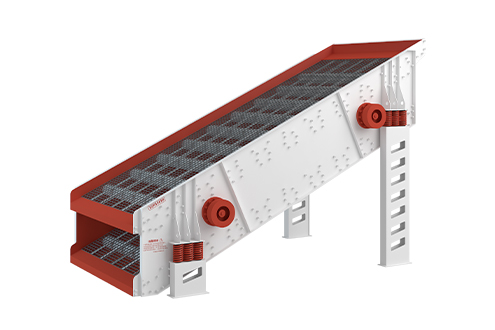

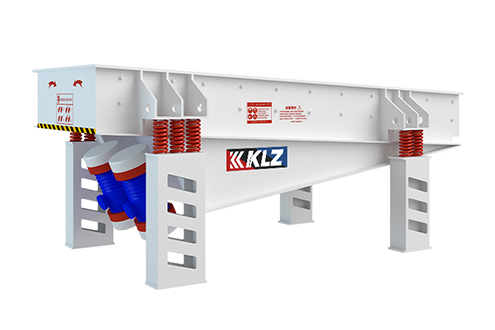

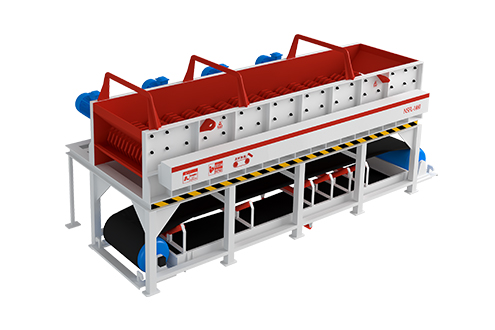

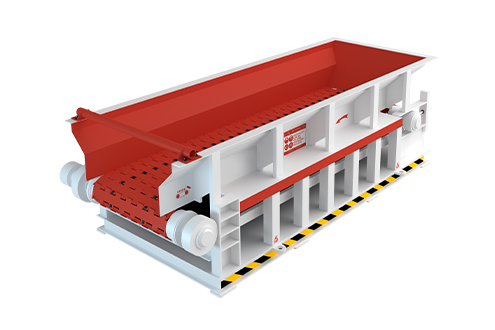

Vibrating Feeder

Vibrating Feeder is a feeding equipment designed to continuously and uniformly transport bulk materials to crushers, screens, or conveyors. Using vibration to move materials along a trough, it ensures smooth flow without clogging or surges. Widely used in mining, metallurgy, coal, construction, and chemical industries, Vibrating Feeder features simple structure, stable operation, and adjustable feeding capacity.