Introduction

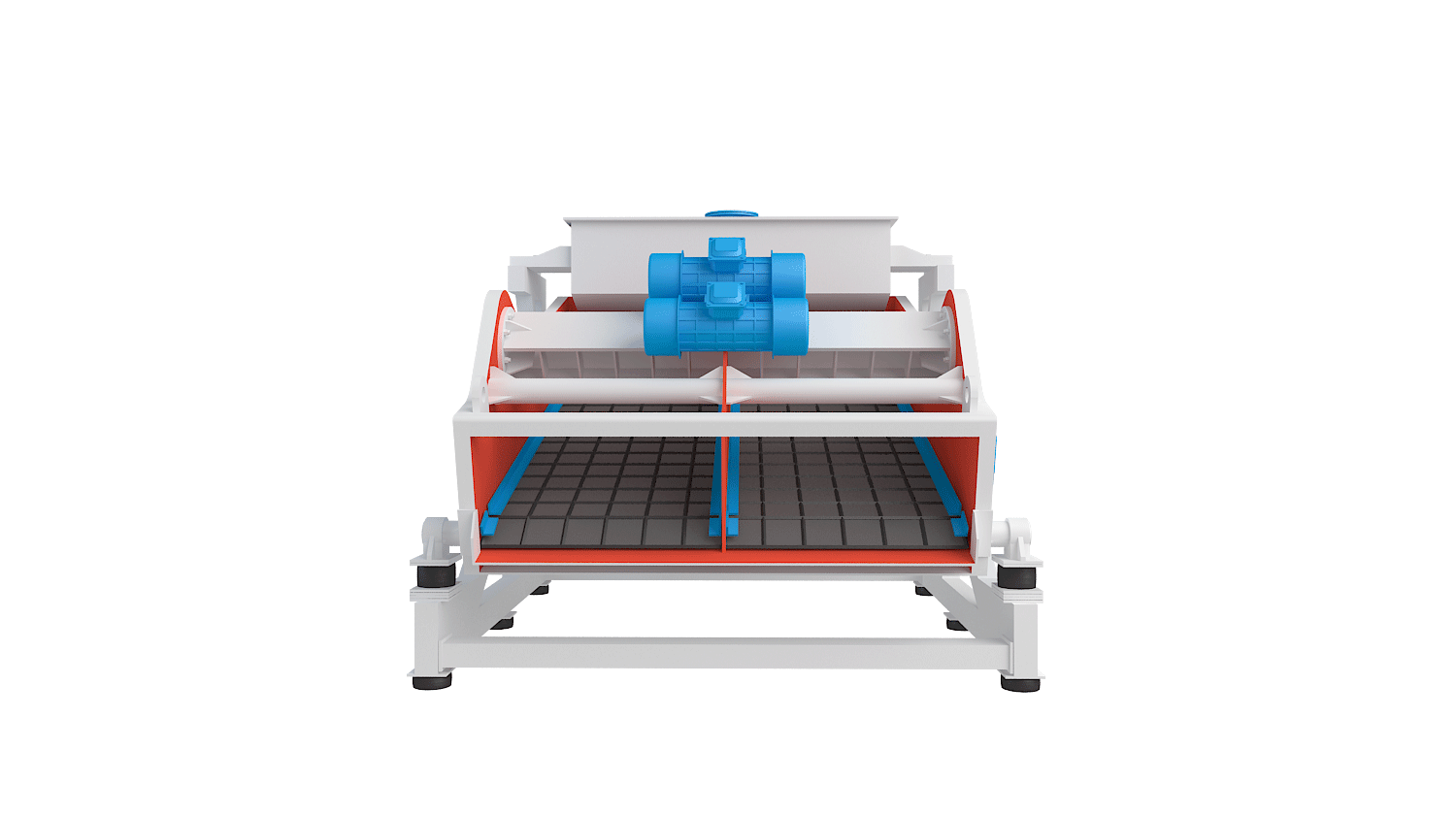

