| Model | Feeding inlet size (mm) |

Outlet size (mm) |

Max feeding size (mm) |

Outlet adjustable scope (mm) |

Capacity (t/h) |

| K0710 | 700 | 100 | 580 | 100-130 | 310-400 |

| K0909 | 900 | 90 | 750 | 90-120 | 380-510 |

| K0913 | 900 | 130 | 750 | 130-160 | 625-770 |

| K0917 | 900 | 170 | 750 | 170-190 | 815-910 |

| K1216 | 1200 | 160 | 1000 | 160-190 | 1250-1480 |

| K1221 | 1200 | 210 | 1000 | 210-230 | 1560-1720 |

| K1417 | 1400 | 170 | 1200 | 170-200 | 1750-2060 |

| K1422 | 1400 | 220 | 1200 | 210-230 | 2160-2370 |

| K1618 | 1600 | 180 | 1350 | 180-210 | 2400-2800 |

| K1623 | 1600 | 230 | 1350 | 210-240 | 2800-3200 |

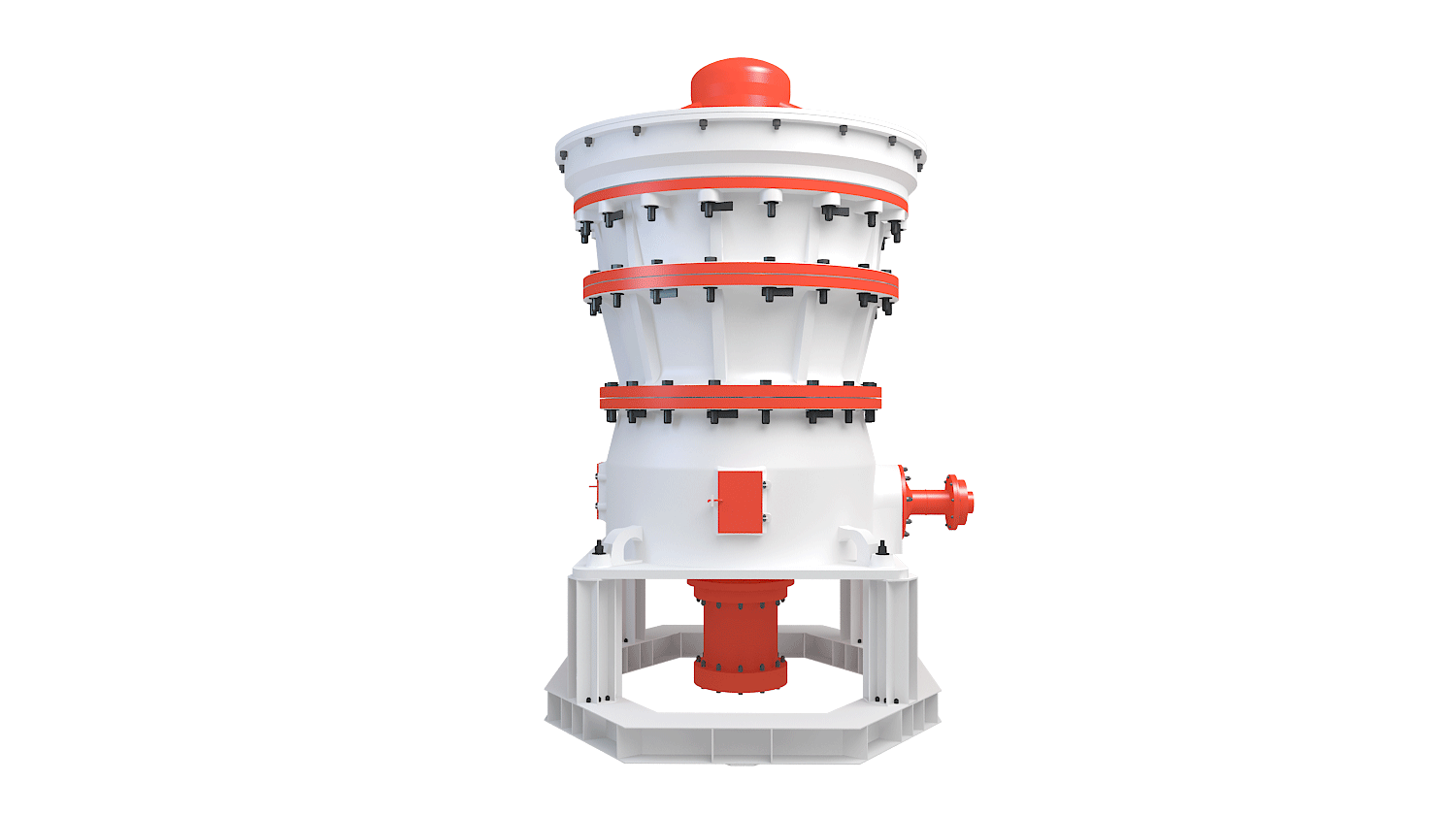

