Introduction

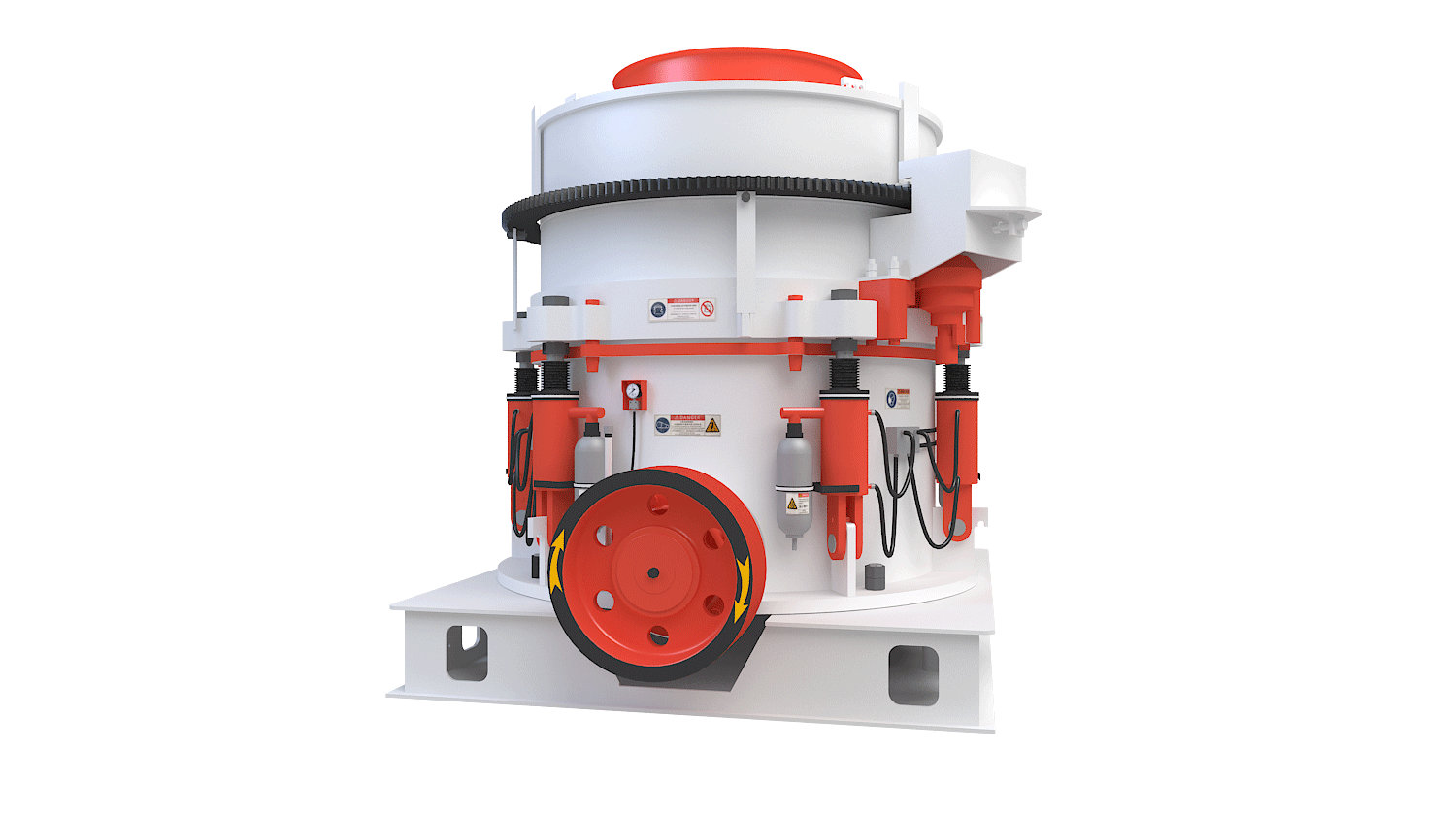

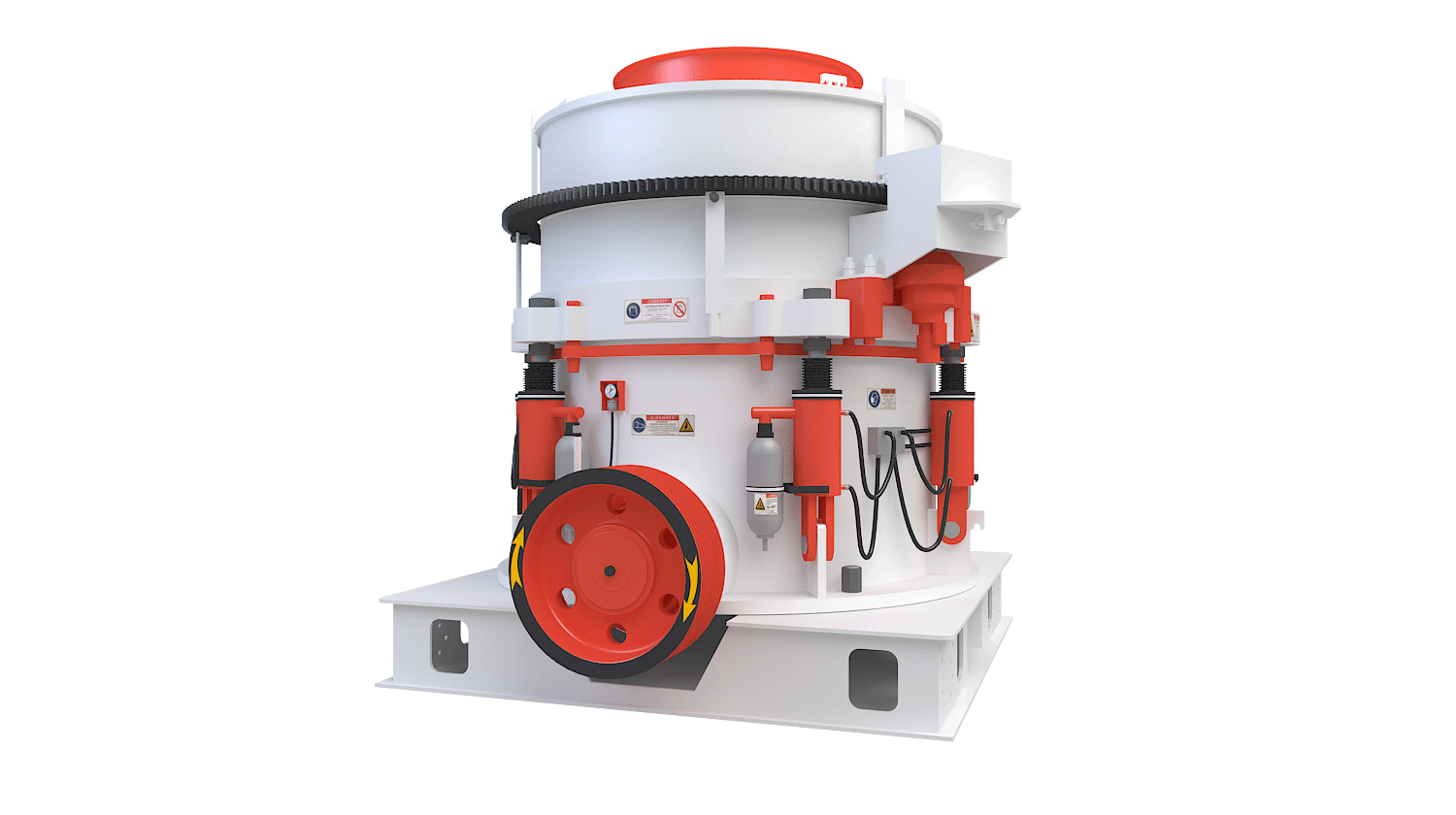

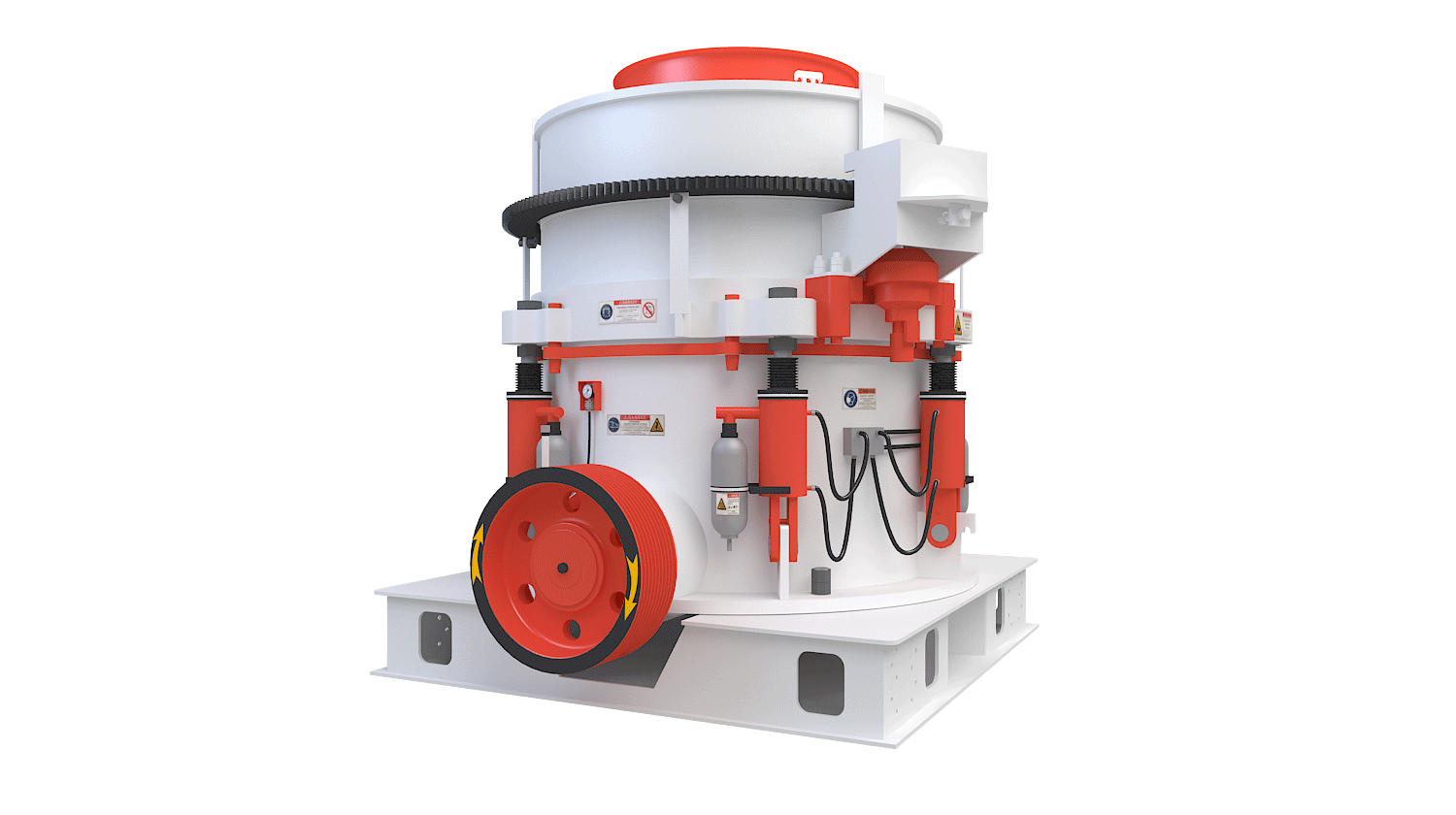

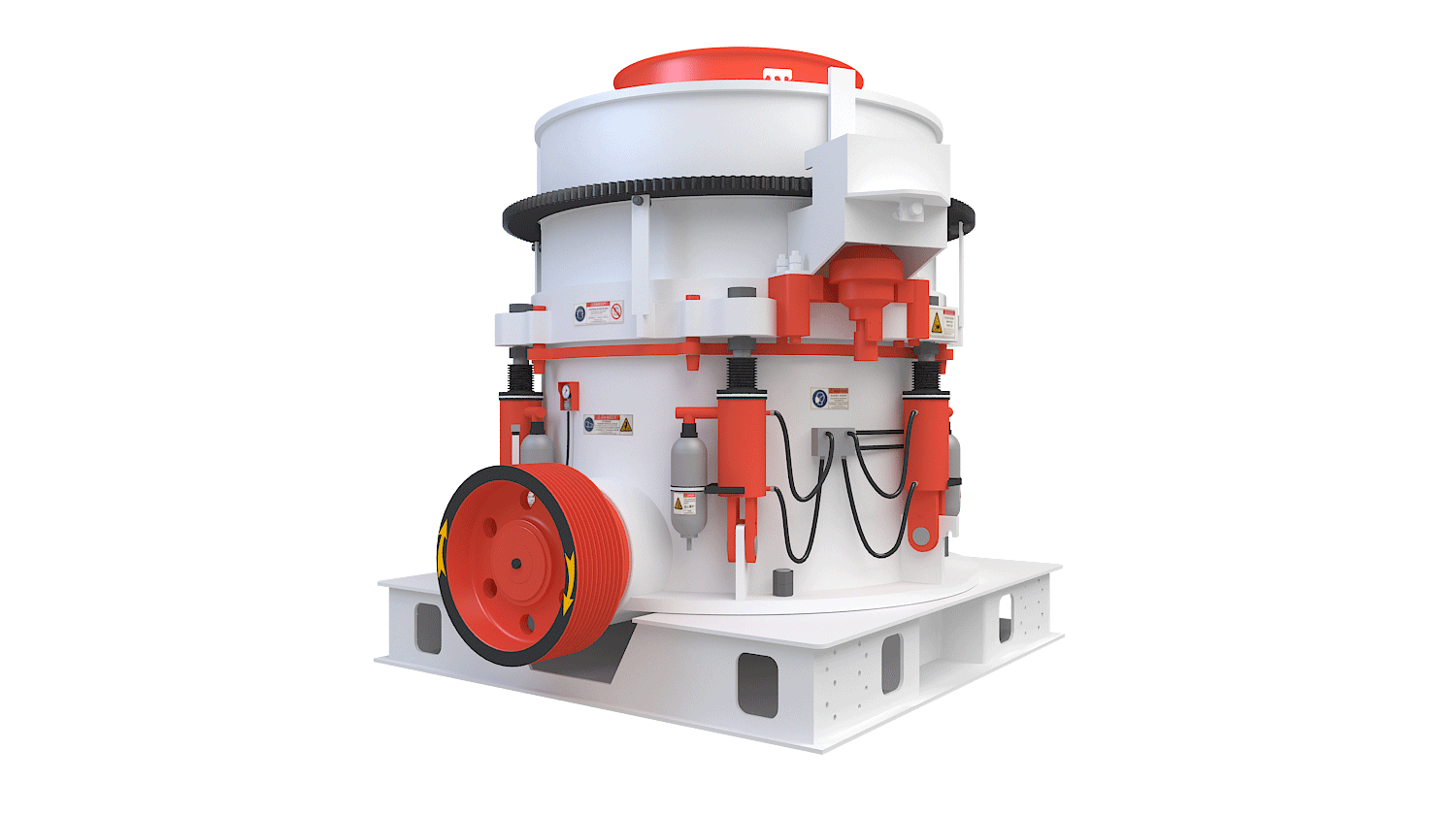

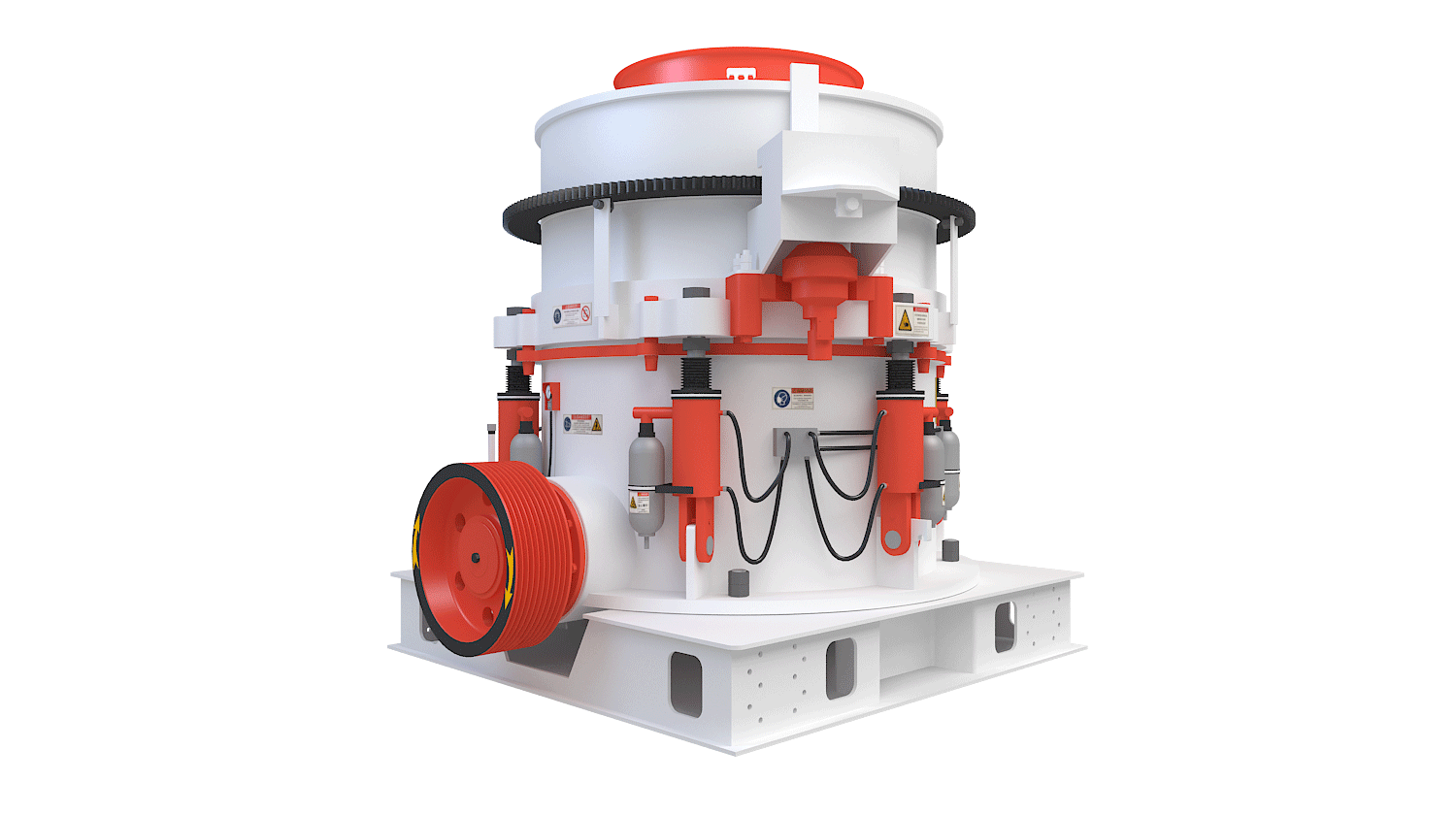

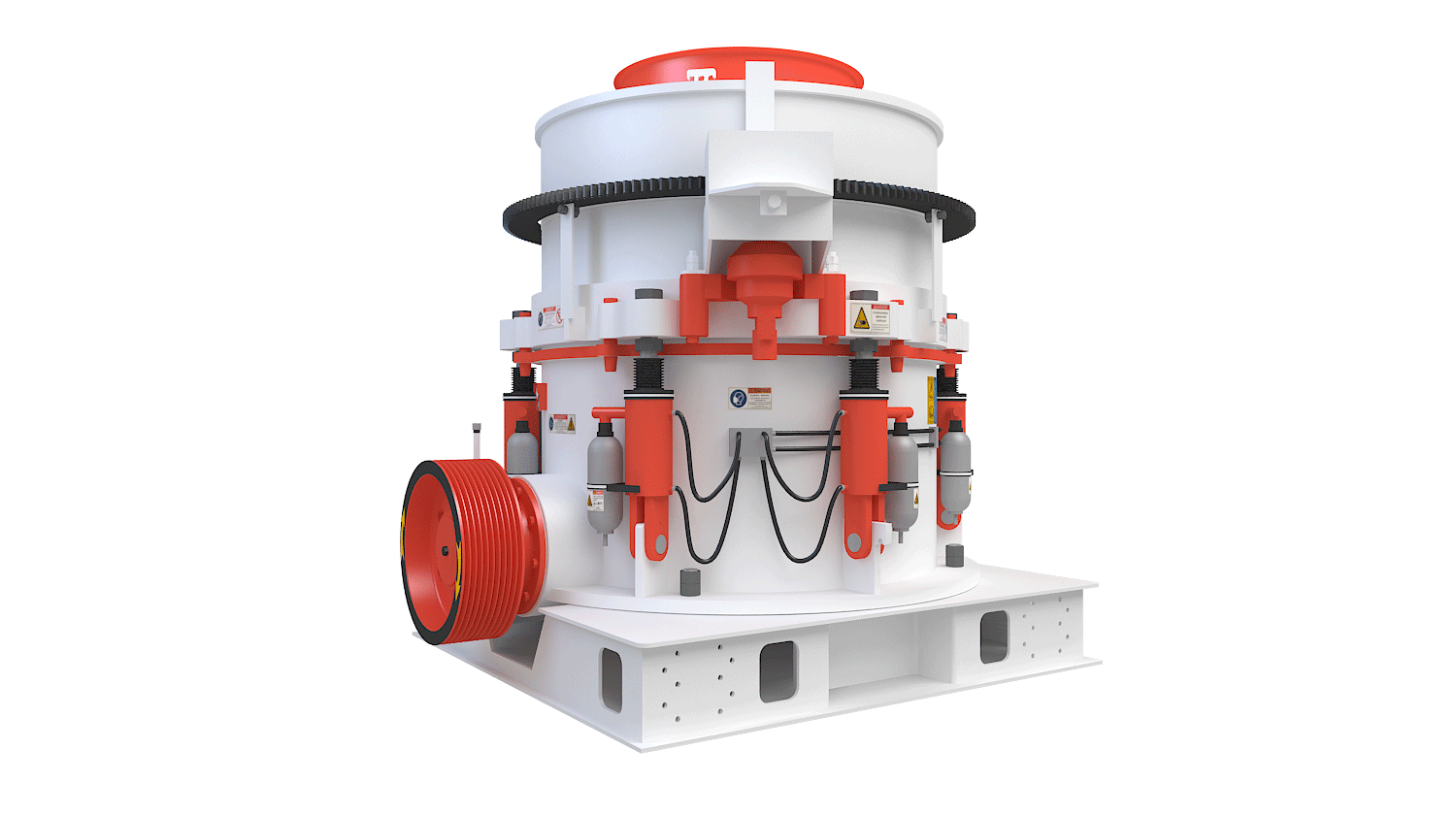

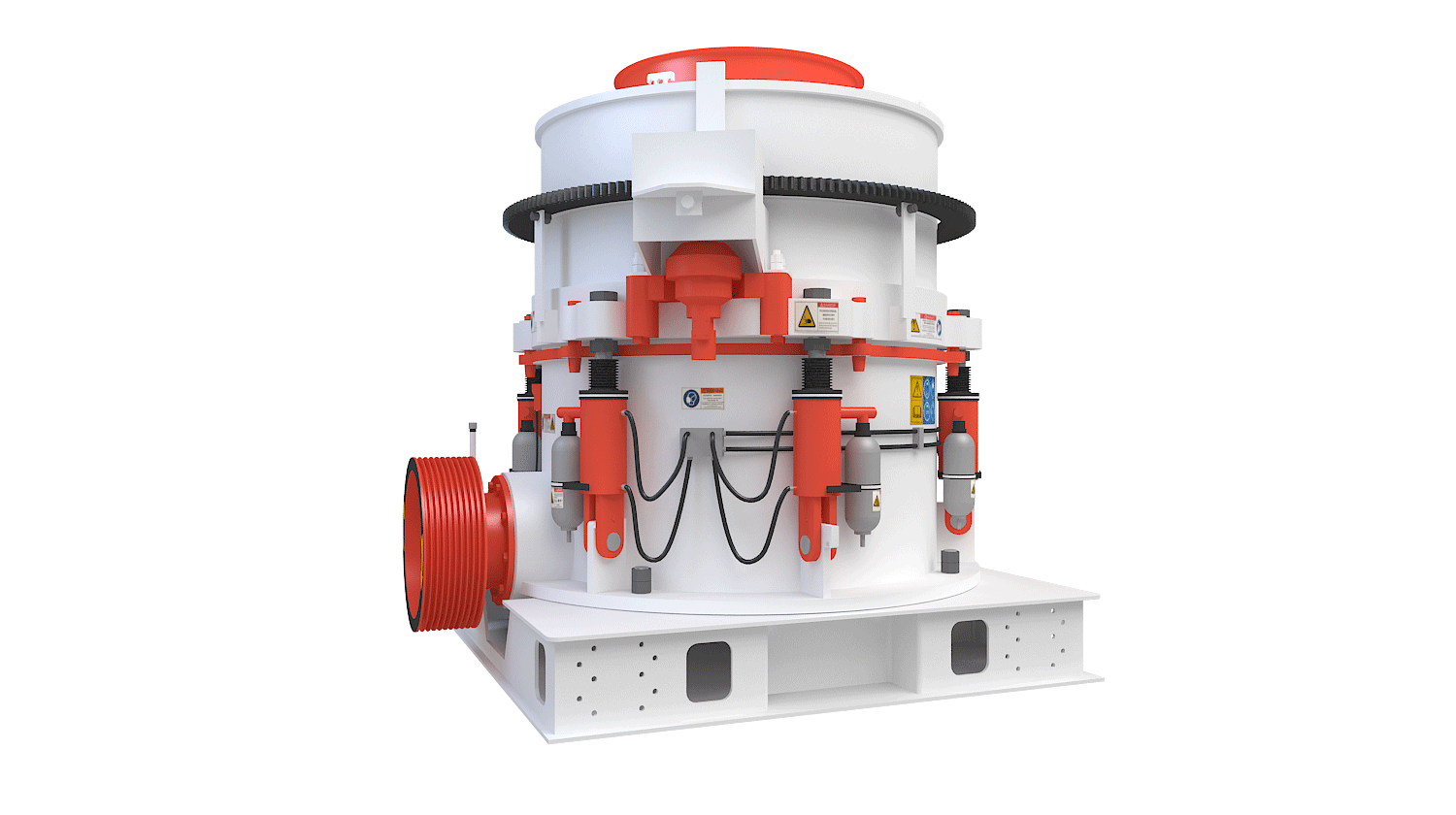

