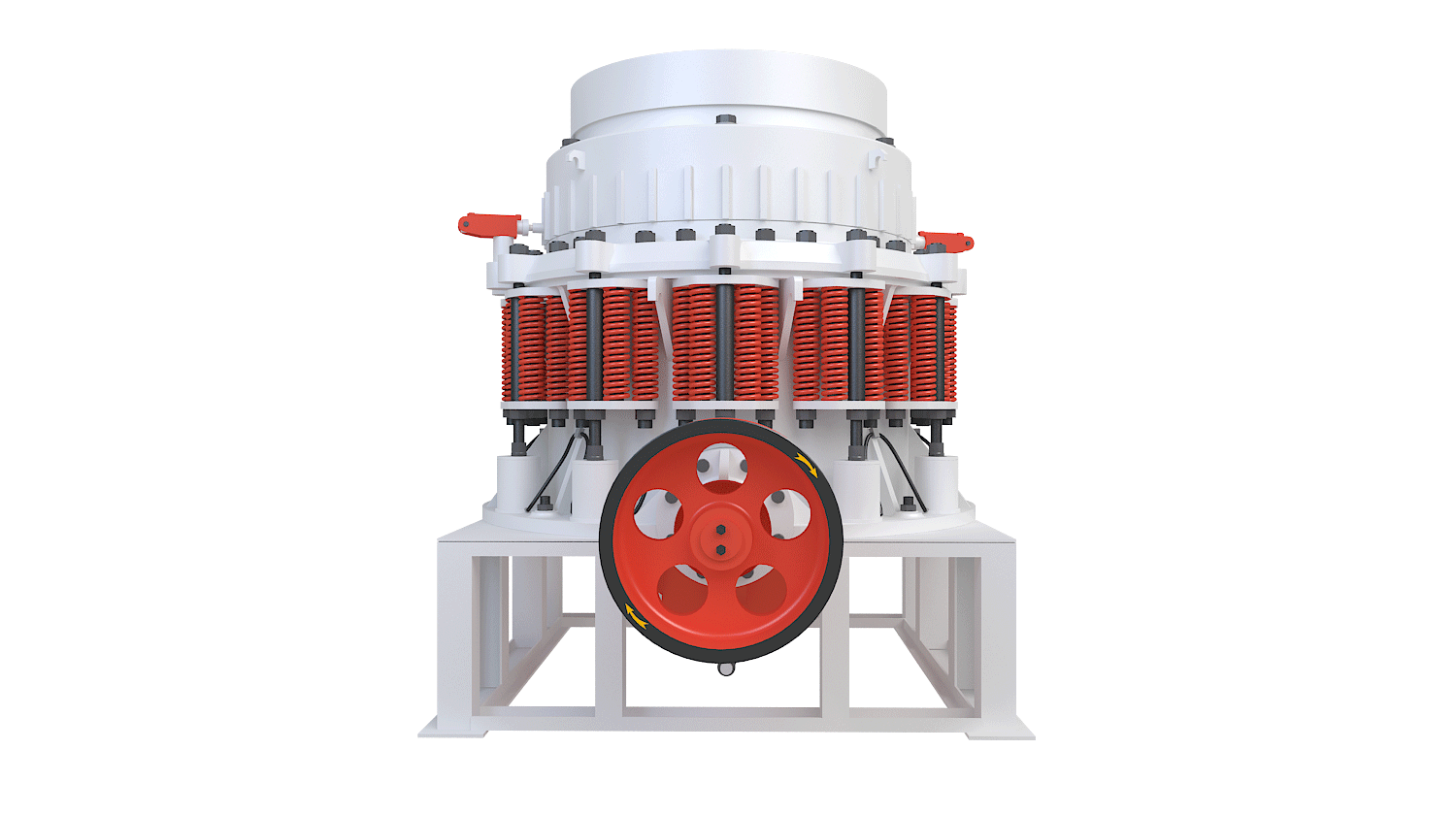

| Model | Function | Stroke (mm) |

Max feed size (mm) |

Discharge port adjustment range (mm) |

Capacity (t/h) |

Motor Power (kw) |

Weight (t) |

| K 1200C-D | Coarse crushing | 22 | 180 | 19-50 | 110-250 | 132 | 16 |

| K 1400C-D | Coarse crushing | 30 | 235 | 25-65 | 210-530 | 220 | 25 |

| K 1400Z-D | Medium crushing | 30 | 215 | 22-50 | 200-500 | 220 | 25 |

| K 1400Z-X | Medium crushing | 25 | 180 | 19-45 | 180-475 | 220 | 25 |

| K 1650C2-D | Coarse crushing | 34 | 300 | 31-65 | 280-610 | 250 | 35 |

| K 1650C-D | Coarse crushing | 34 | 260 | 25-65 | 265-580 | 250 | 35 |

| K 1650Z-D | Medium crushing | 34 | 240 | 19-50 | 240-550 | 250 | 35 |