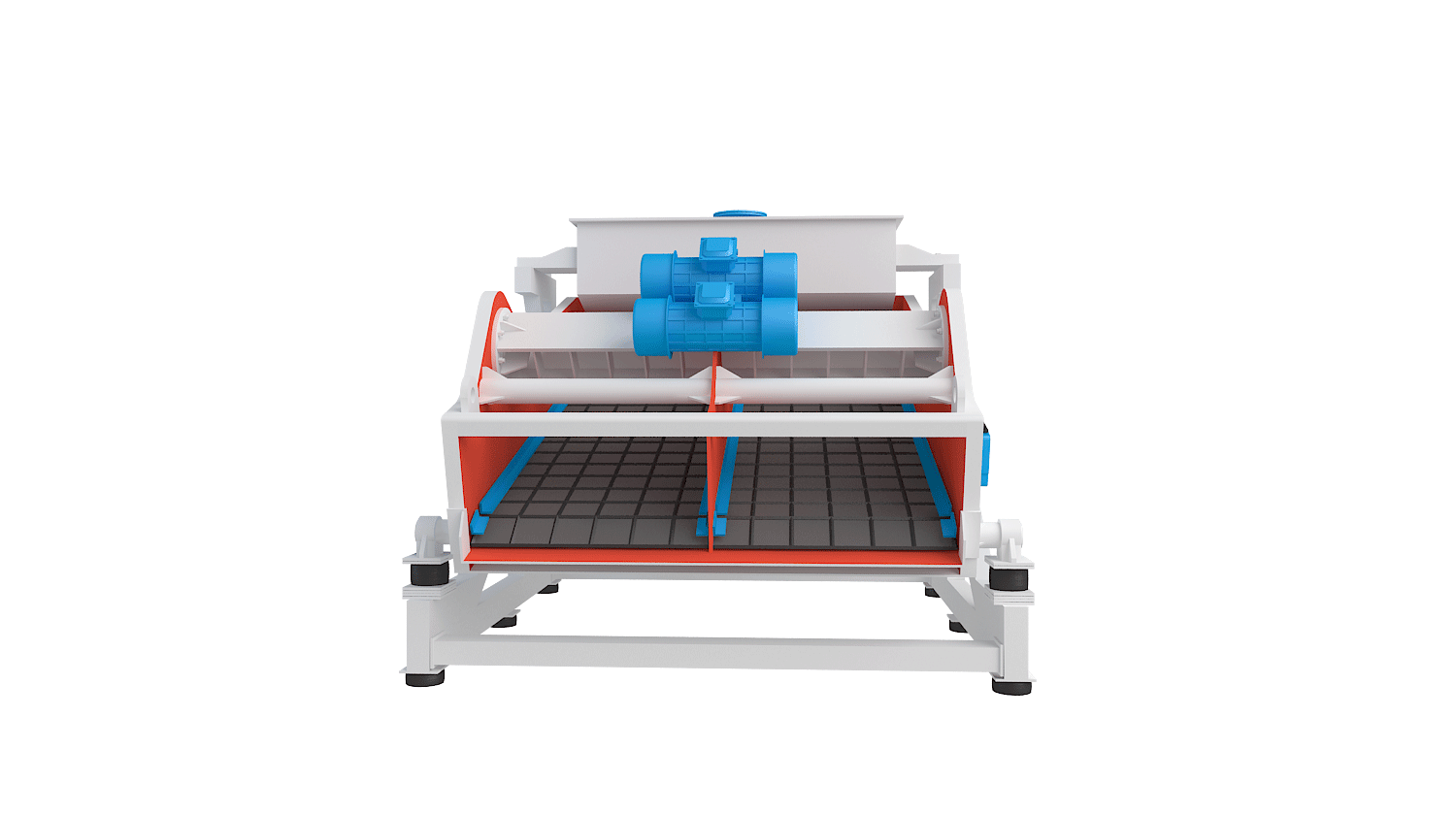

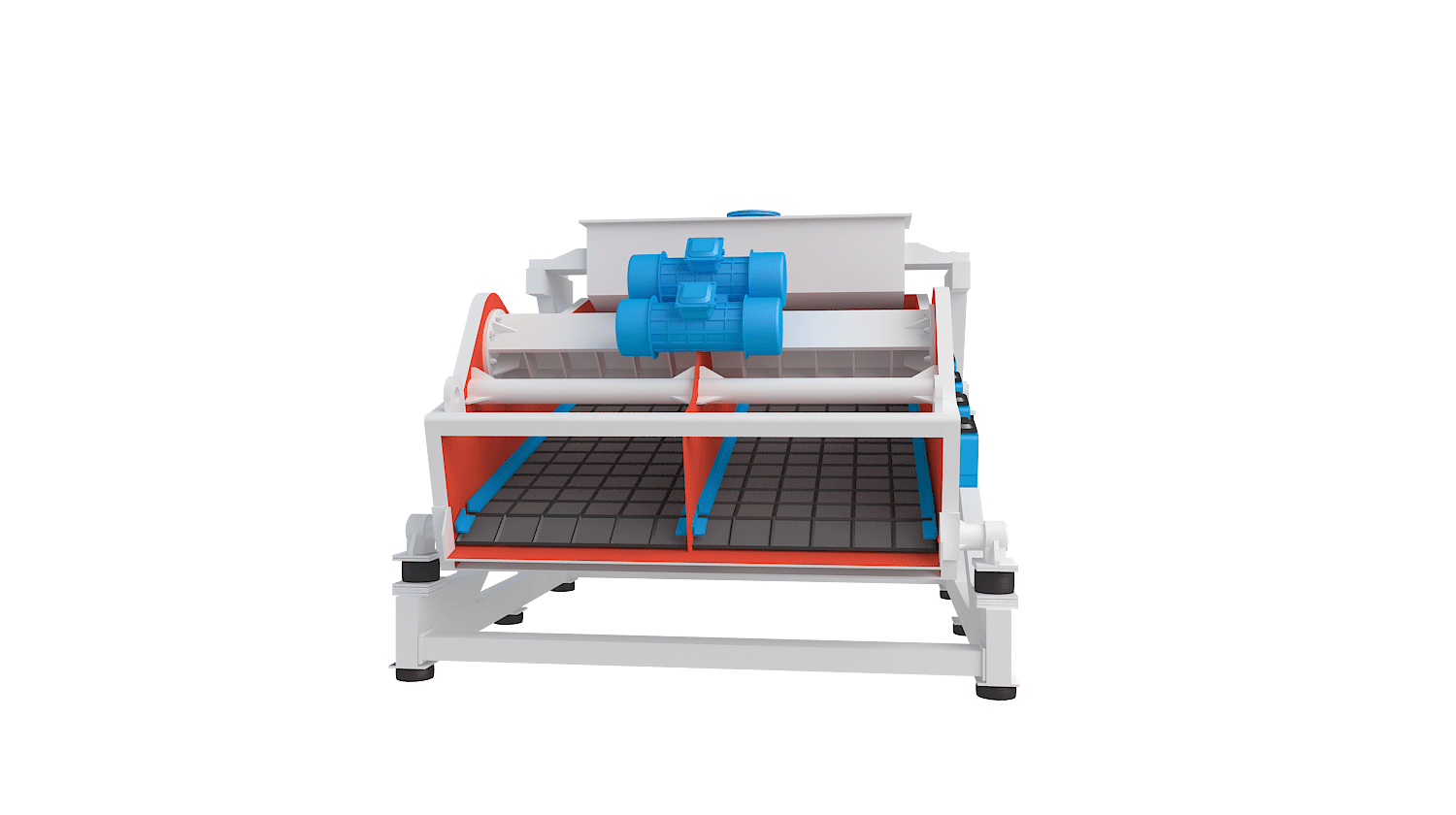