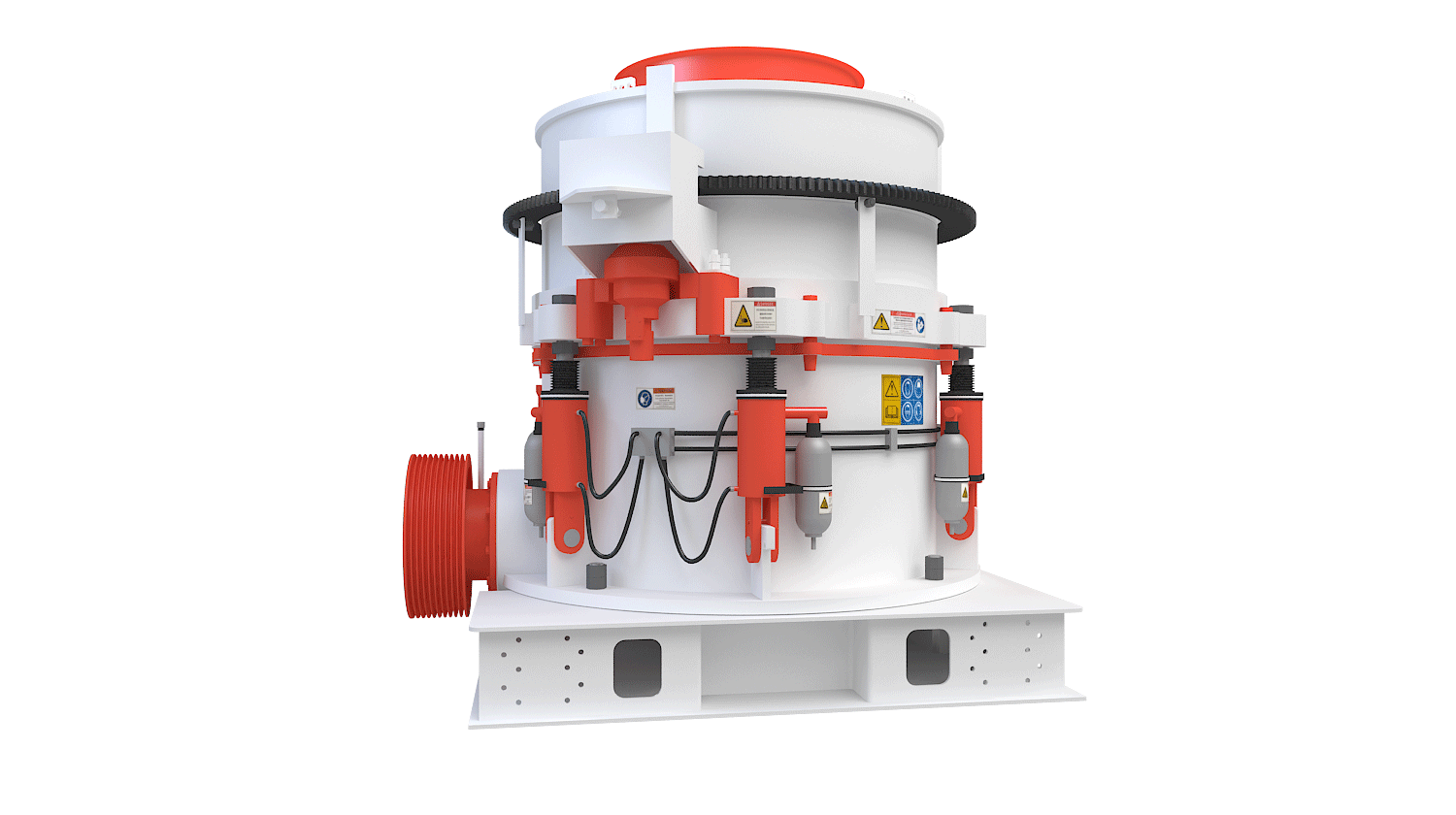

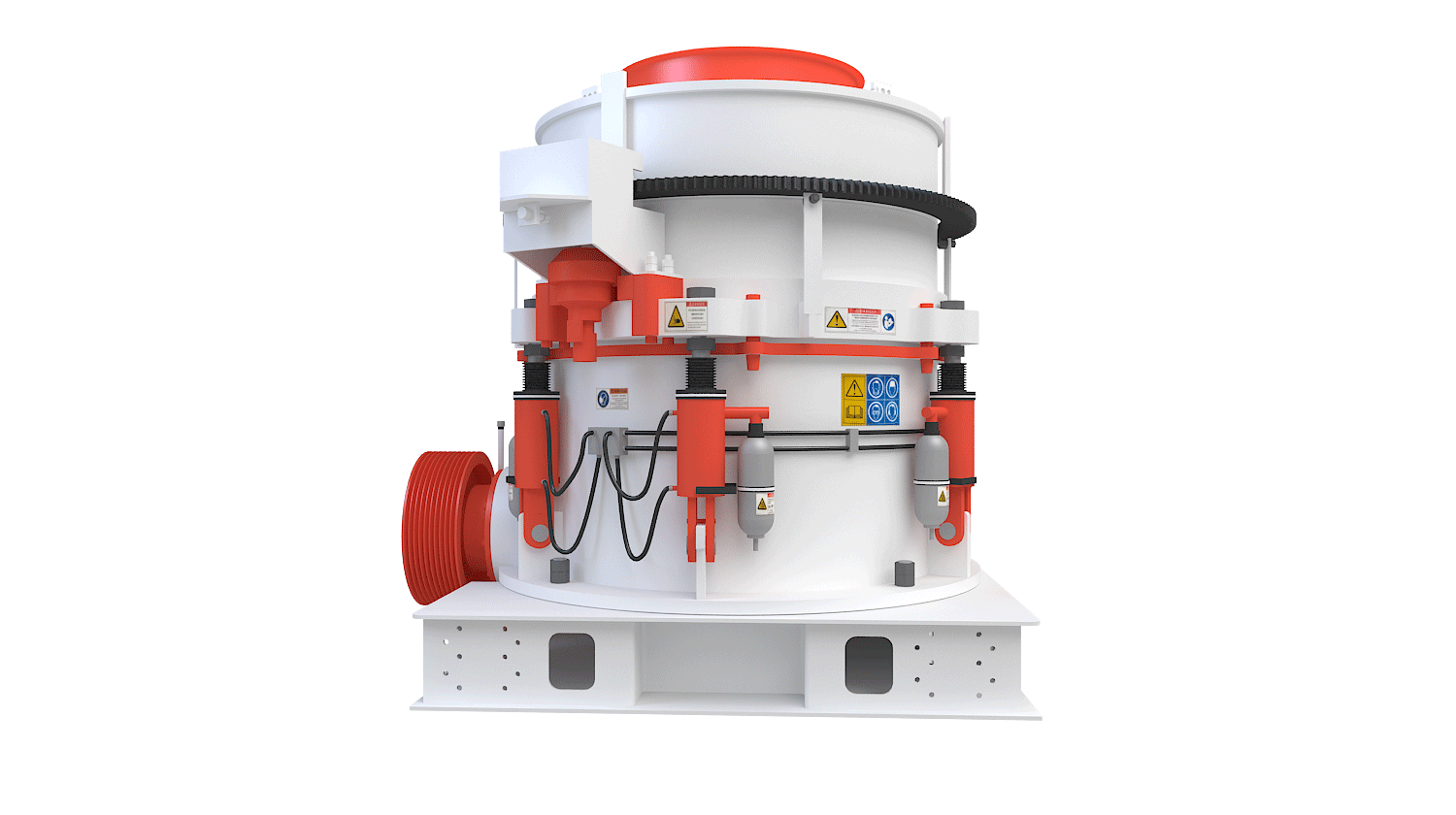

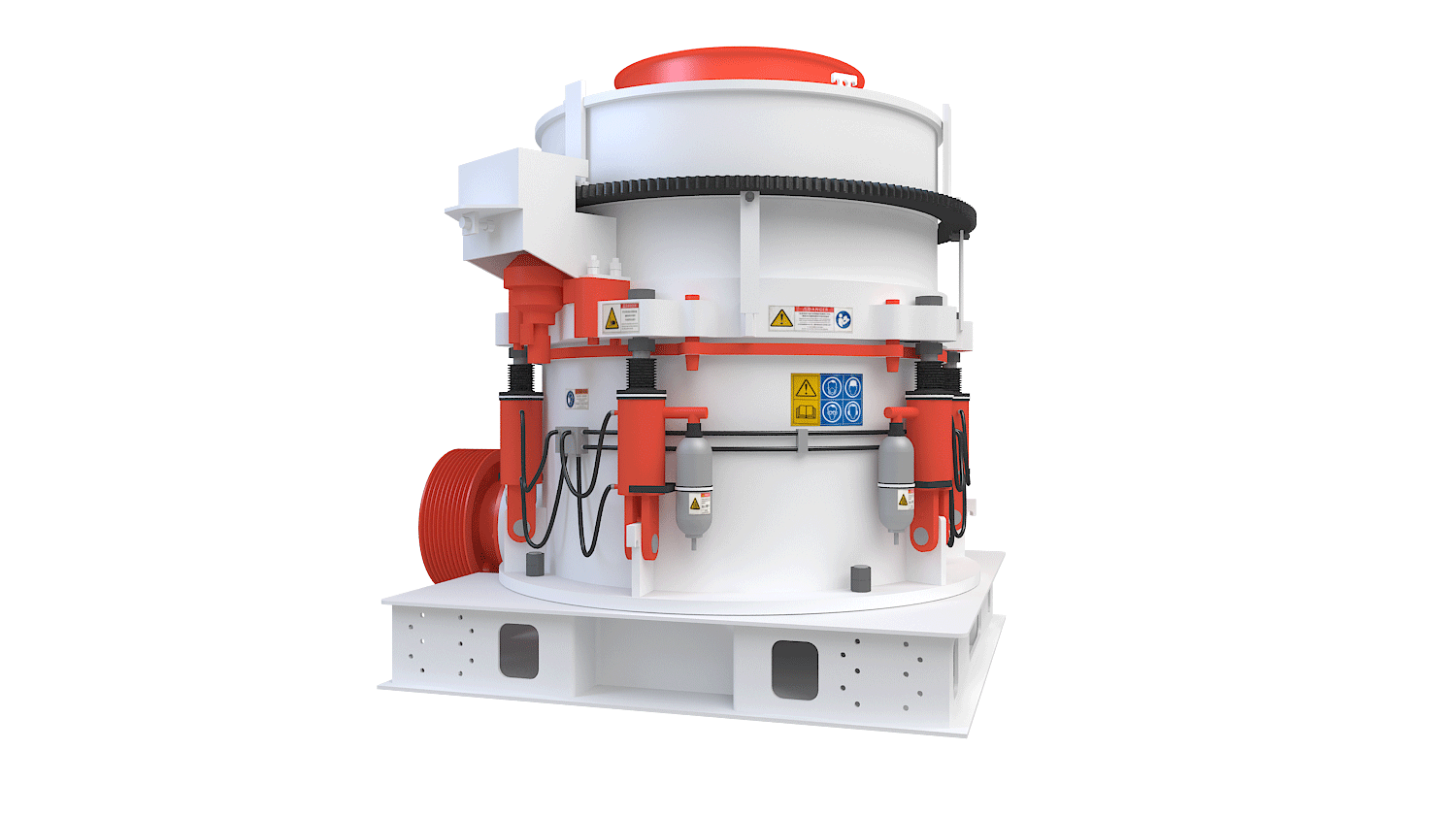

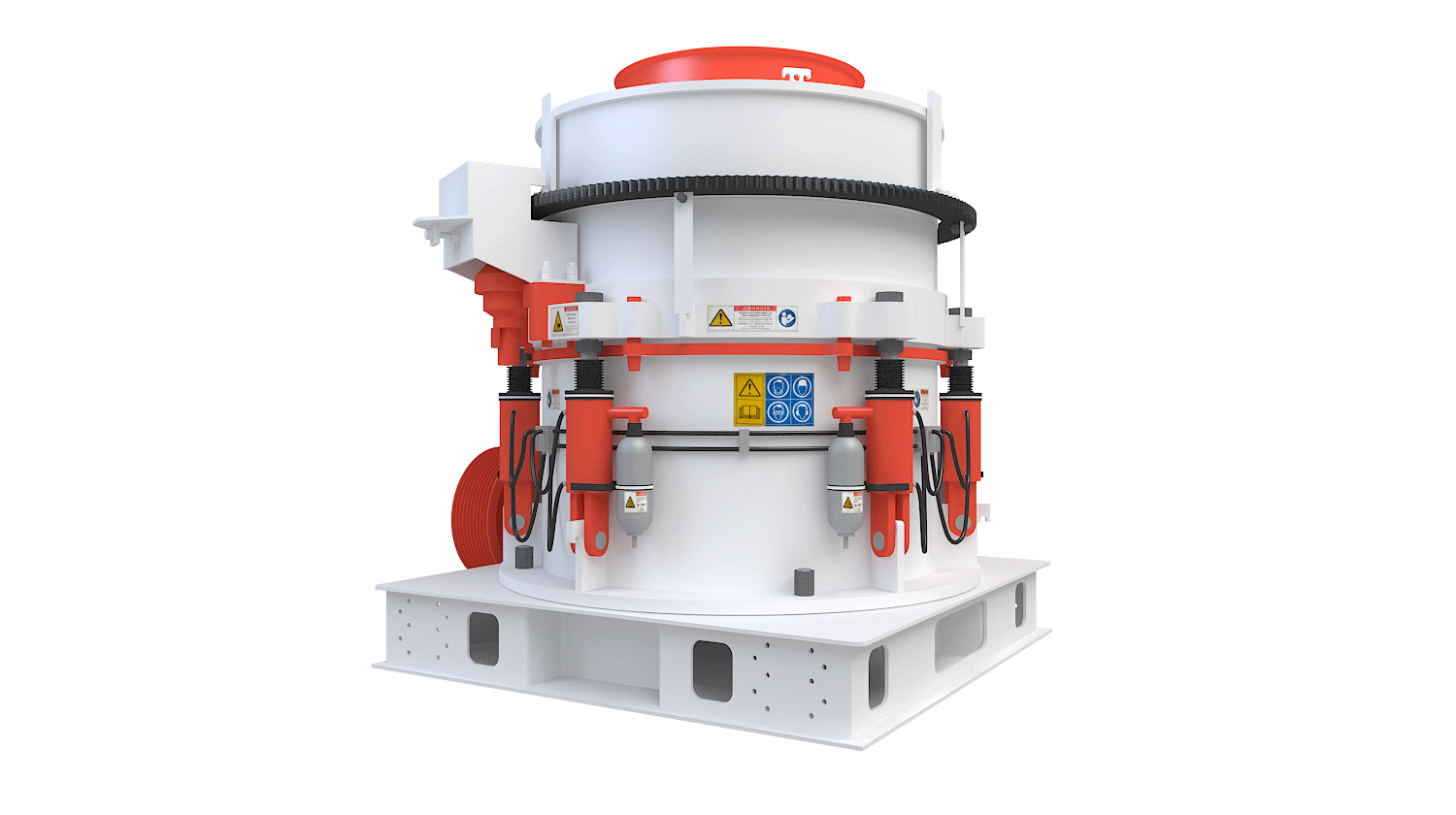

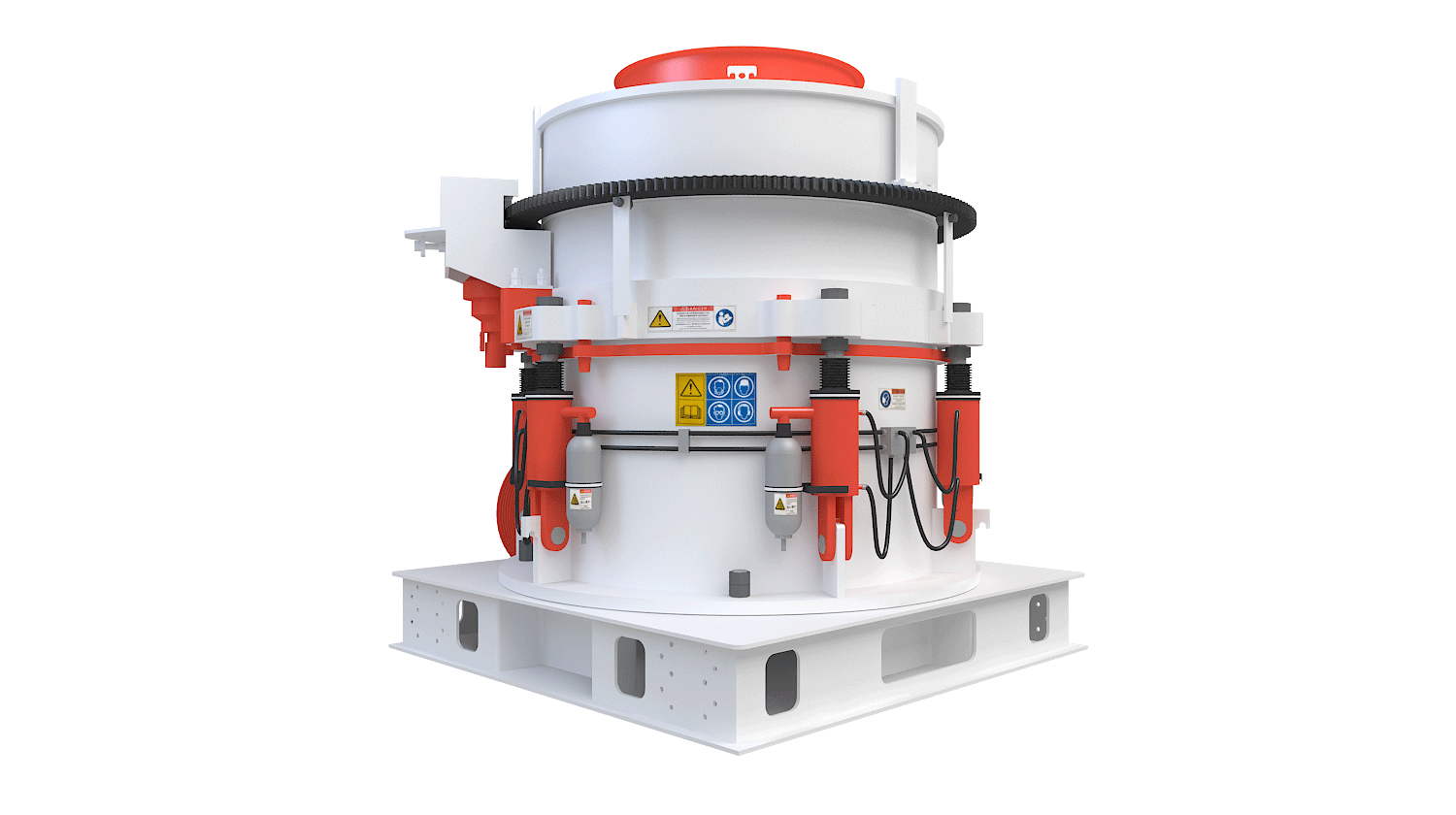

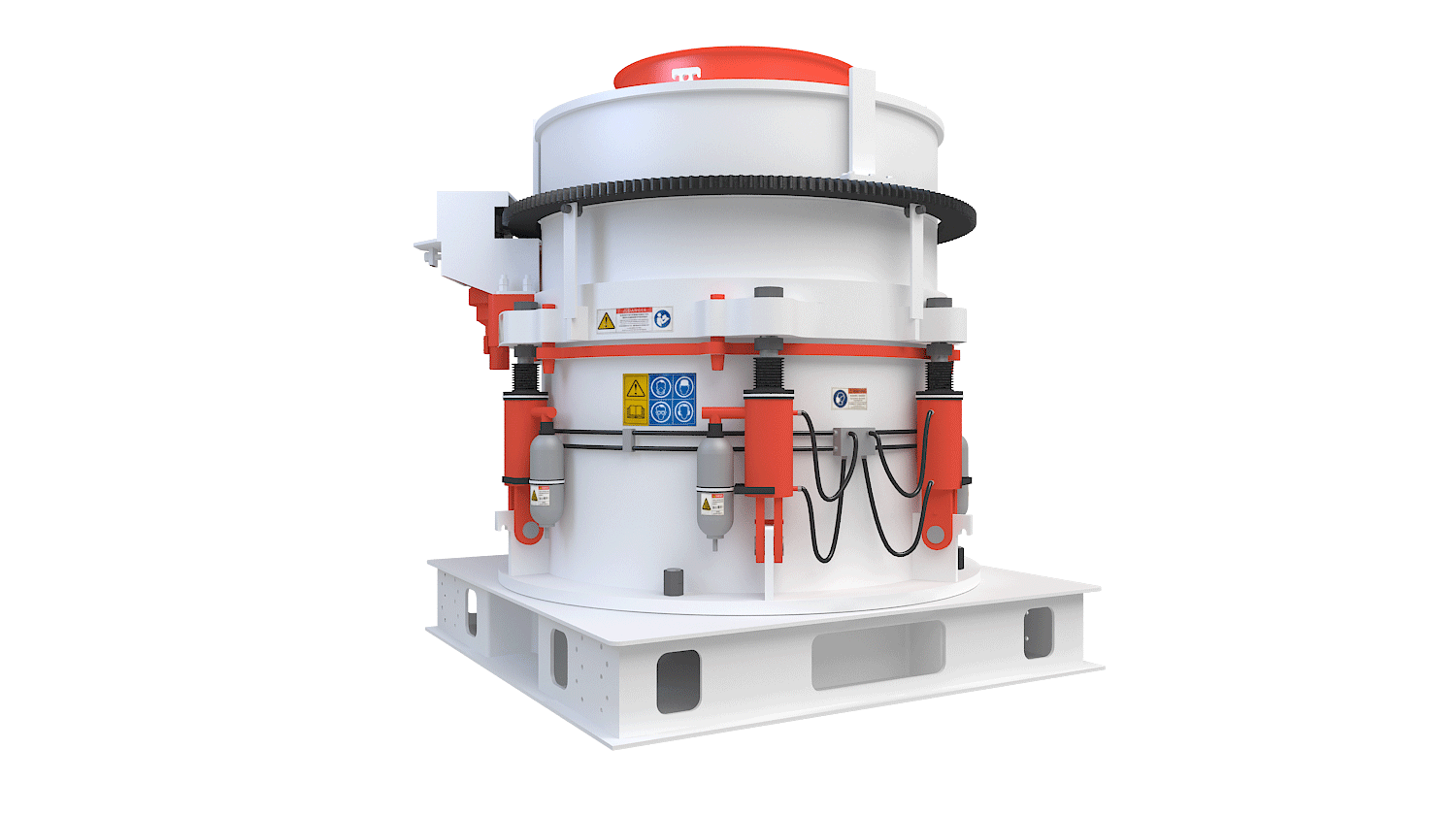

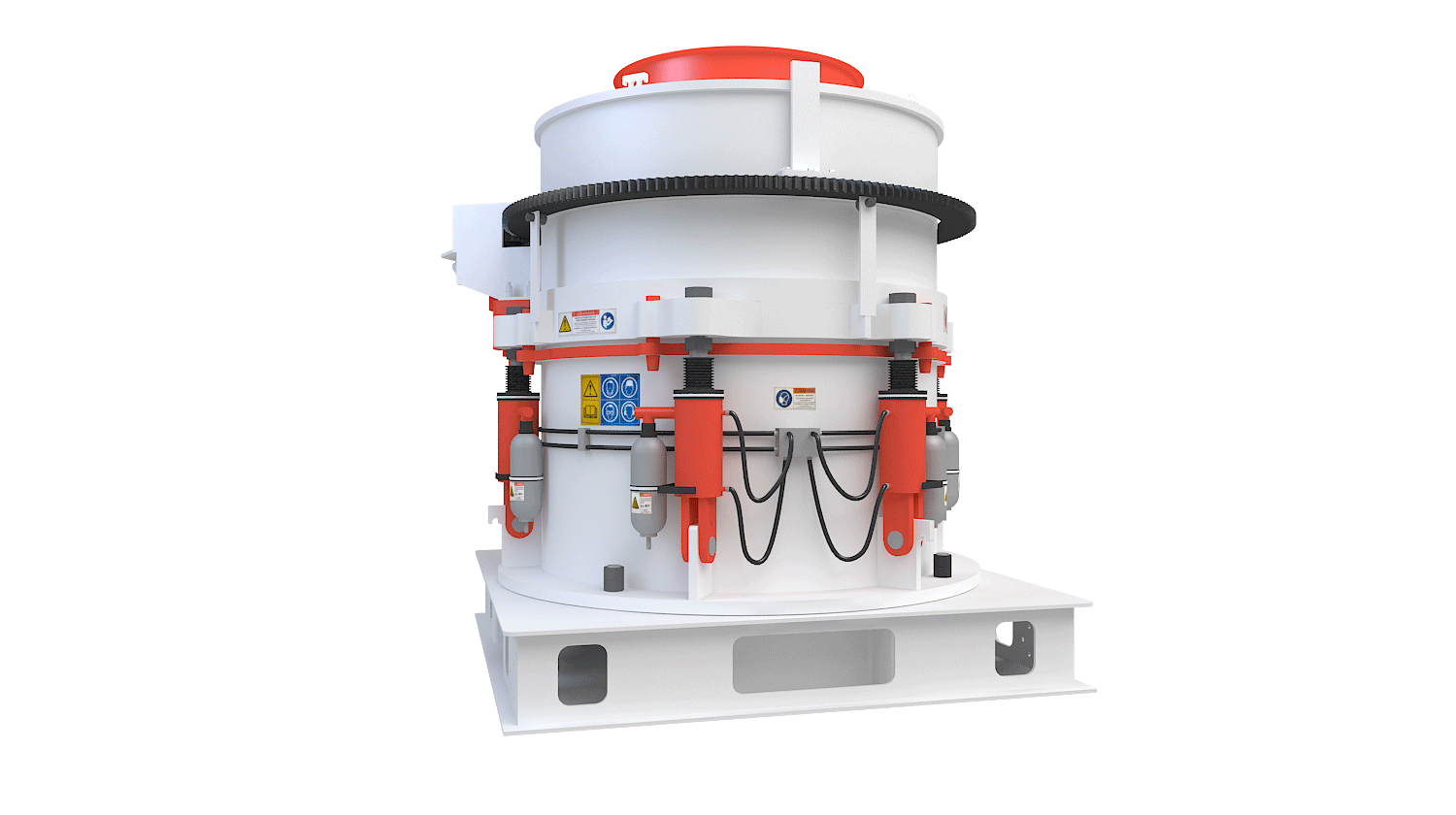

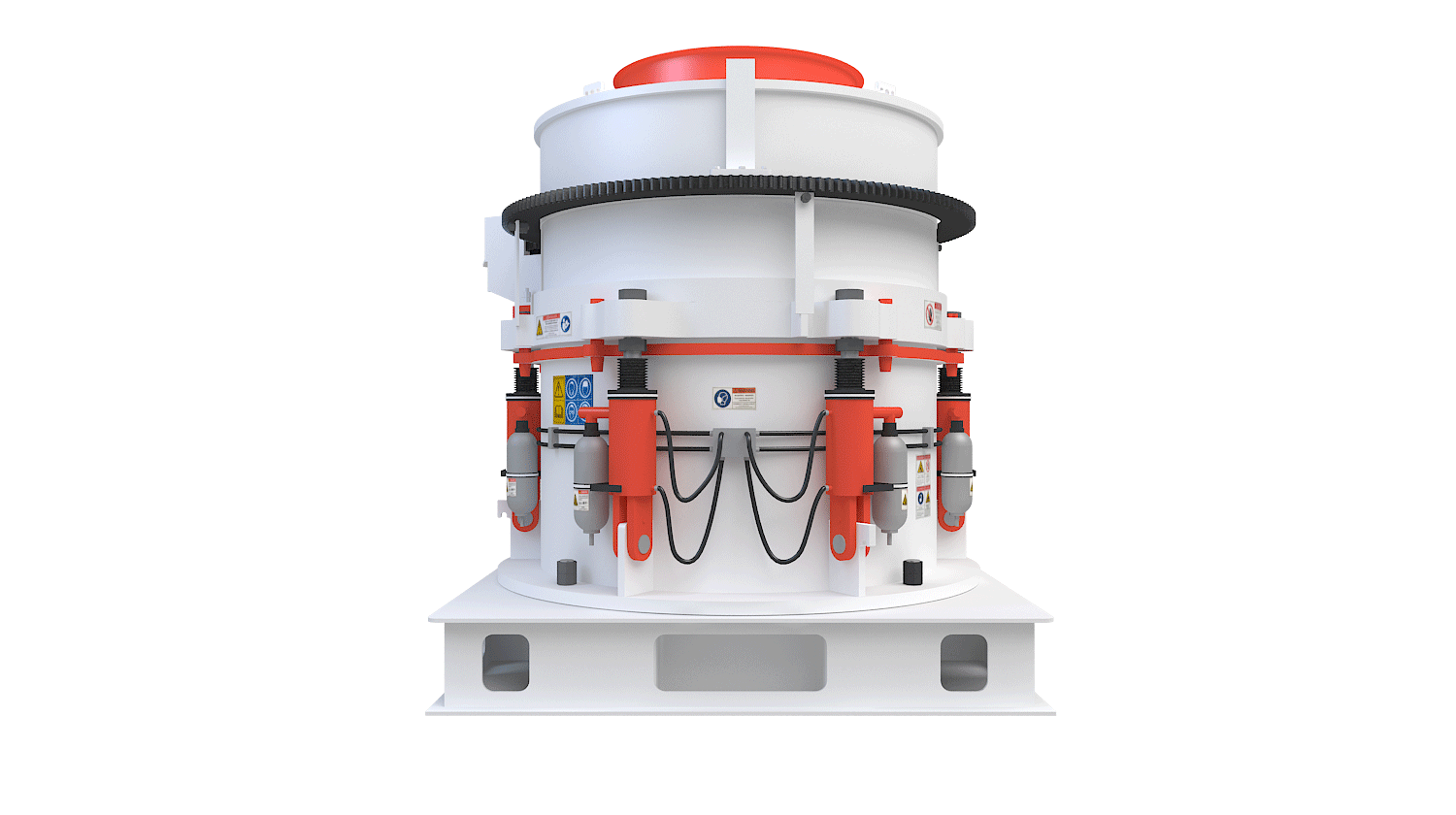

