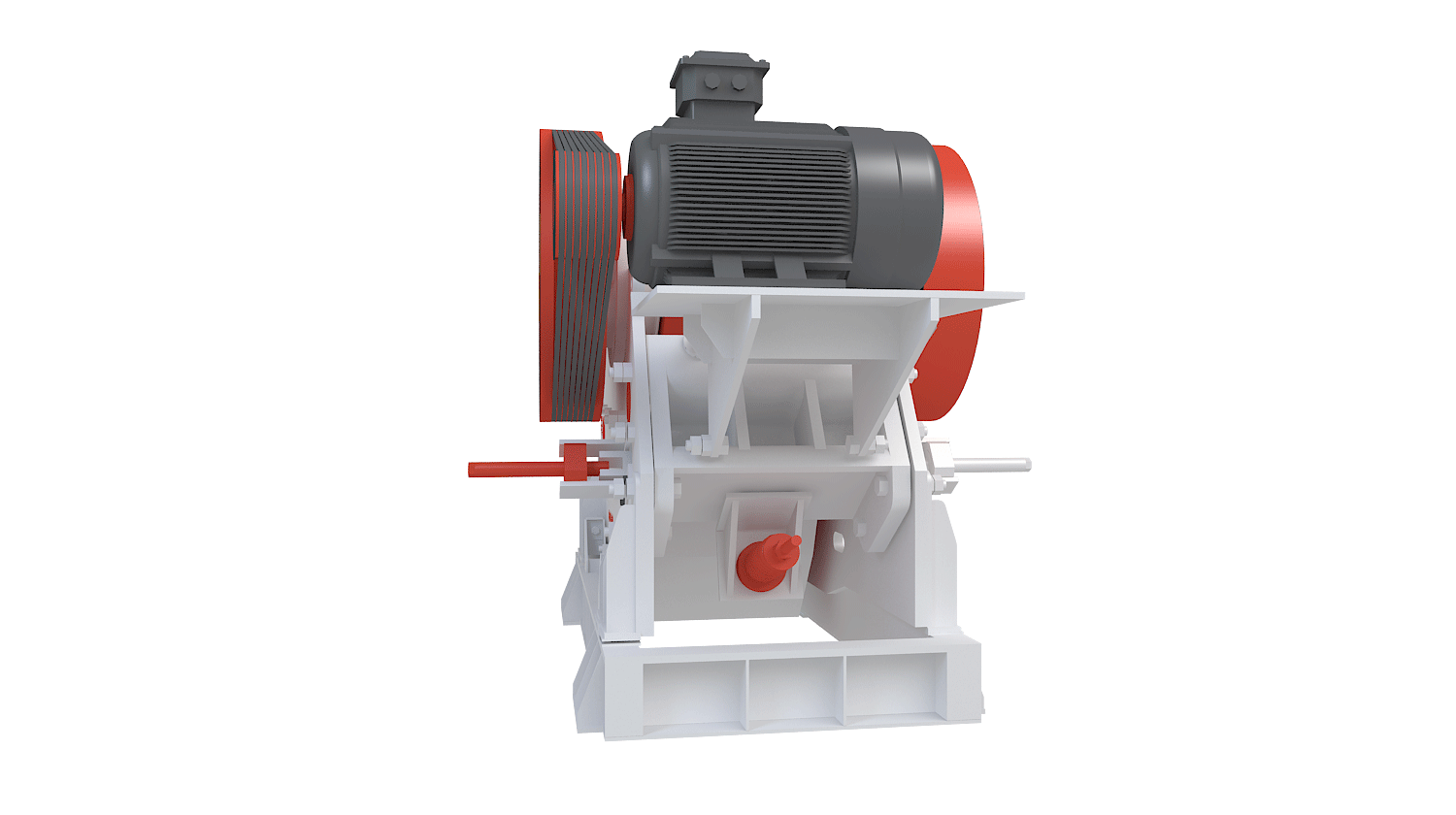

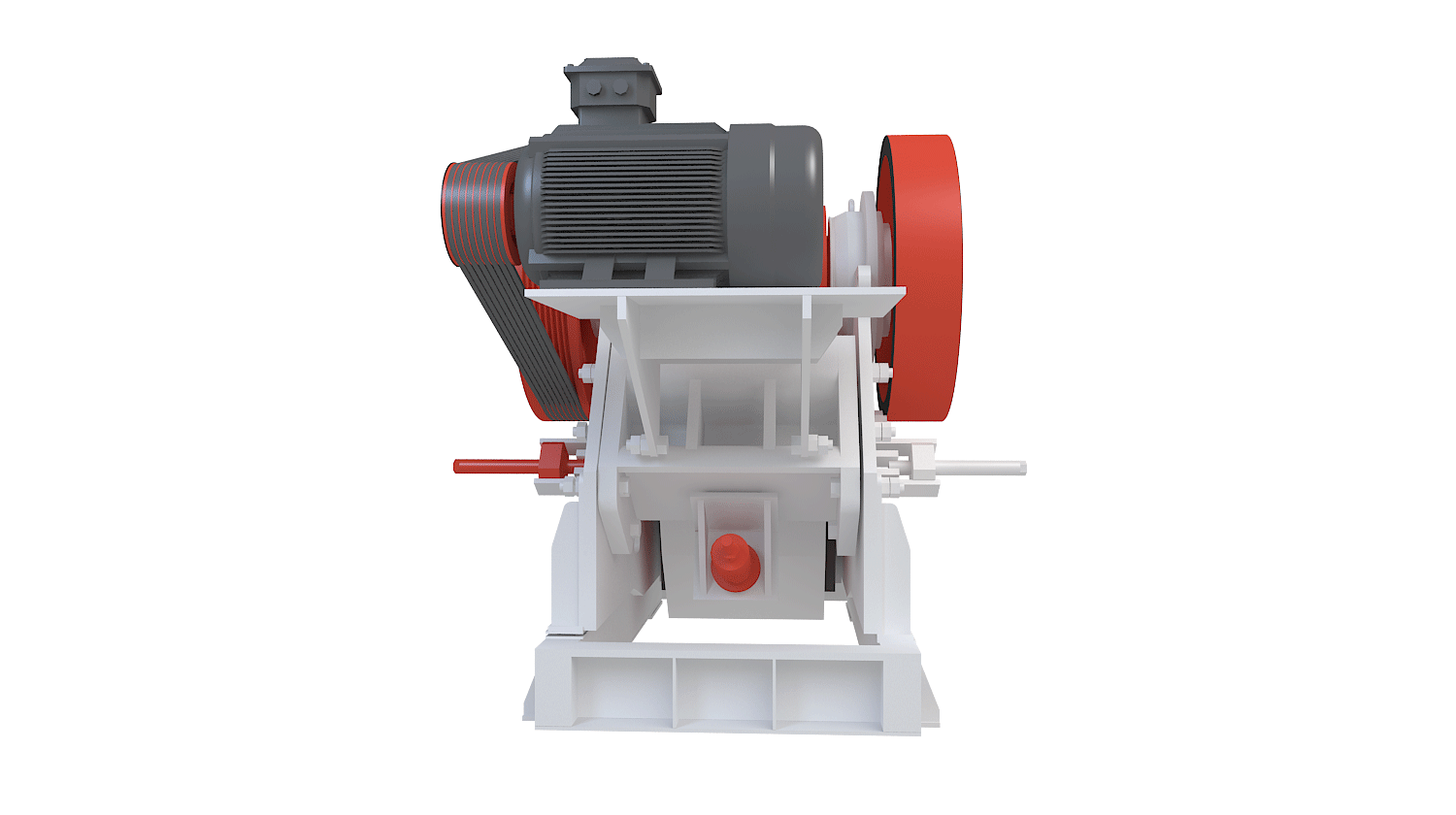

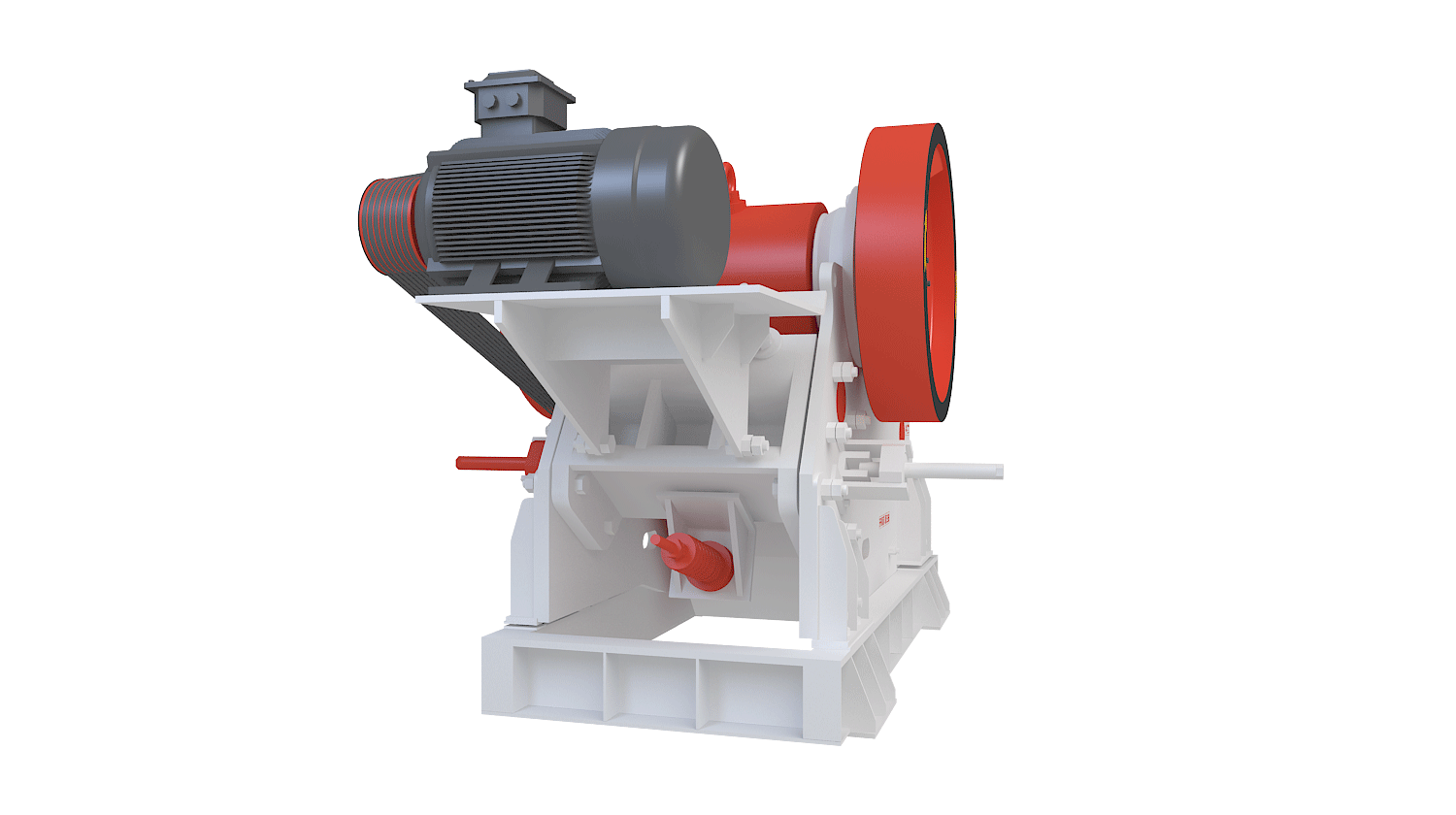

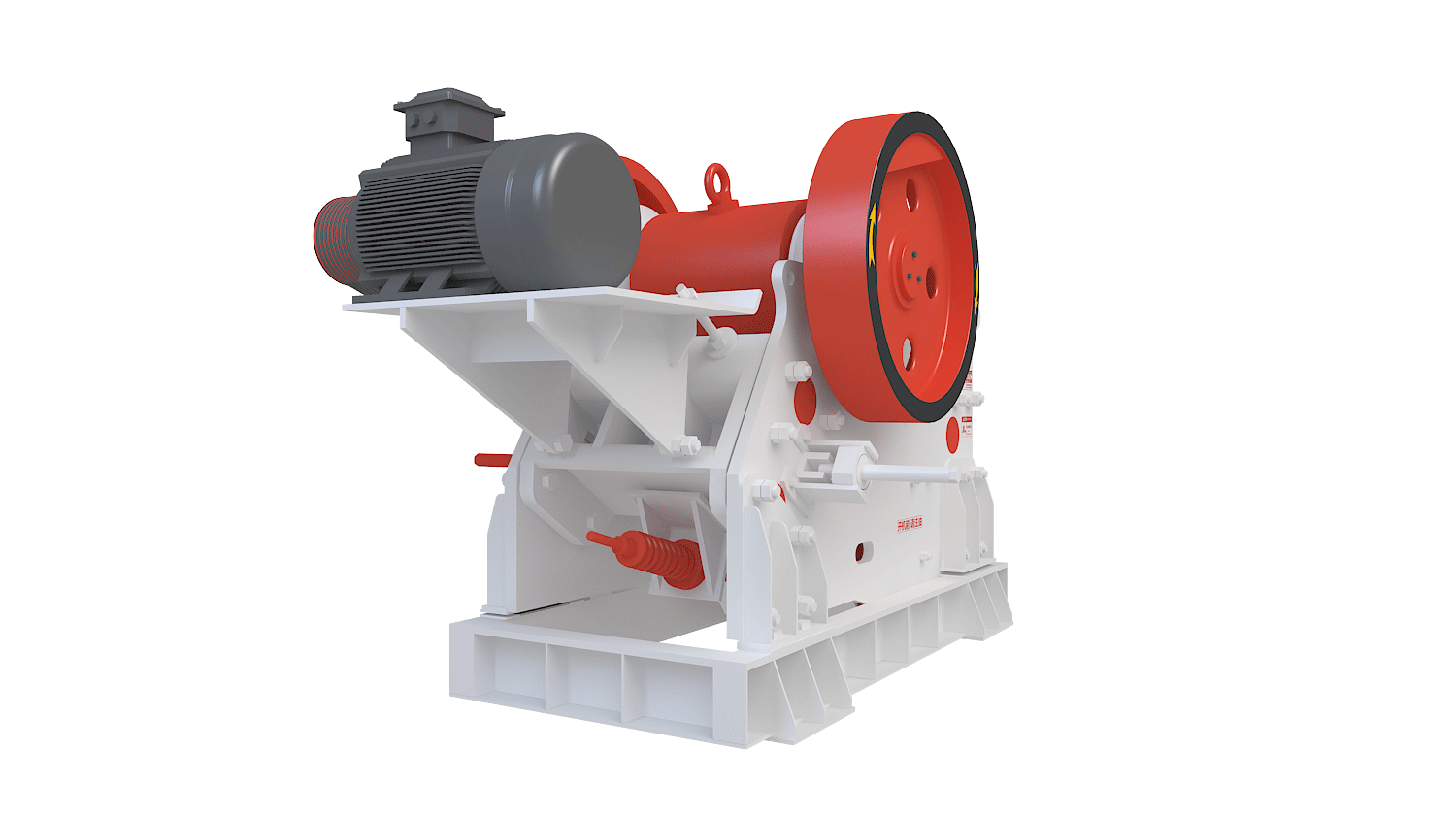

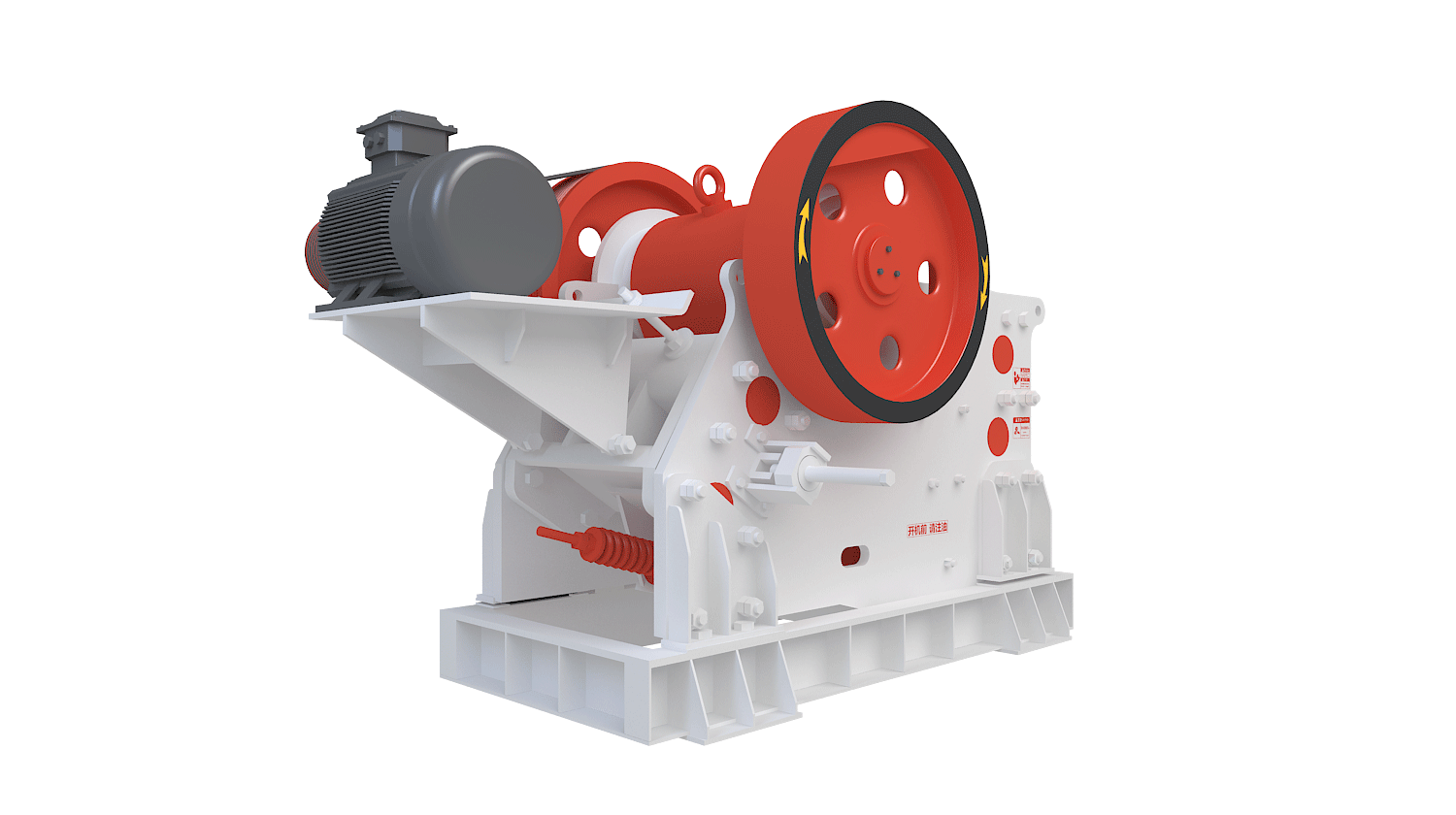

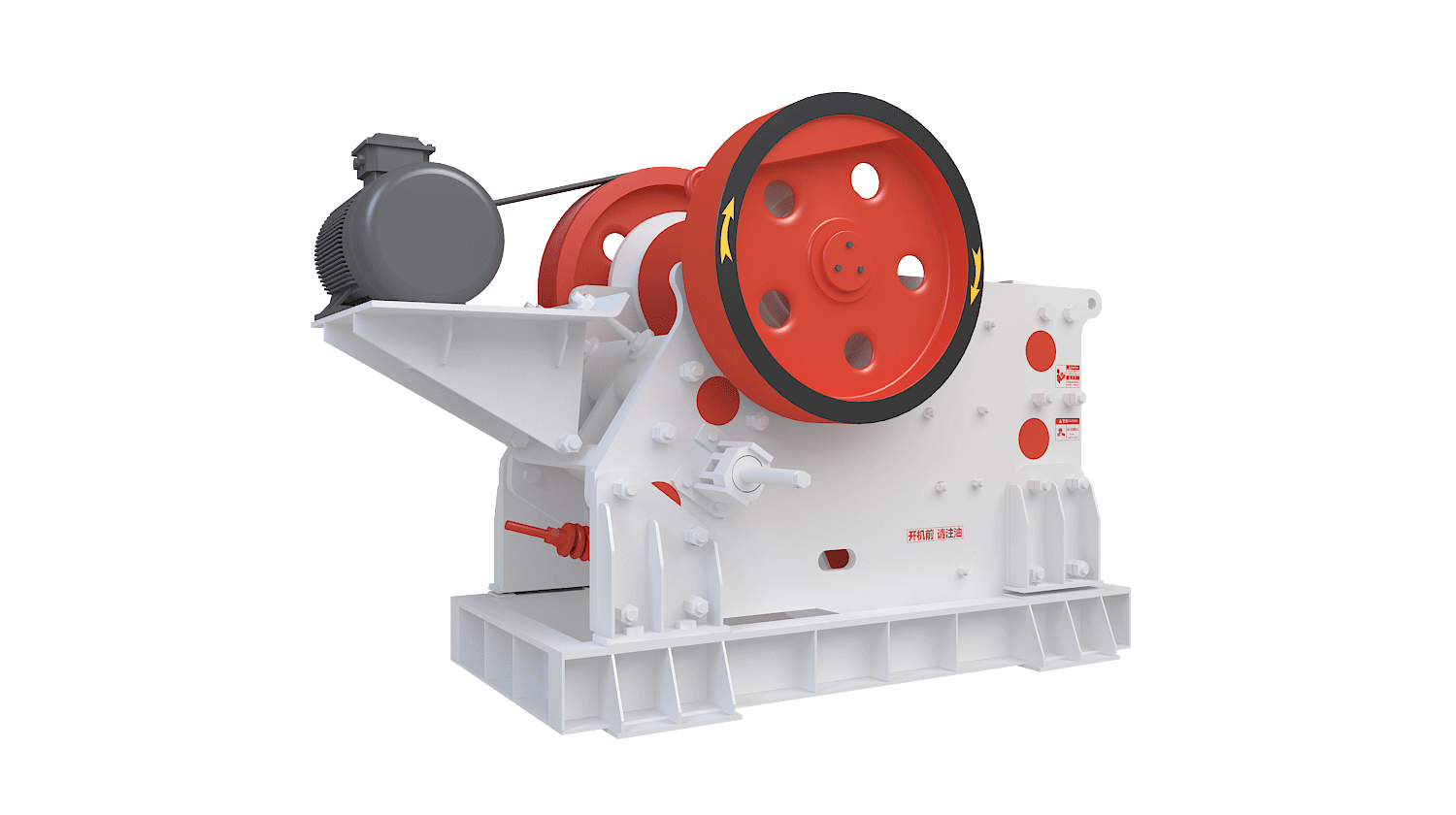

