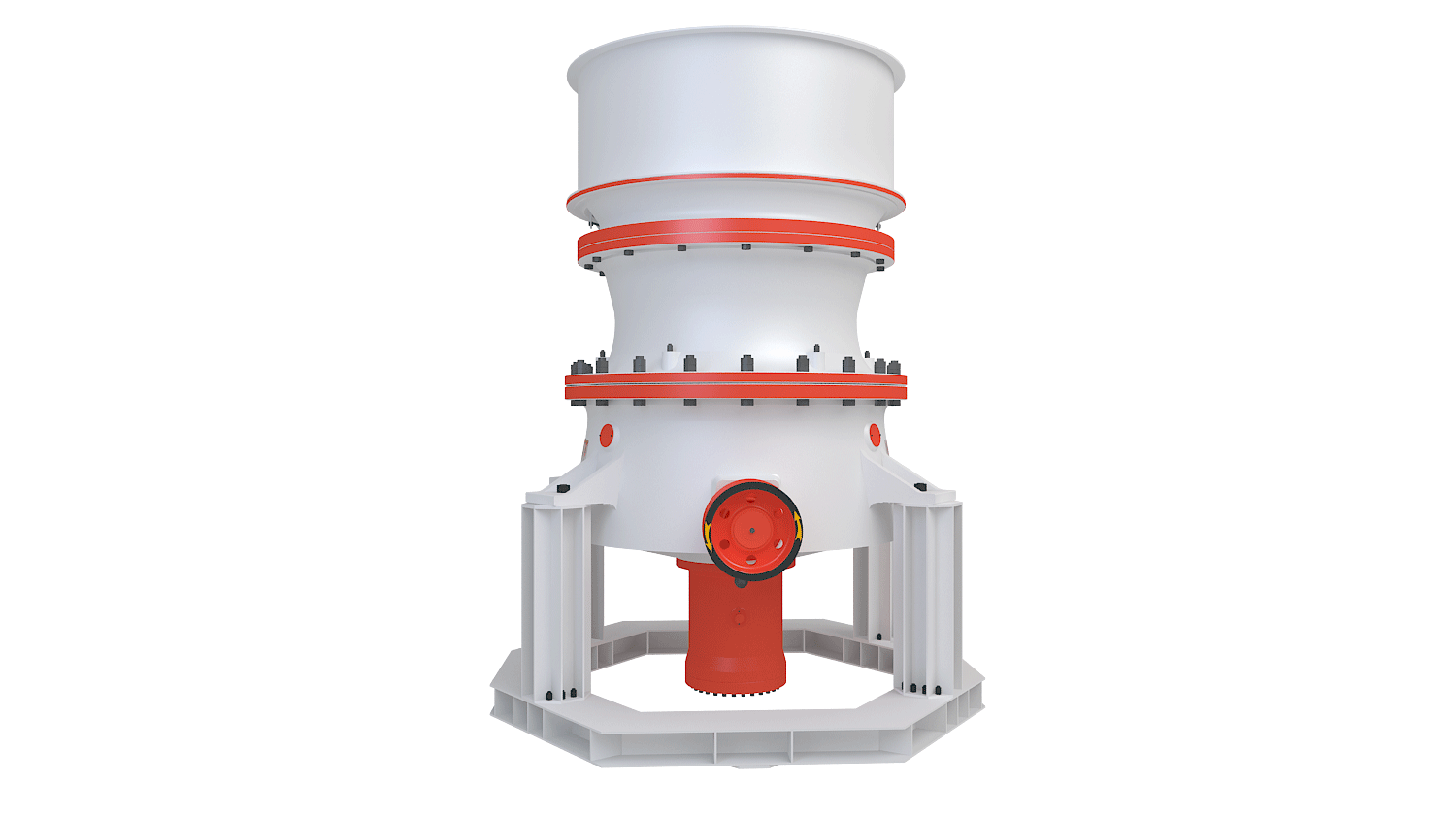

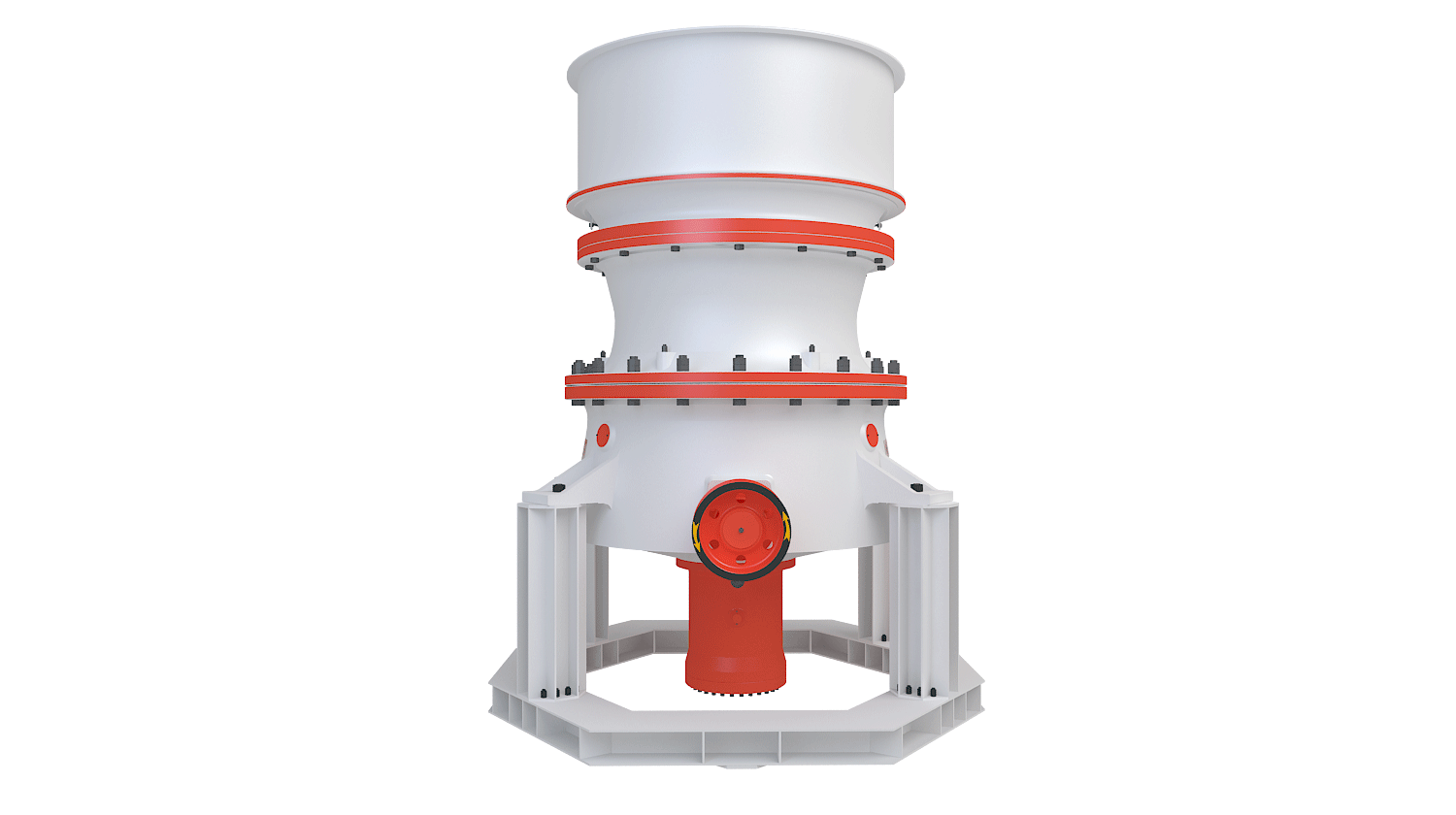

| Model | Type | Feed port (mm) |

Max feed size (mm) |

Discharge port size (mm) |

Motor power (kw) |

Weight (kg) |

Capacity (t/h) |

| GP100 | A | 150 | 120 | 7-39 | 90 | 5800 | 35-135 |

| B | 130 | 105 | |||||

| C | 100 | 85 | |||||

| GP200 | A | 225 | 180 | 12-45 | 200-220 | 12700 | 85-350 |