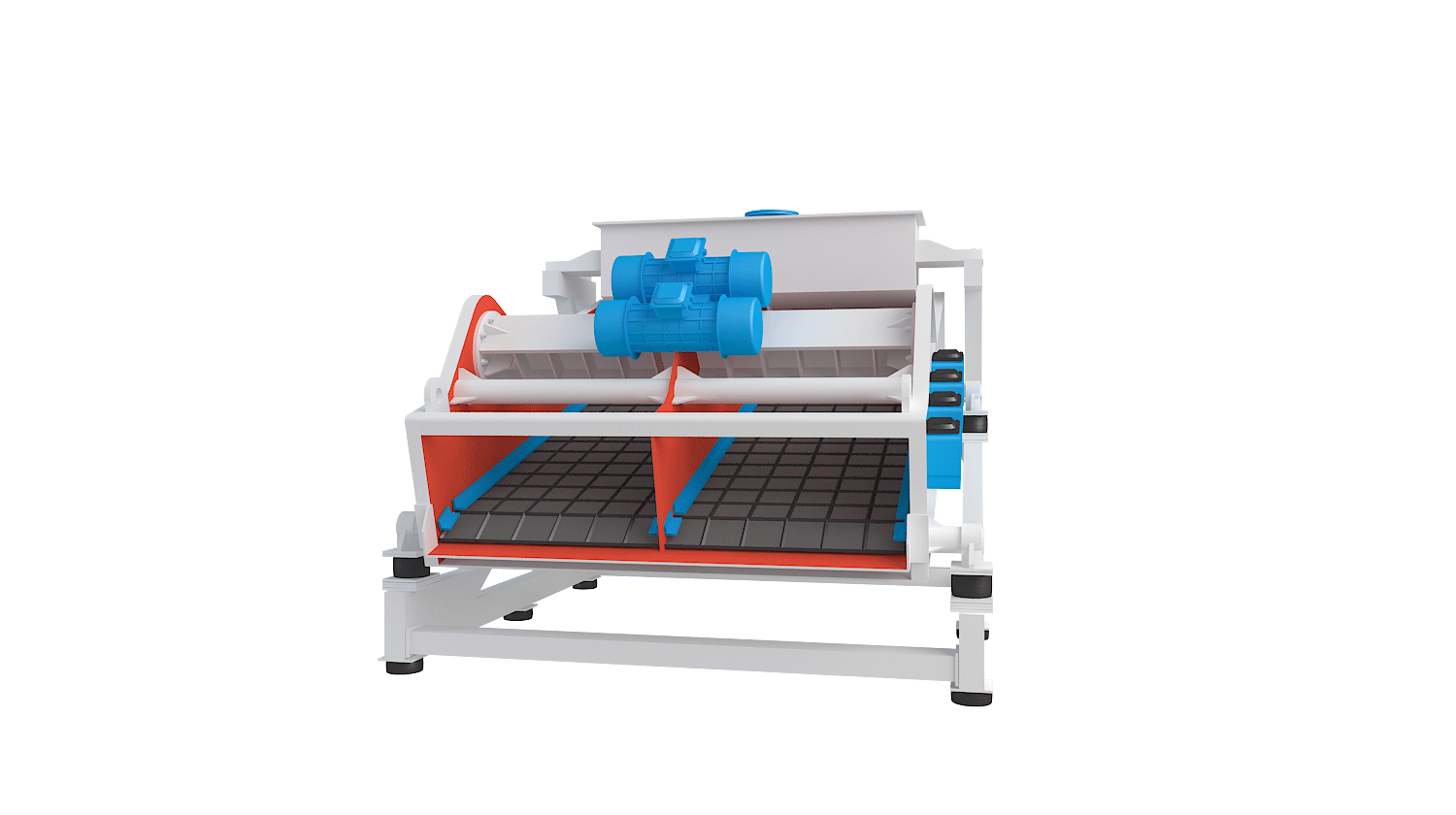