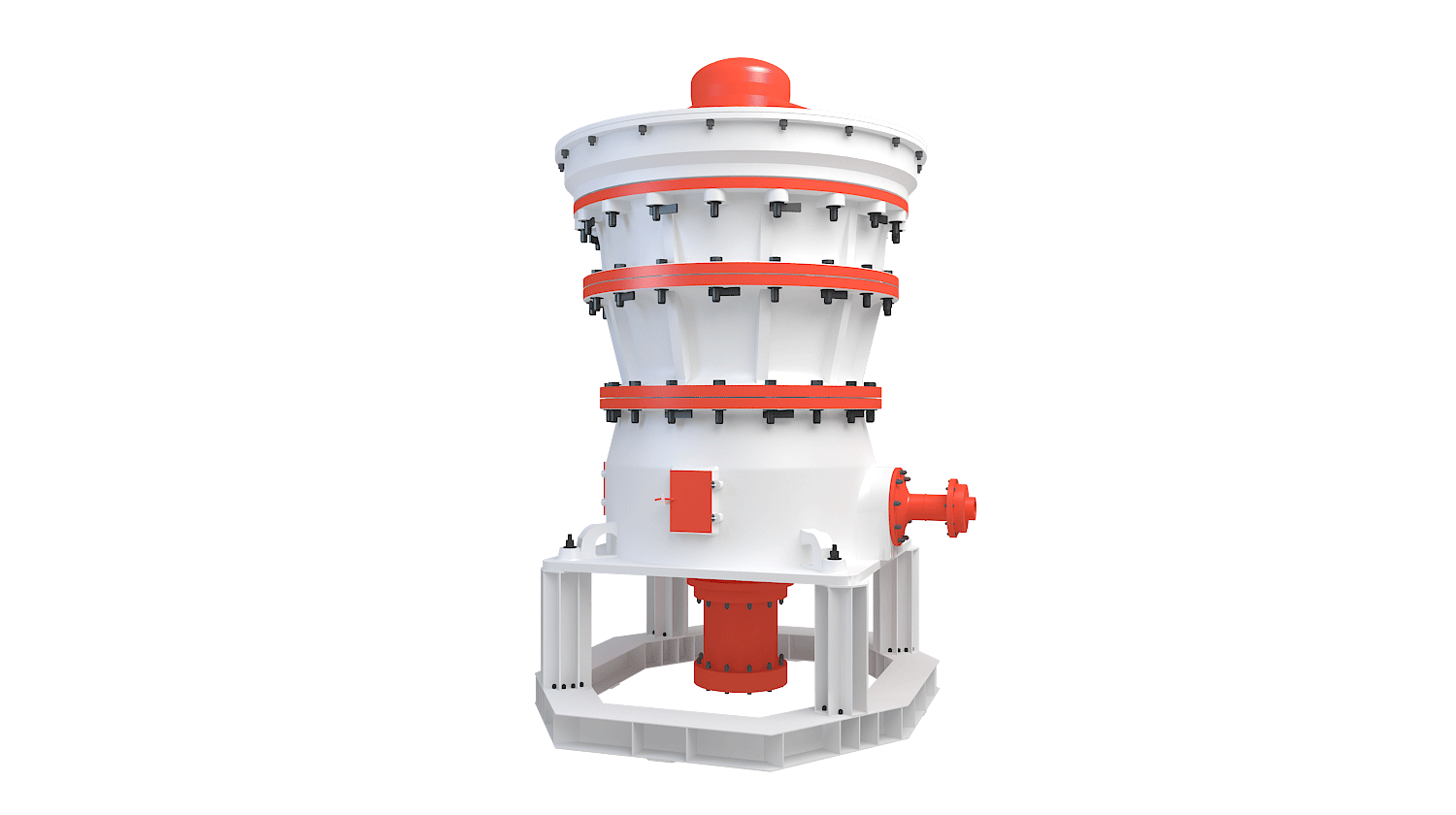

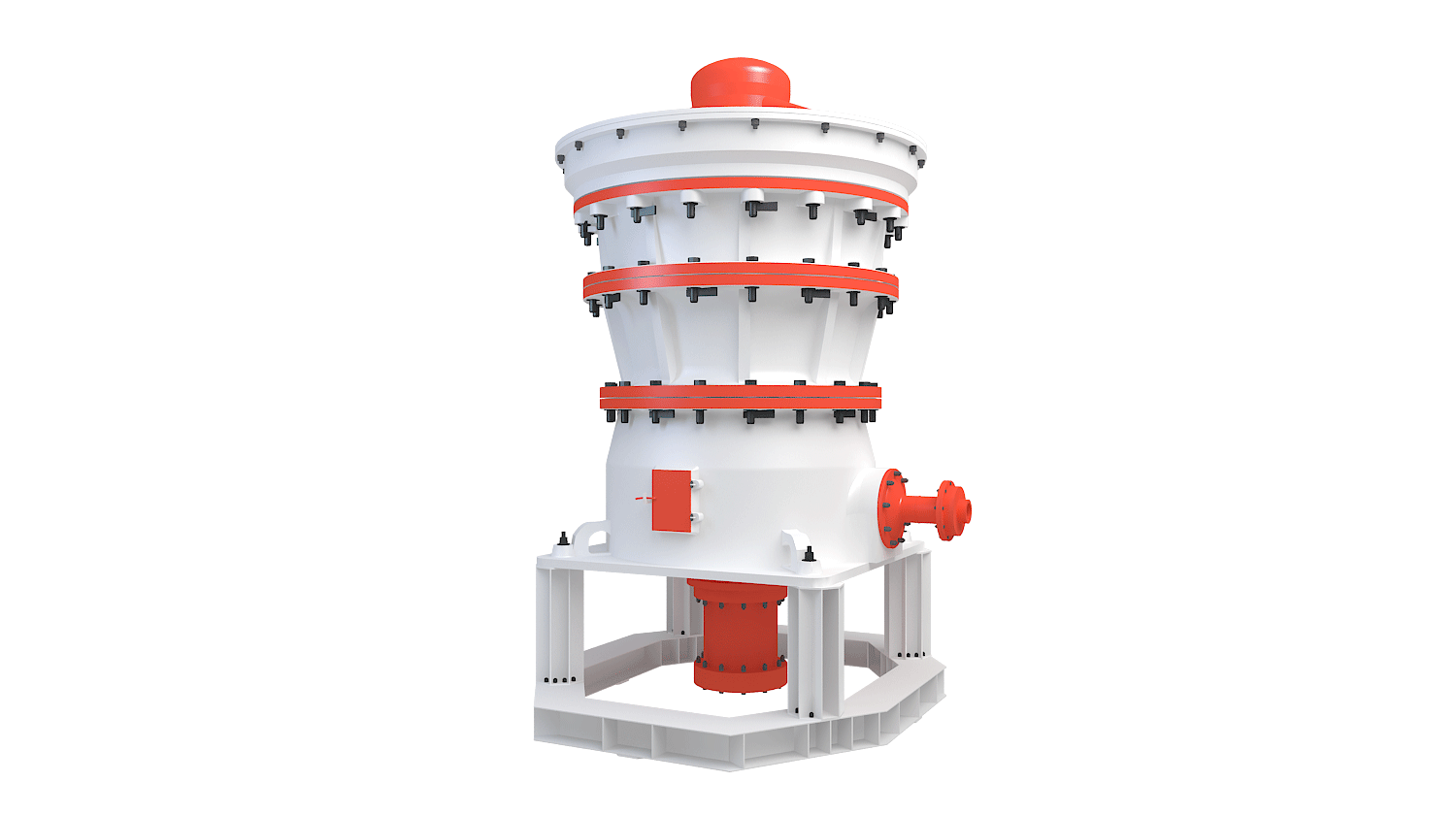

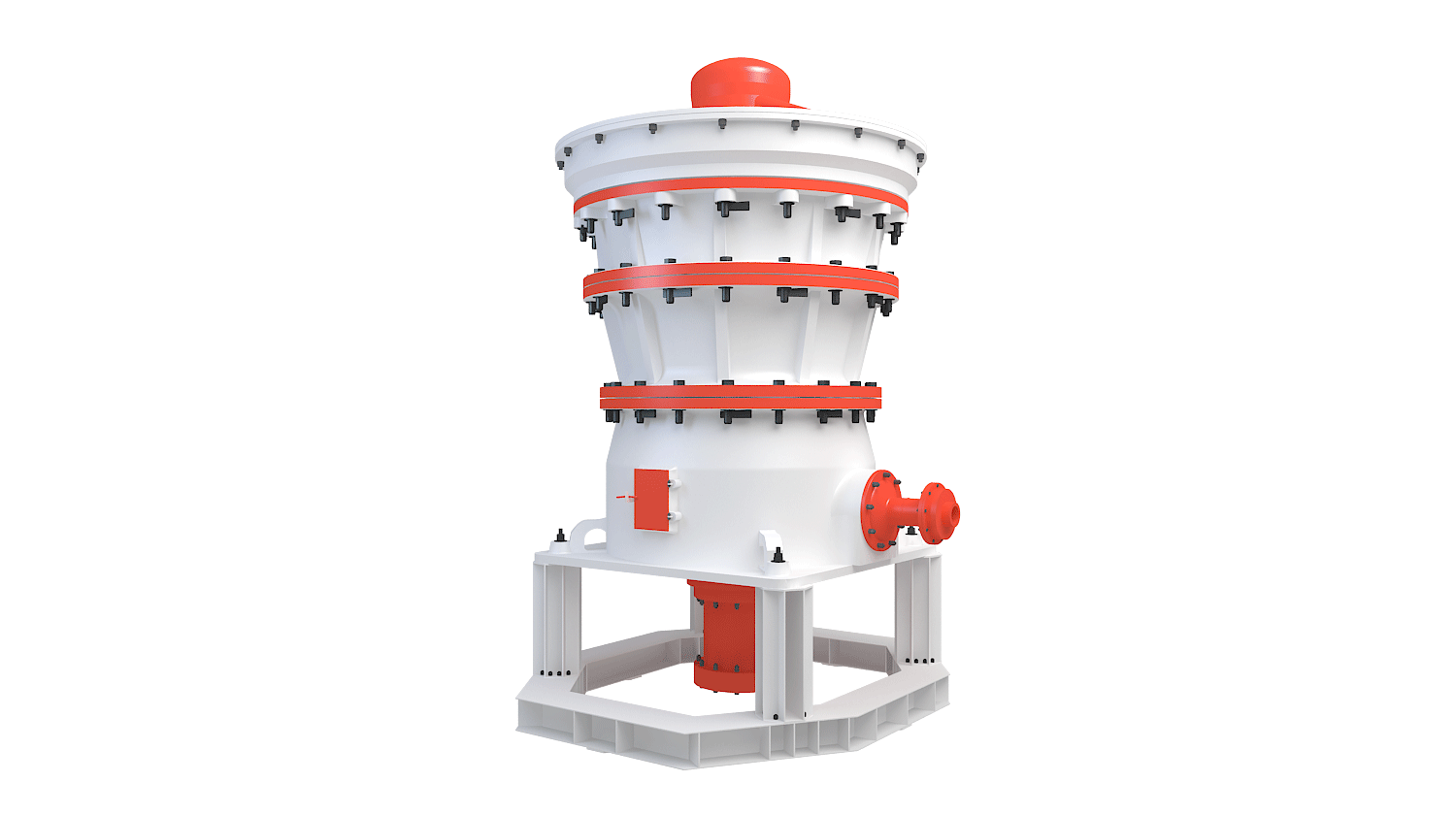

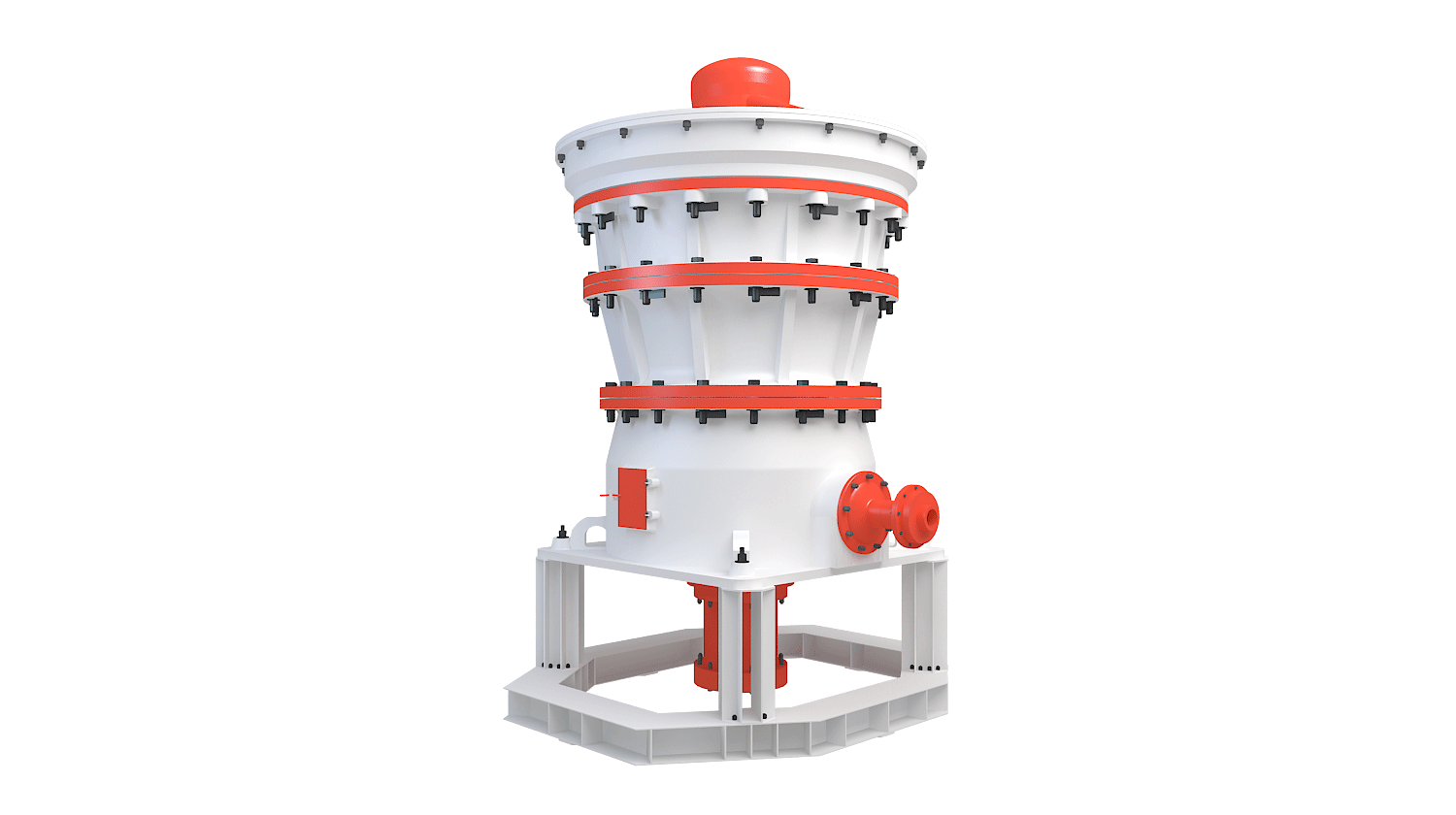

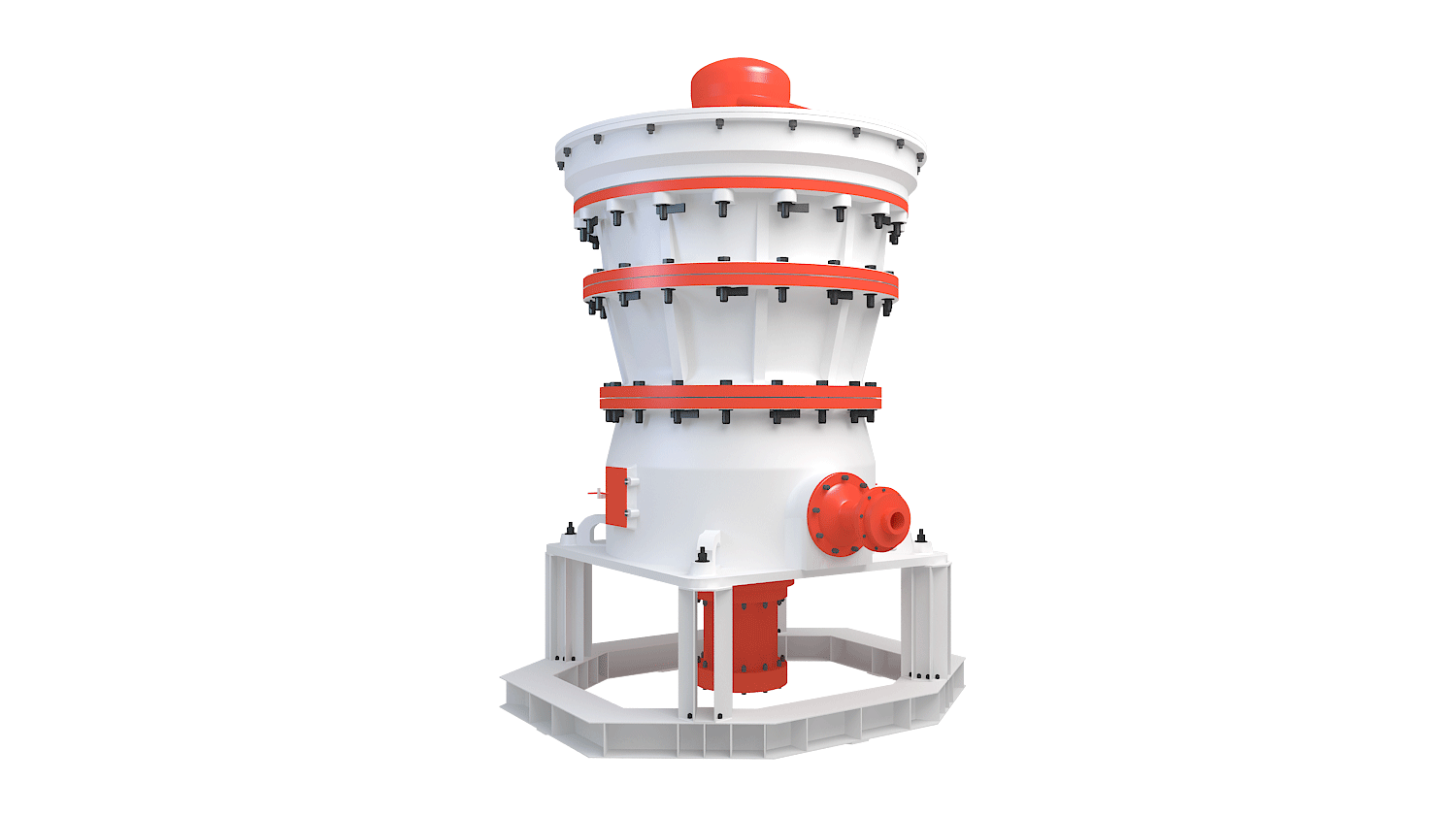

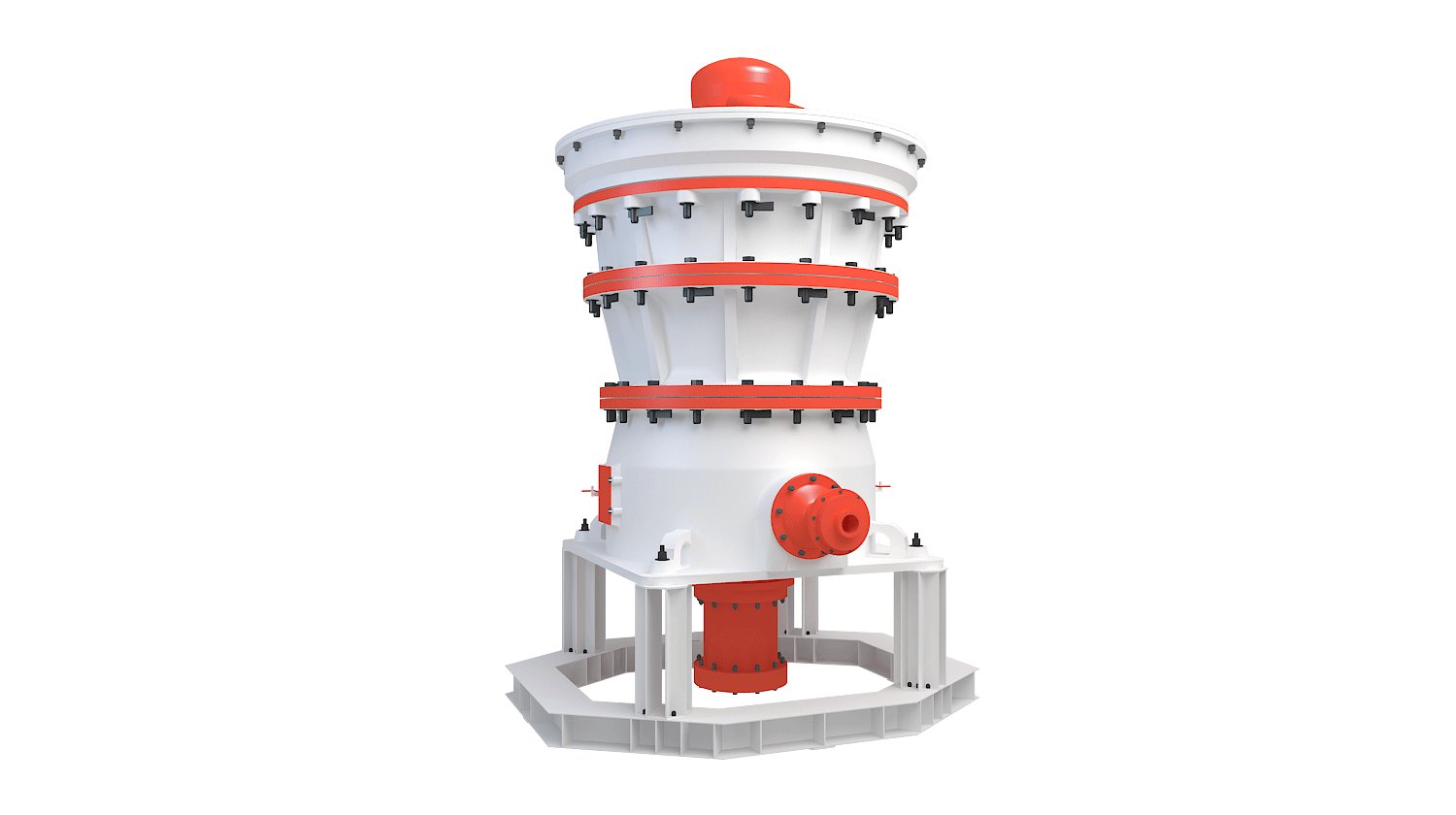

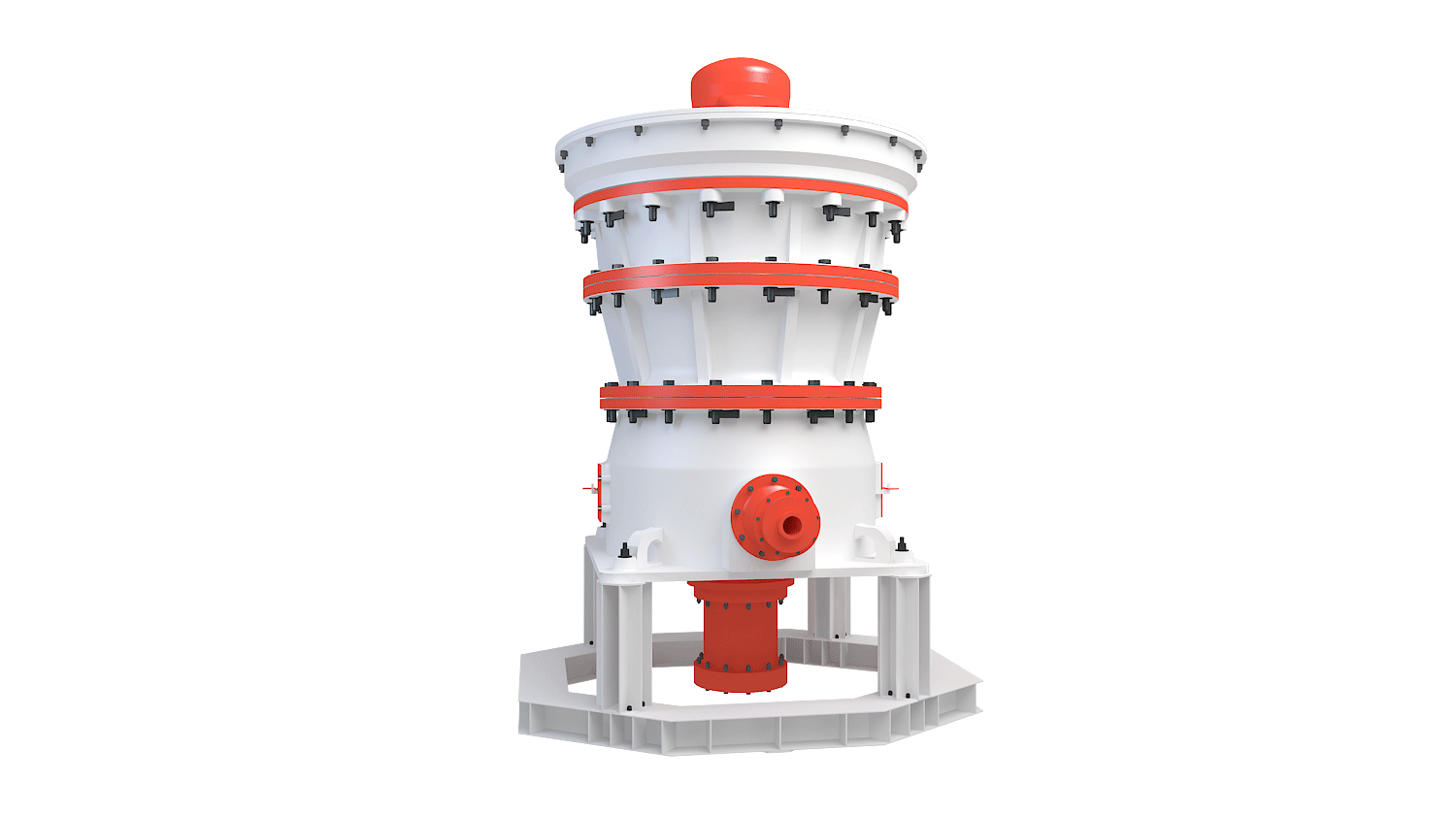

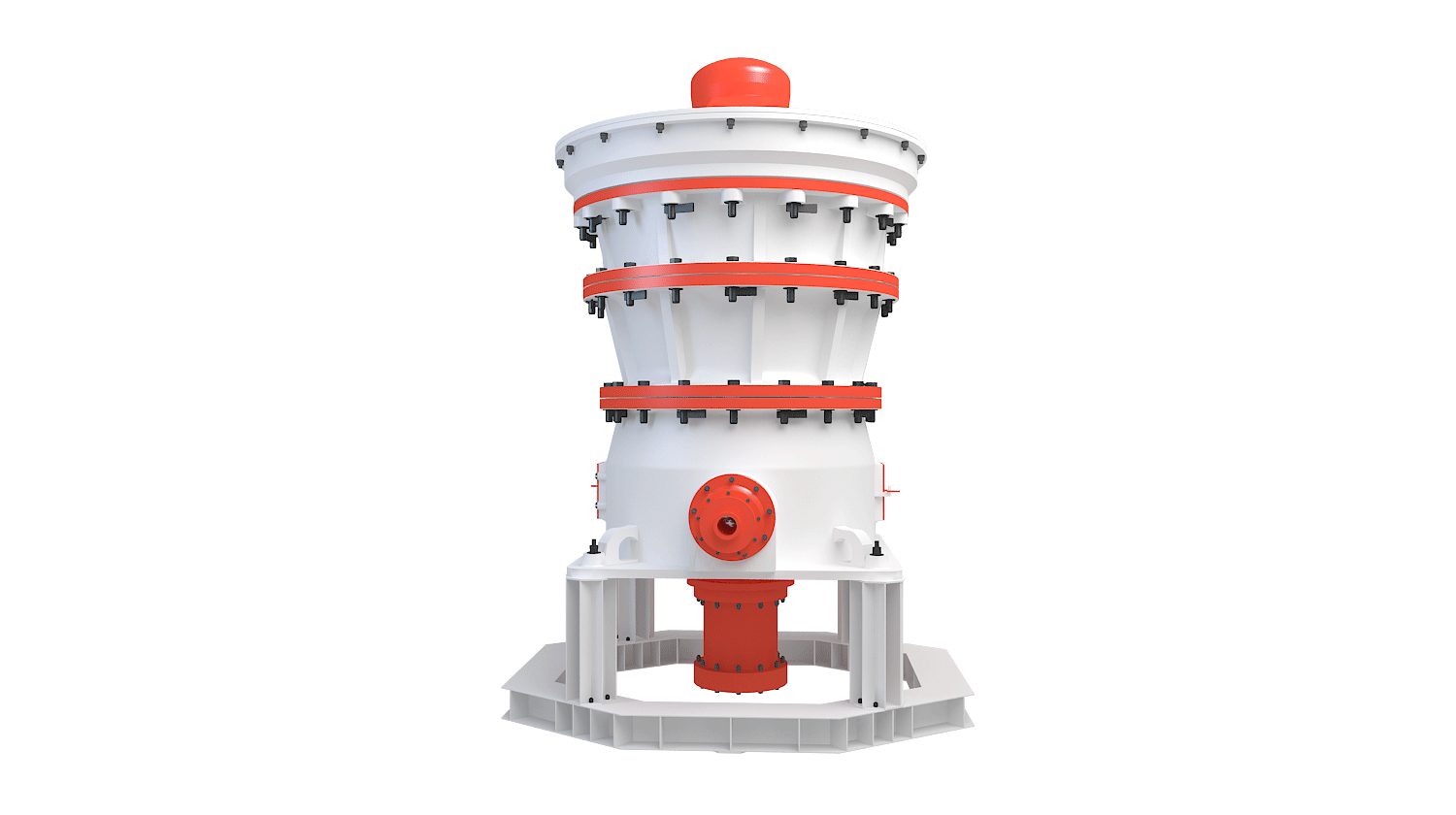

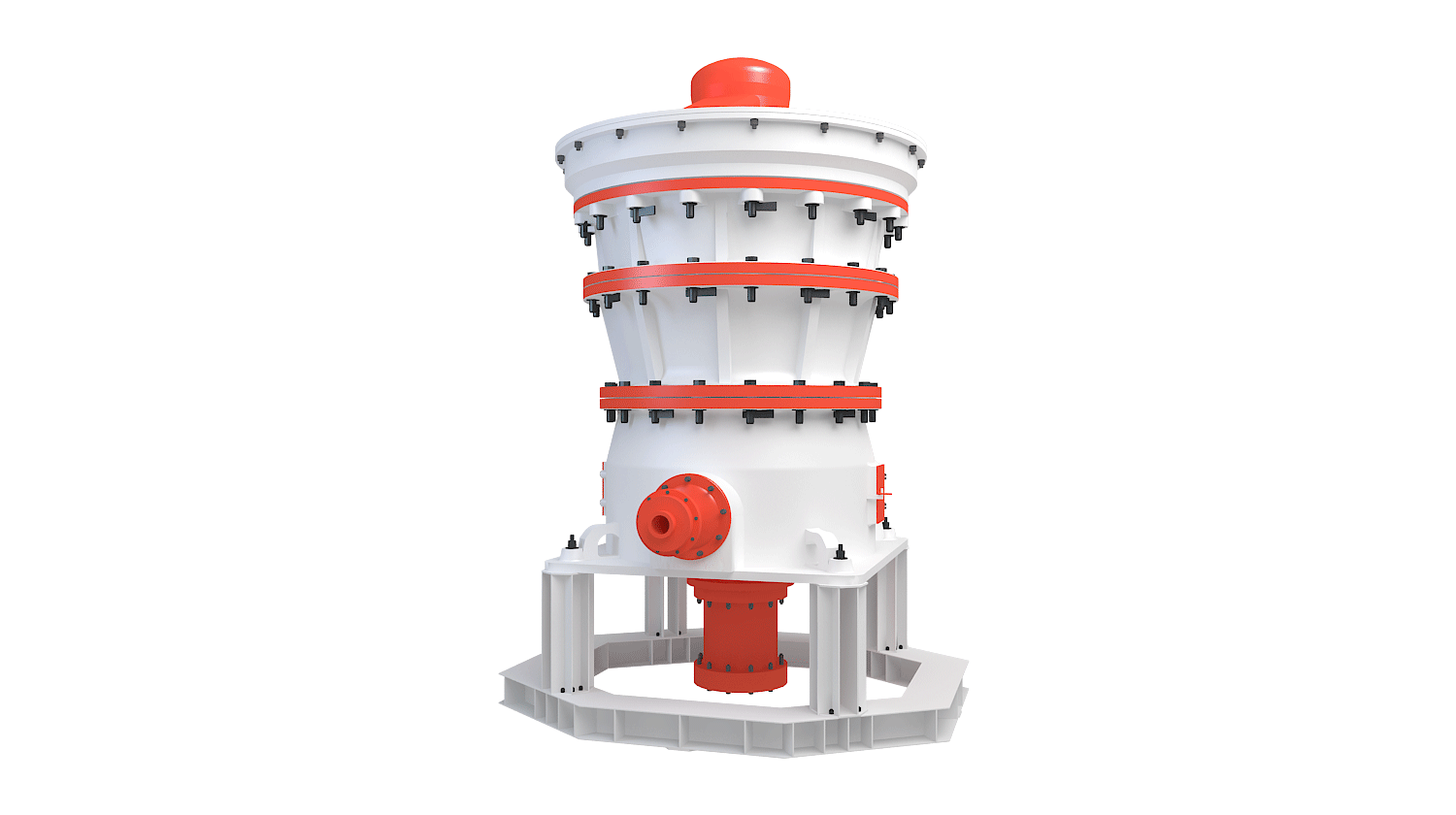