| B | 150 | 120 | |||||

| C | 80 | 60 | |||||

| GP300 | A | 225 | 180 | 10-50 | 250-280 | 16700 | 140-490 |

| B | 150 | 125 | |||||

| C | 80 | 60 | |||||

| GP500 | A | 280 | 220 | 12-45 | 315-355 | 27000 | 245-715 |

| B | 150 | 125 | |||||

| C | 100 | 80 |

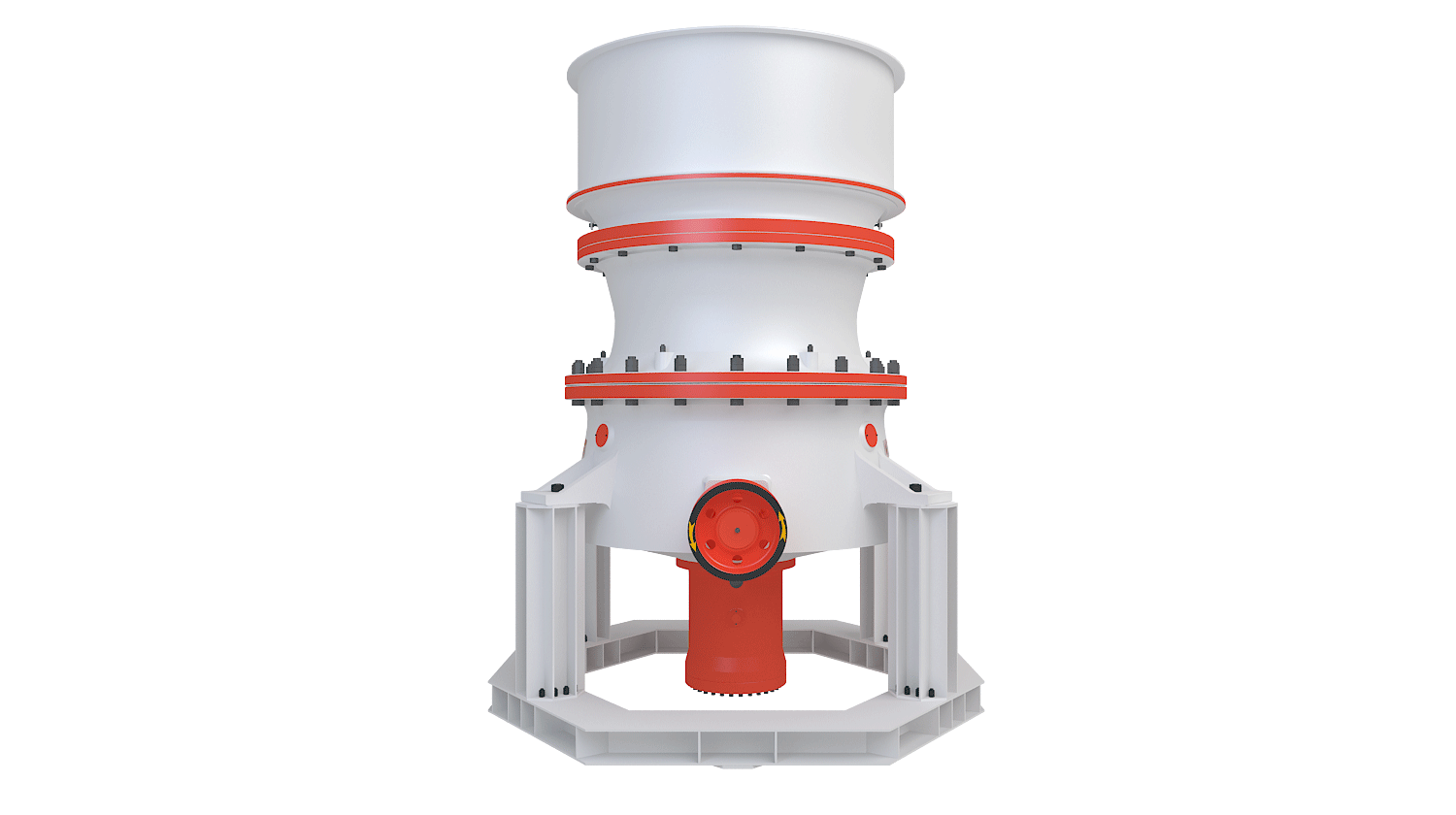

| Model | Type | Feed port (mm) |

Max feed size (mm) |

Discharge port size (mm) |

Motor power (kw) |

Weight (kg) |

Capacity (t/h) |

| GP100S | A | 320 | 250 | 35-100 | 75-90 | 9500 | 140-520 |

| B | 250 | 210 | |||||

| GP200S | A | 340 | 280 | 35-105 | 160-200 | 13400 | 160-610 |

| B | 250 | 210 | |||||

| GP300S | A | 380 | 320 | 35-100 | 220-250 | 18200 | 250-870 |

| B | 280 | 240 | |||||

| GP500S | A | 500 | 420 | 45-105 | 280-315 | 32700 | 300-1400 |

| B | 380 | 320 |