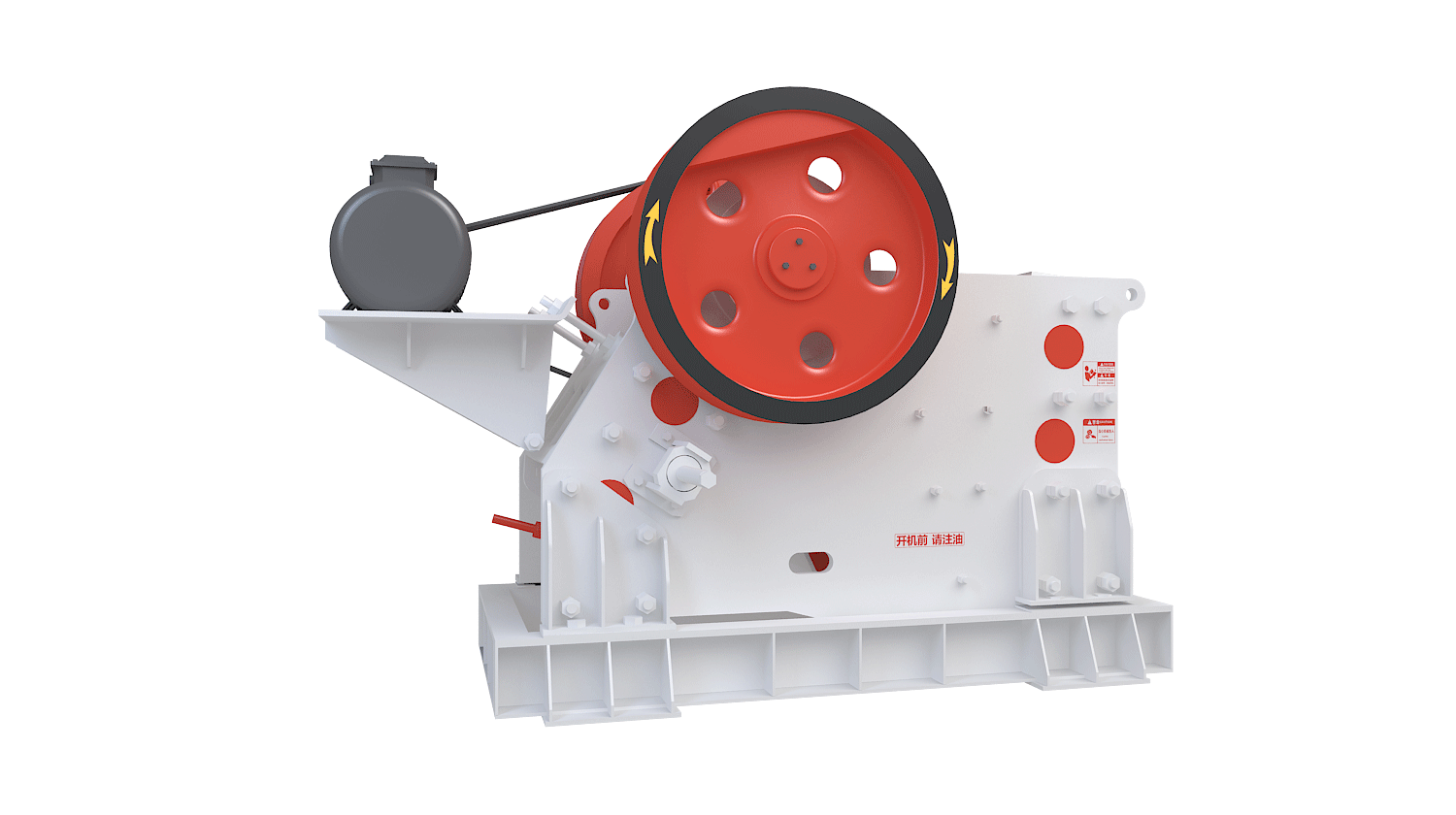

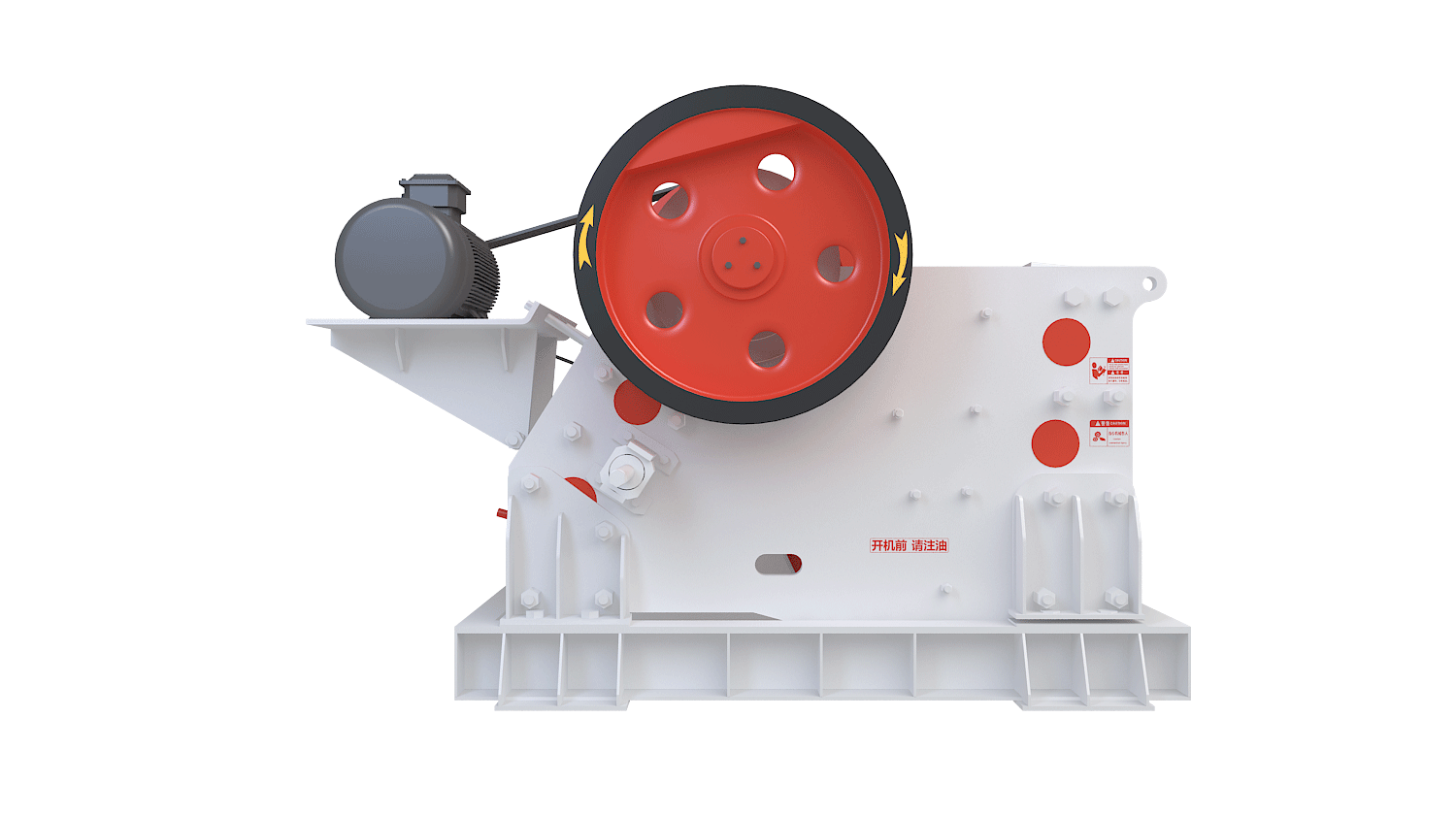

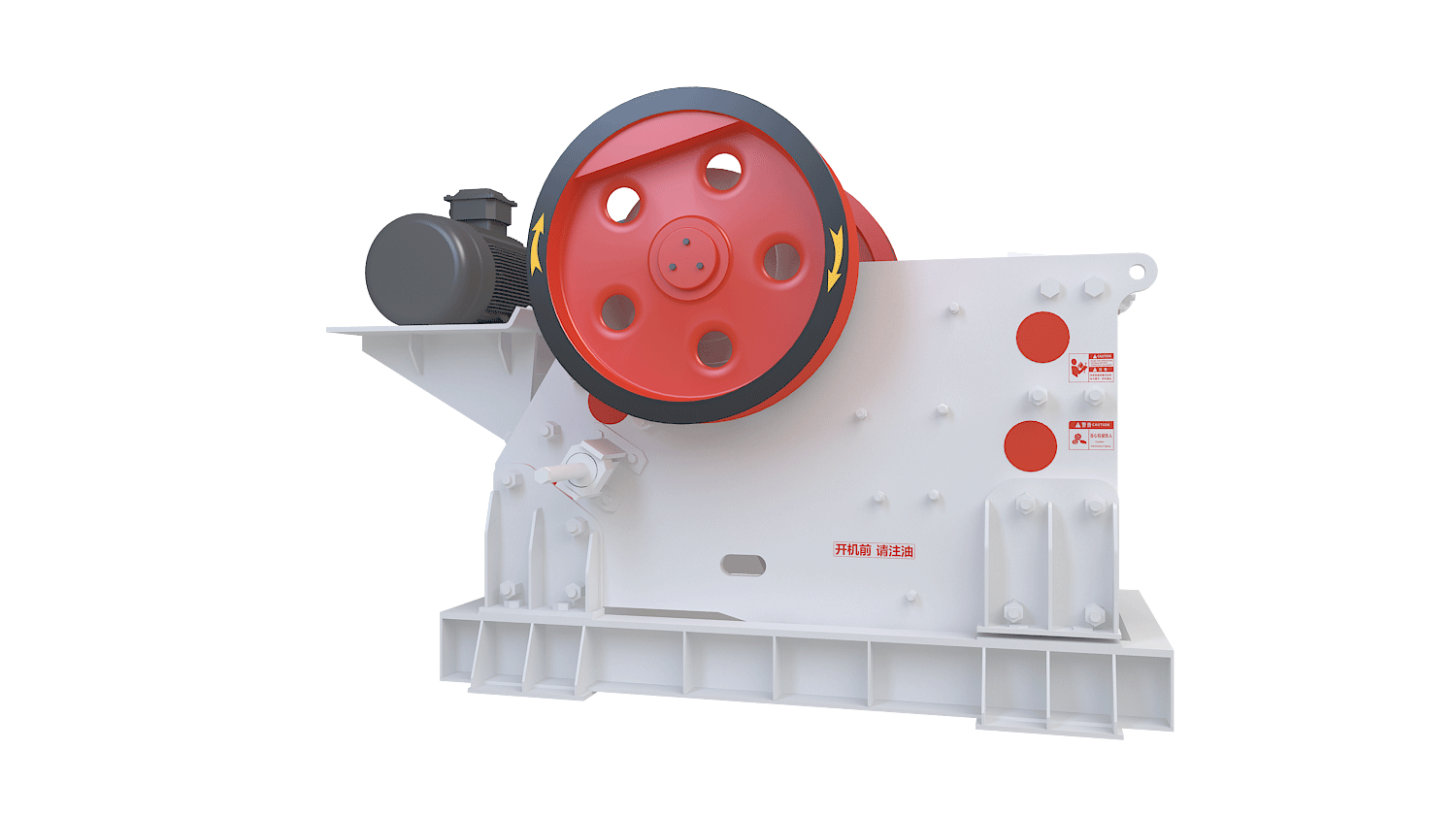

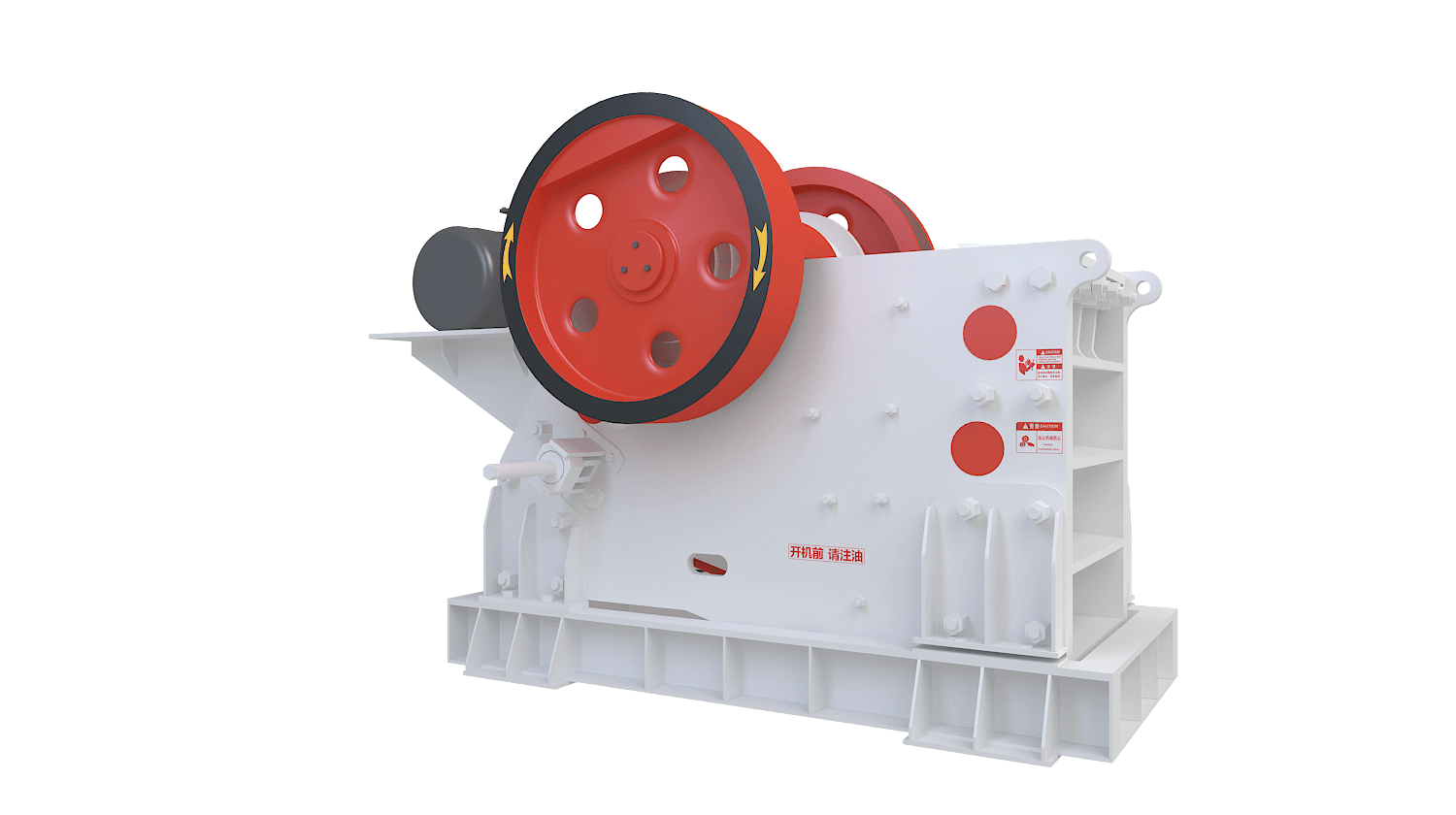

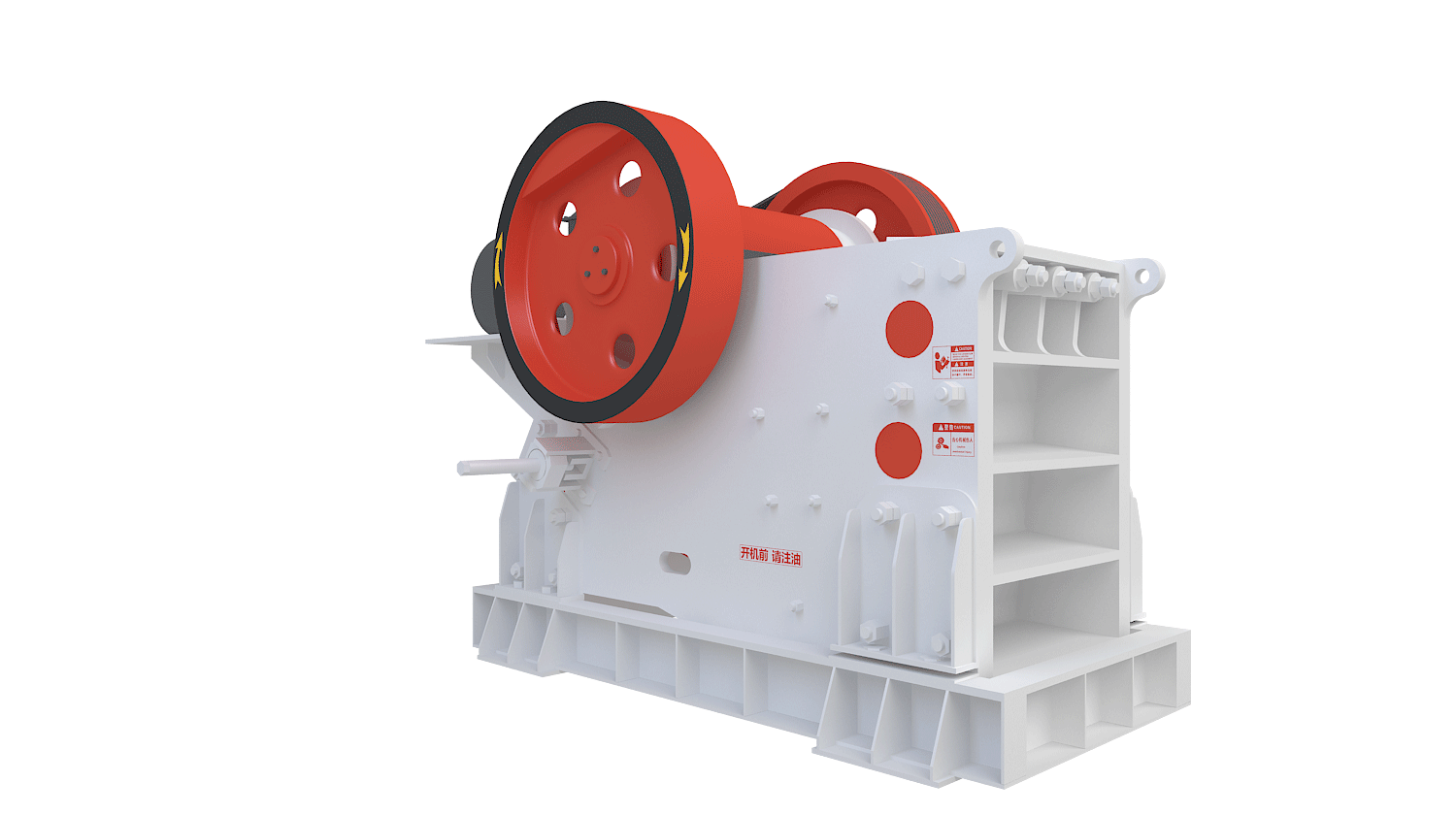

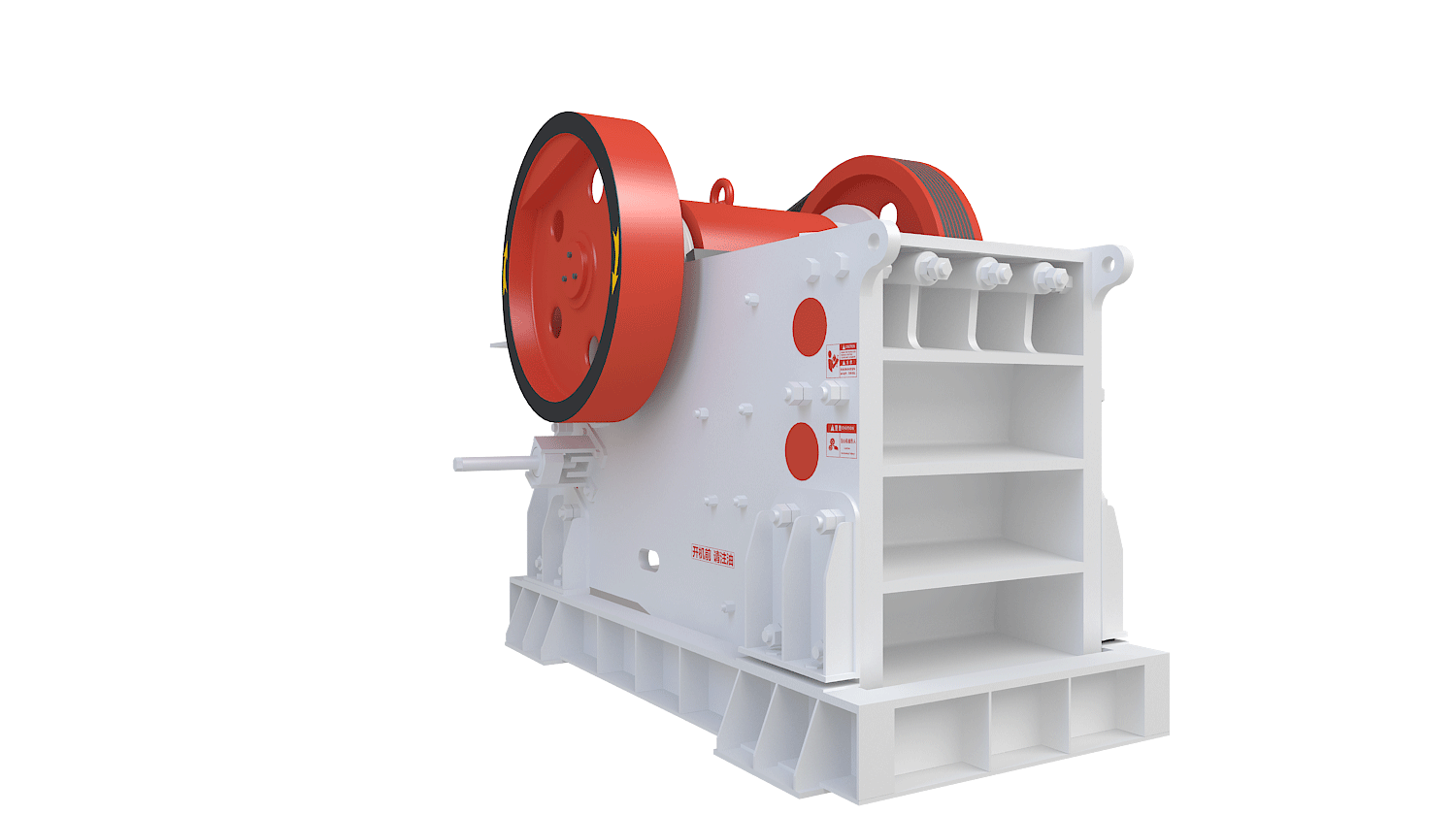