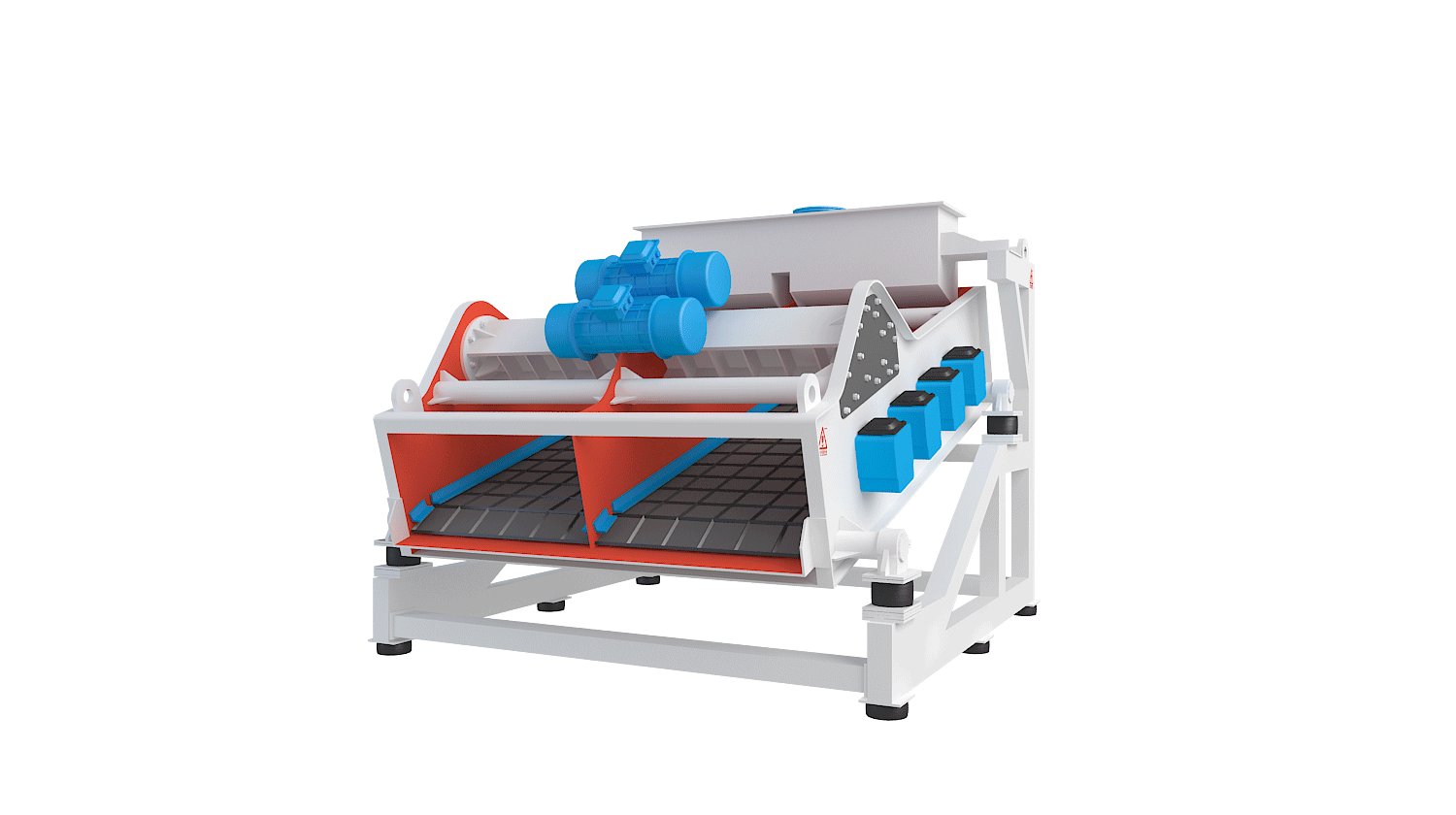