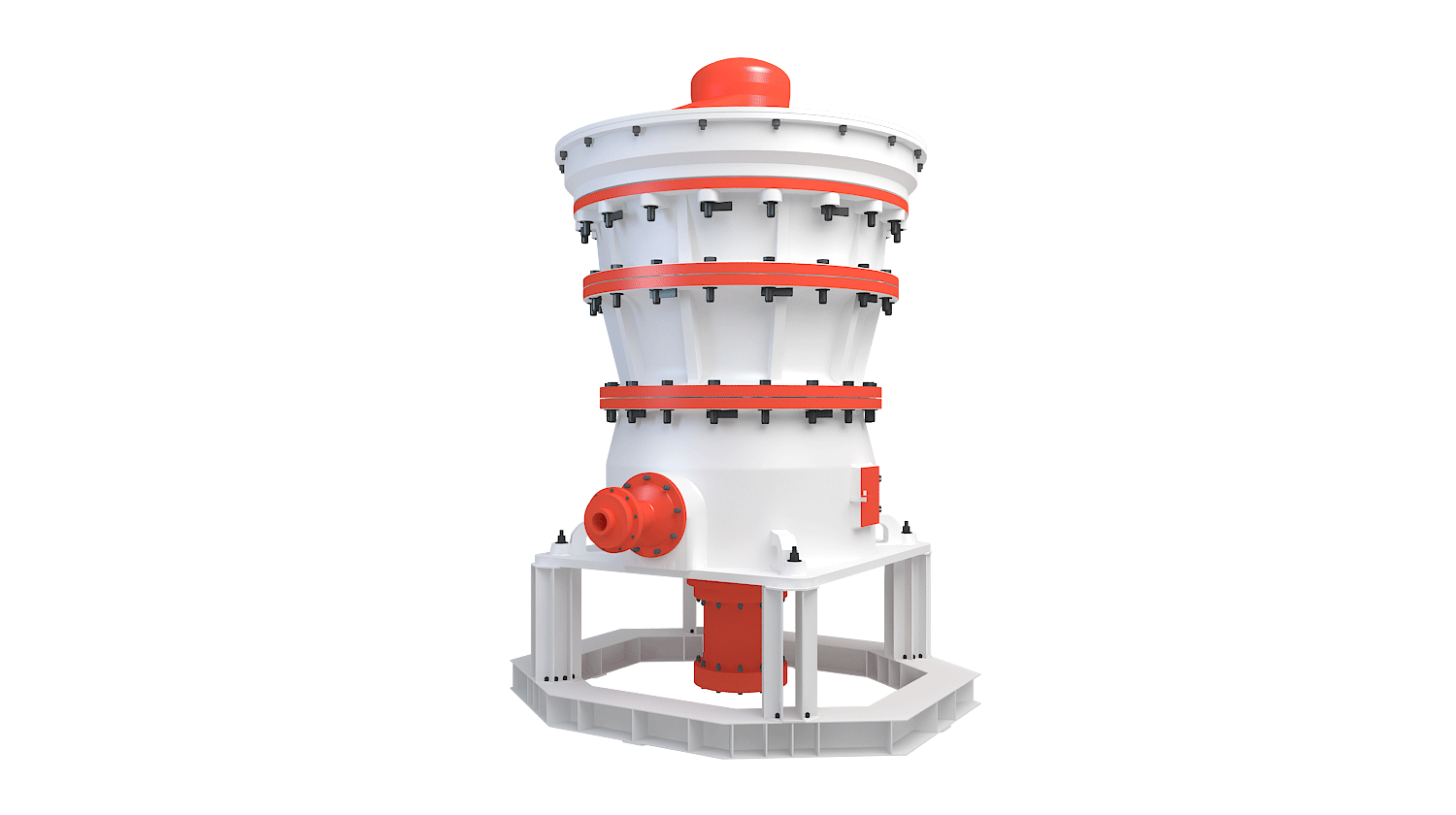

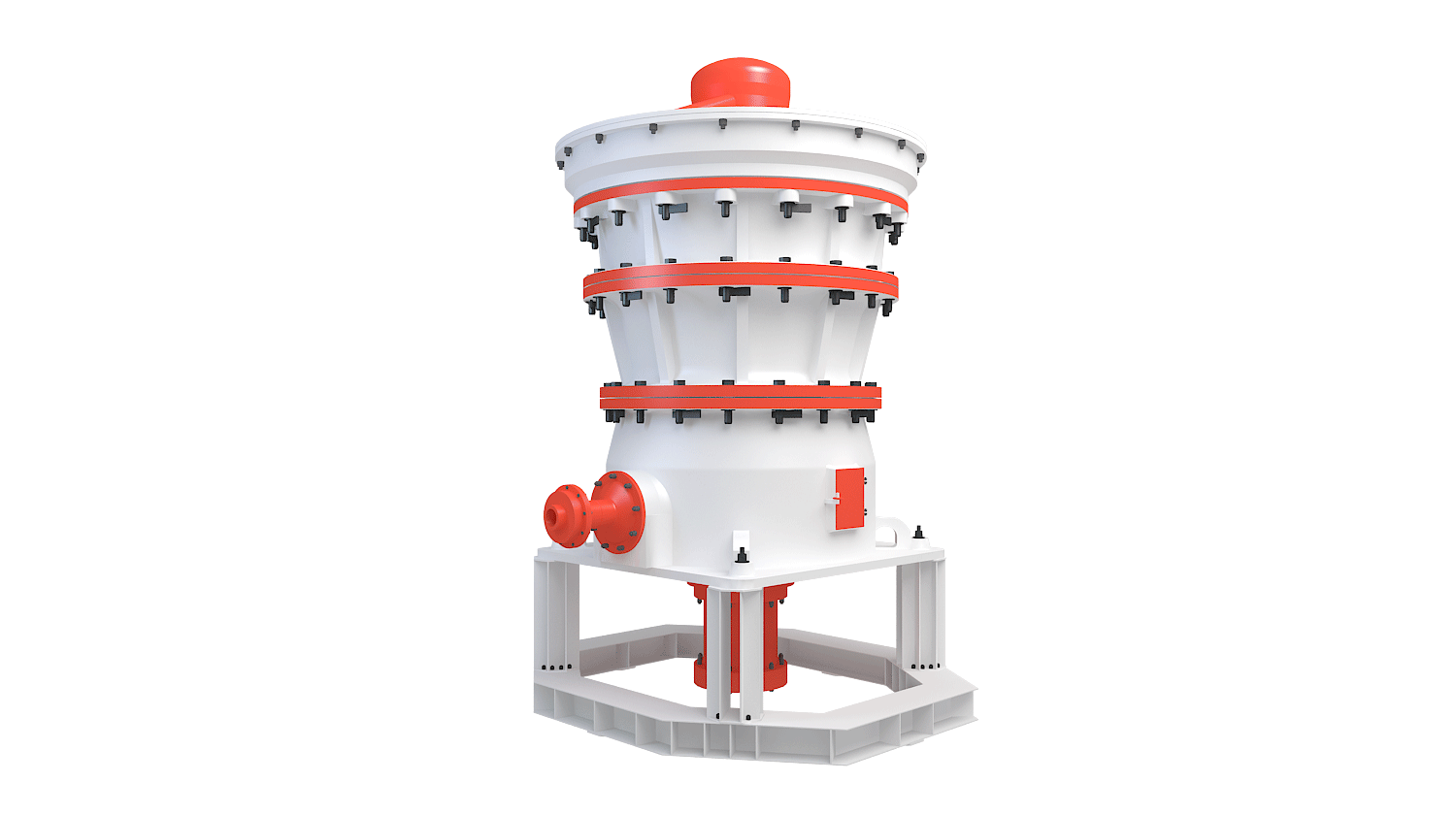

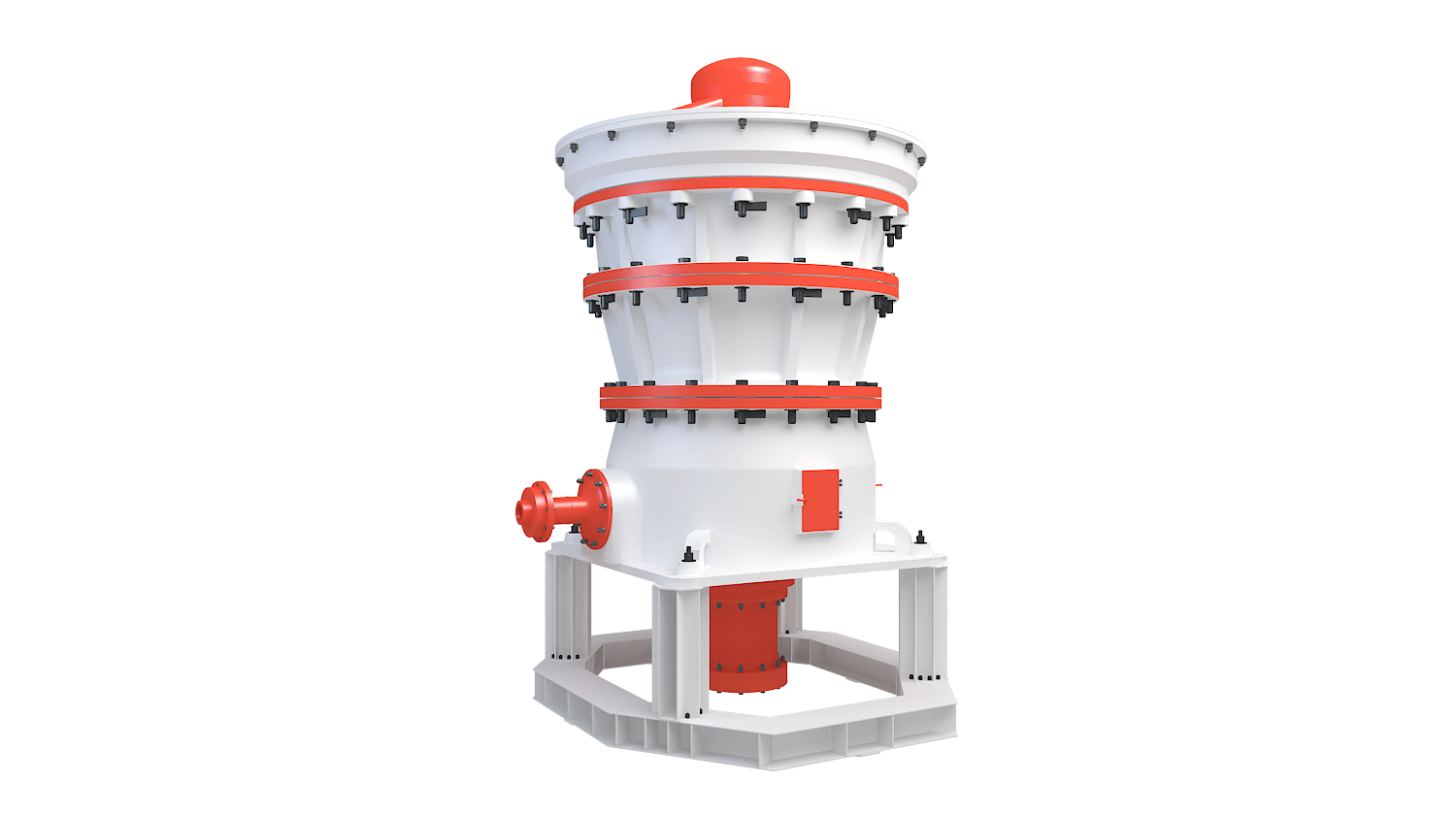

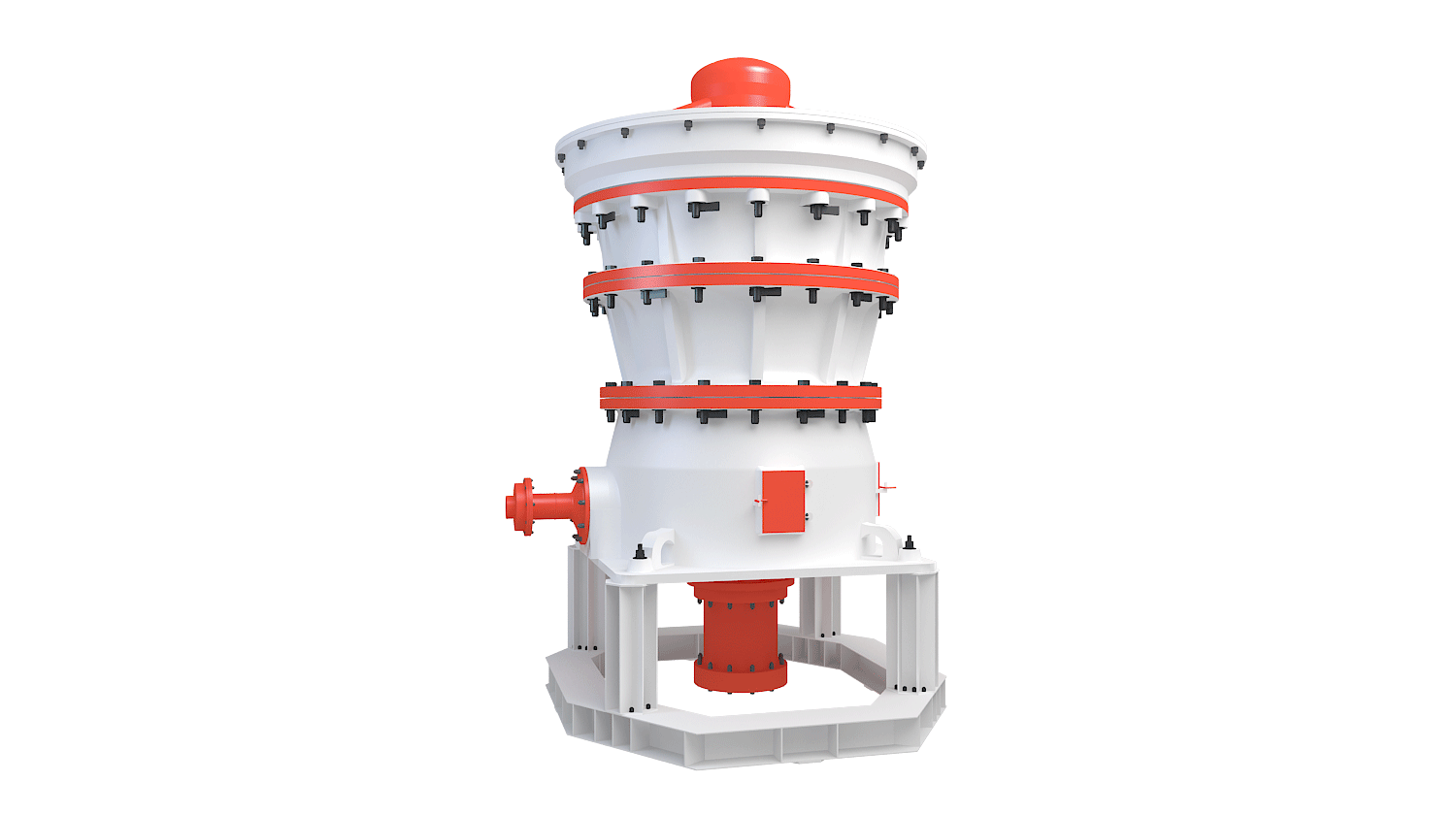

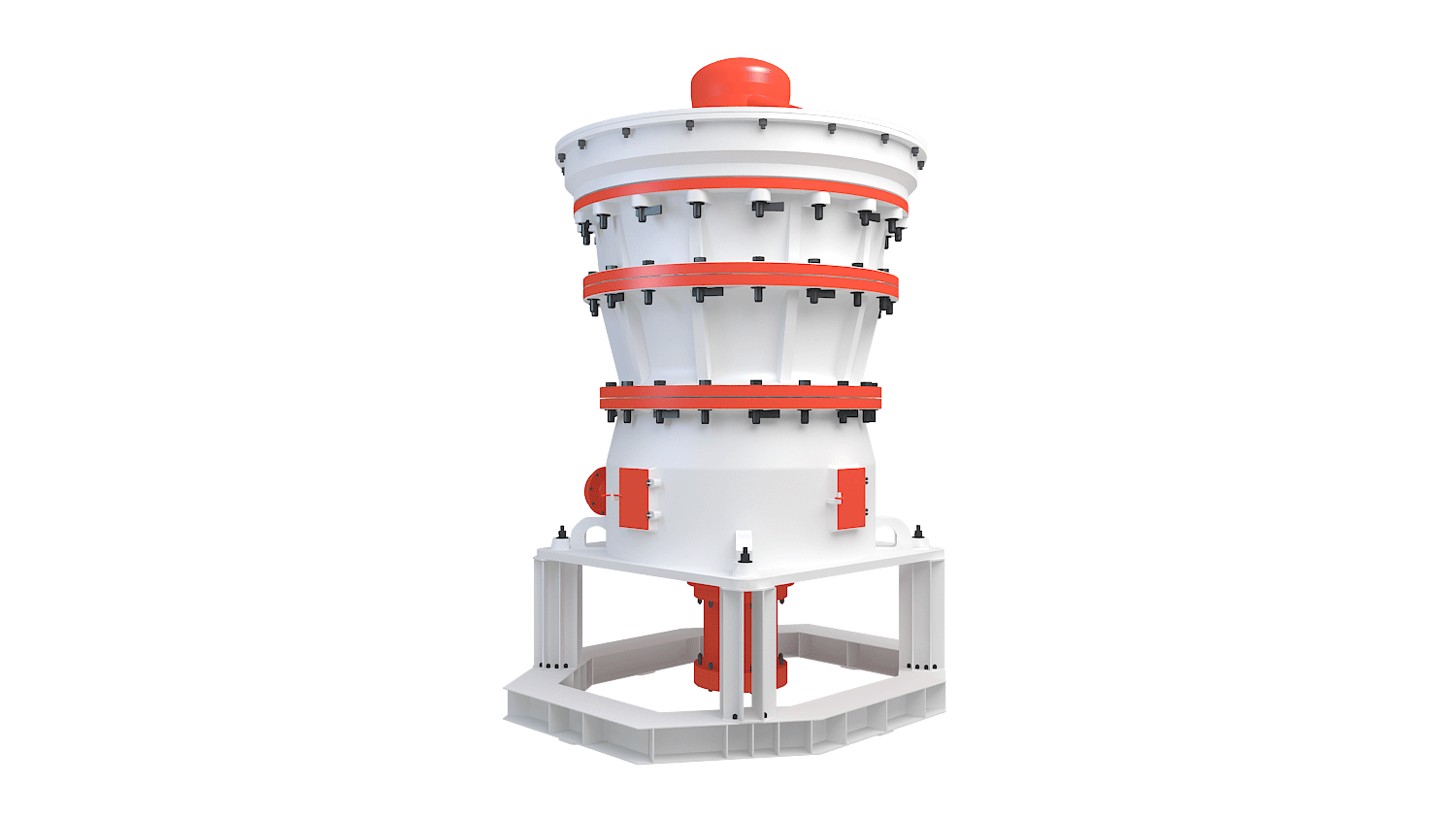

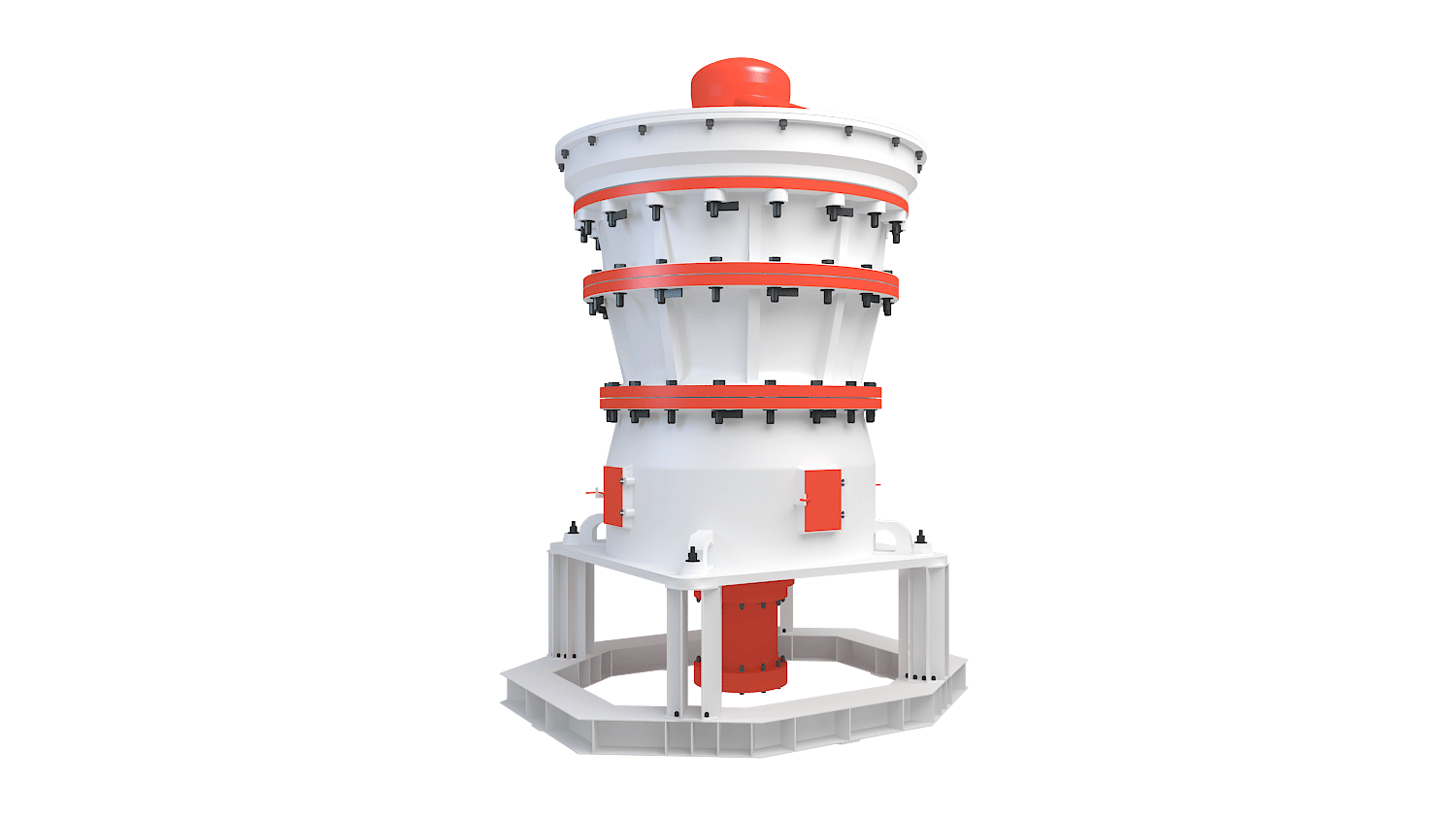

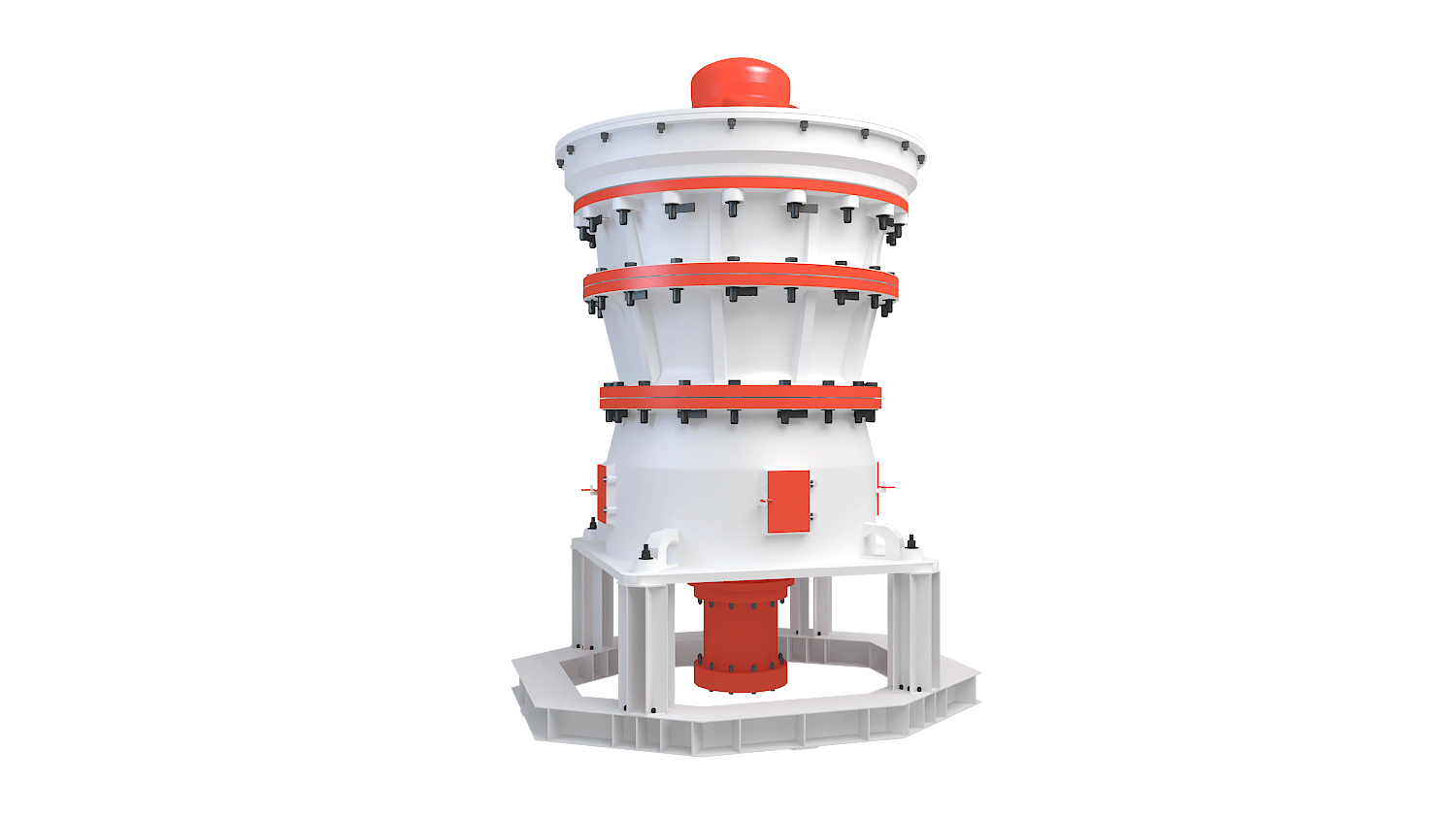

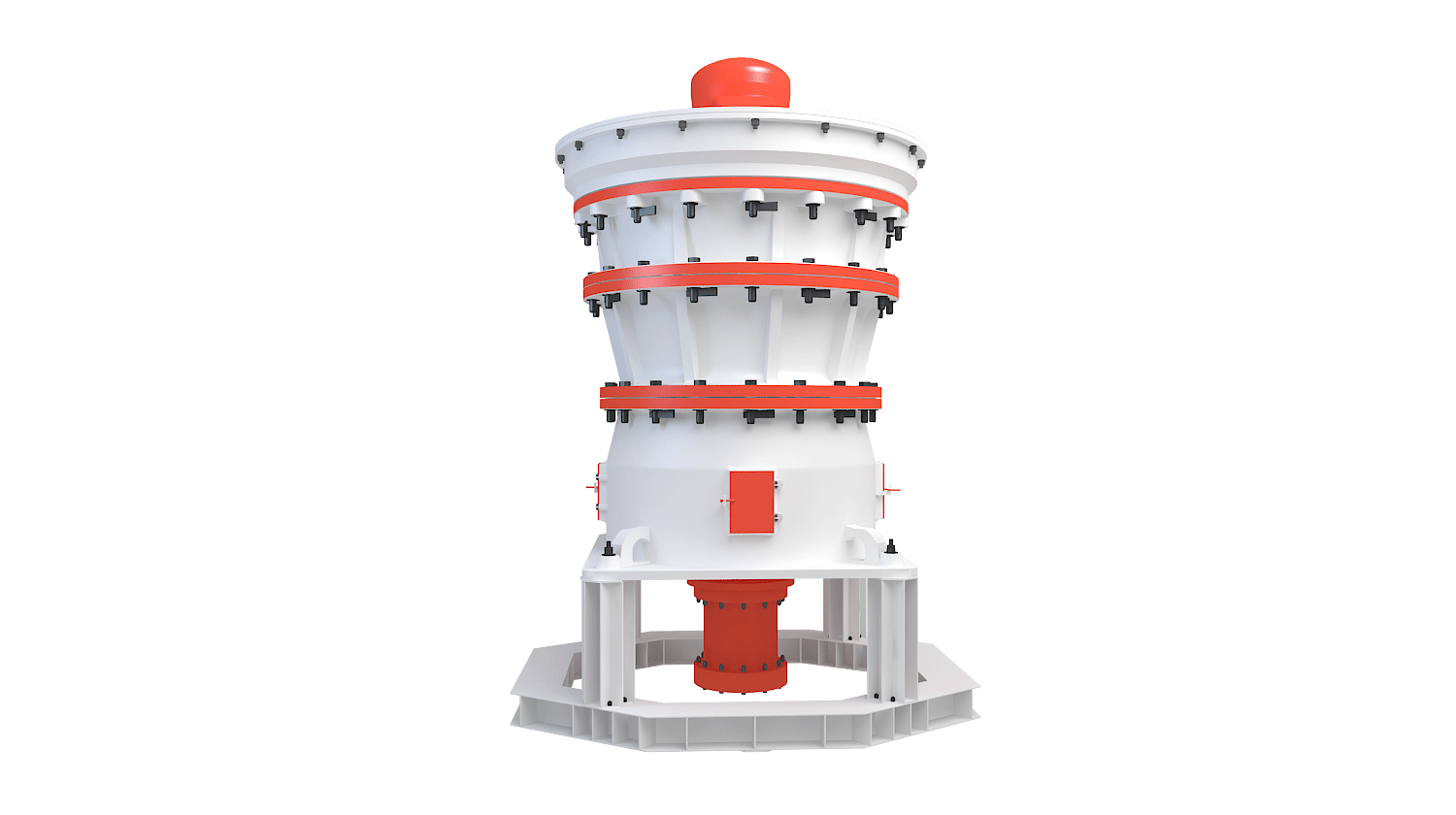

