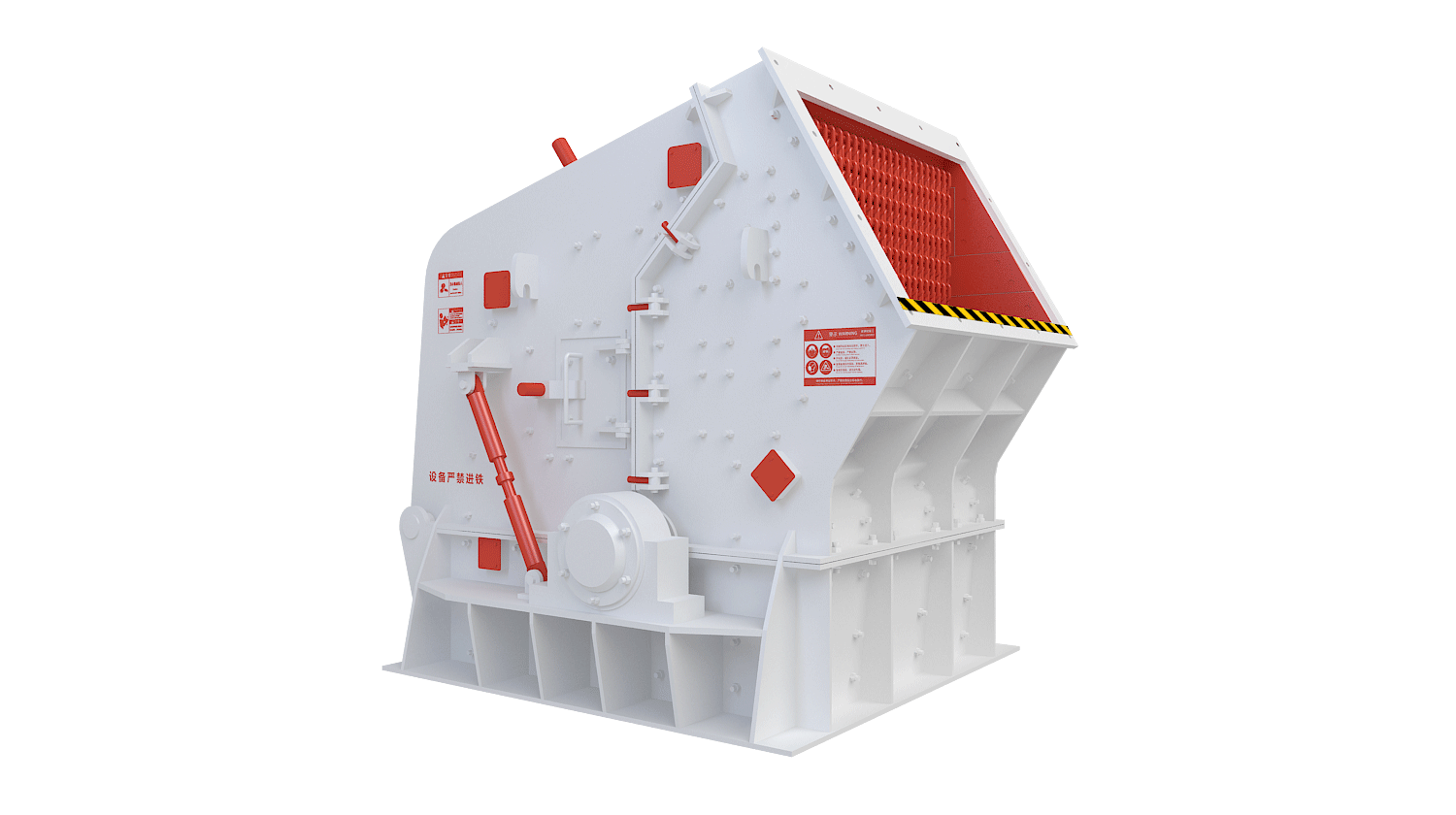

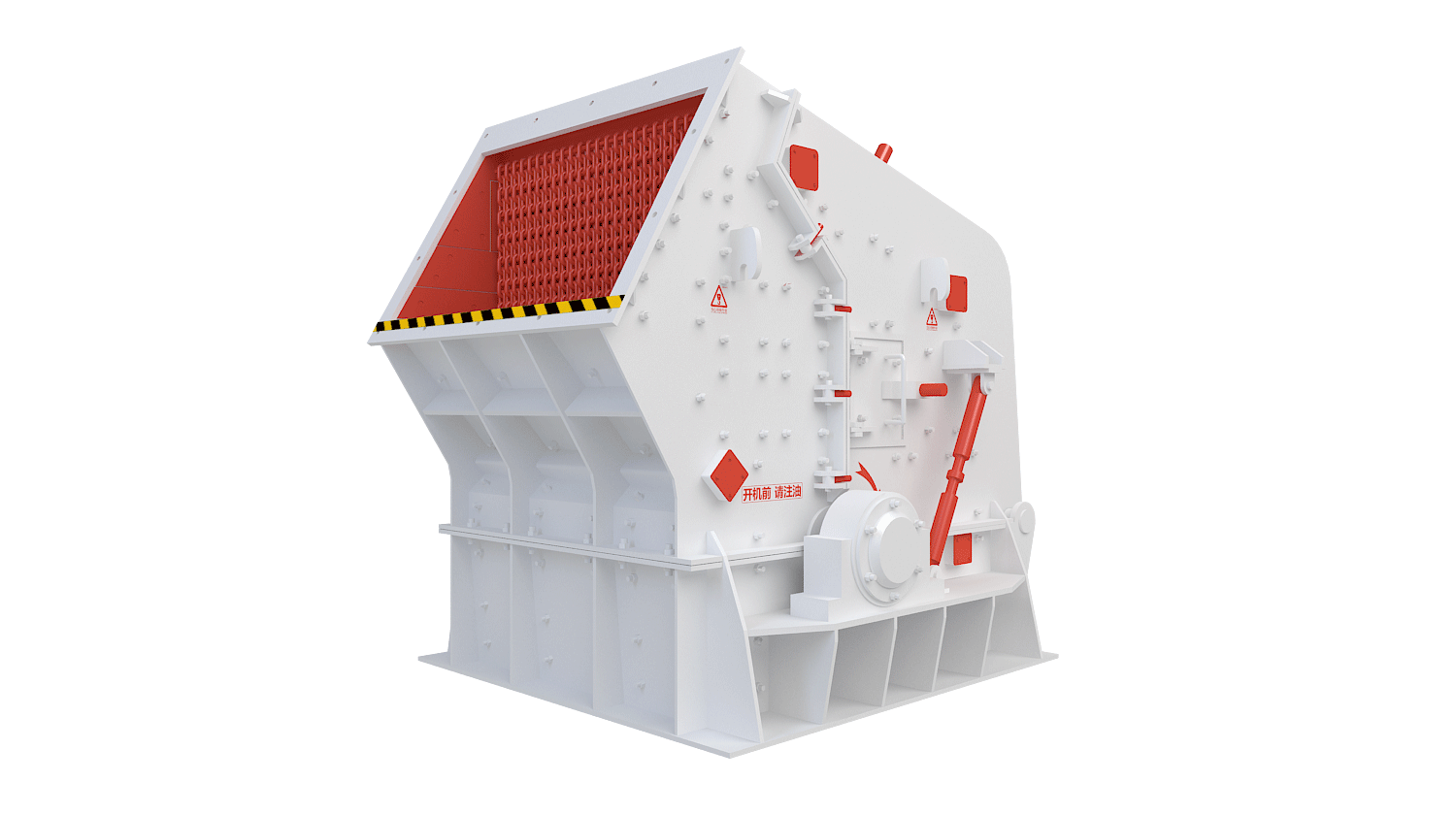

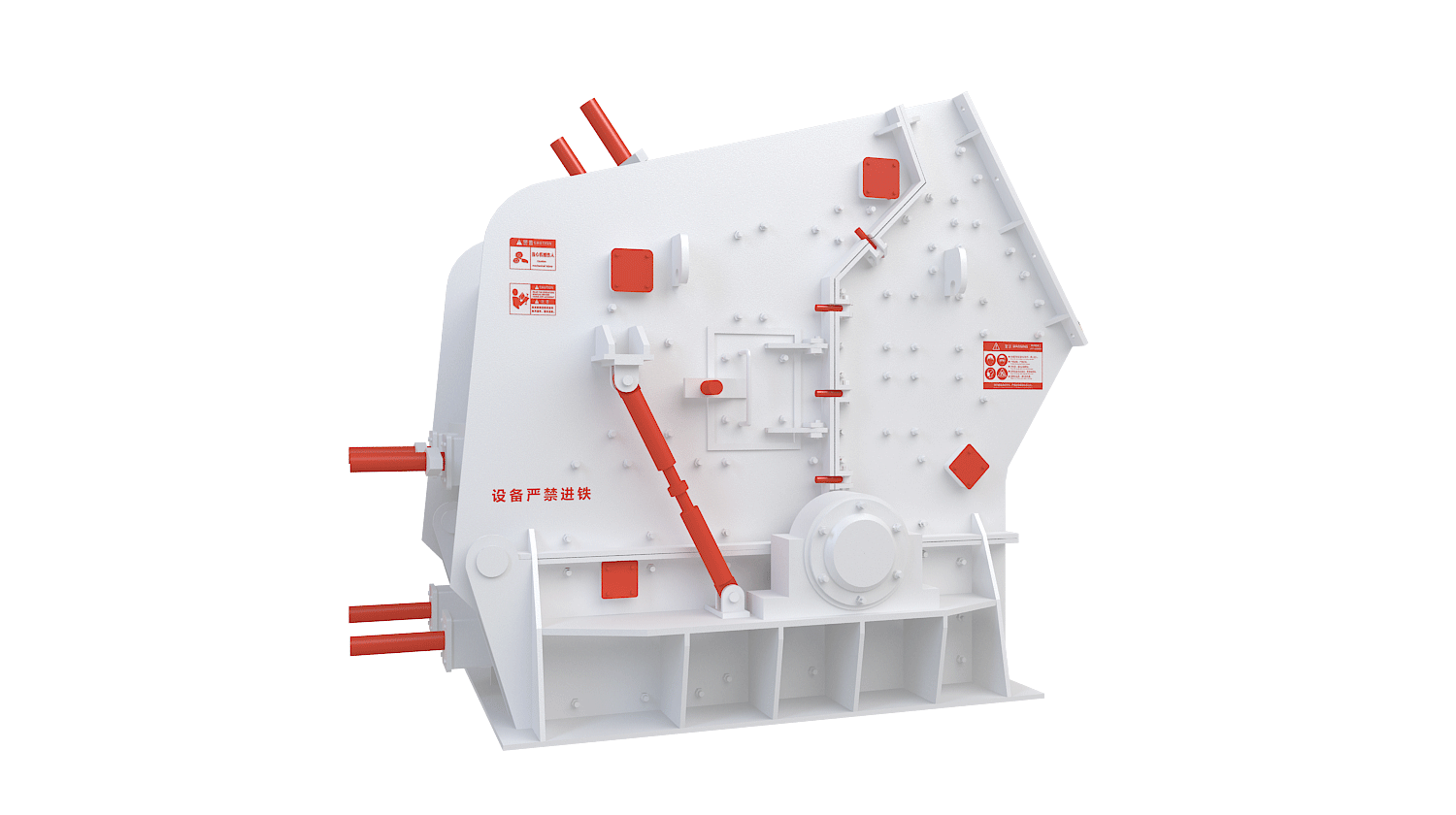

| Model | Specification (mm) |

Feeding inlet size (mm) |

Feed size (mm) |

Production capacity (t/h) |

Power (kw) |

Gross weight (t) |

Overall size (mm) |

| PF1007 | Φ1000×700 | 400×730 | 300 | 30-70 | 45 | 12 | 2330×1660×2300 |

| PF1010 | Φ1000×1050 | 400×1080 | 350 | 50-90 | 55 | 15 | 2370×1700×2390 |

| PF1210 | Φ1250×1050 | 400×1080 | 350 | 70-130 | 110 | 17.7 | 2680×2160×2800 |

| PF1214 | Φ1250×1400 | 400×1430 | 350 | 100-180 | 132 | 22.4 | 2650×2460×2800 |

| PF1315 | Φ1320×1500 | 860×1520 | 500 | 130-250 | 200 | 27 | 3180×2720×3120 |

| PF1320 | Φ1320×2000 | 860×2030 | 500 | 160-350 | 250 | 30 | 3200×3100×3120 |

| PF1520 | Φ1500×2000 | 990×2030 | 700 | 200-550 | 315 | 50 | 3960×3560×3330 |

| PF1820 | Φ1800×2000 | 1260×2030 | 800 | 400-800 | 630 | 83 | 4400×3860×4010 |