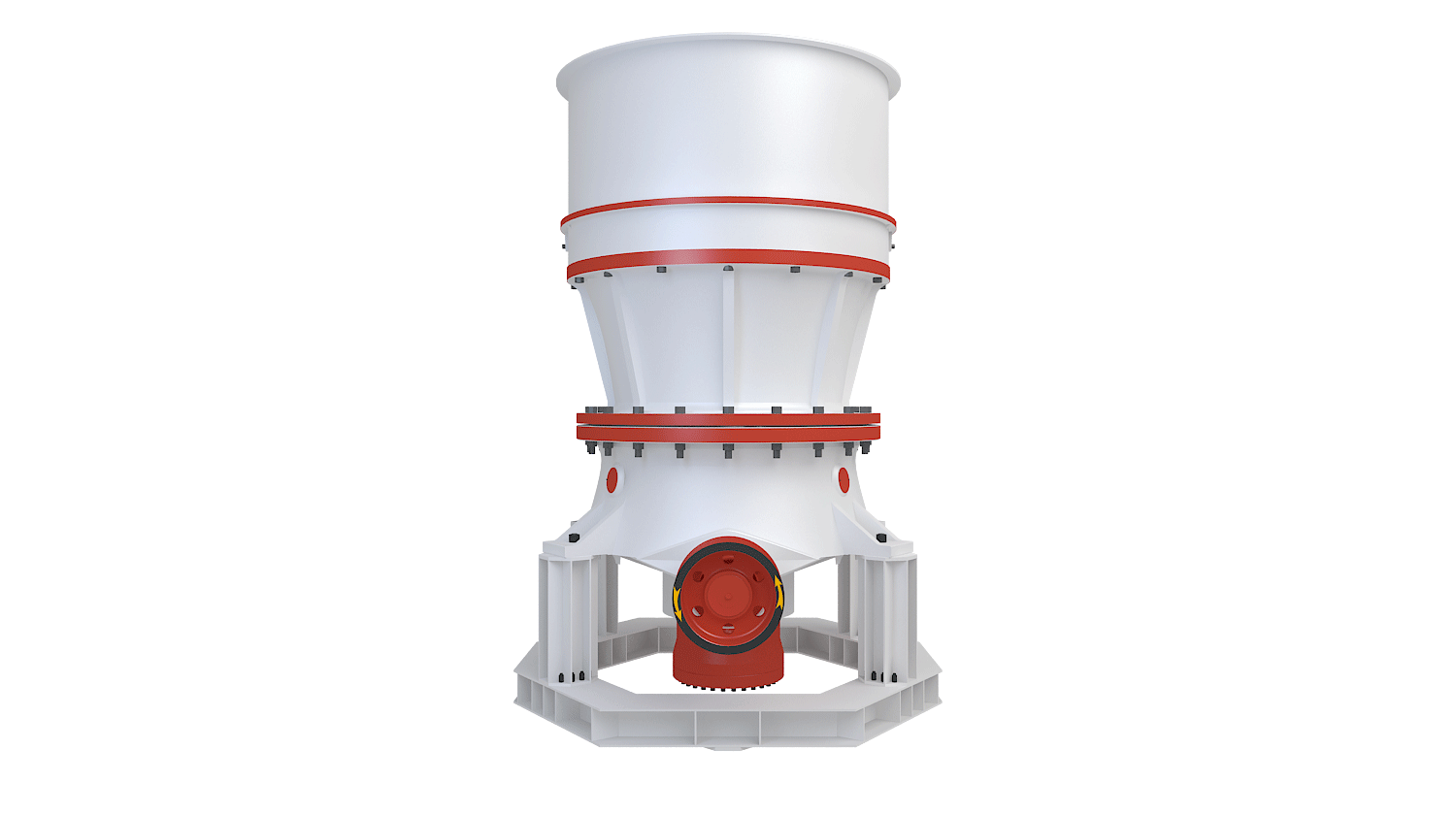

| Model | Type | Max feeding port (mm) |

Min feeding port (mm) |

Power (kw) |

Capacity (t/h) |

| CS420 | EC | 240 | 120 | 90 | 88-128 |

| C | 200 | 130 | 78-118 | ||

| CS430 | EC | 360 | 180 | 150 | 126-344 |

| C | 300 | 150 | 108-301 | ||

| MC | 235 | 80 | 91-275 | ||

| CS440 | EC | 450 | 180 | 250 | 267-601 |

| C | 400 | 150 | 225-511 | ||

| MC | 300 | 80 | 195-486 | ||

| CS660 | EC | 560 | 220 | 315 | 349-1050 |

| C | 500 | 150 | 318-892 |