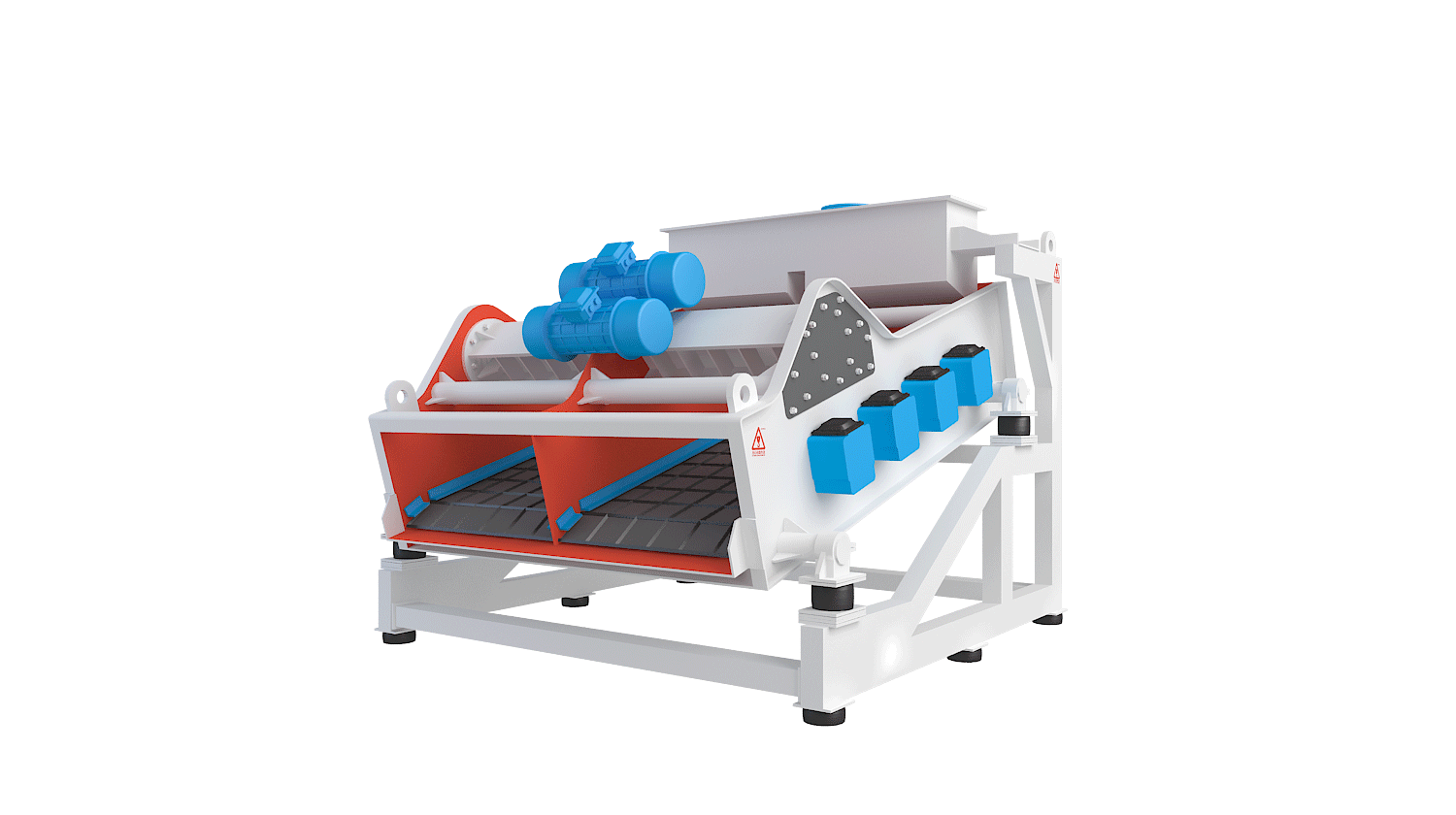

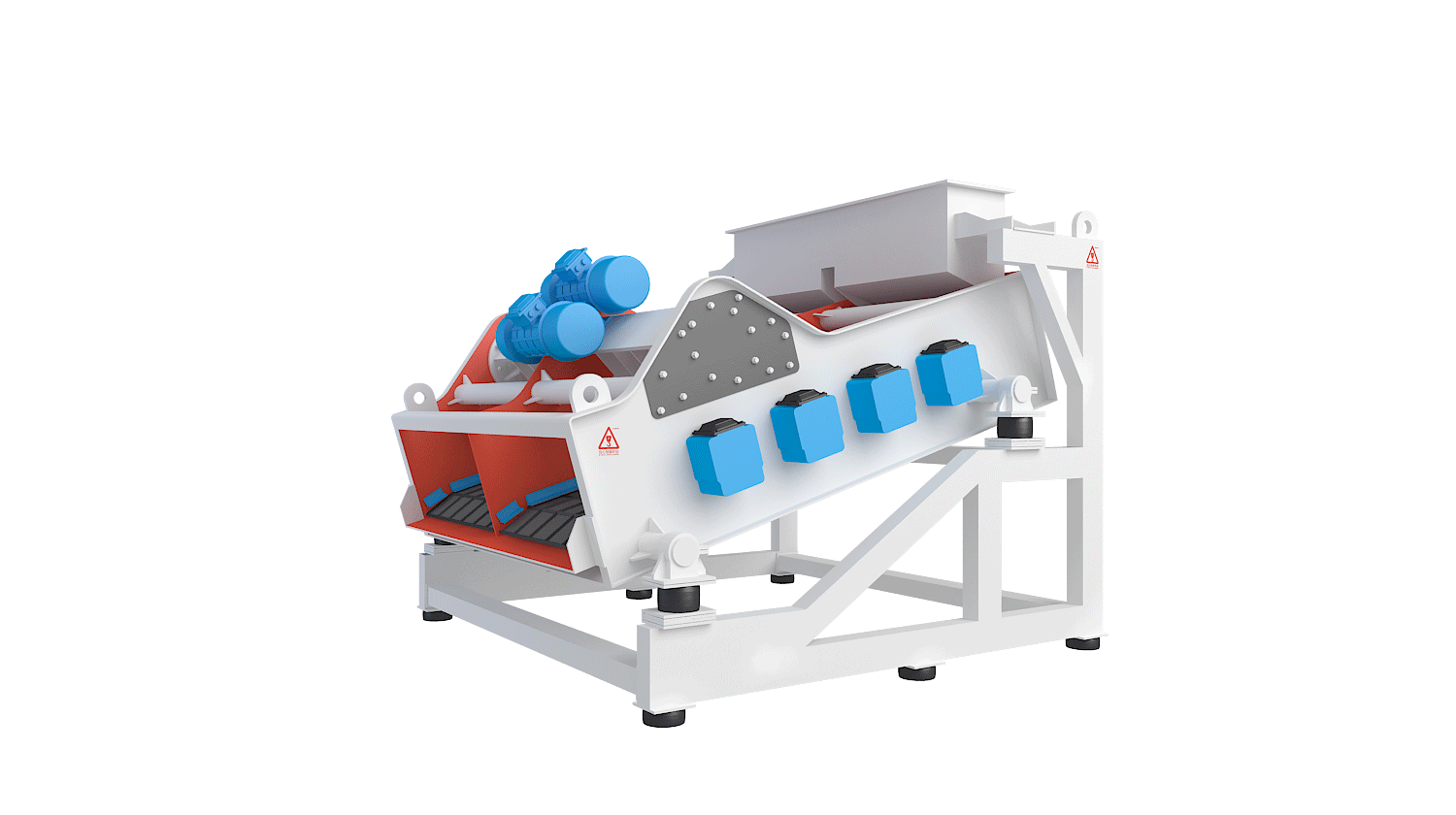