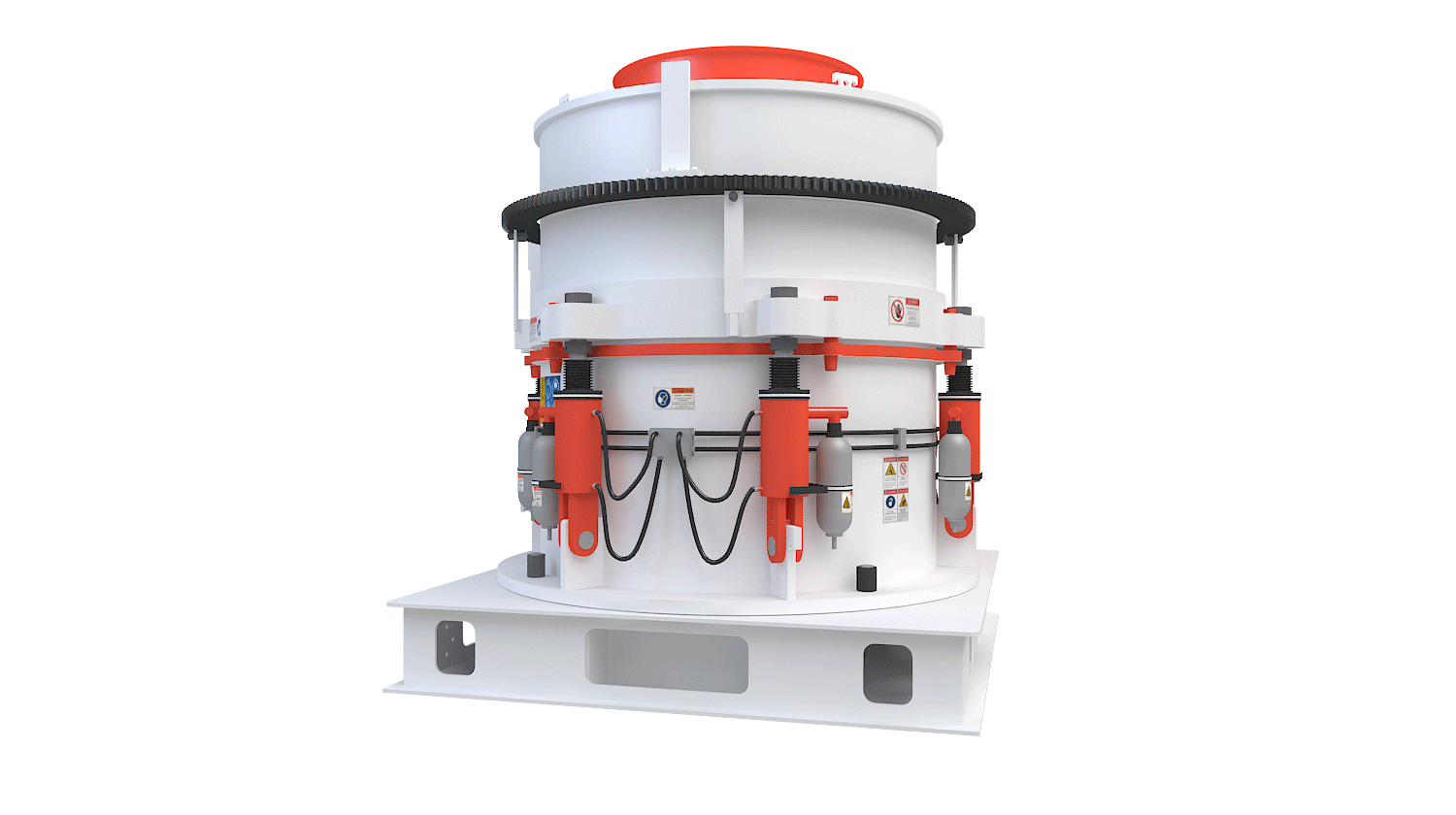

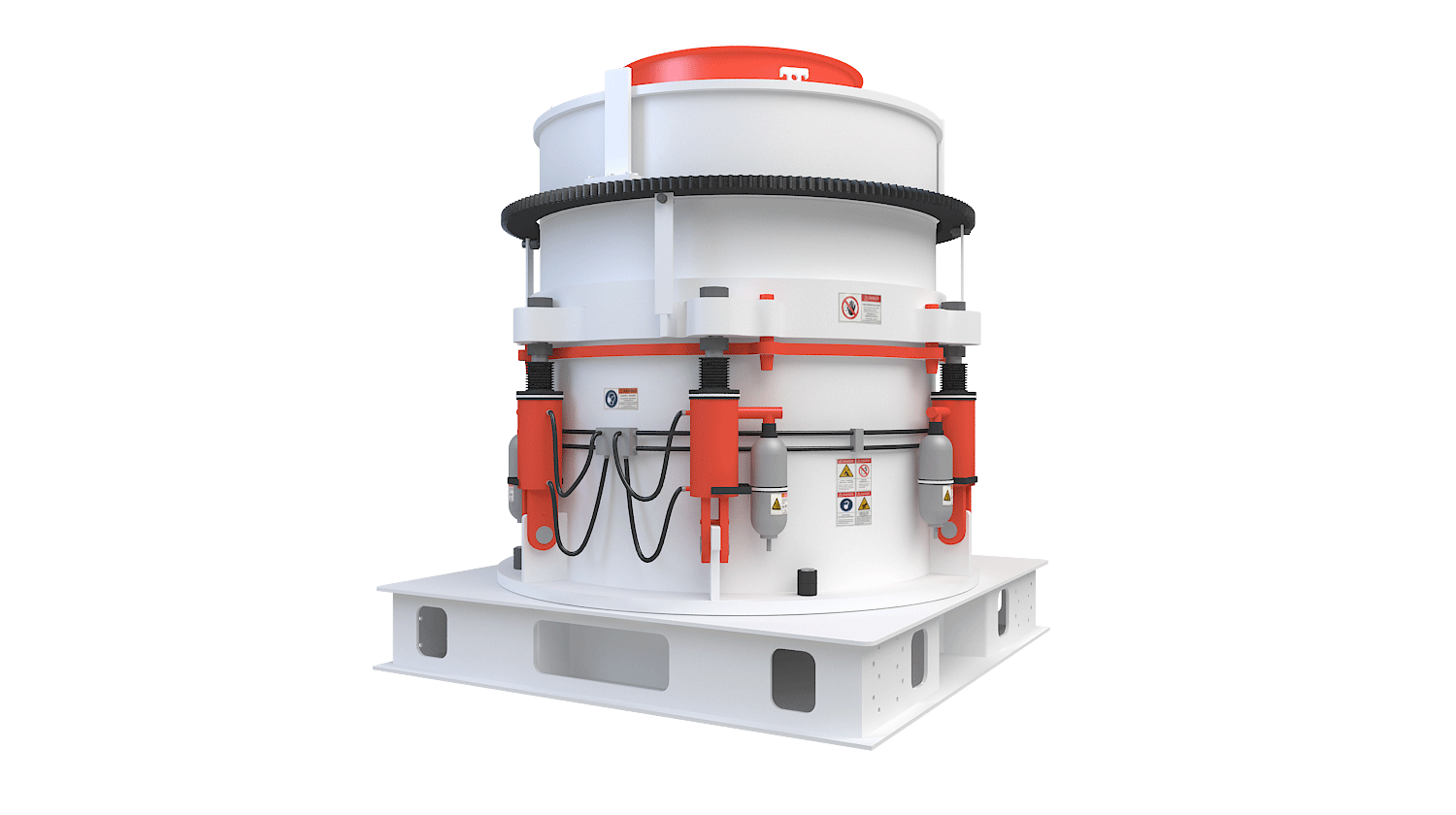

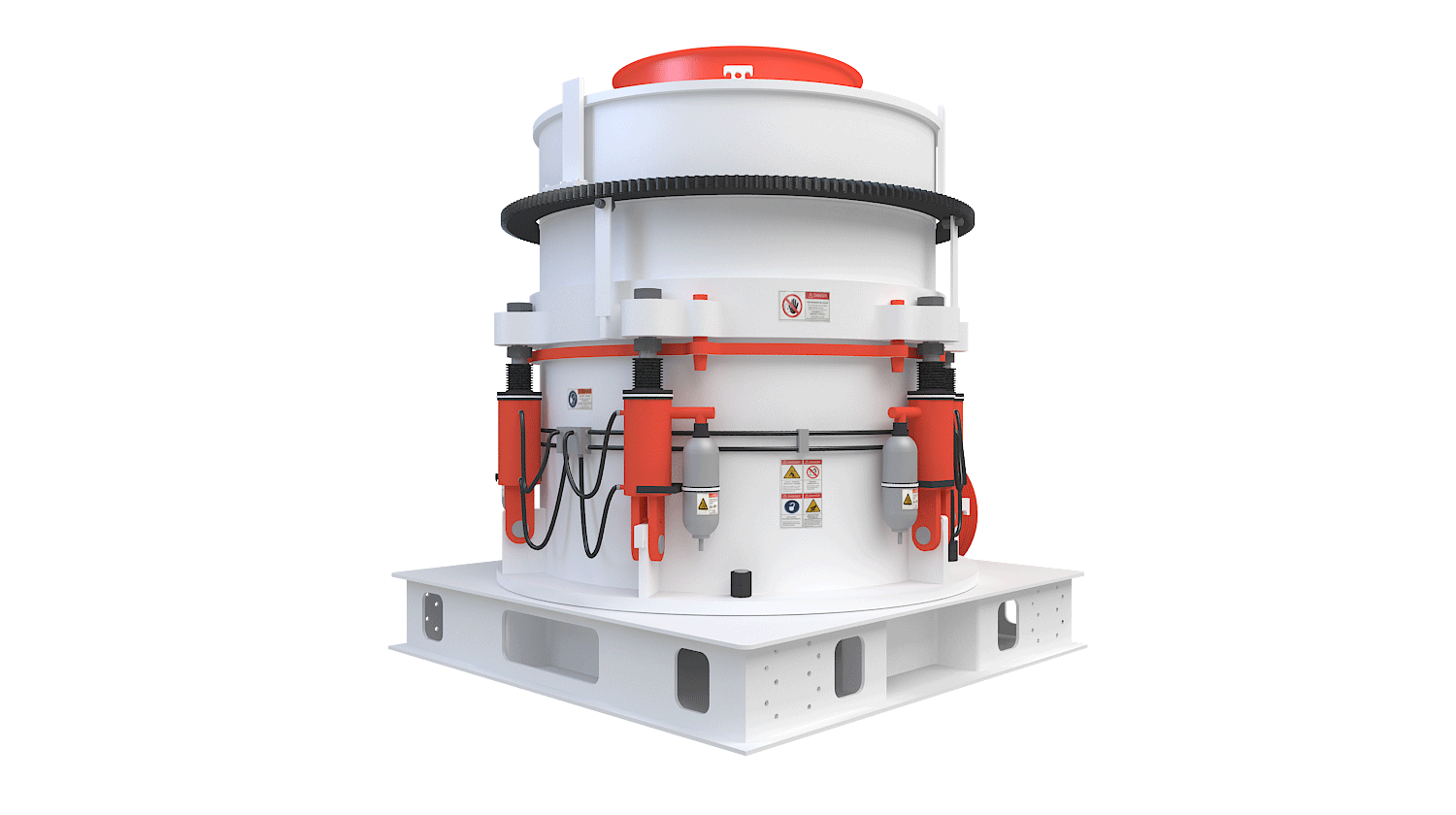

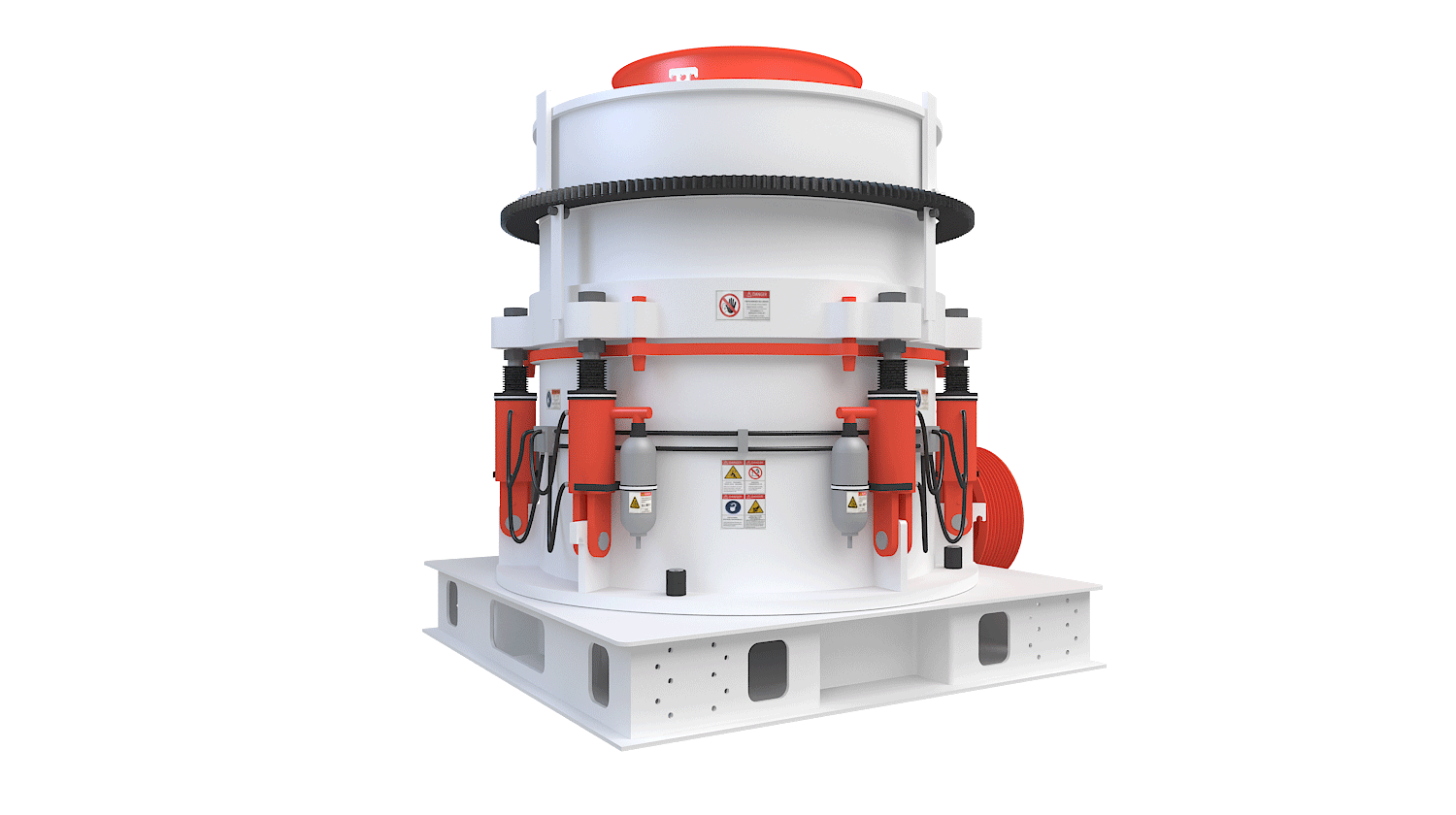

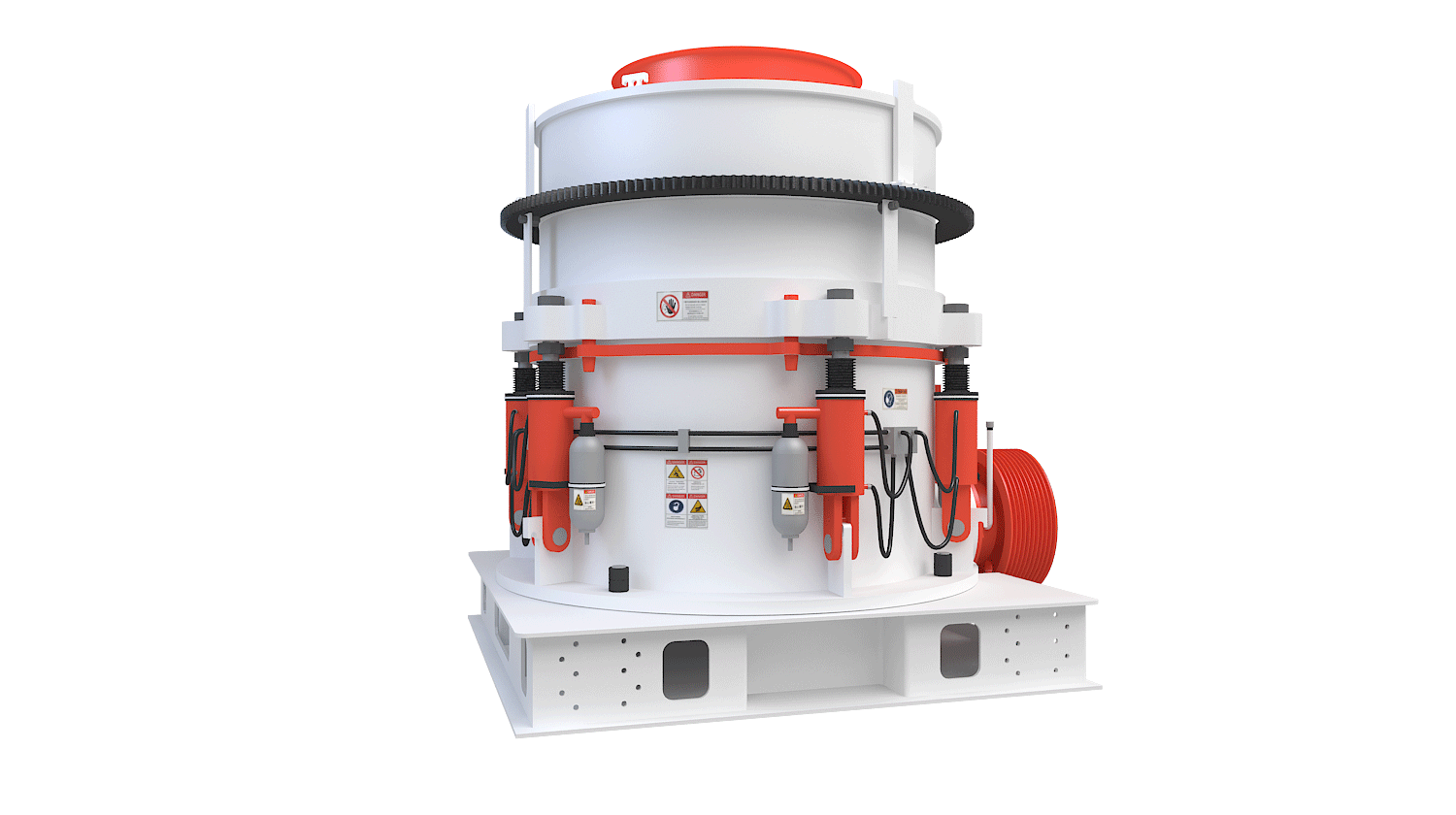

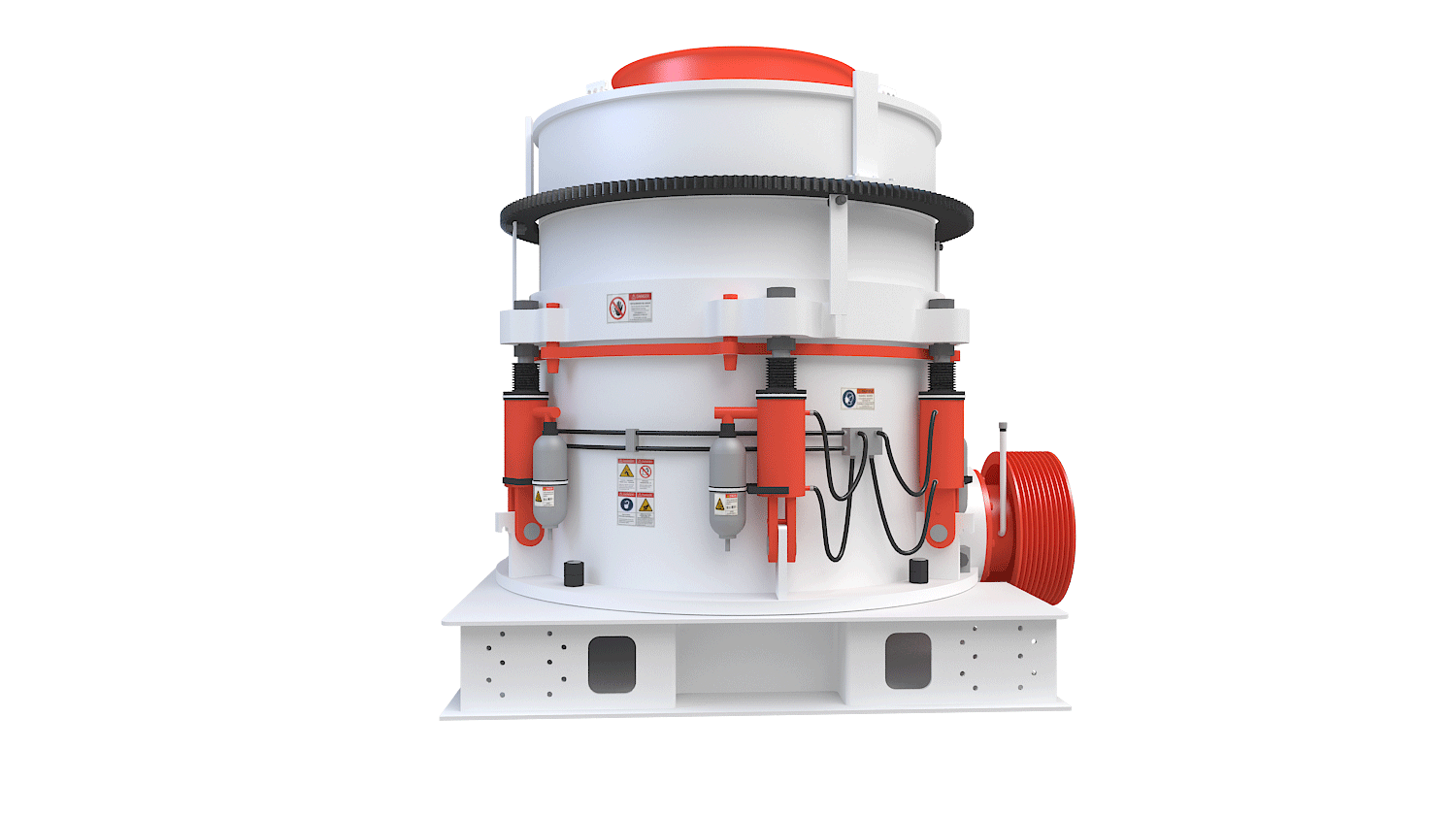

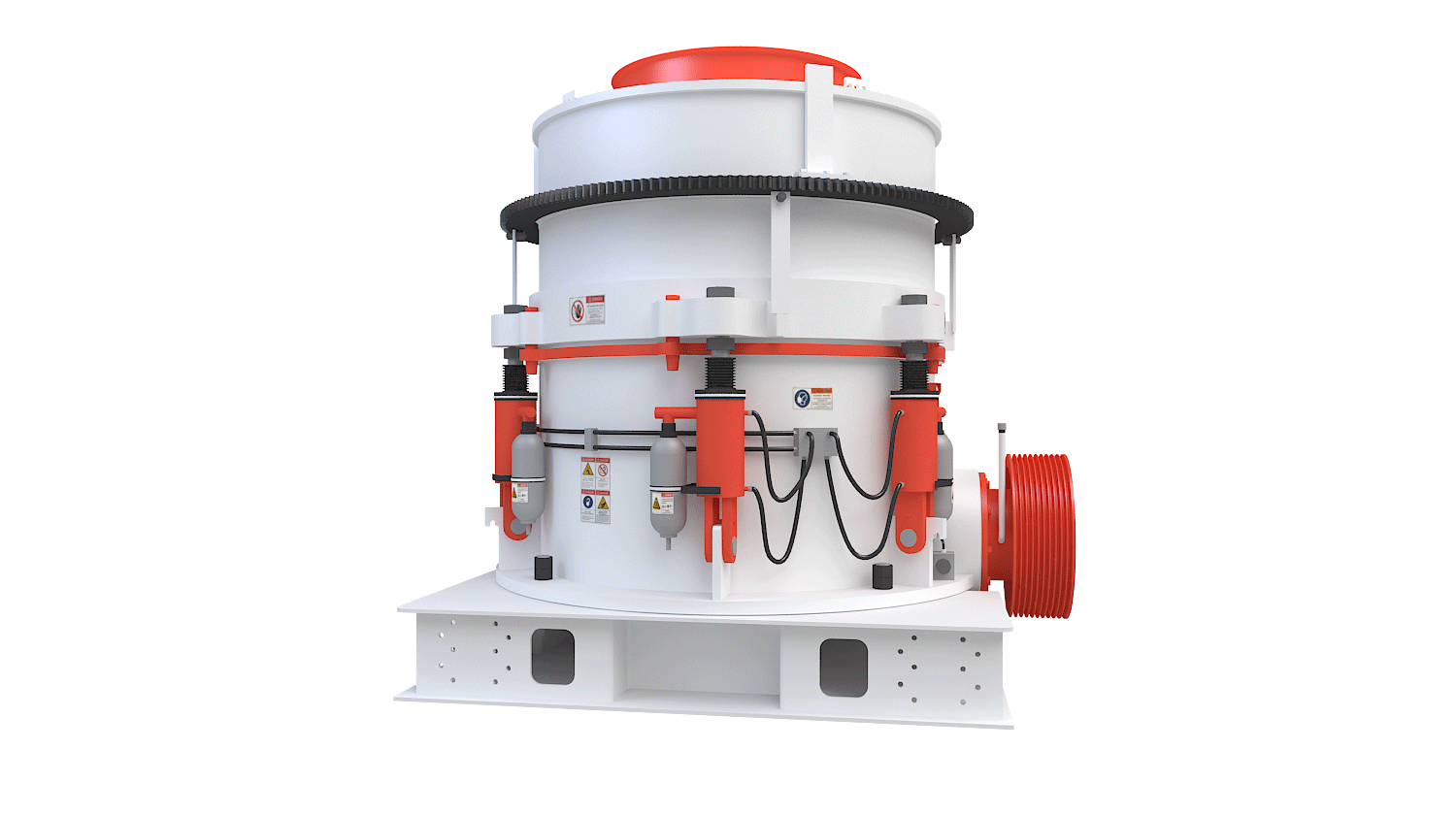

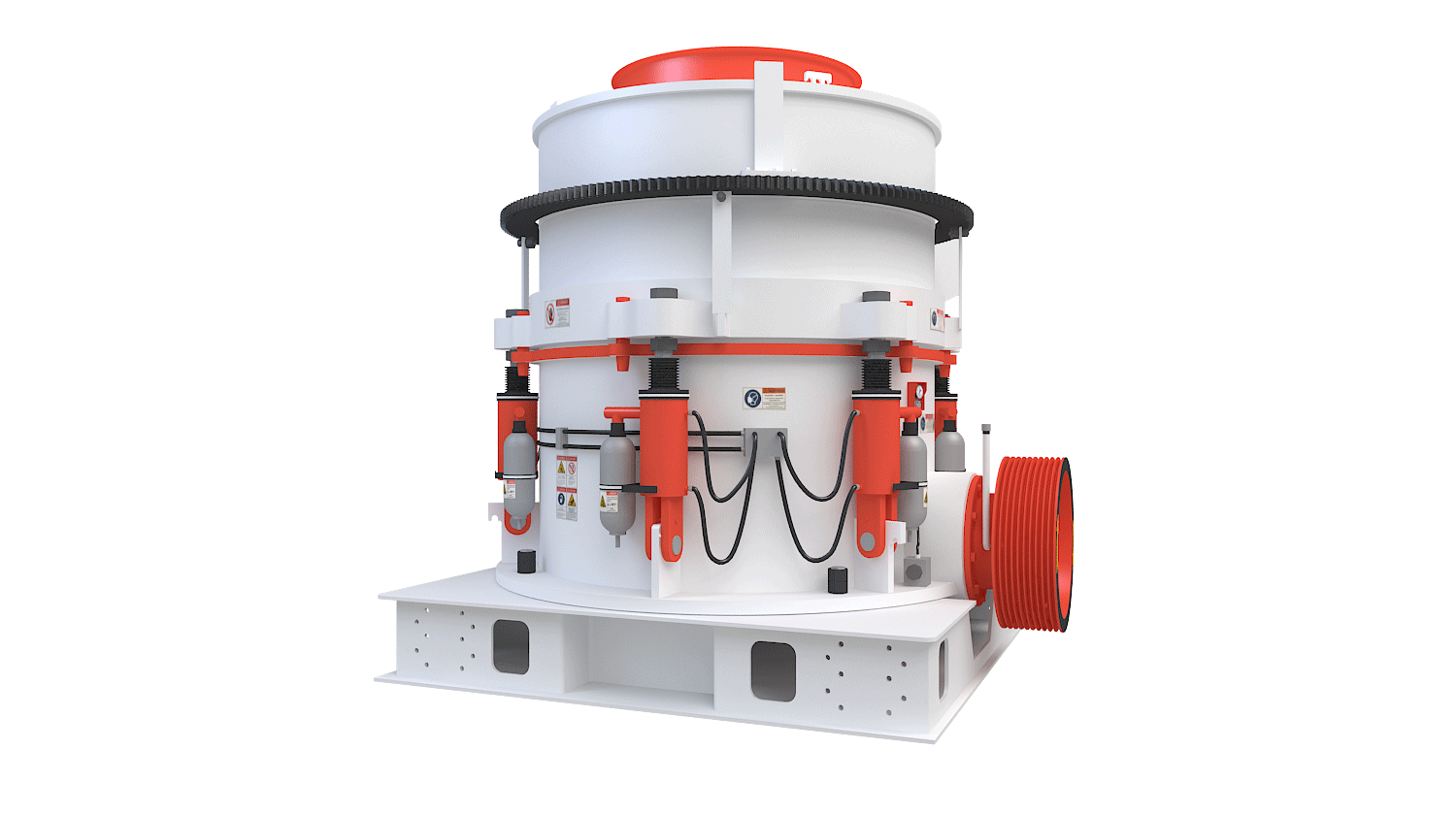