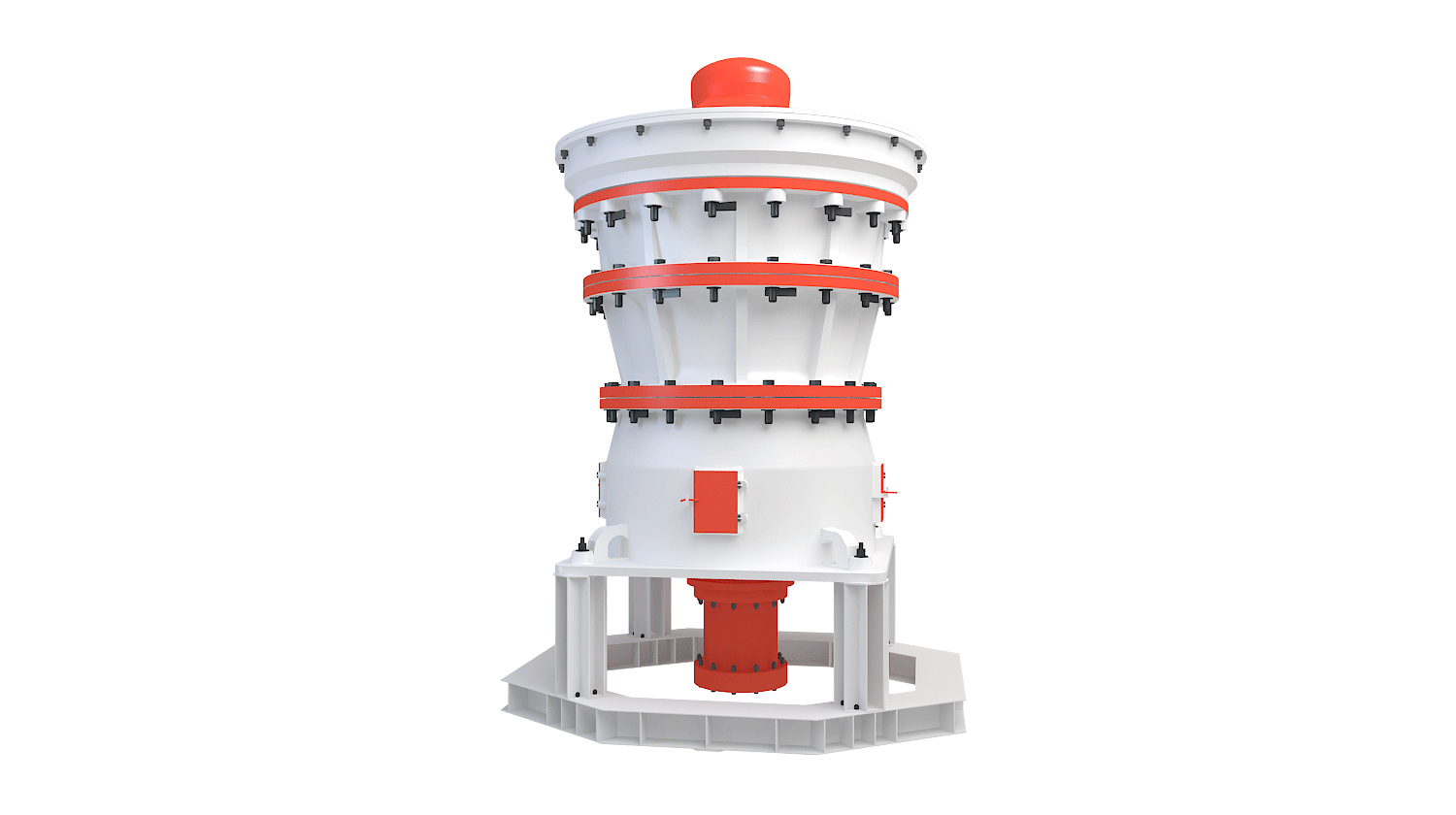

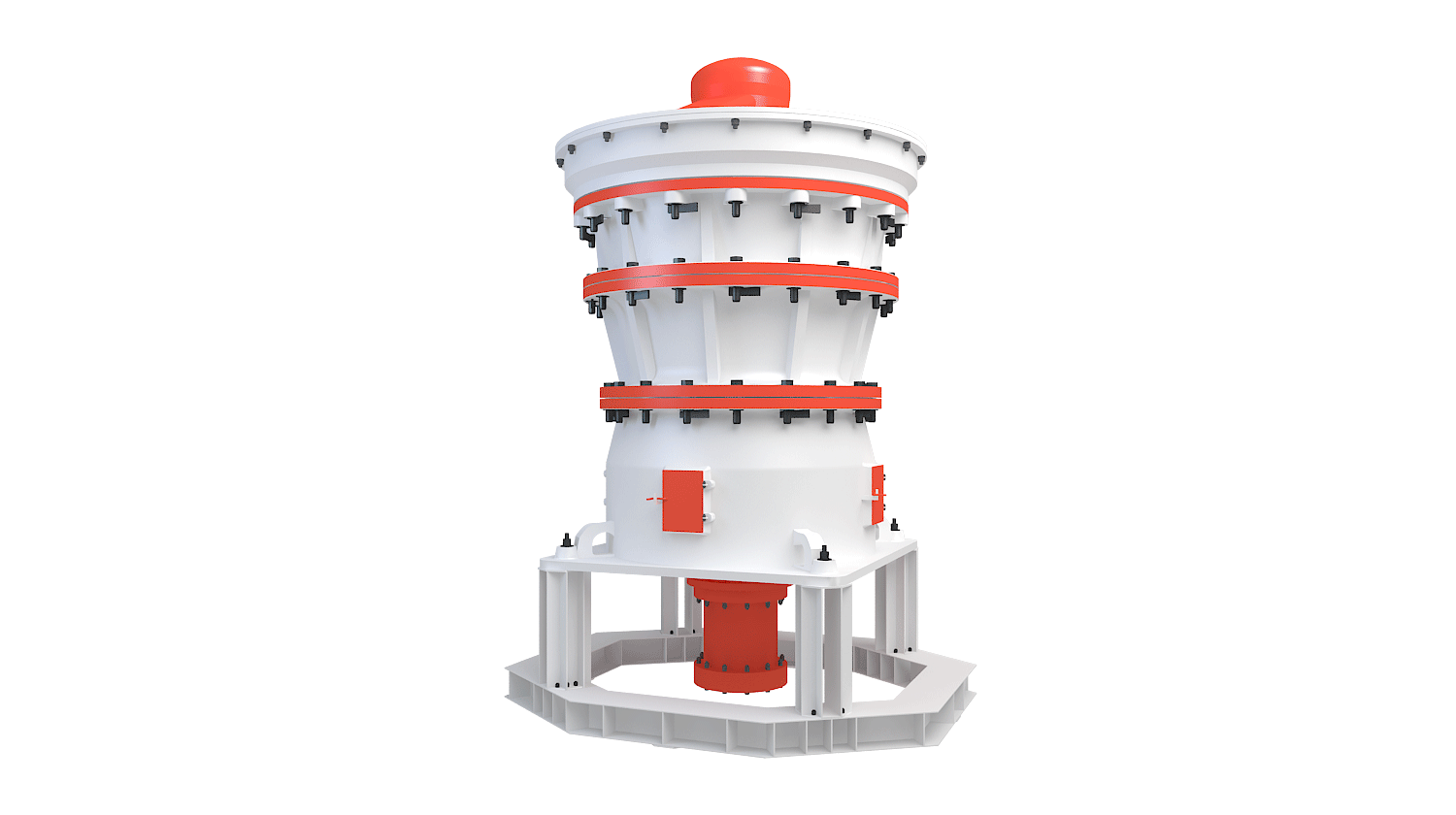

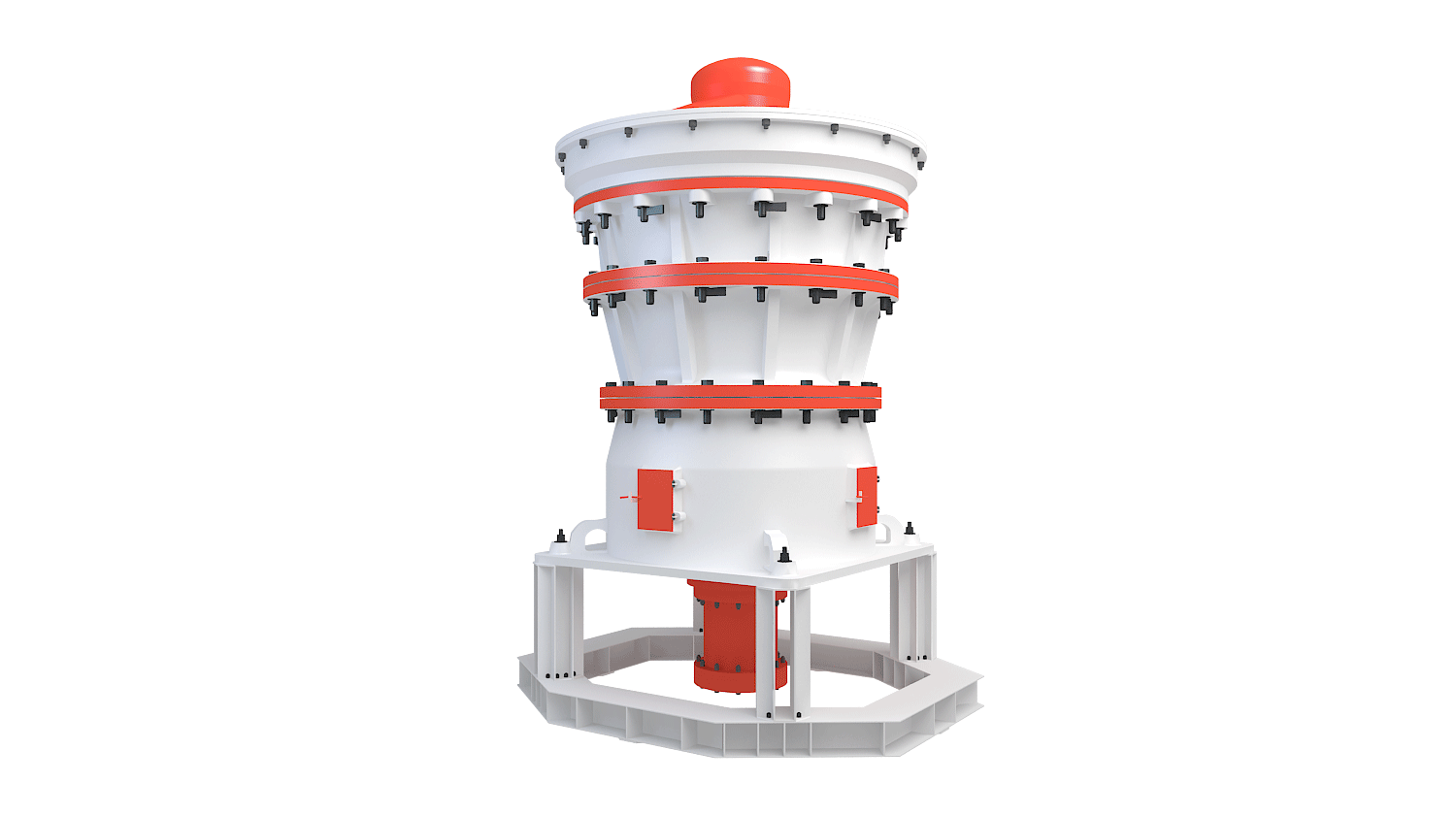

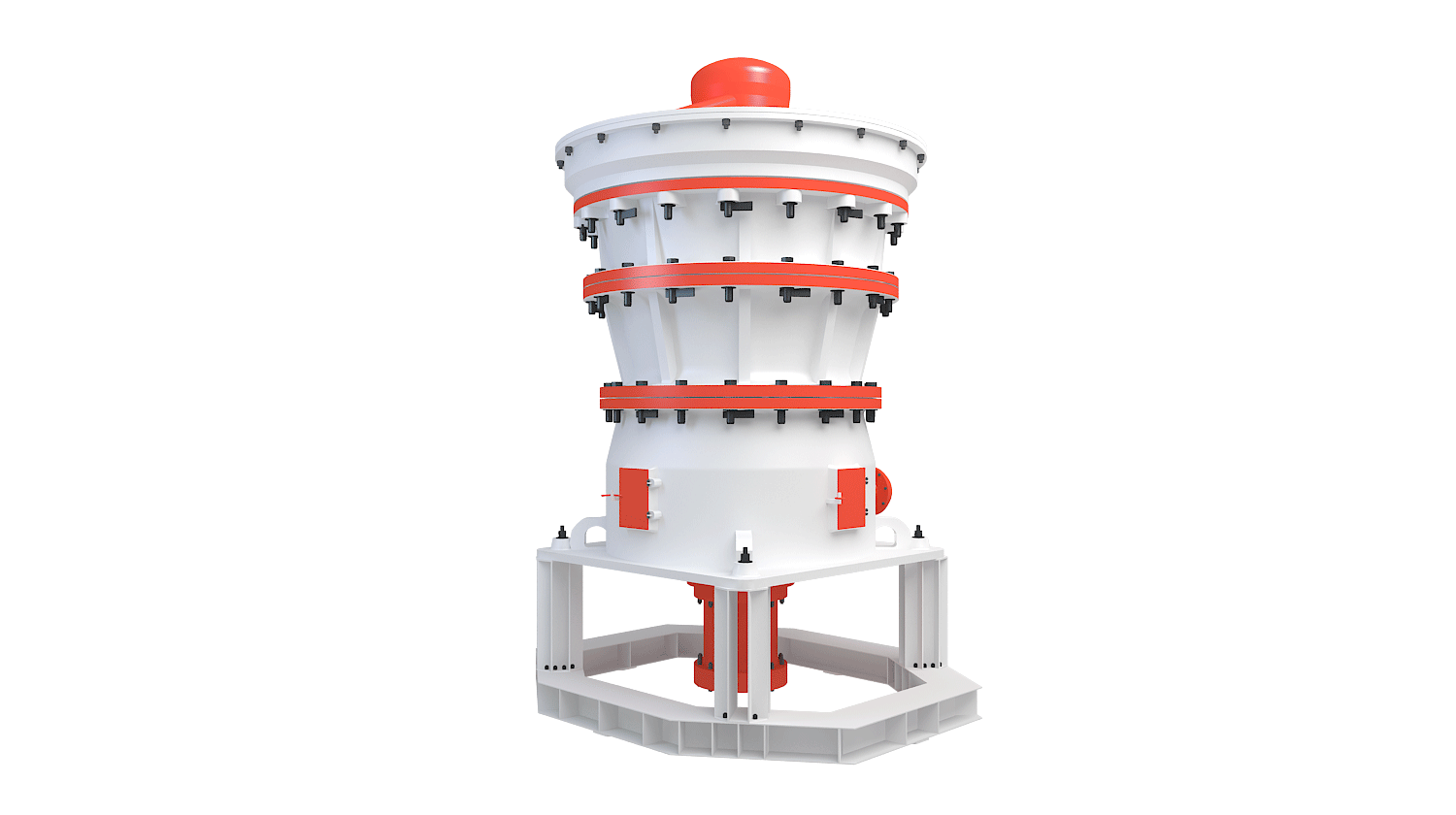

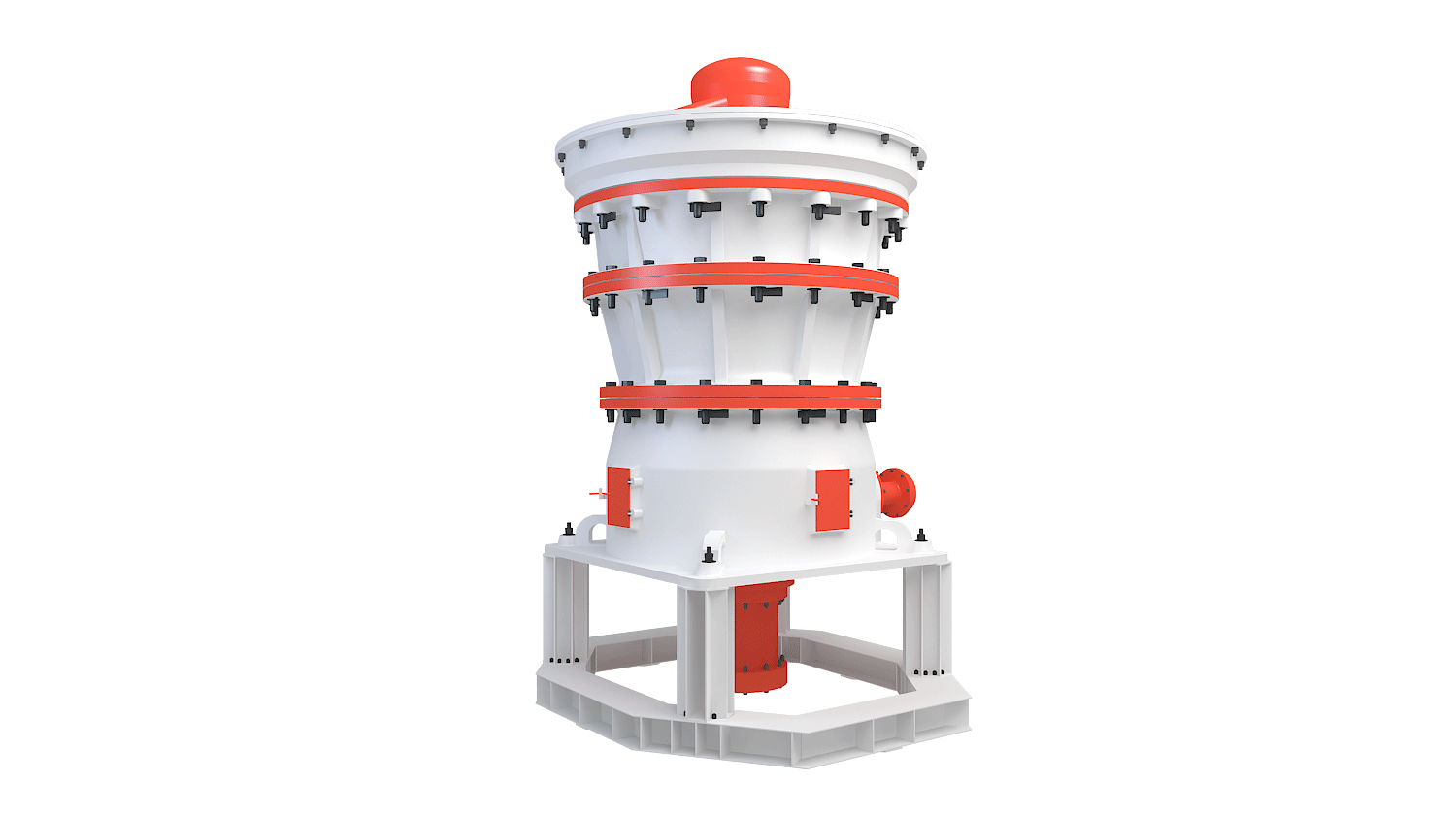

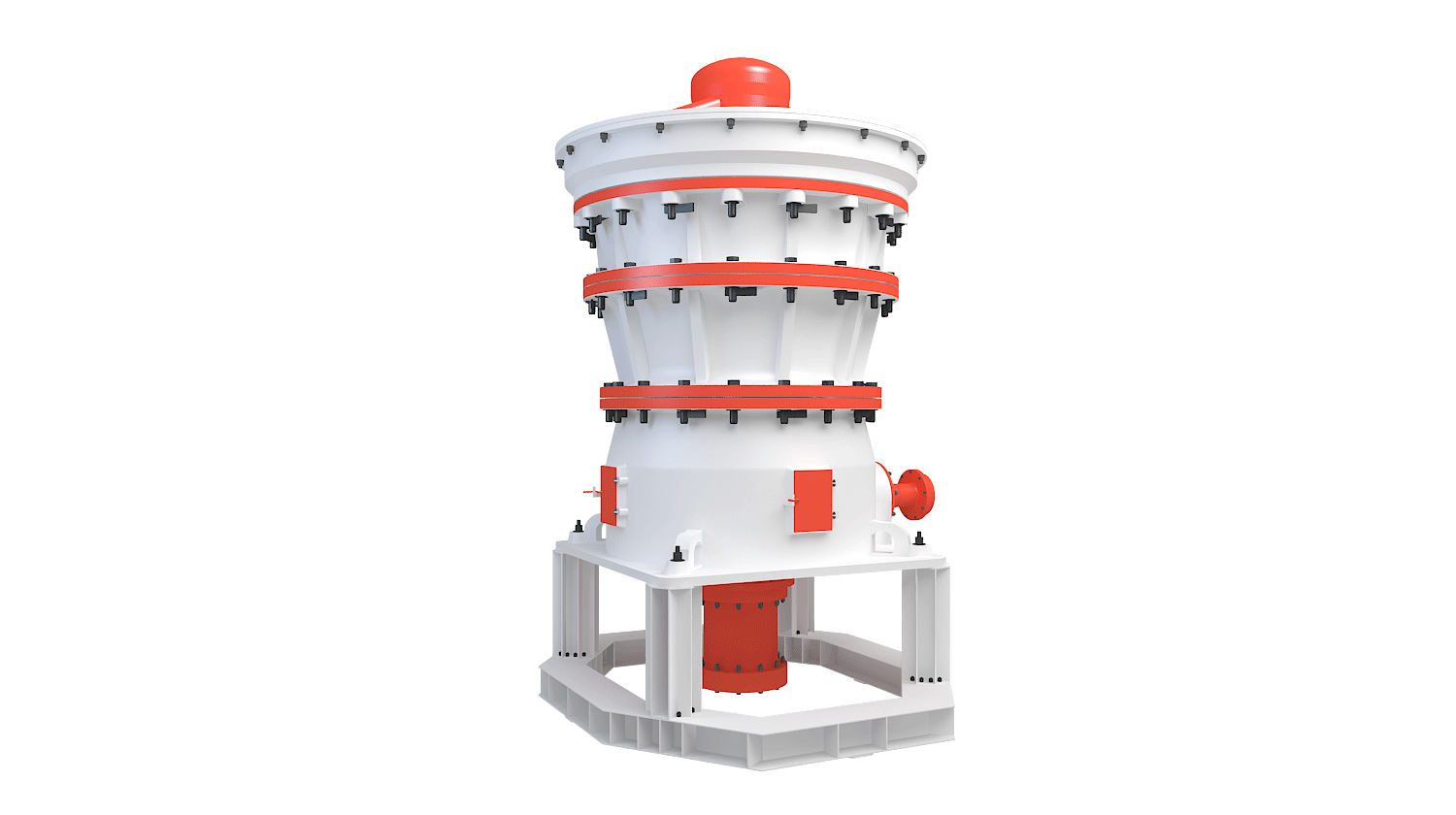

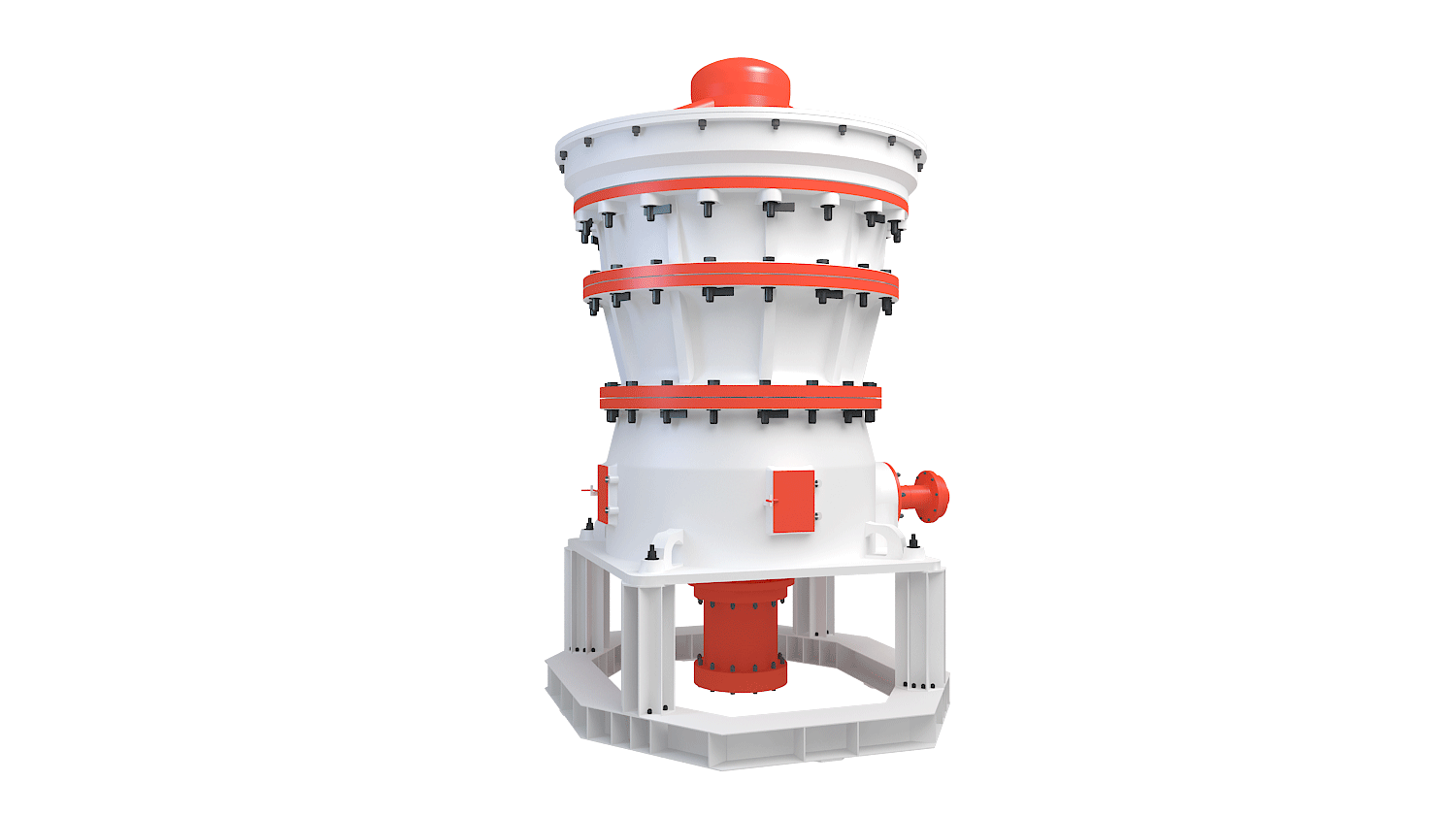

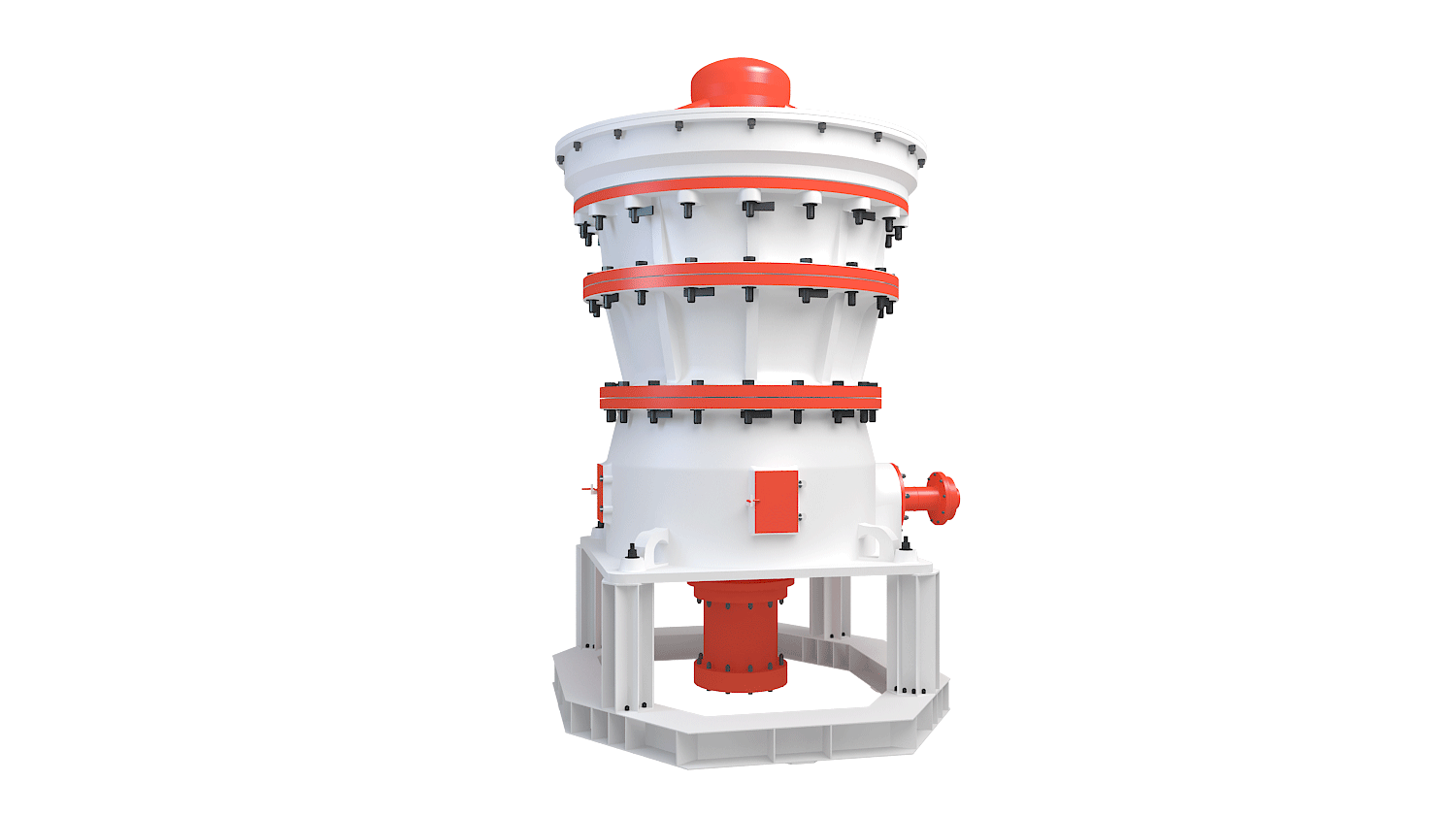