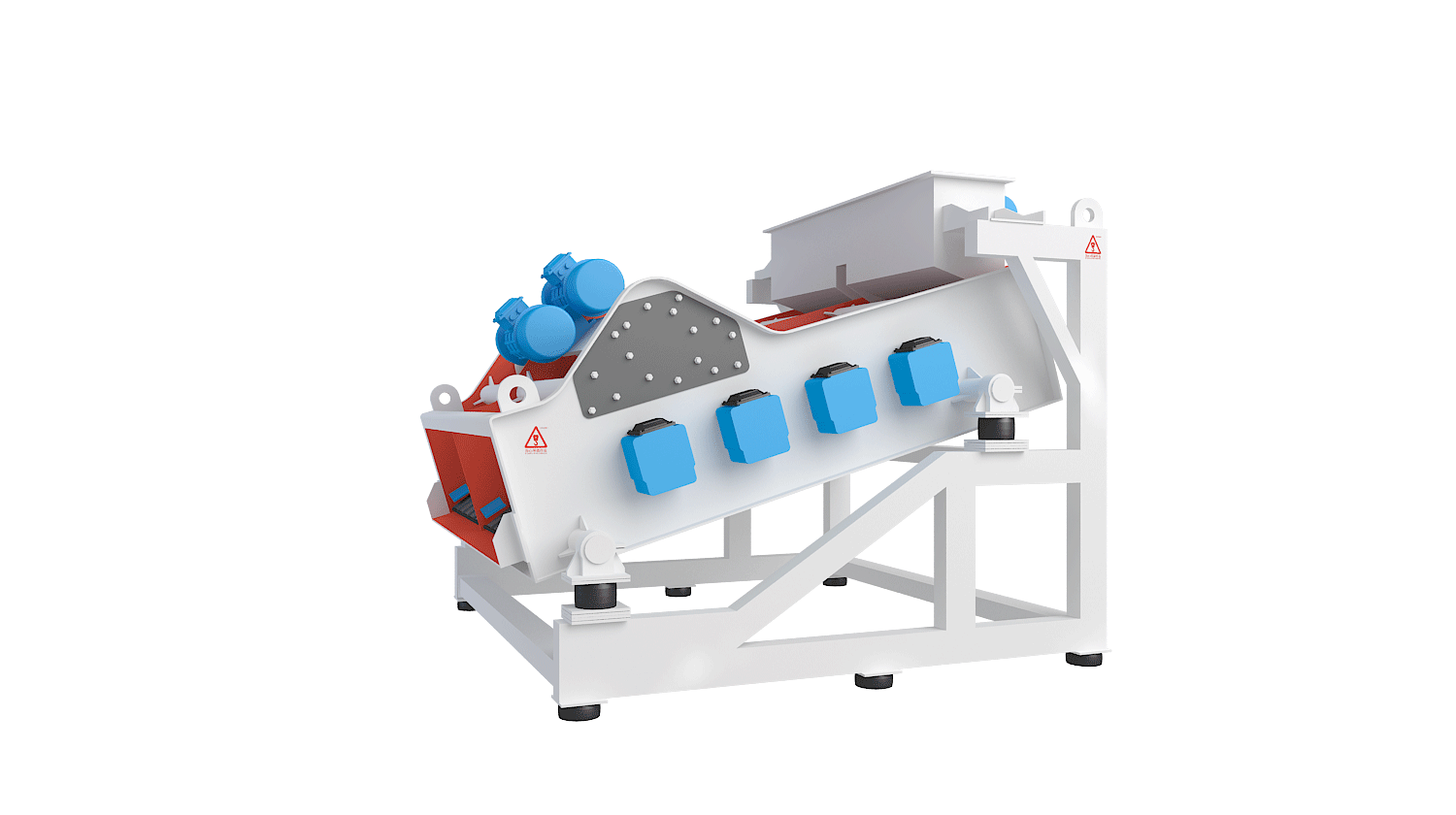