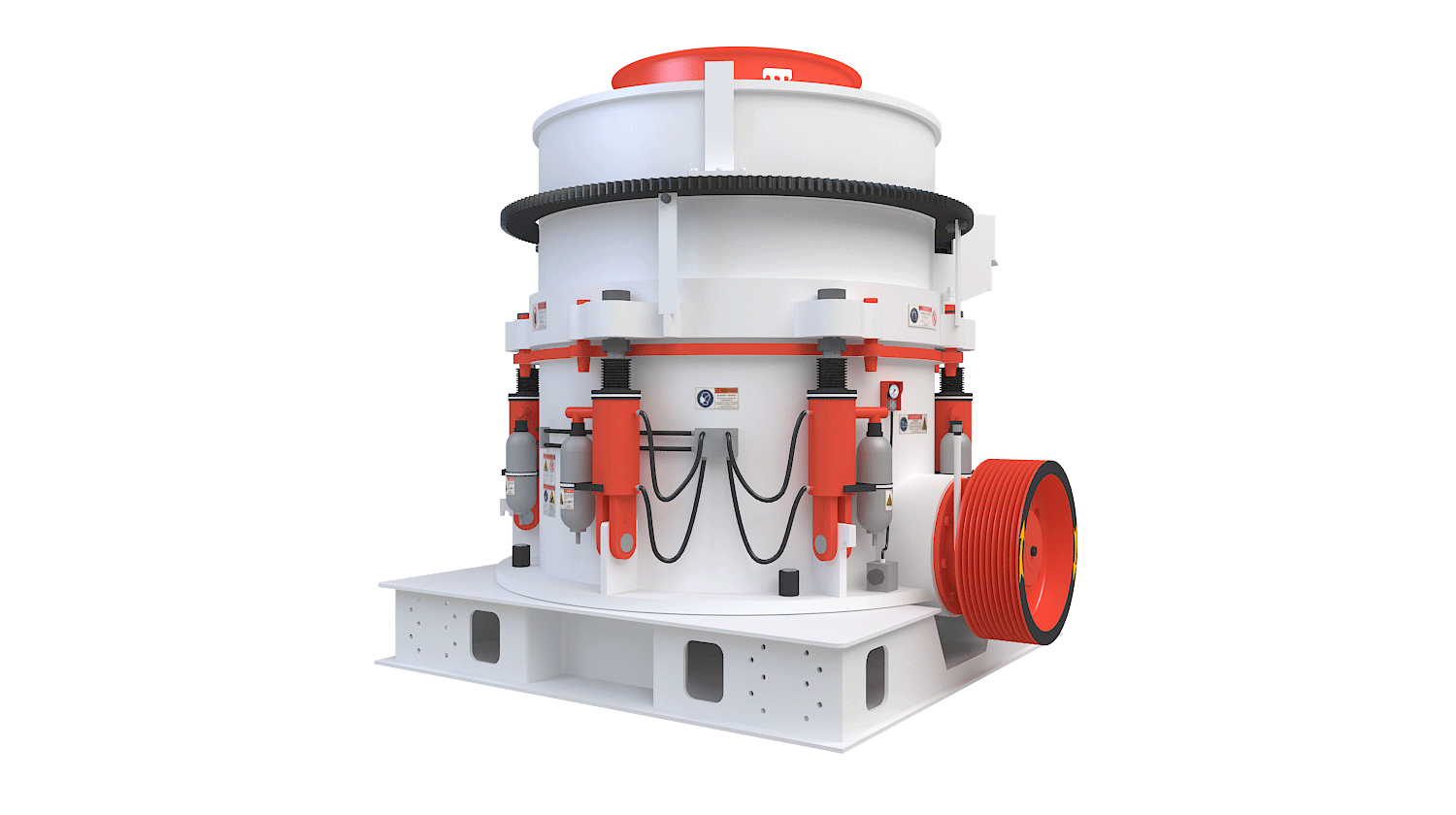

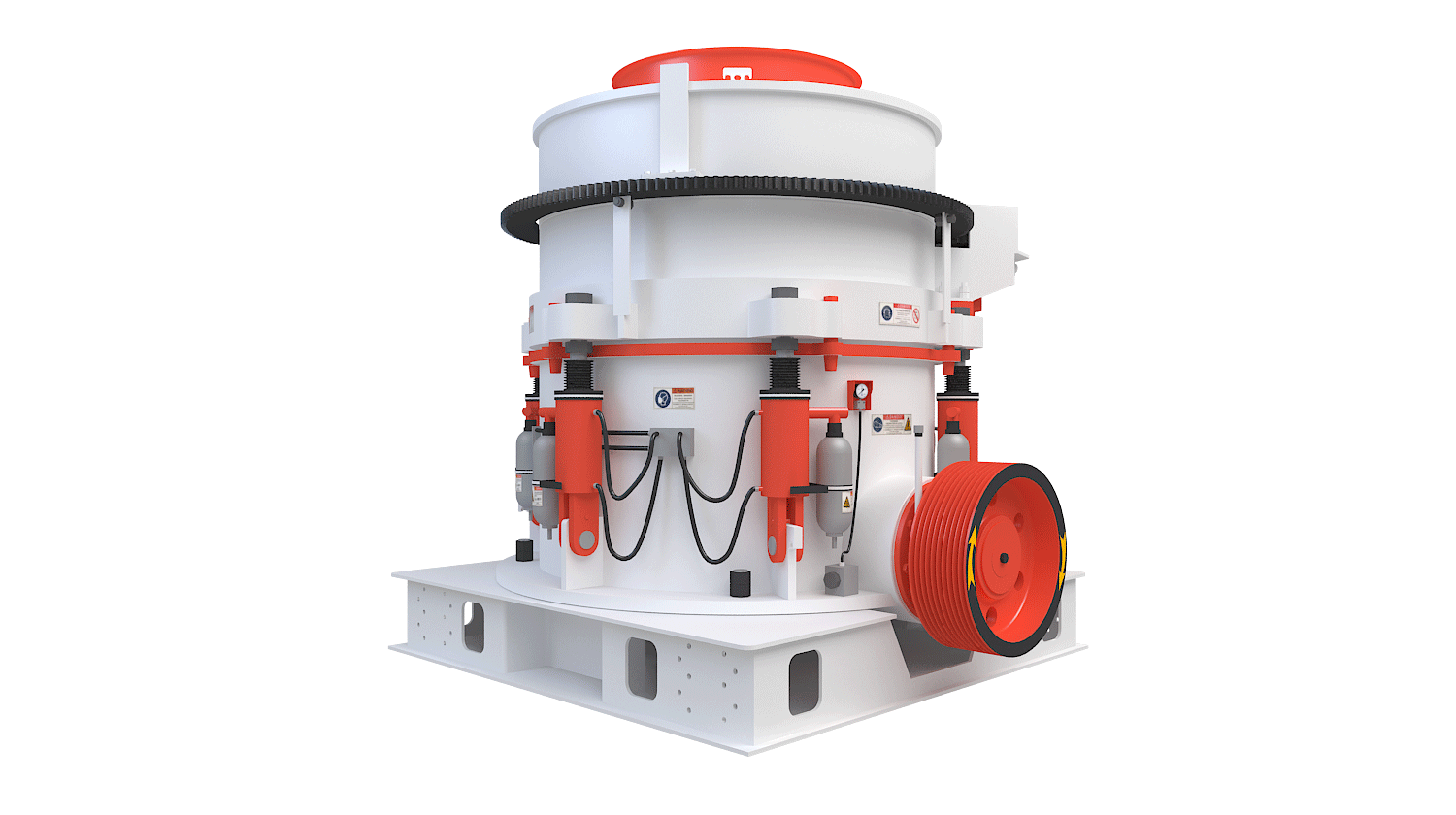

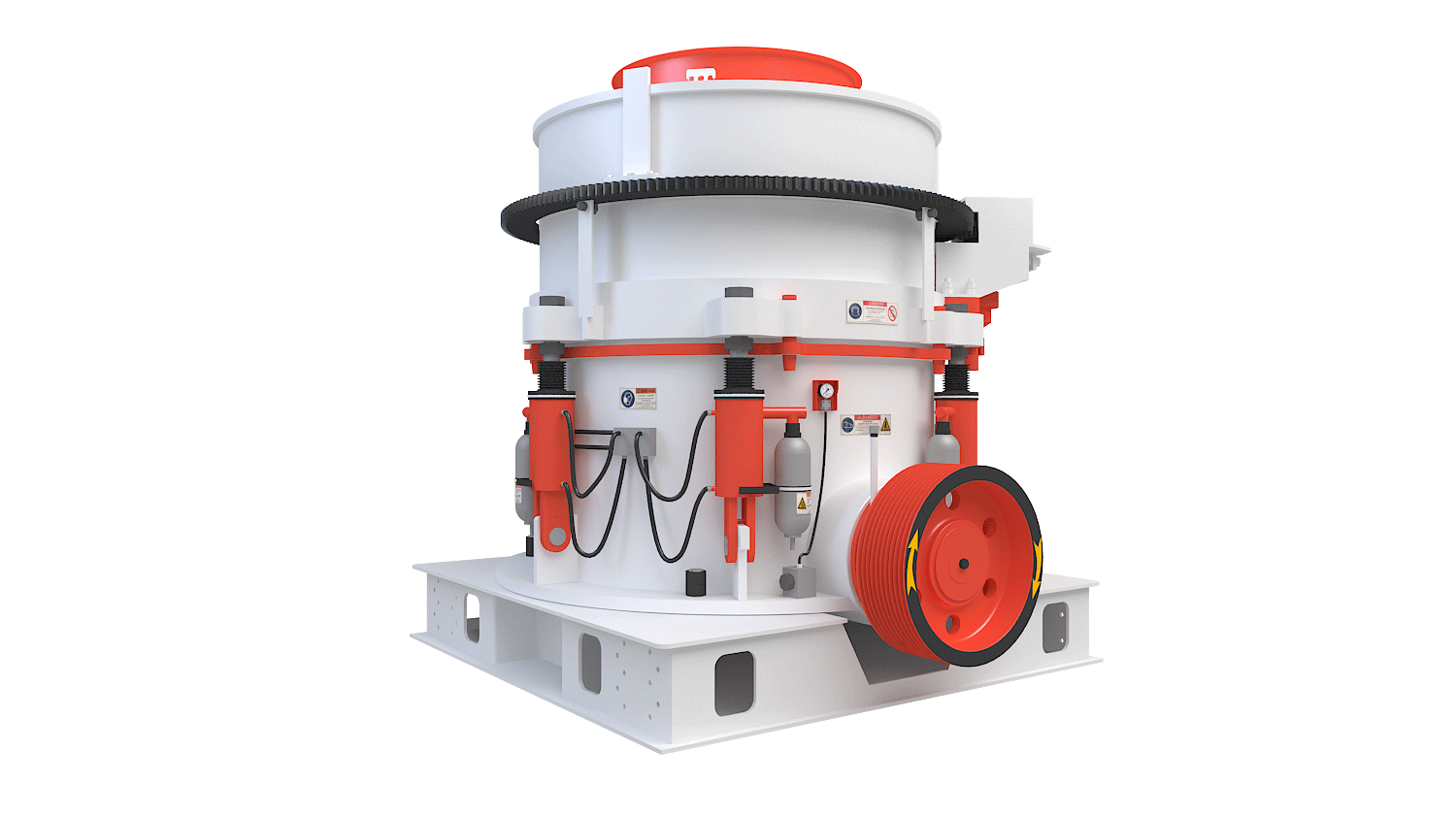

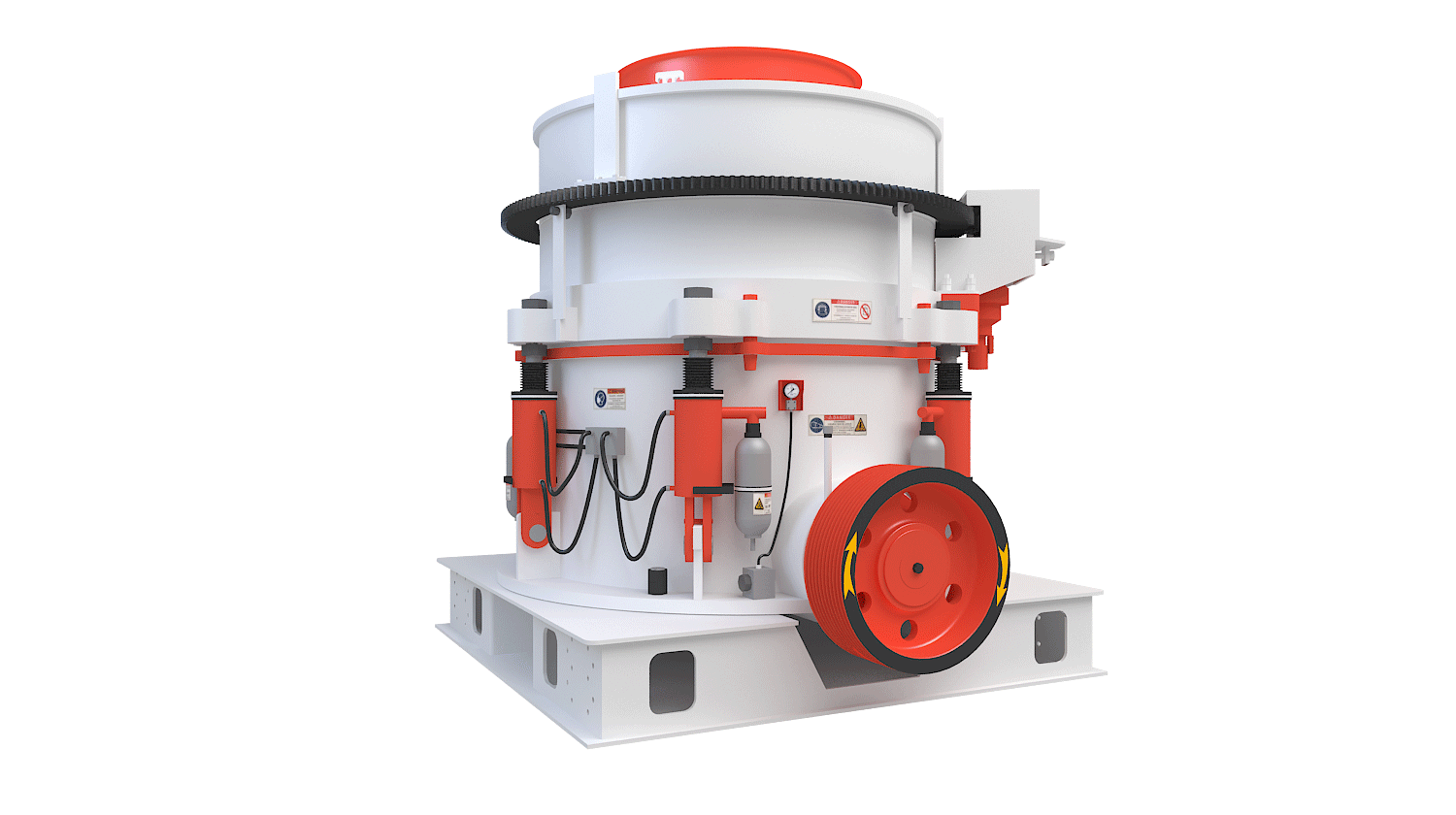

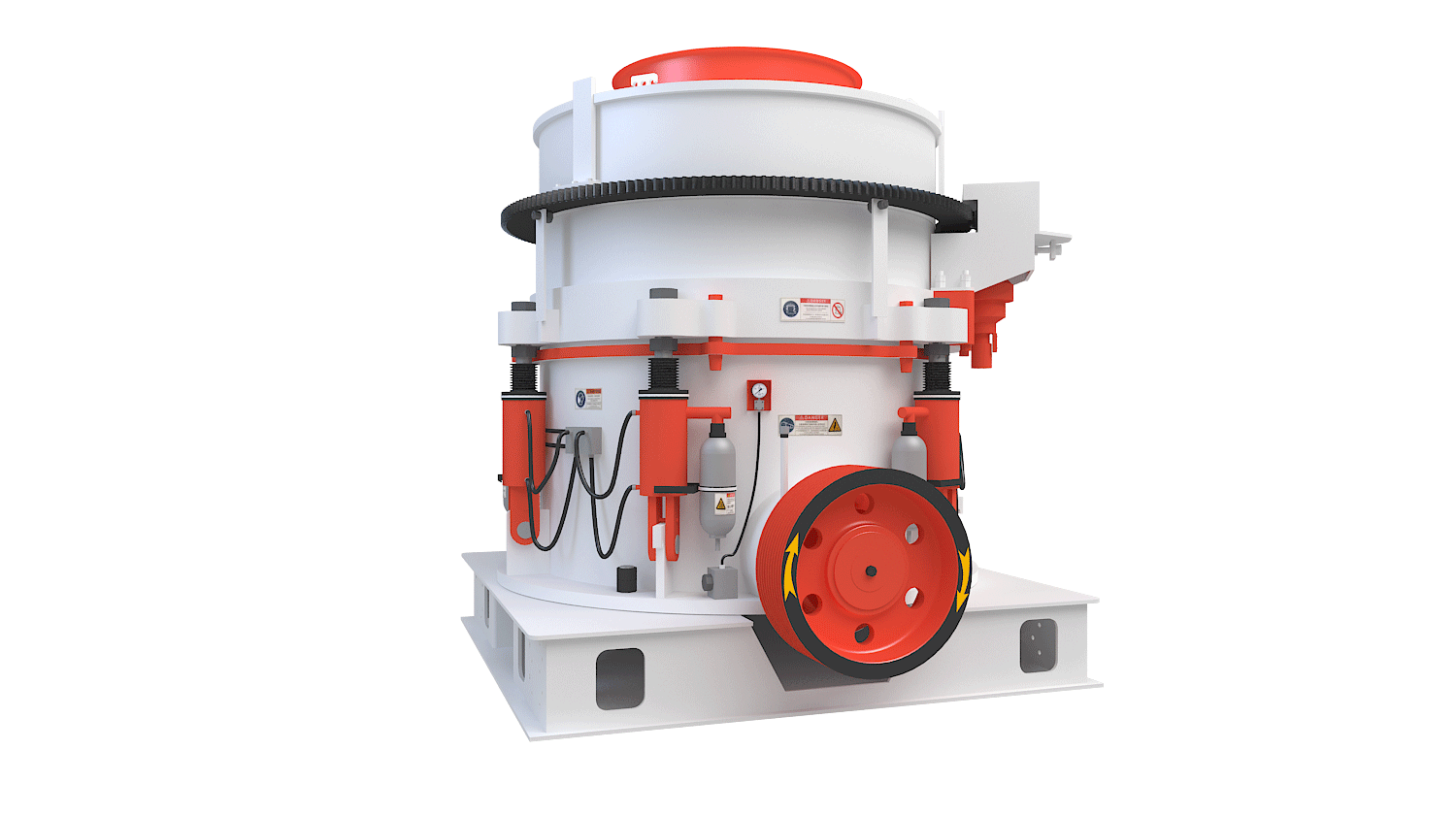

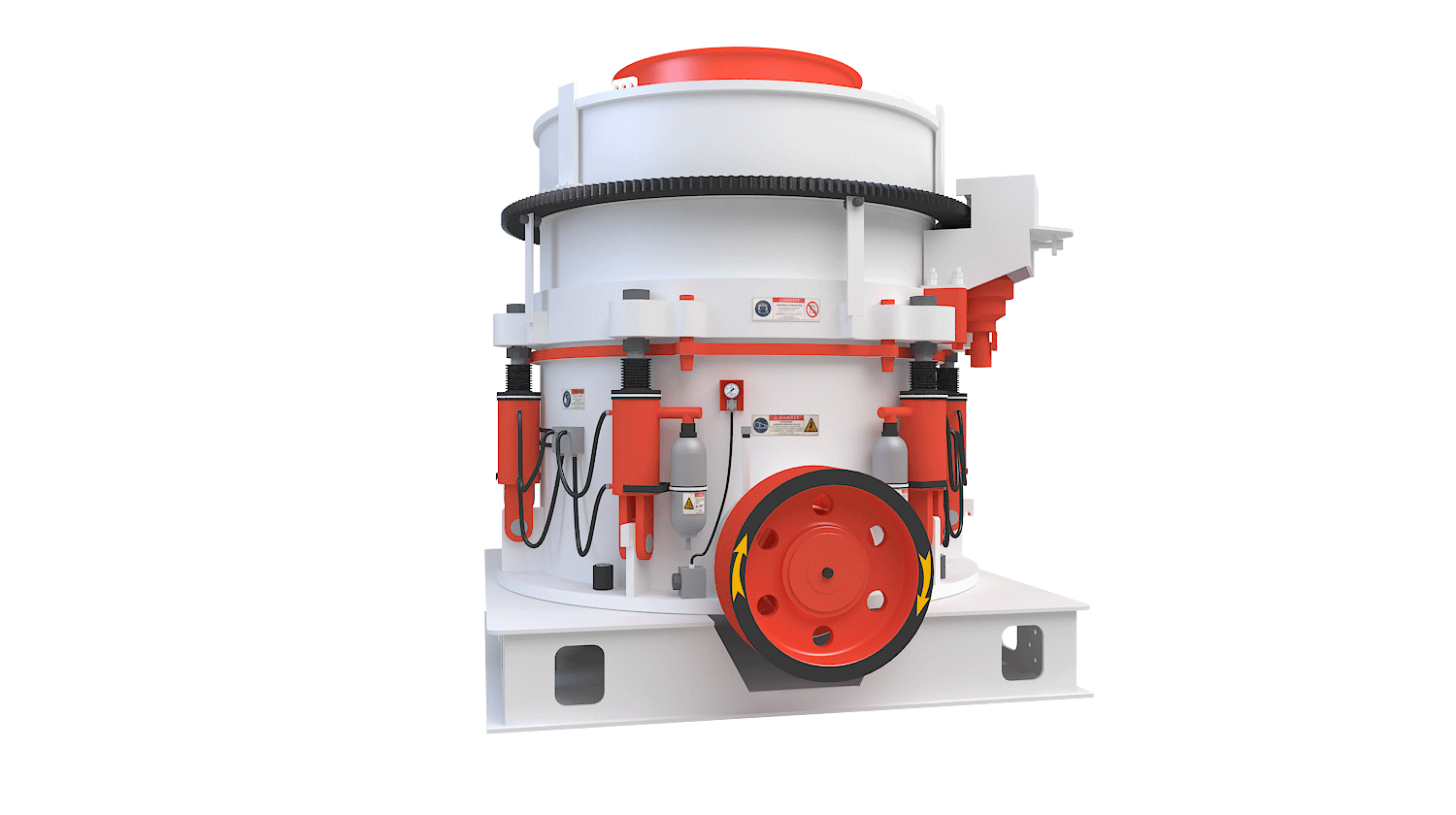

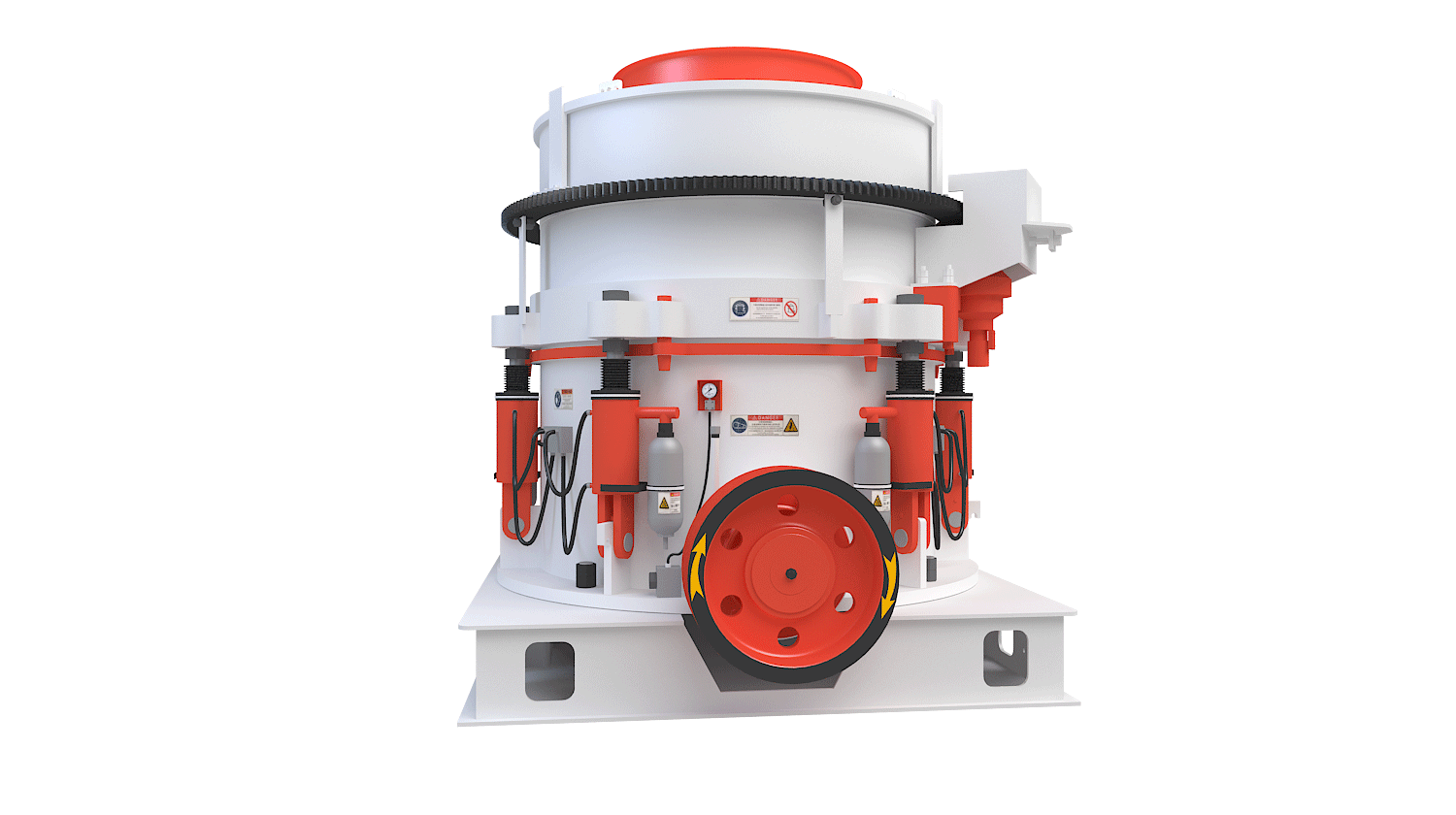