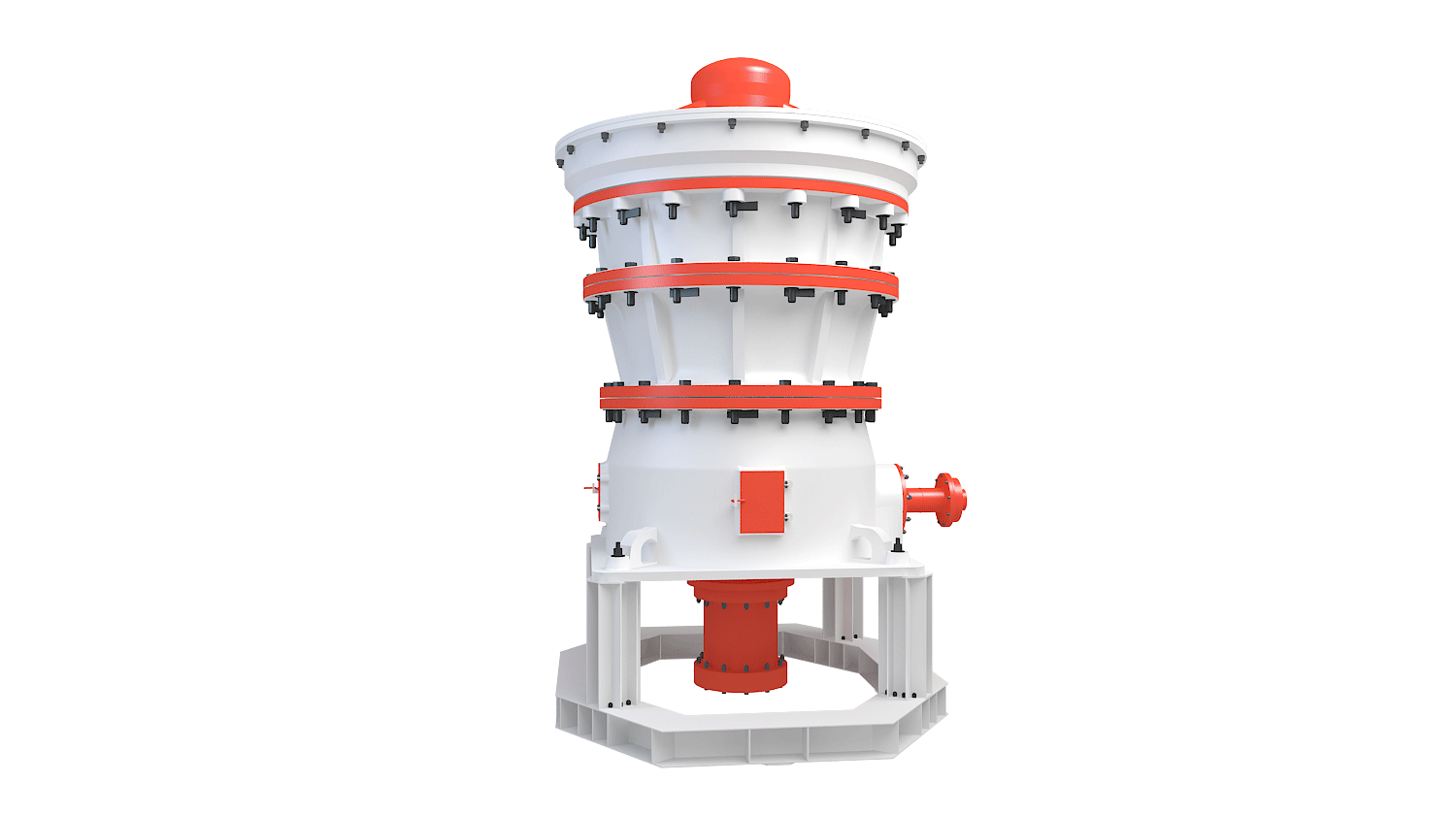

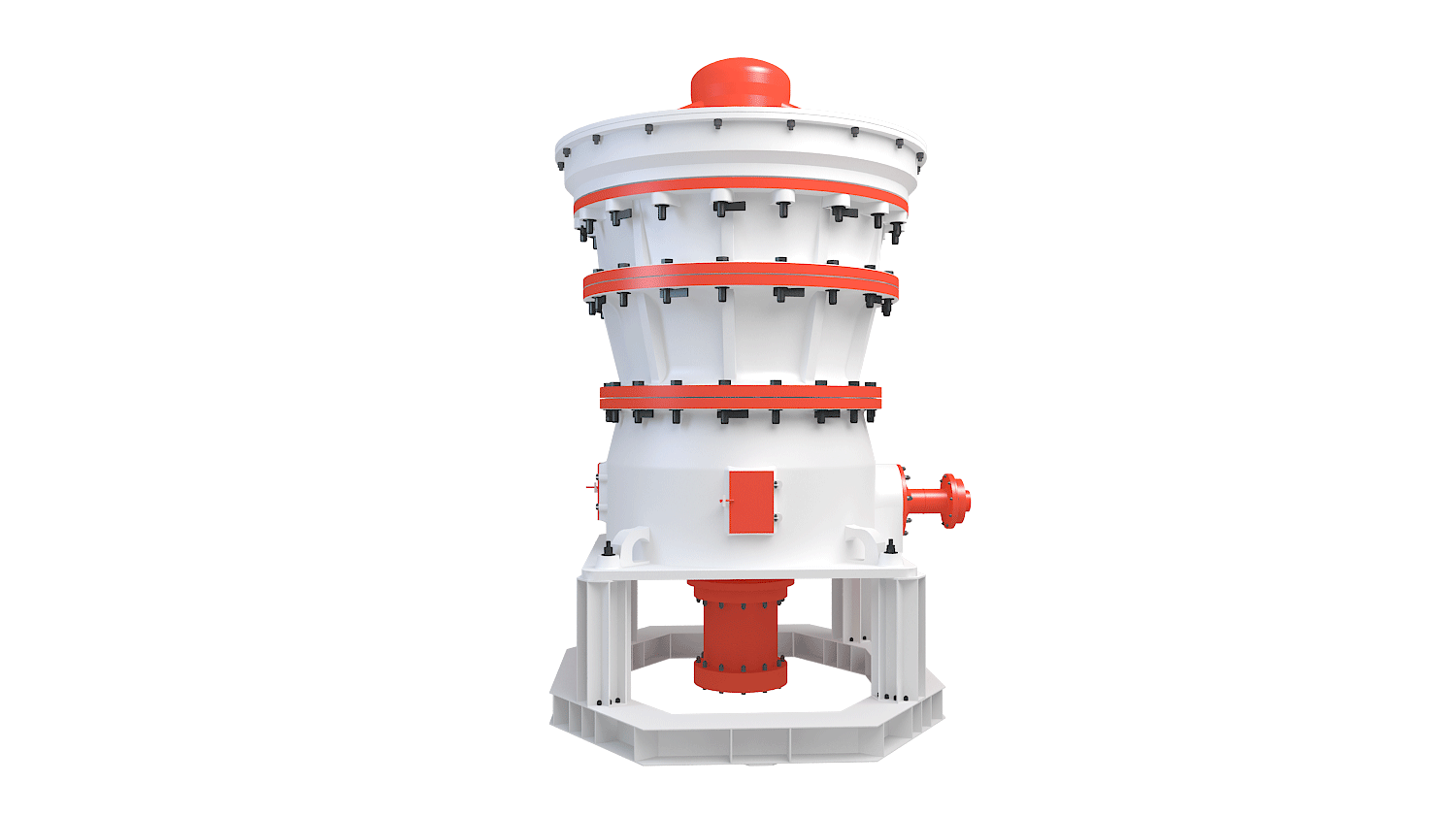

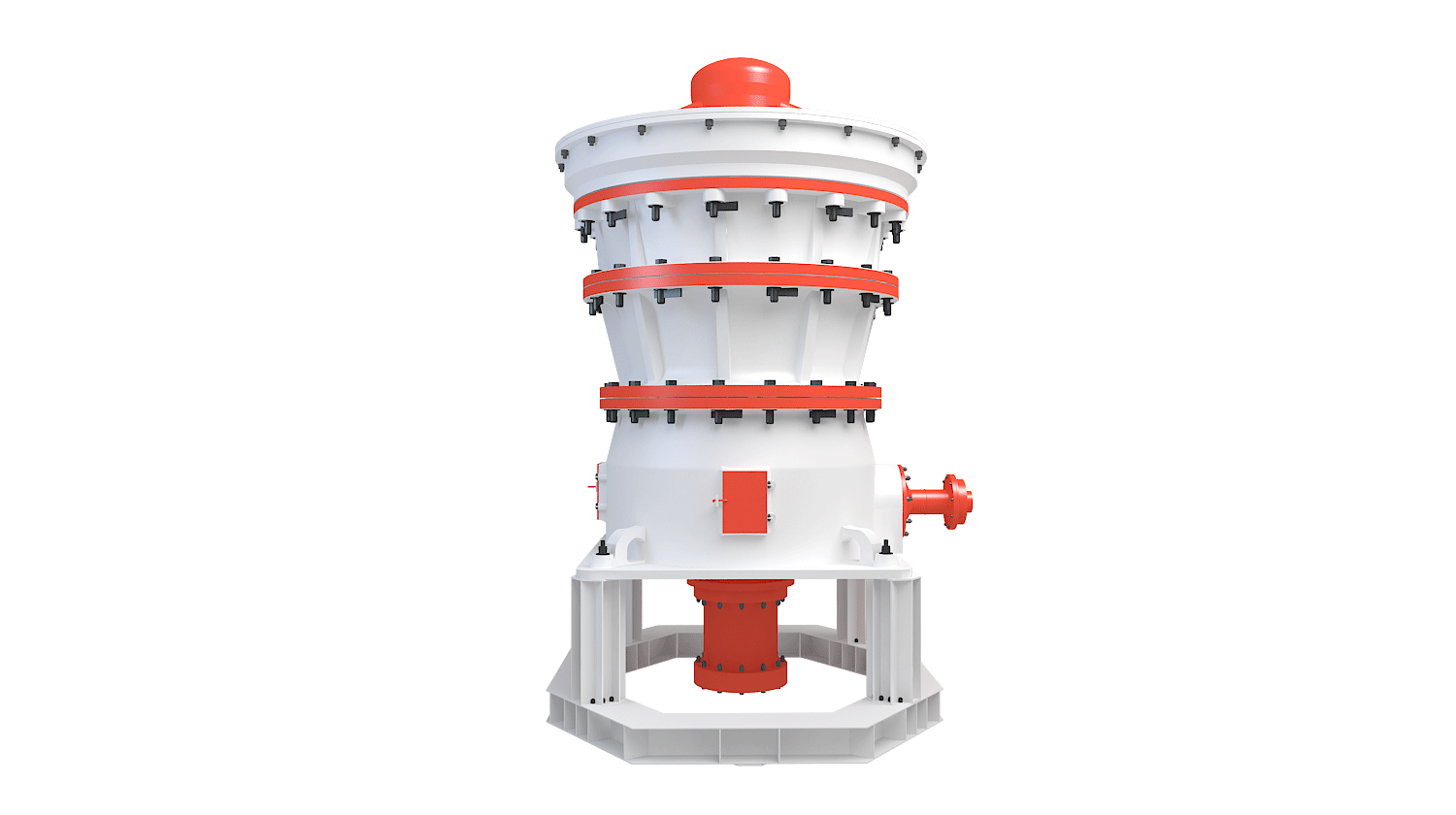

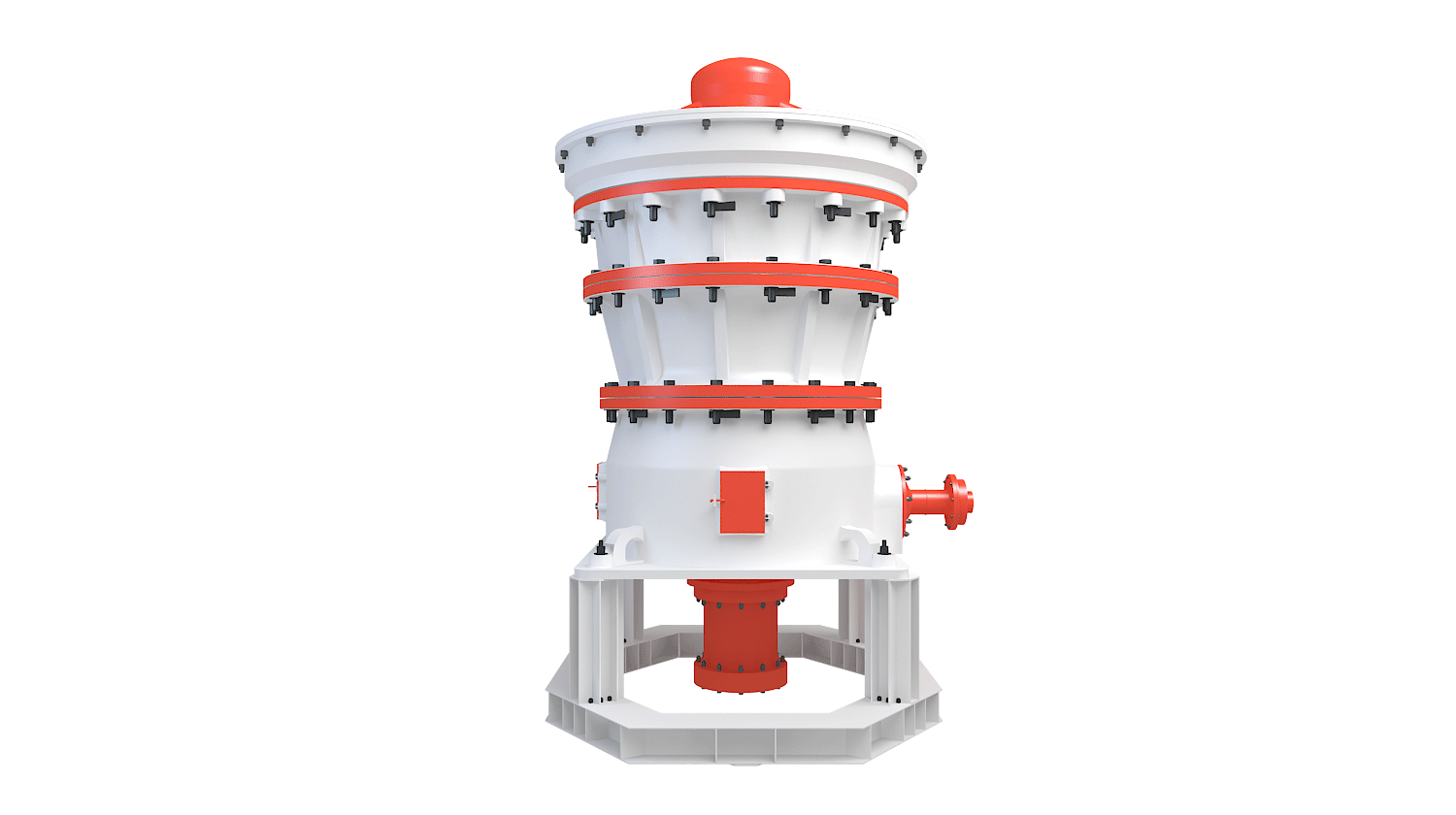

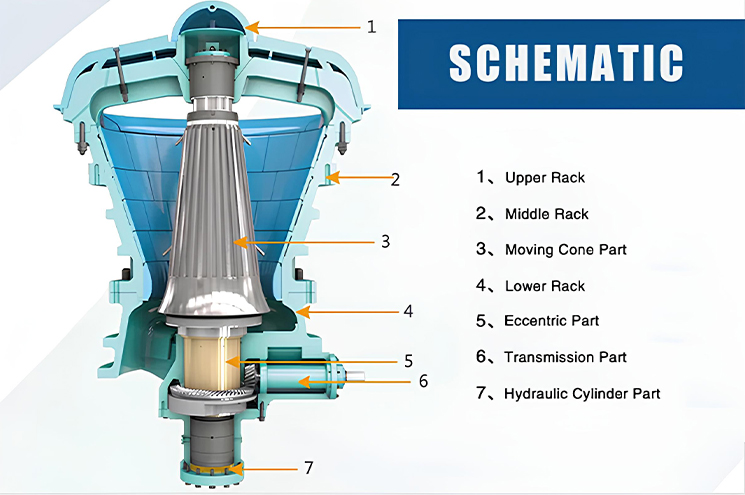

Gyratory crusher operates based on the principle of compressive force, which is generated through the gyrating motion of a mantle that moves within a concave or bowl-shaped fixed outer shell. At the heart of the machine is a vertically mounted spindle, which is supported at the top and bottom and connected to a conical-shaped mantle. As the spindle slowly rotates, the mantle gyrates eccentrically around the central axis, creating a continuous crushing action within the chamber.

Material is fed into the top of the crusher and gradually moves downward under gravity through the narrowing gap between the mantle and the concave. During this process, the material is subjected to repeated compression and shearing forces, which reduce it to smaller, more uniform sizes. The crushed material is then discharged at the bottom of the chamber.