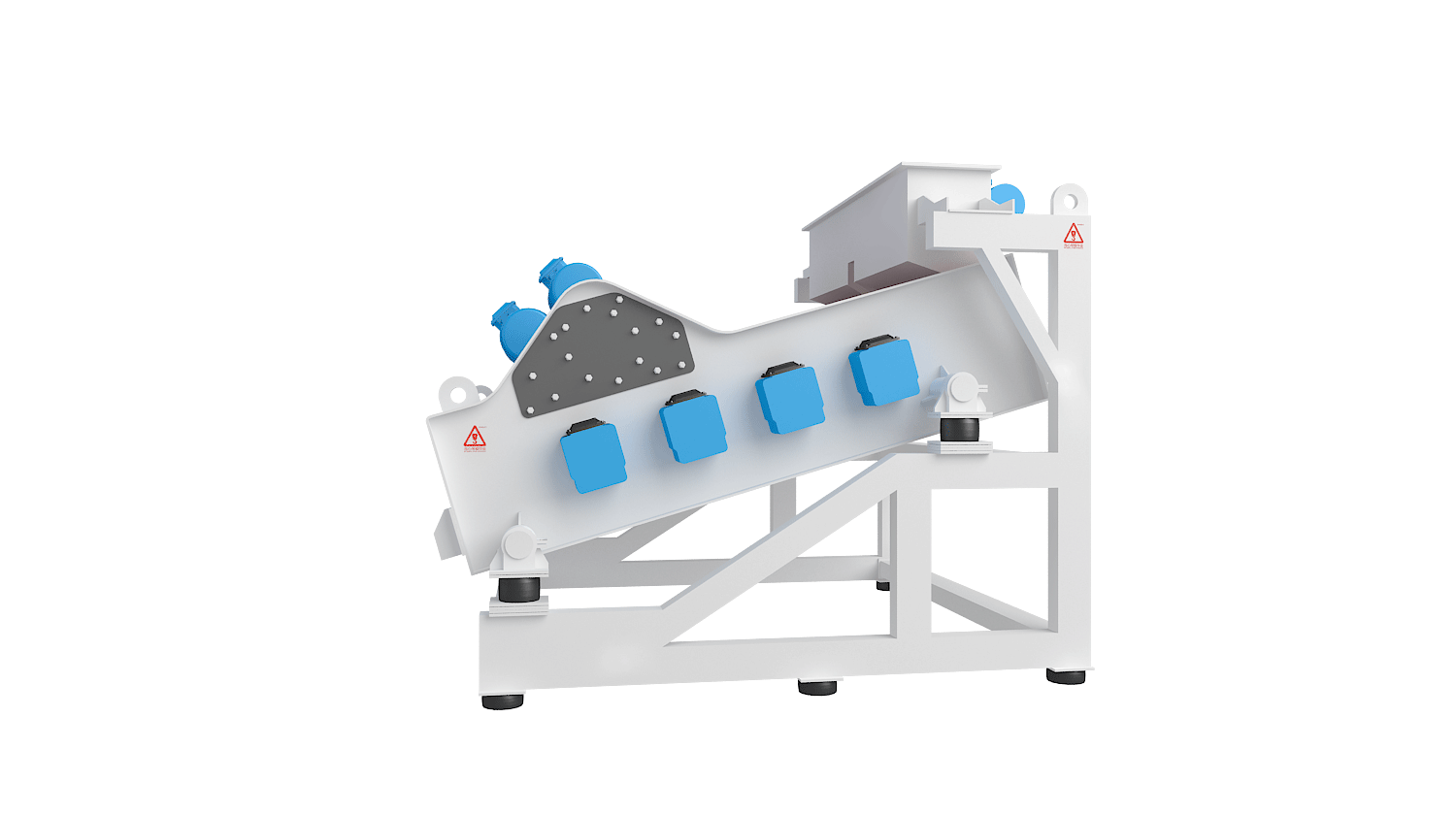

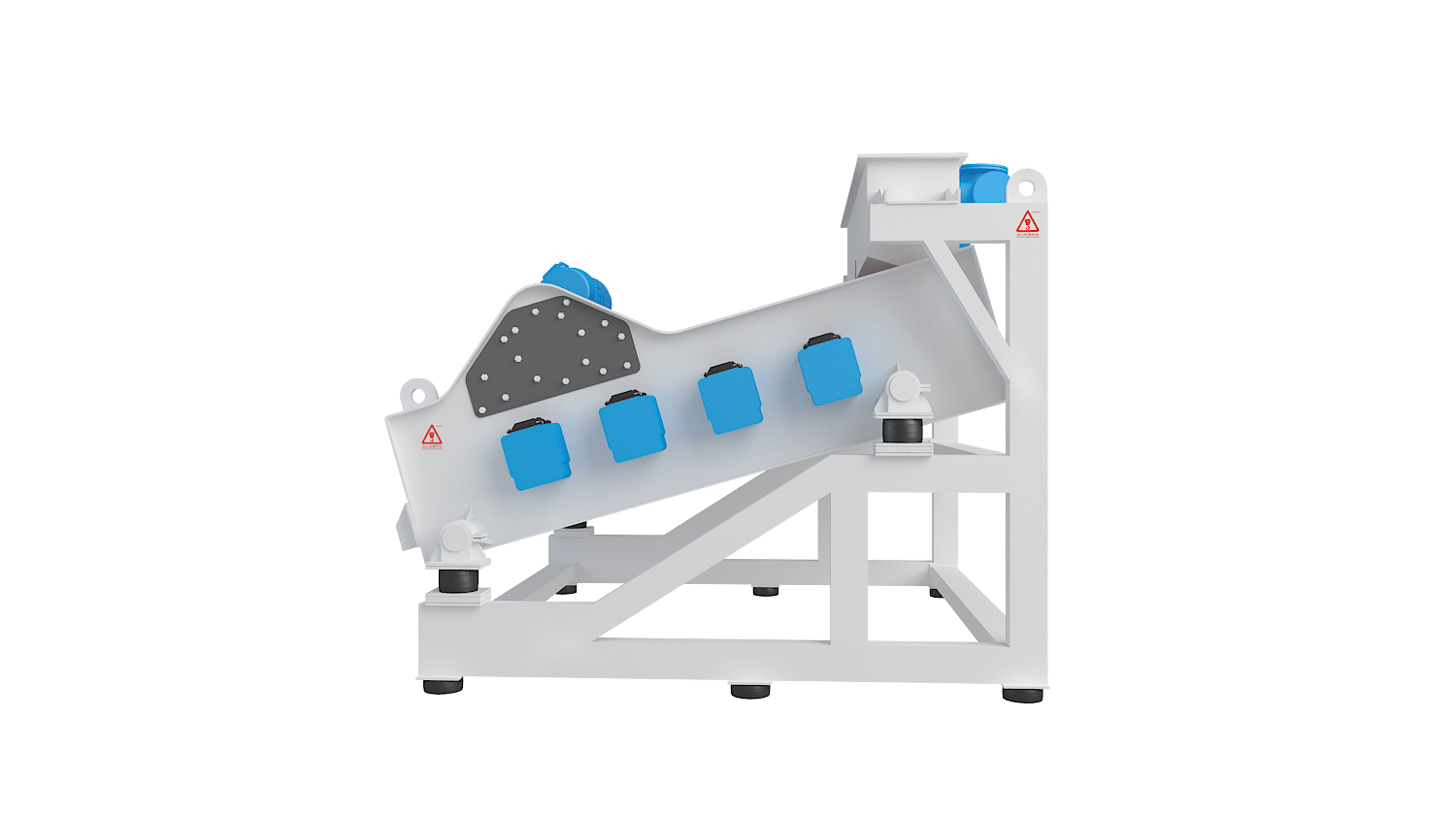