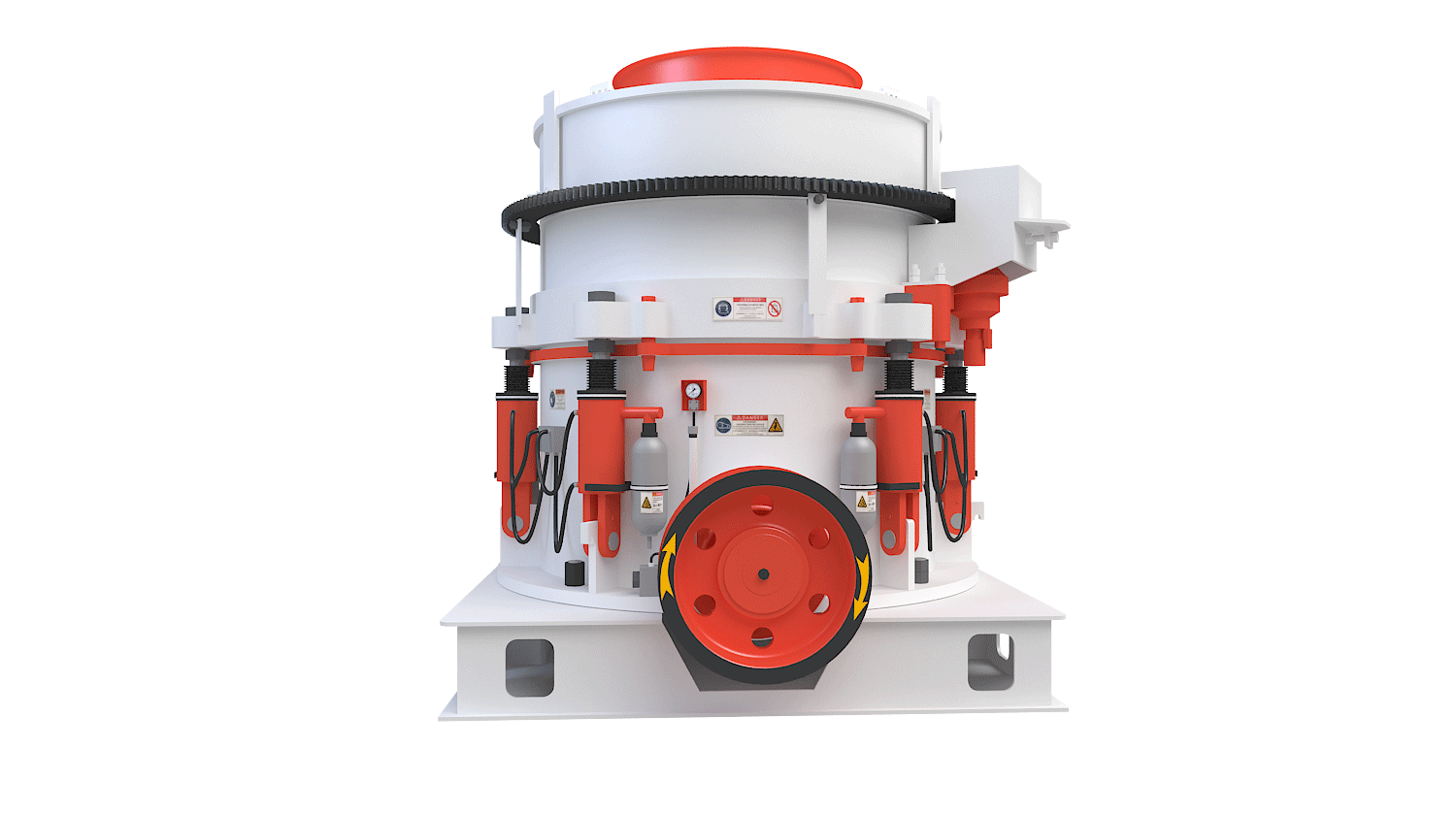

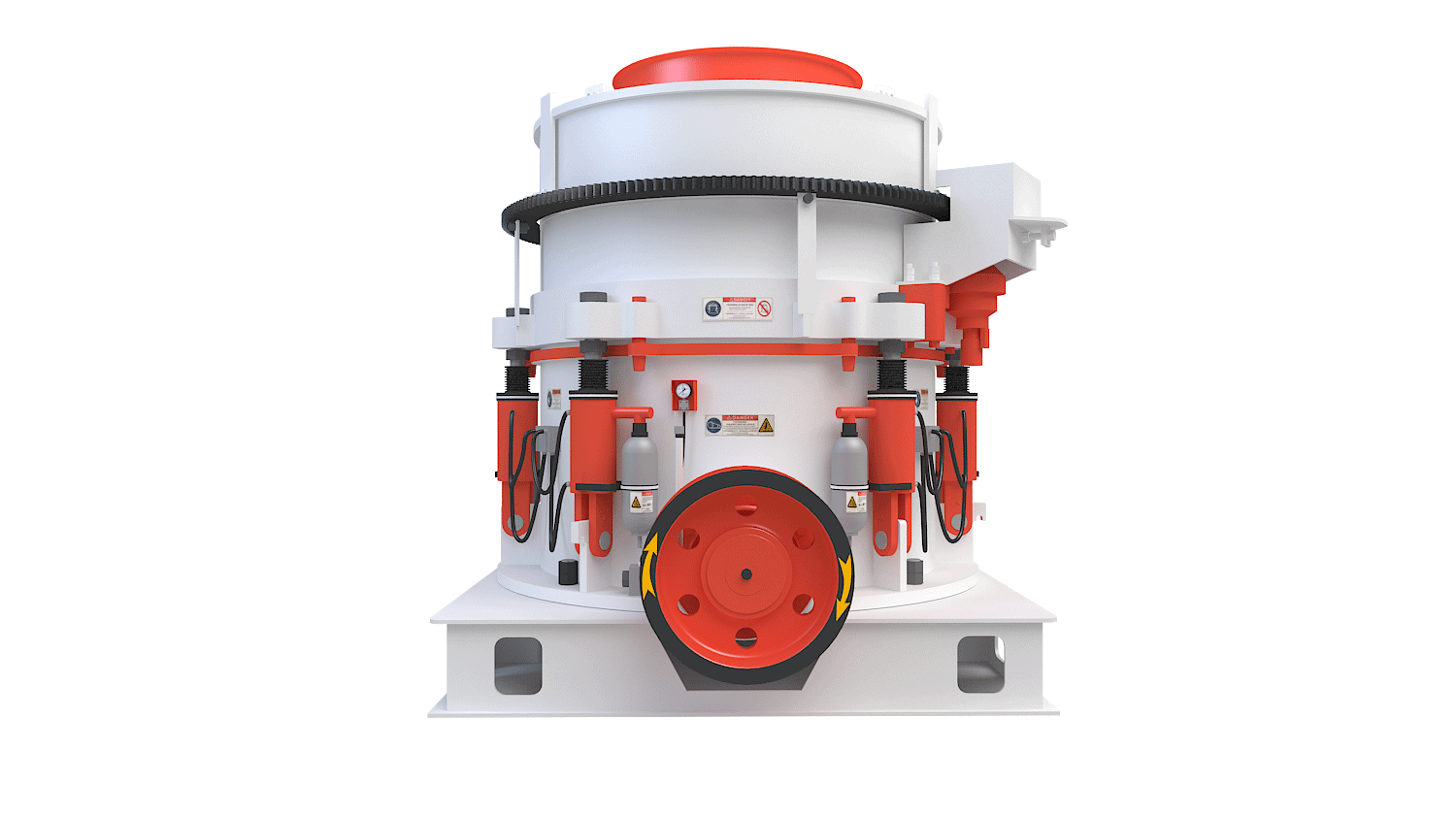

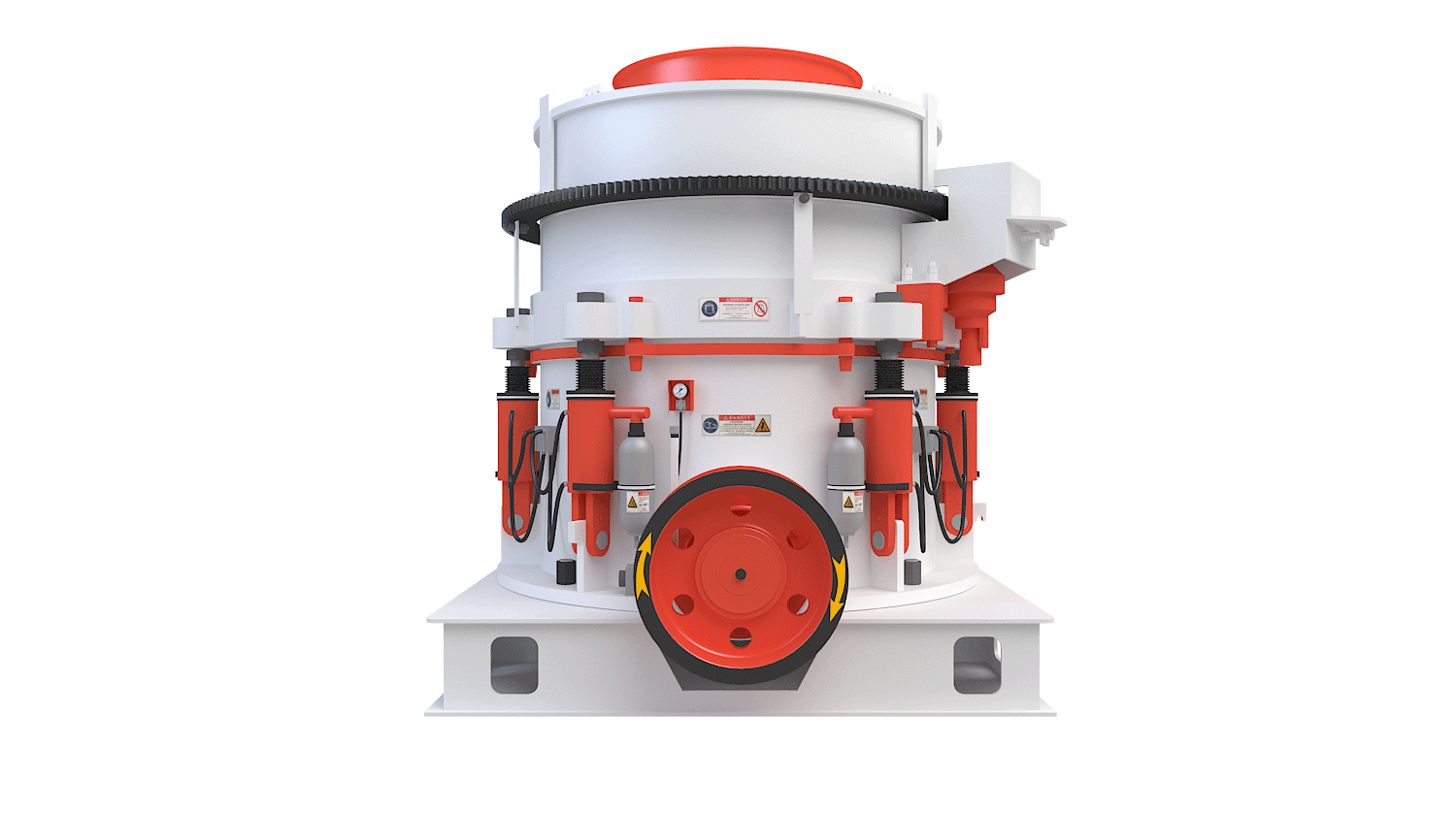

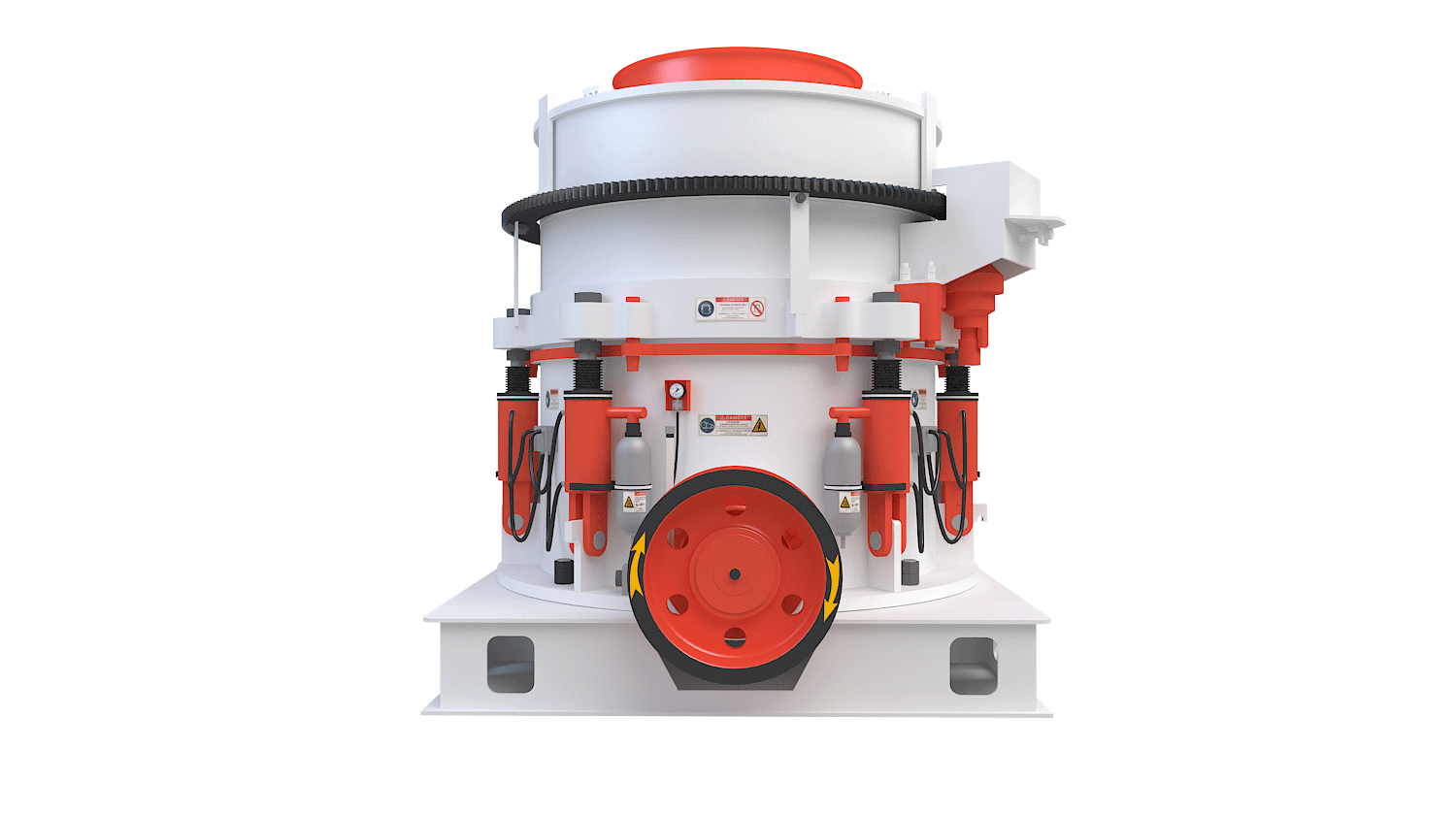

Multi-Cylinder Cone Crusher

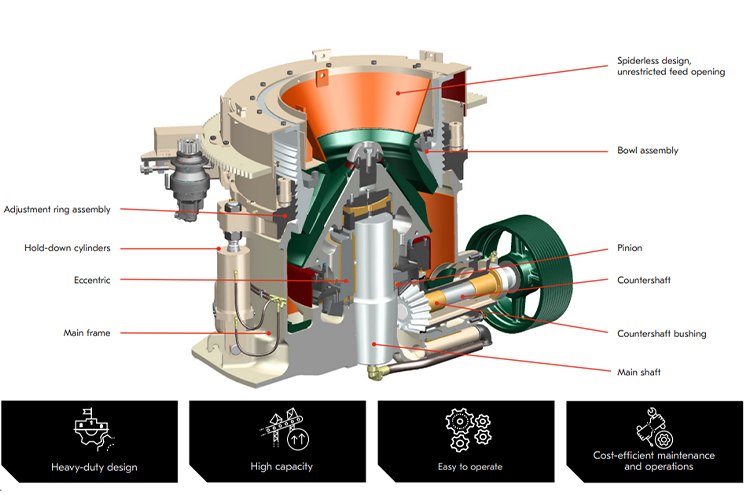

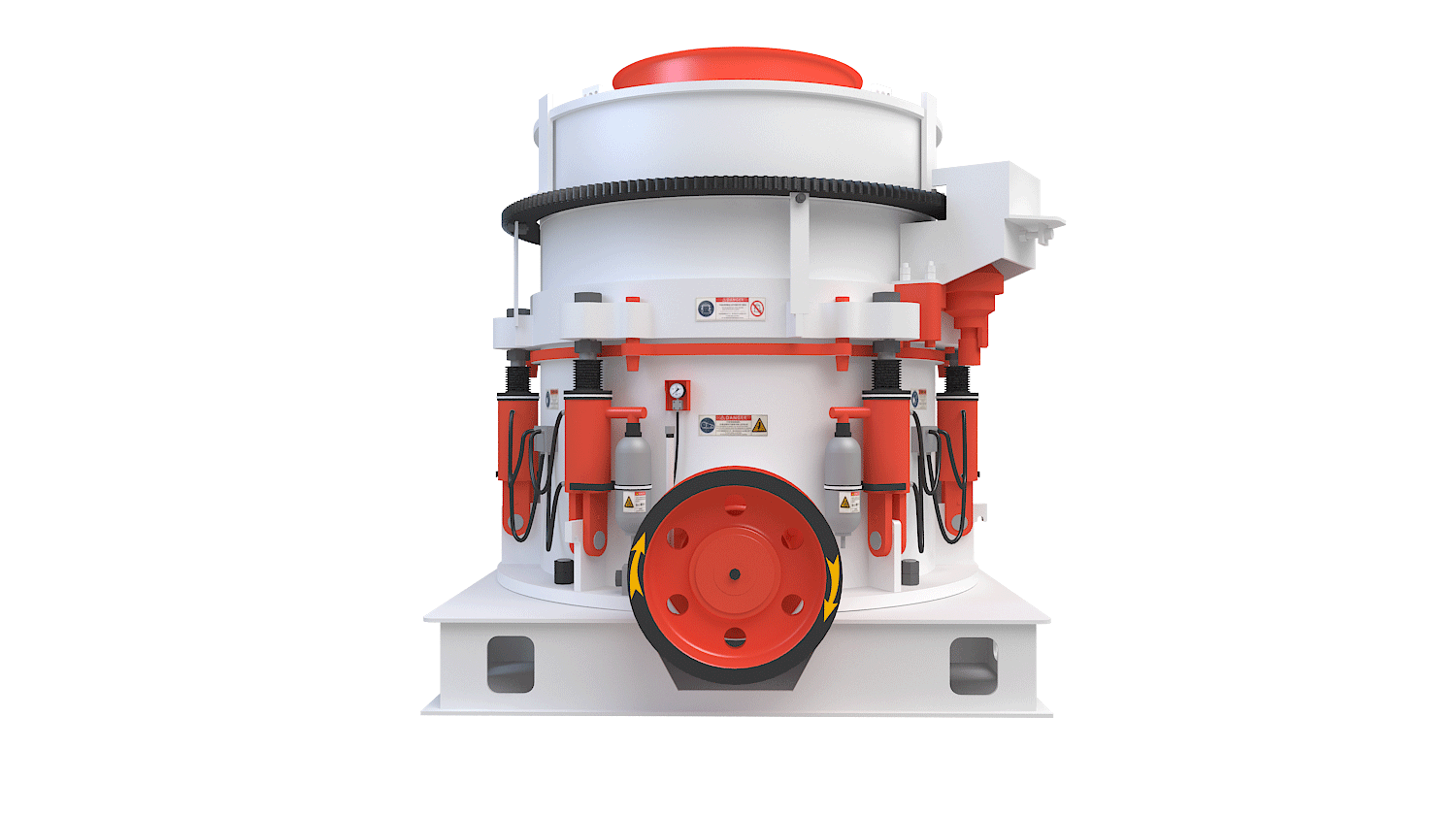

Multi-Cylinder Hydraulic Cone Crusher features an advanced multi-cylinder hydraulic system that enables precise control and automatic adjustment of the crushing chamber, ensuring stability and high efficiency during operation. Designed with a robust crushing cone and wear-resistant materials, it effectively handles hard ores such as granite, basalt, and iron ore. The crusher offers advantages such as a large crushing ratio, high output, low energy consumption, and simple operation. Its hydraulic system provides overload protection and rapid discharge, significantly improving work efficiency and equipment safety. With a compact structure and small footprint, it is easy to install and maintain. This crusher is widely applied in mining, construction waste recycling, metallurgy, and cement production. Its excellent performance and stable operation have made it a preferred choice for many mining enterprises and engineering projects, representing an essential piece of equipment for modern, efficient ore crushing.