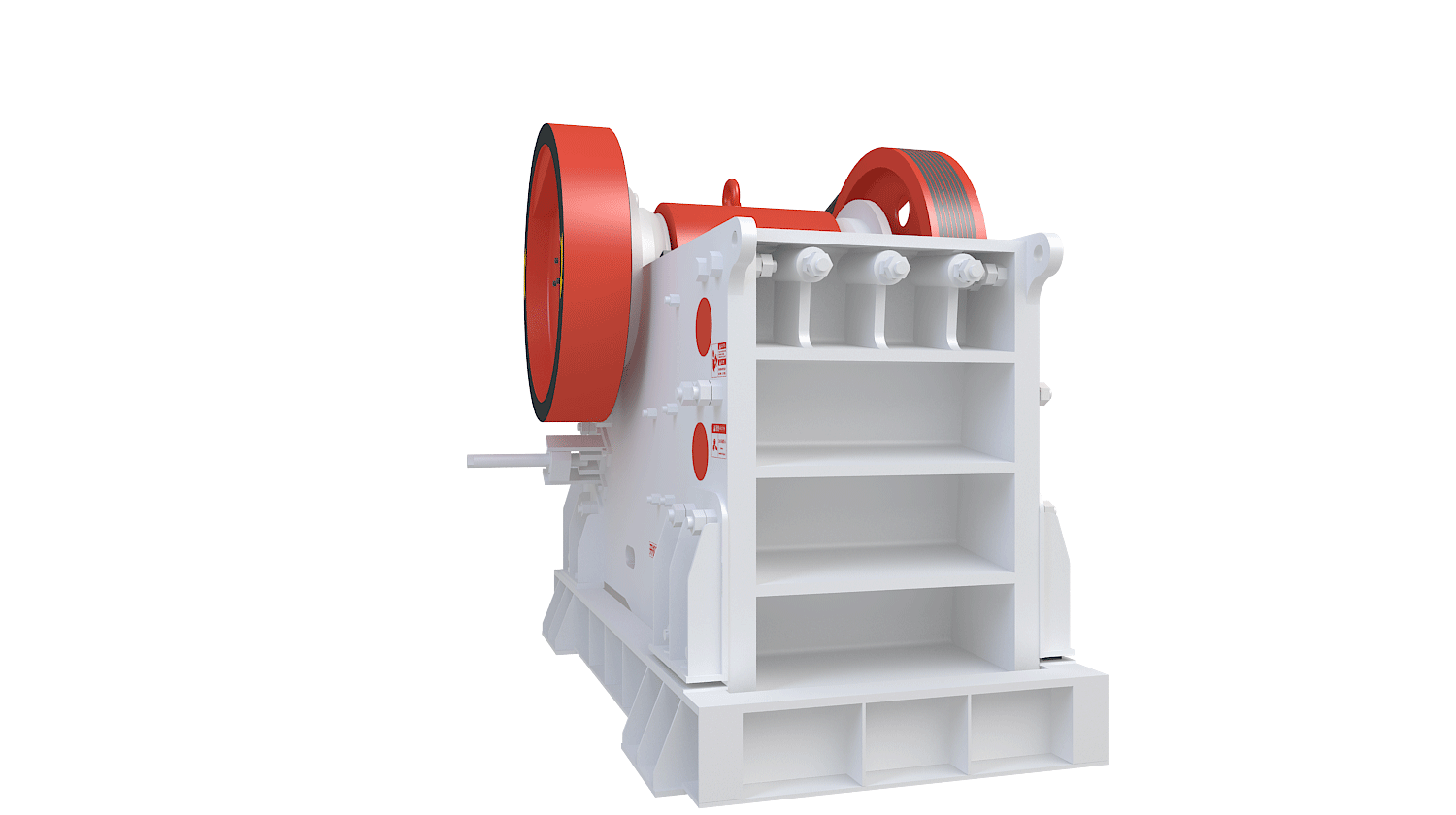

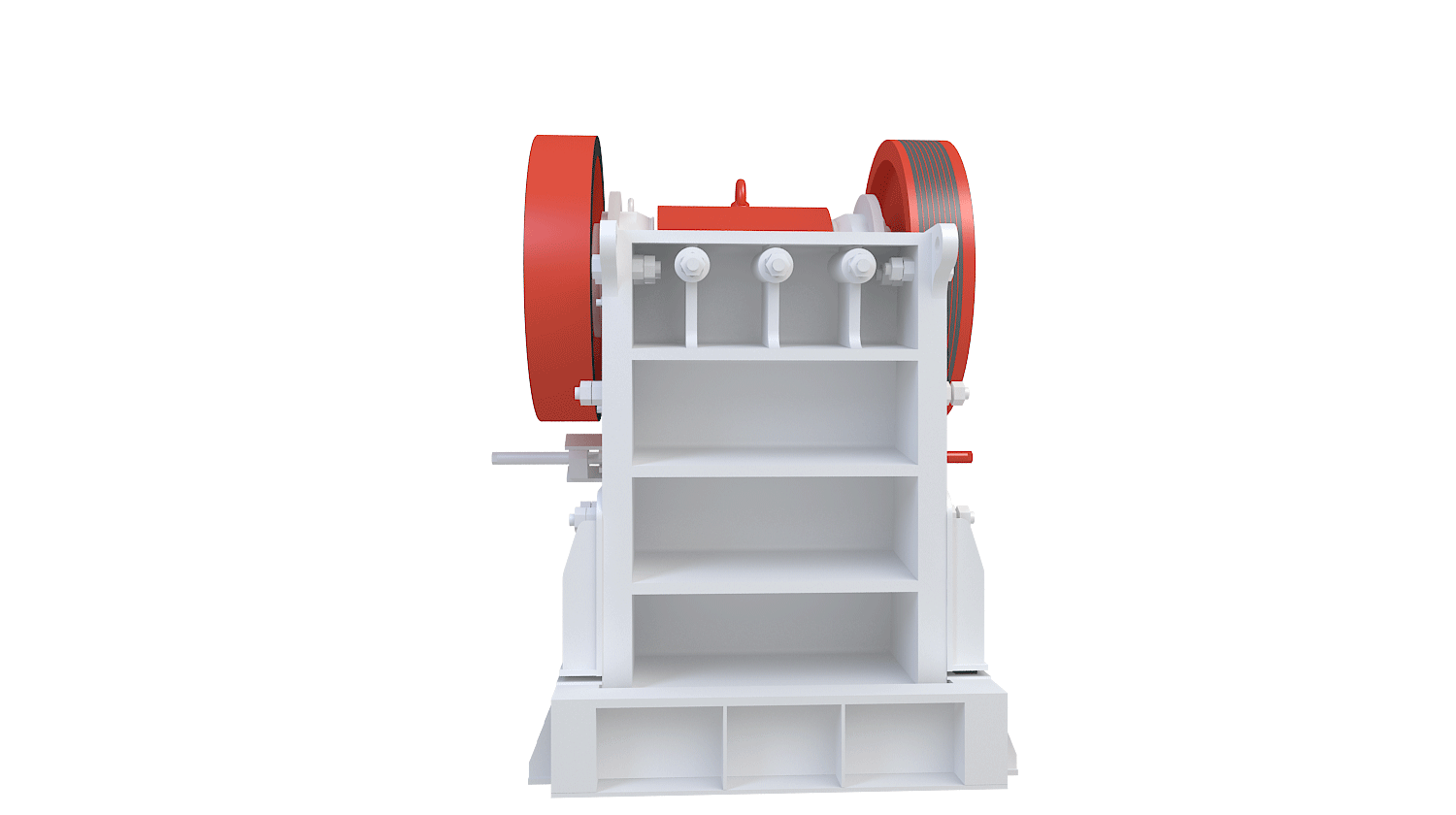

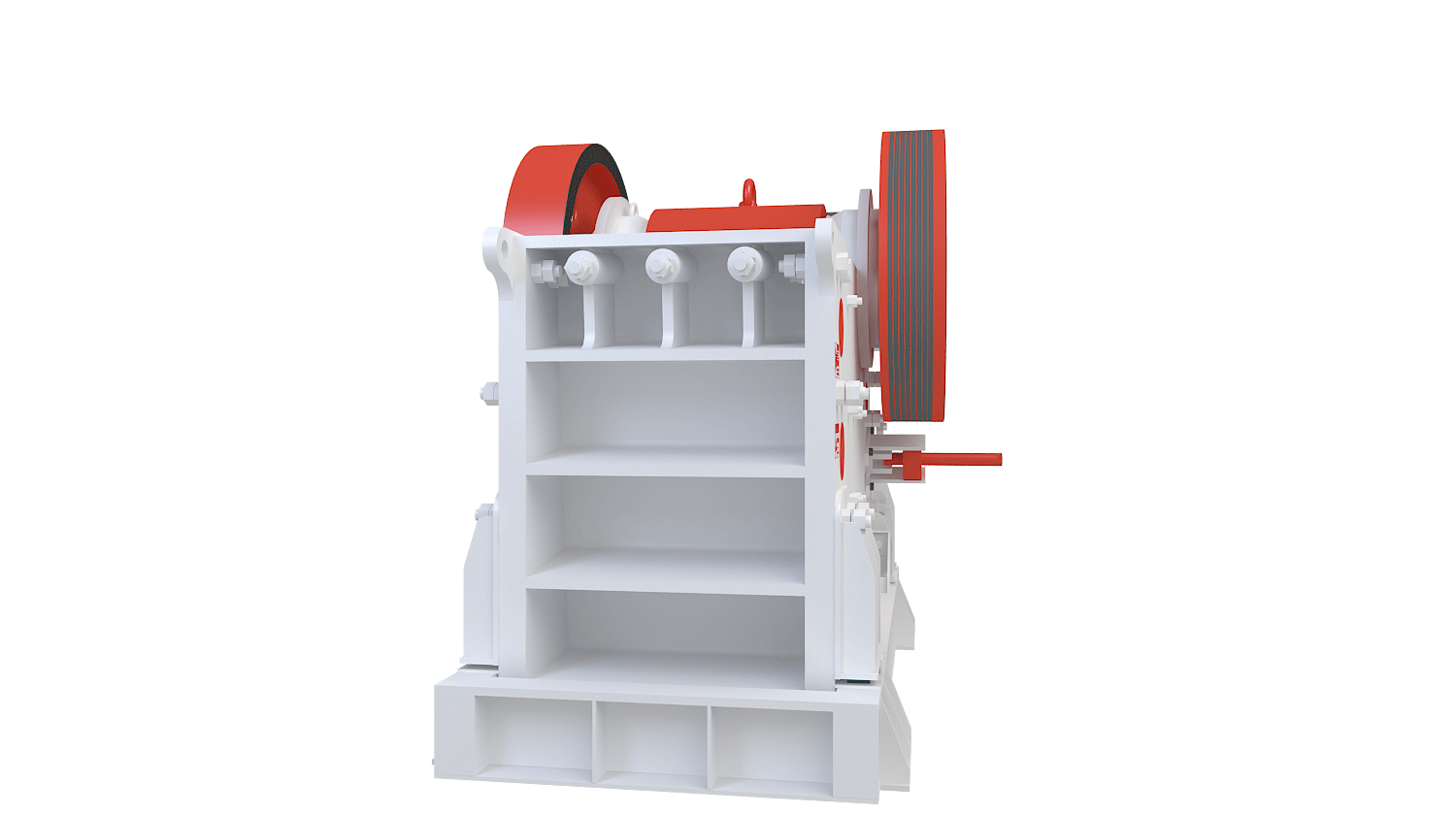

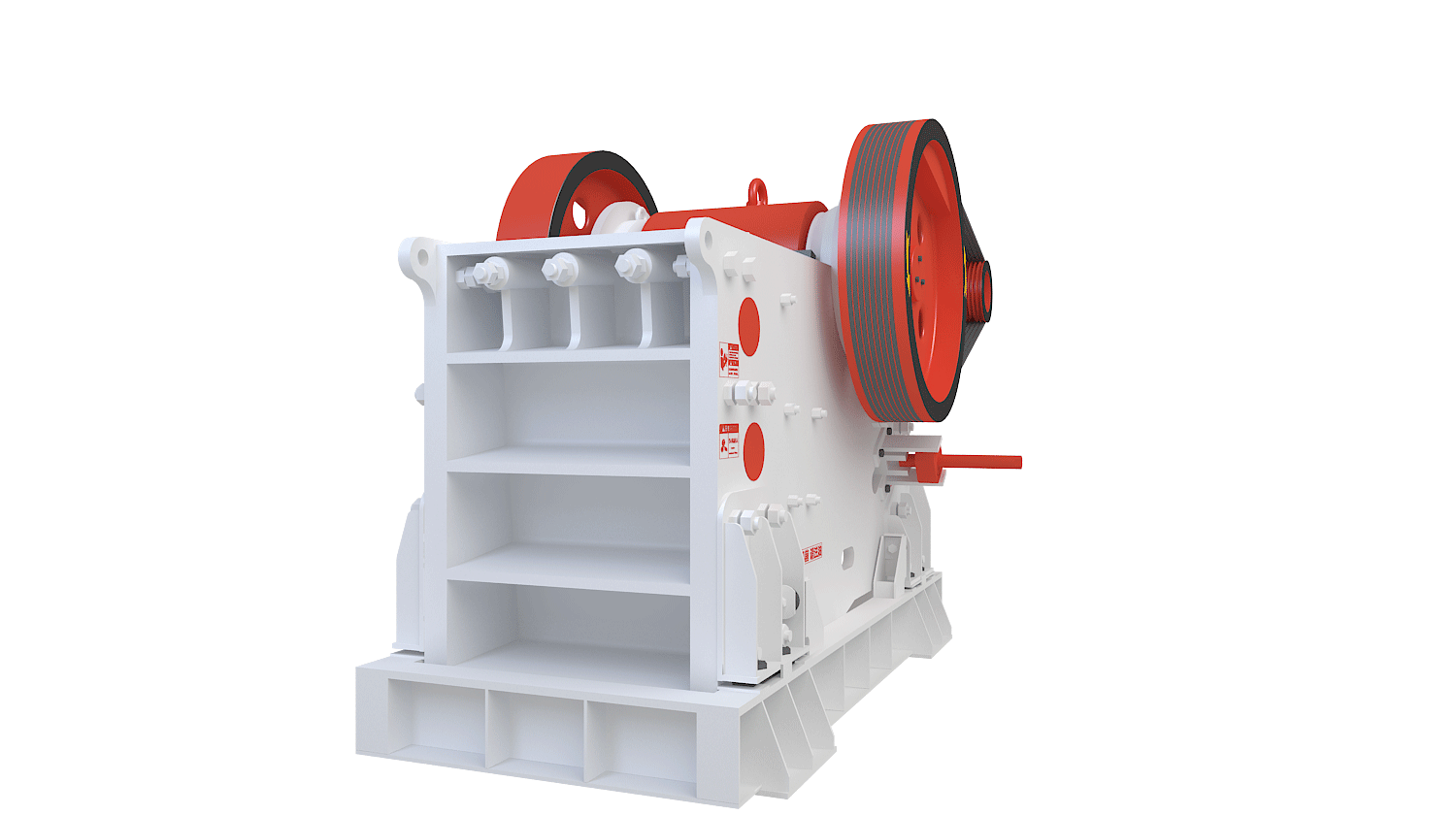

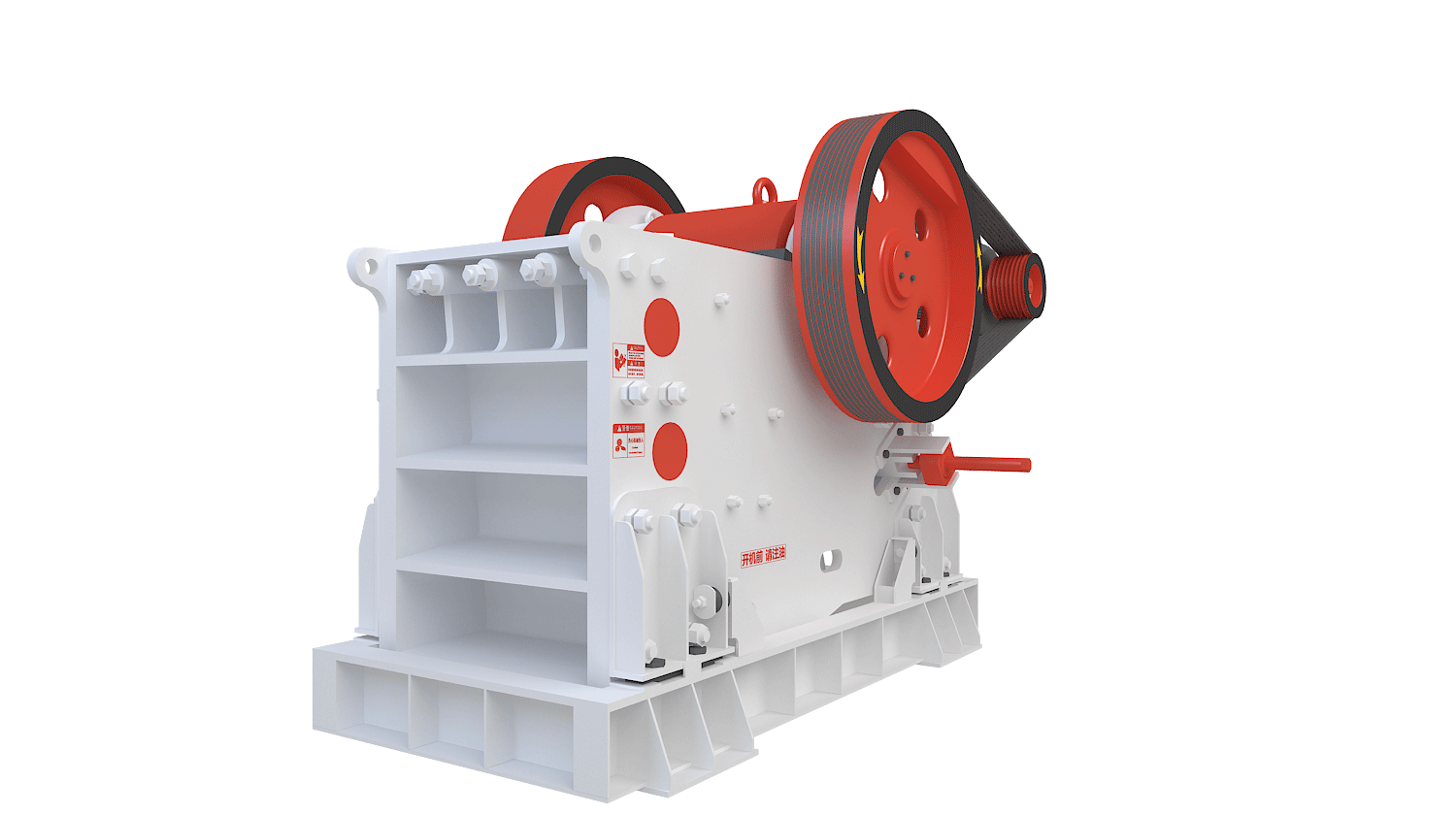

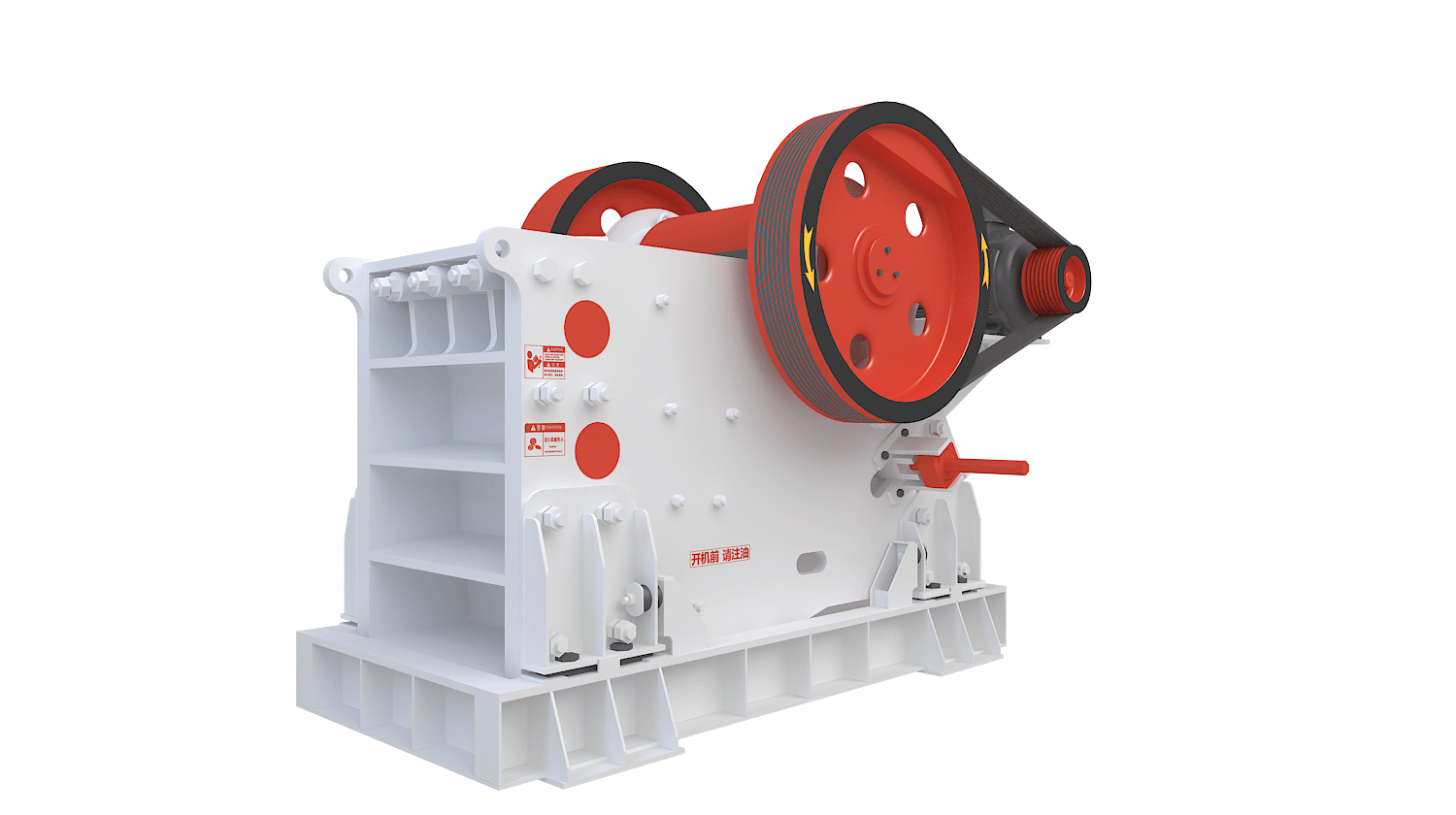

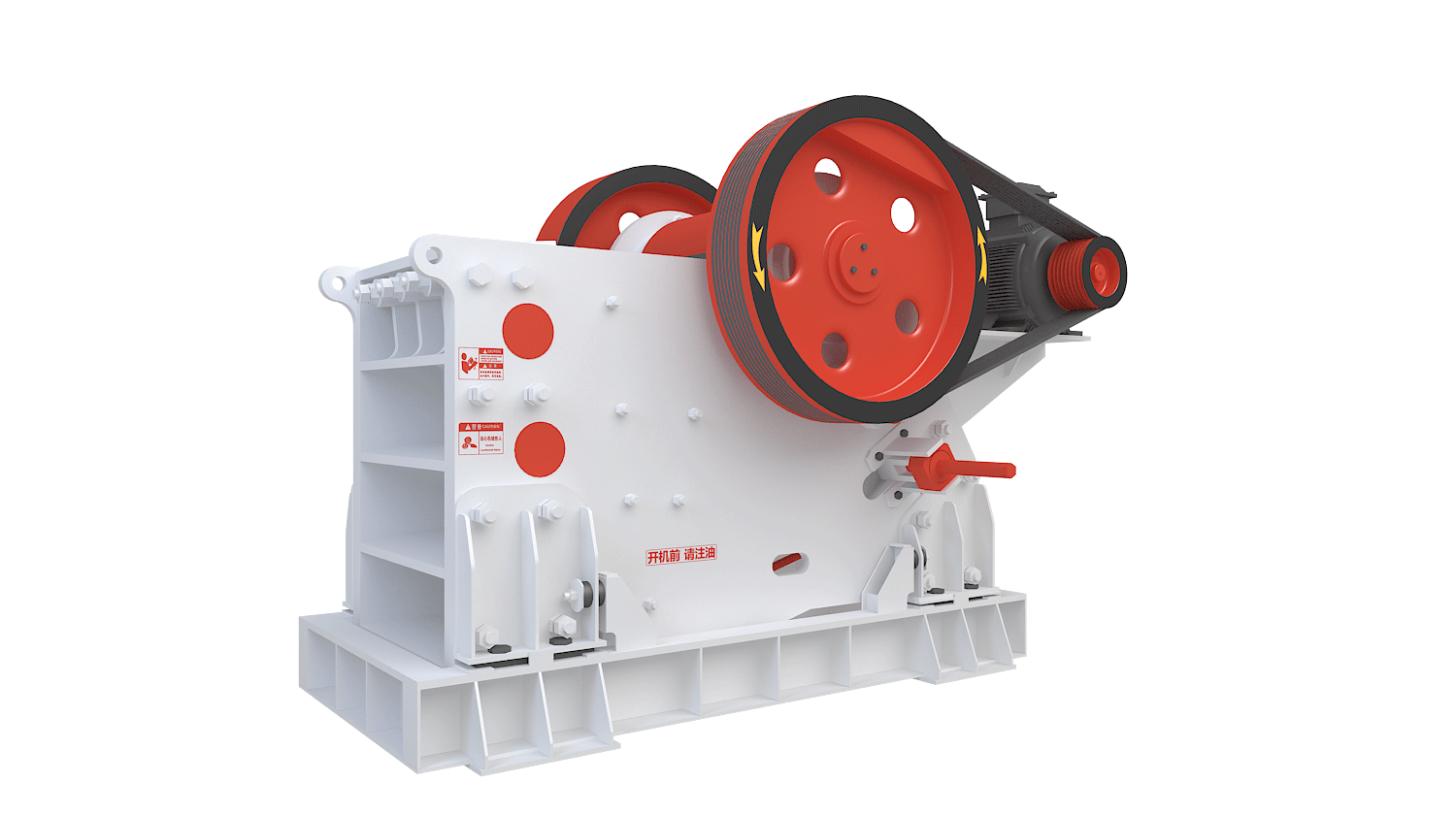

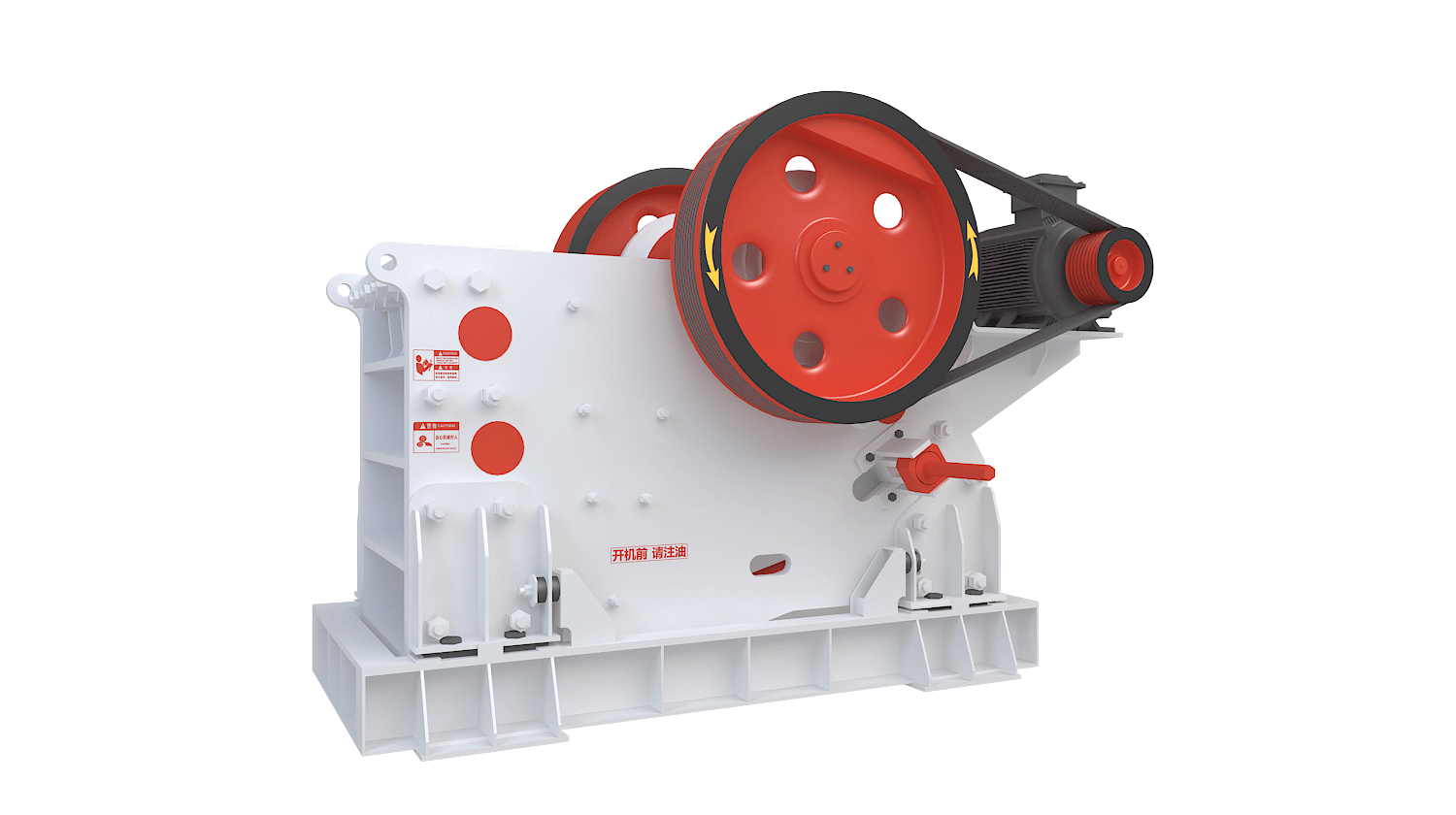

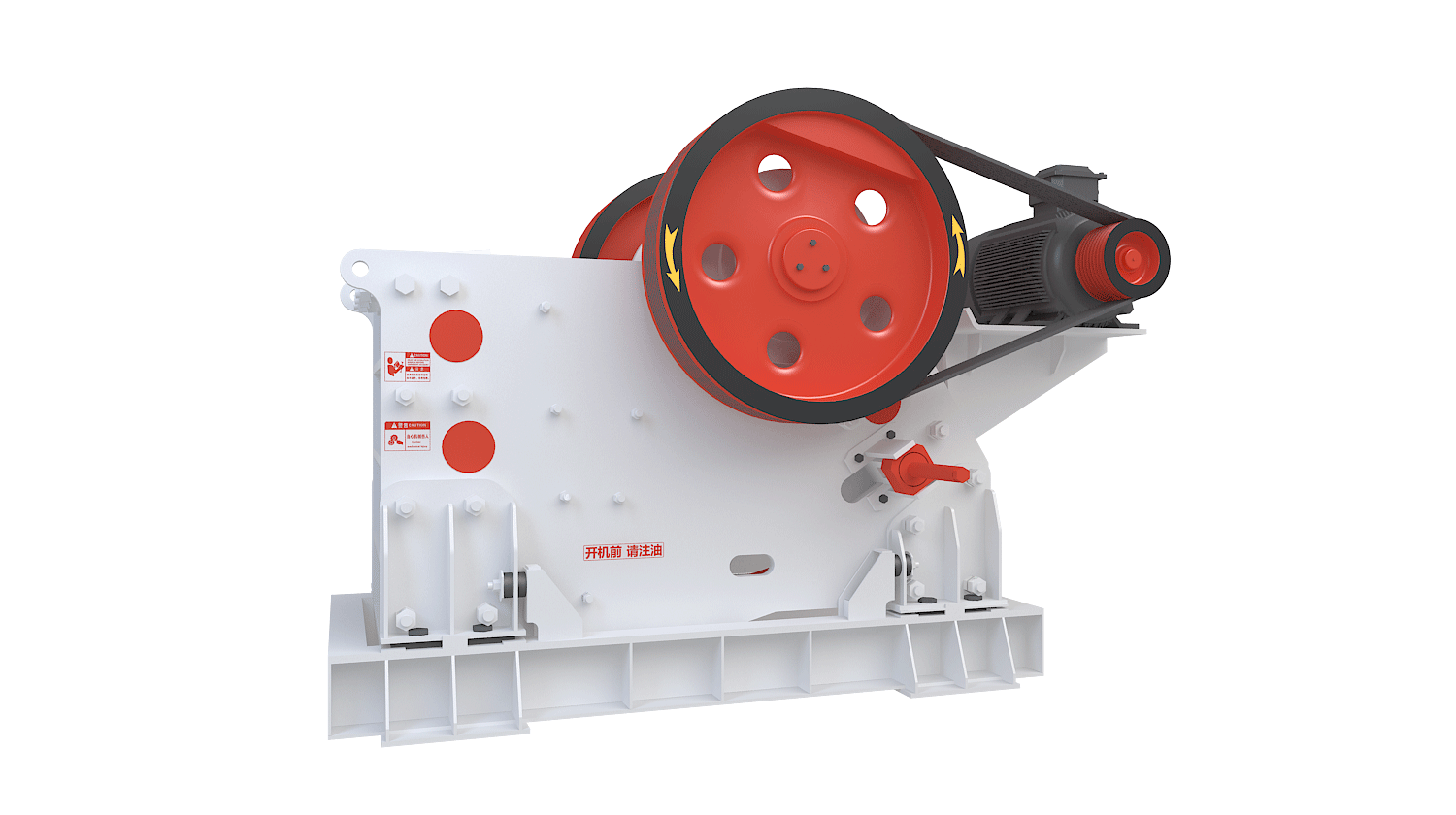

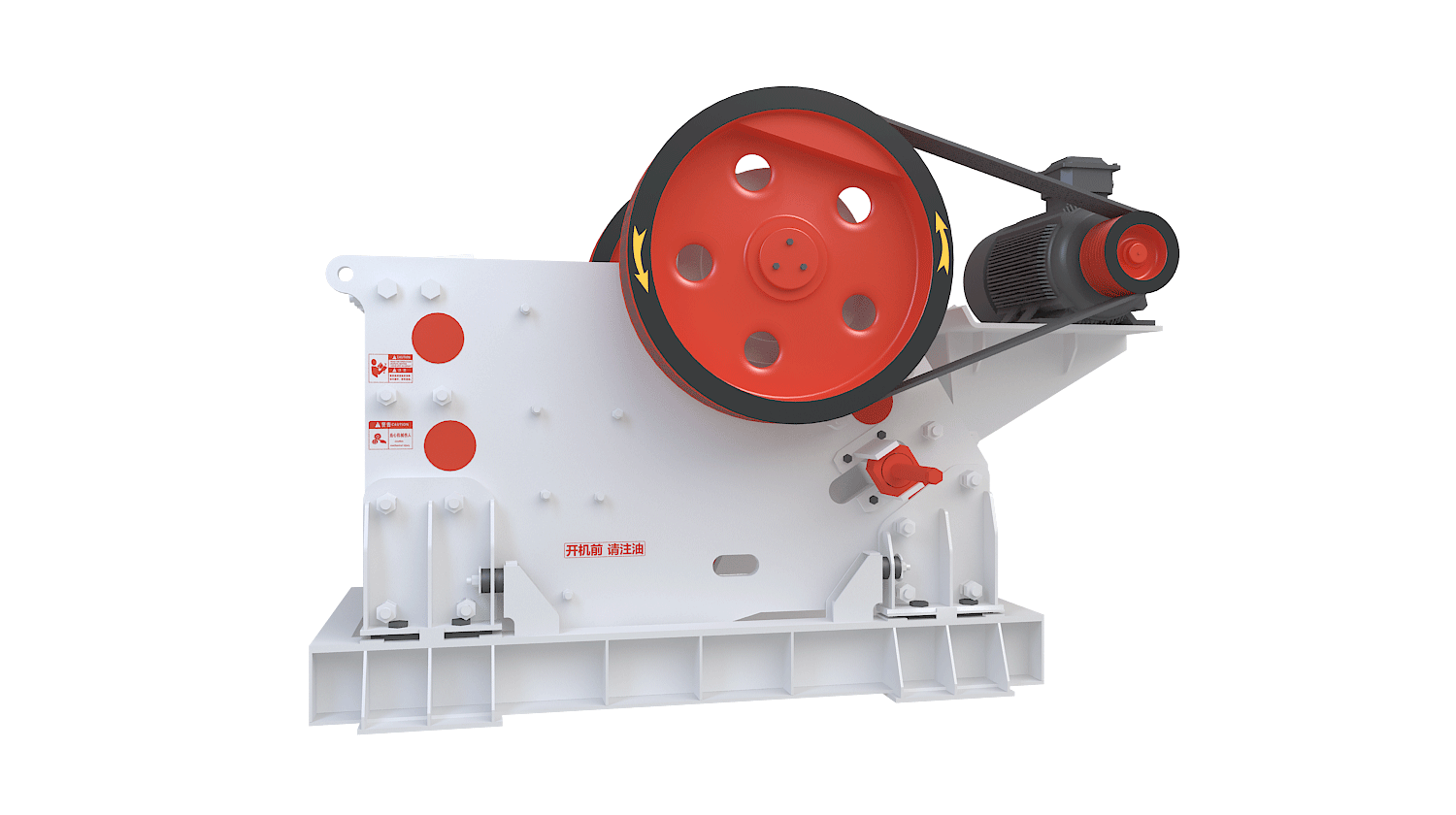

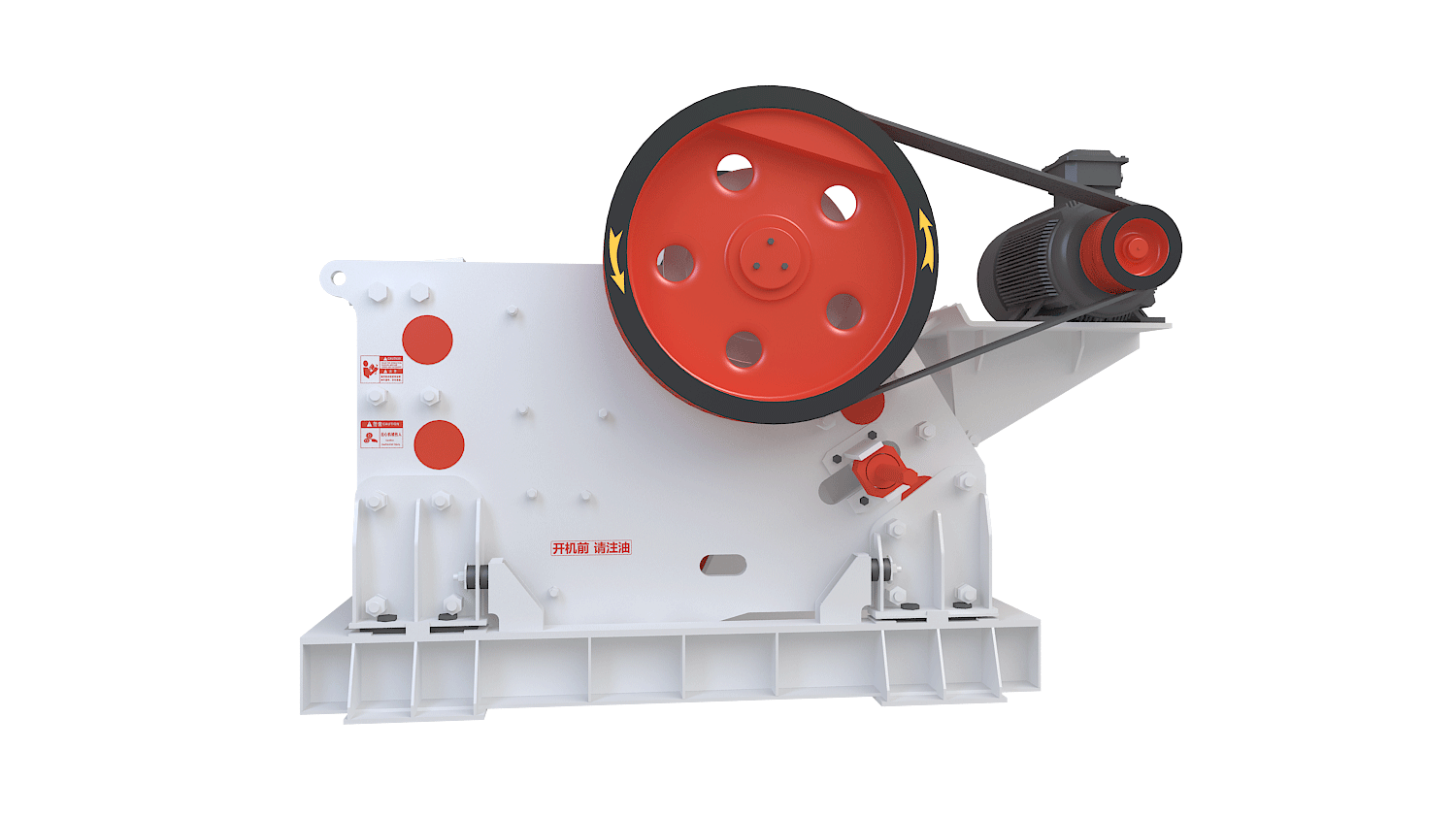

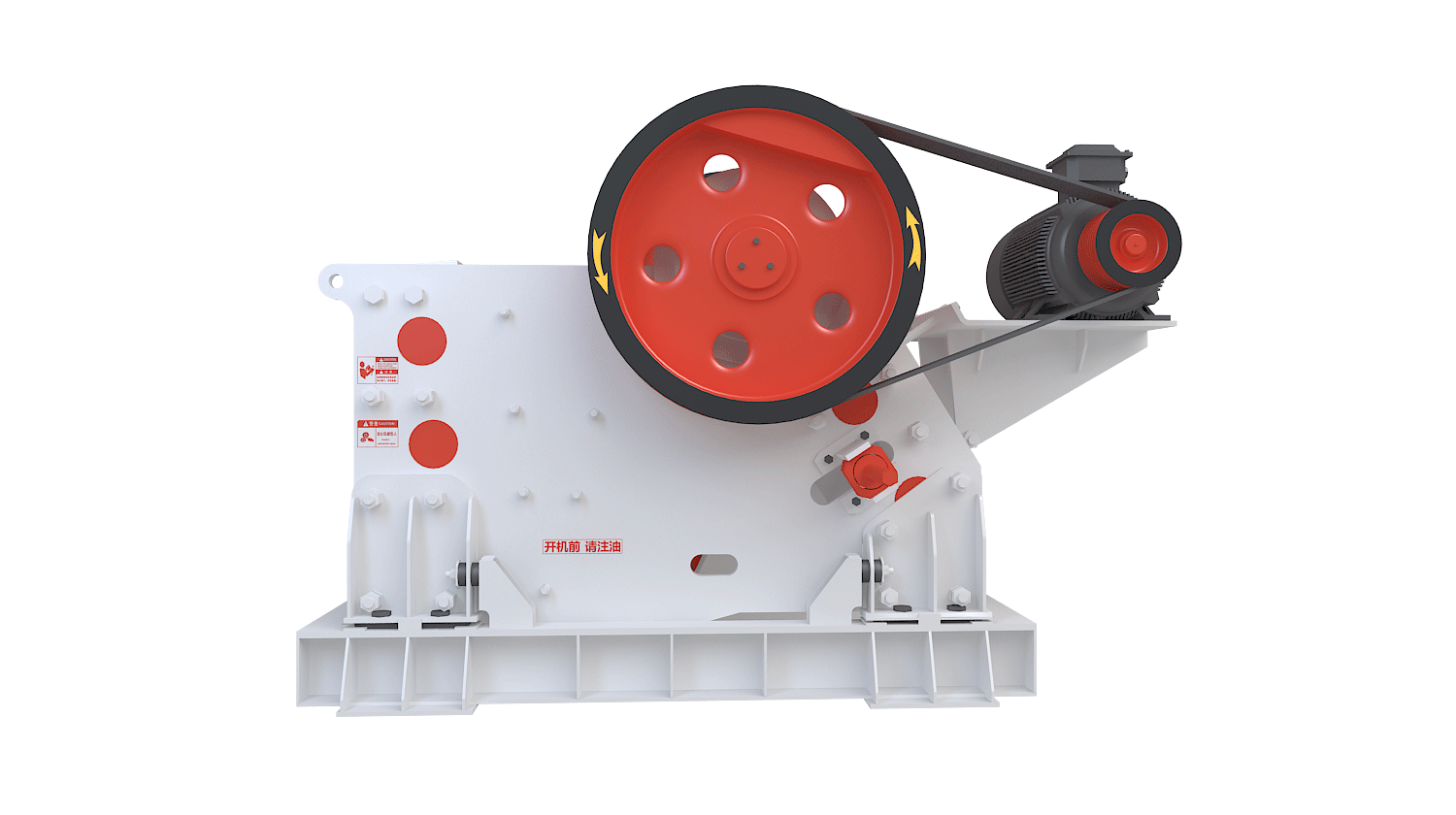

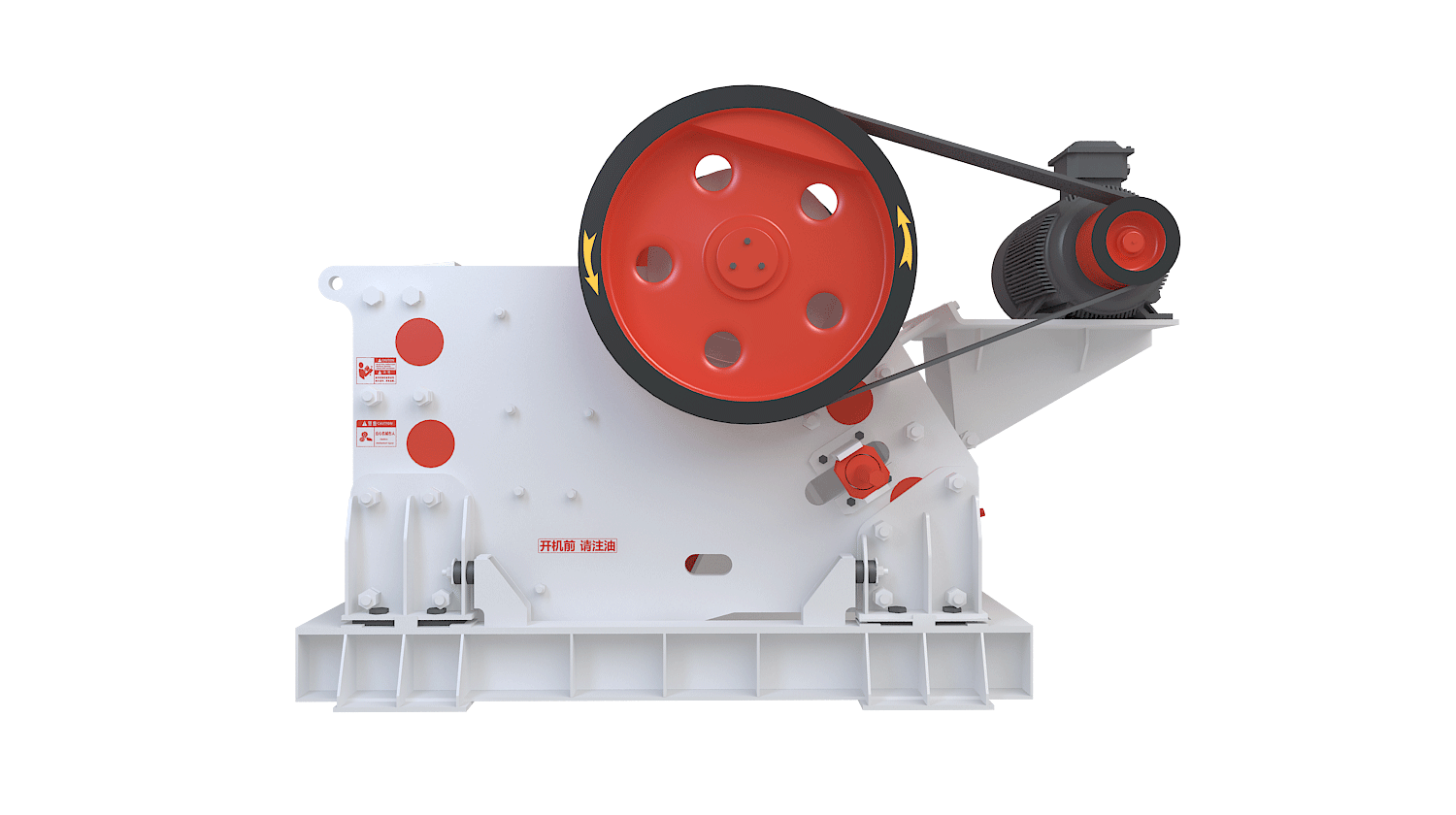

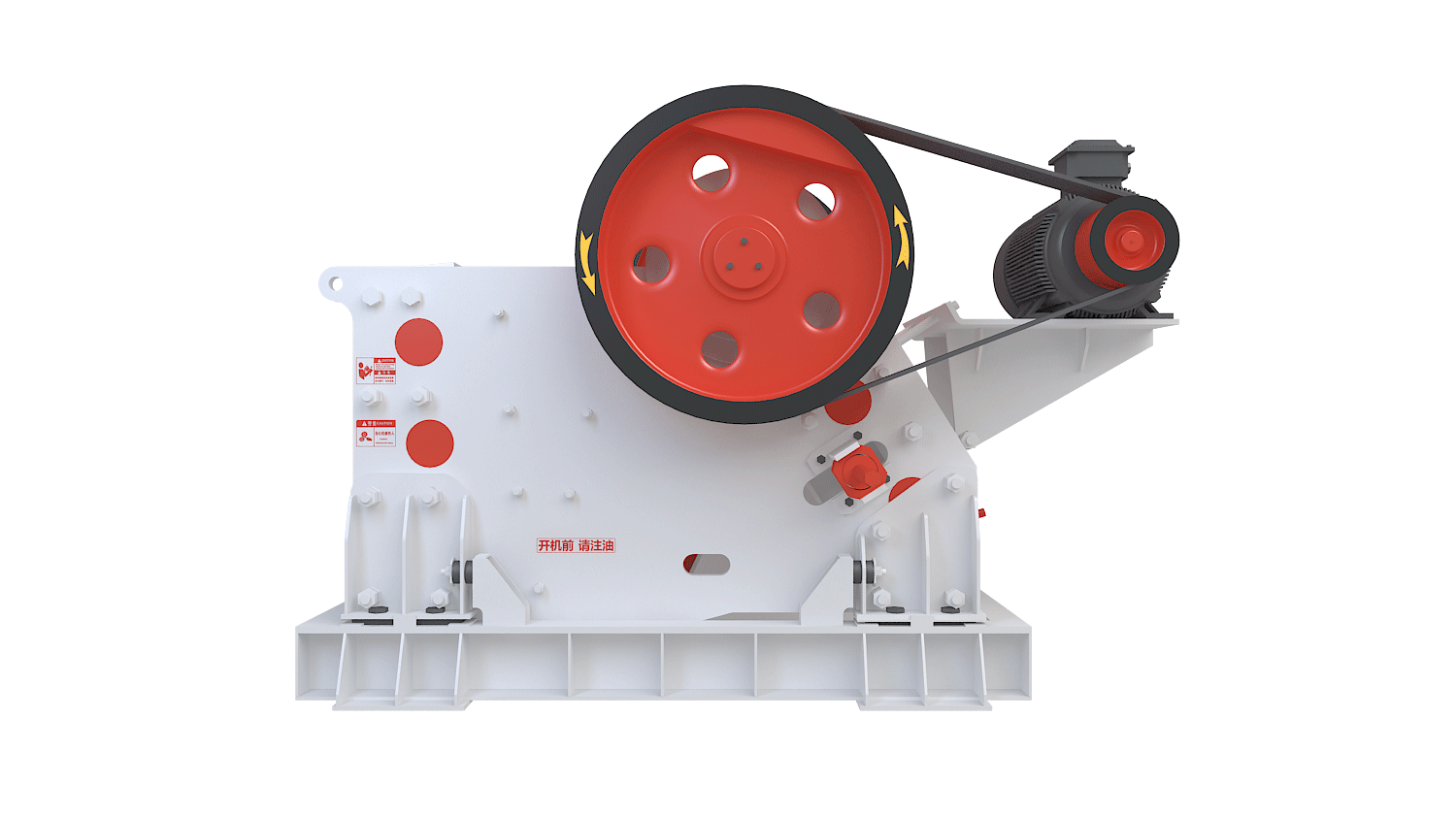

The crushing method of the jaw crusher is a curved extrusion type, and its working principle is to simulate the jaw movement of animals. When working, the motor drives the belt and pulley through the eccentric shaft to move the movable jaw up and down. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, so that the movable jaw is pushed close to the fixed jaw, and the materials are crushed many times through the extrusion, friction and grinding between the two jaws. When the movable jaw descends, the angle between the toggle plate and the movable jaw becomes smaller, and the movable jaw leaves the fixed jaw under the action of the pull rod and the spring, and the crushed material is discharged freely through the discharge port at the lower part of the jaw cavity under the action of gravity. With the continuous rotation of the motor, the movable jaw periodically crushes and discharges materials to achieve mass production.