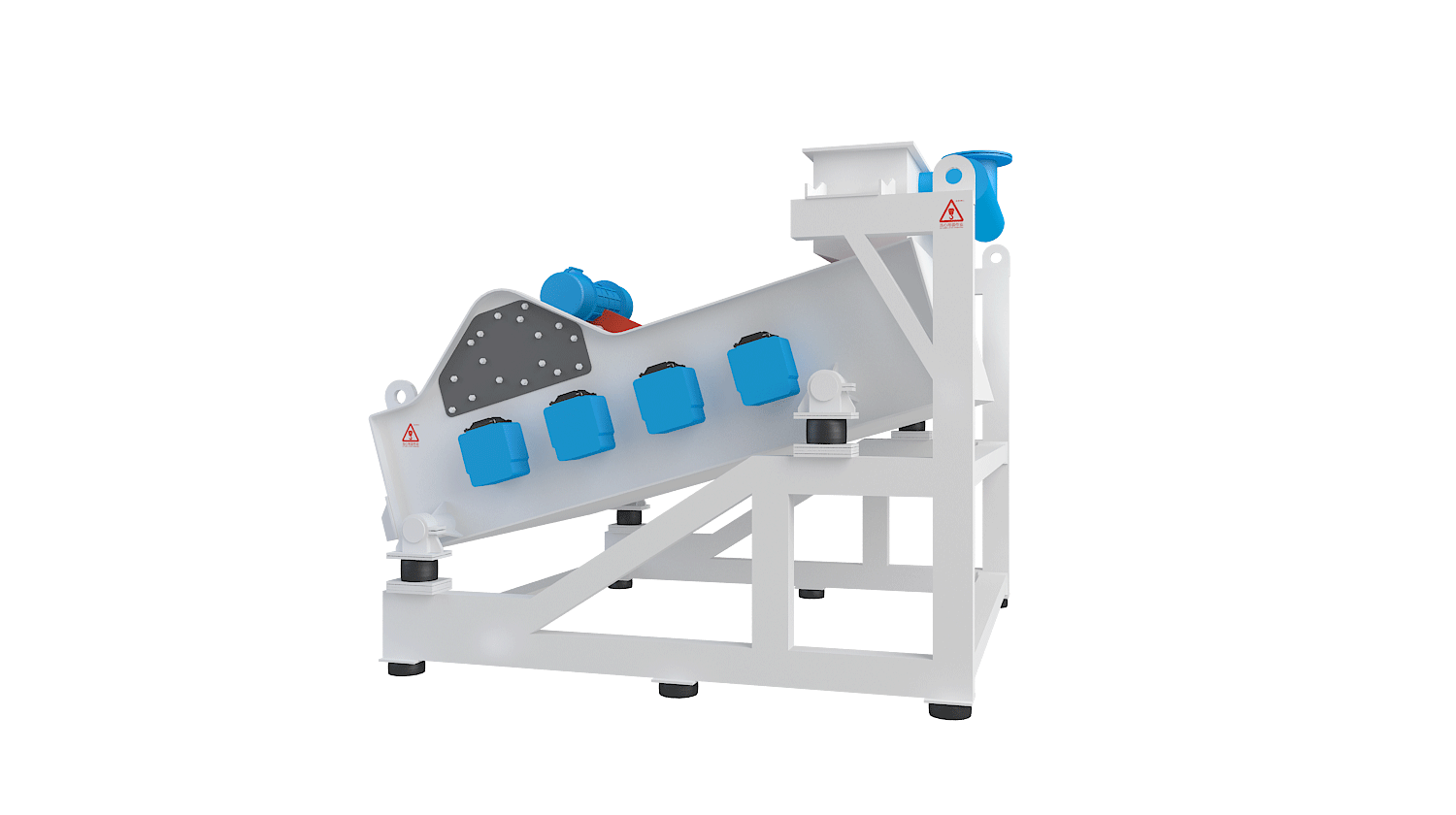

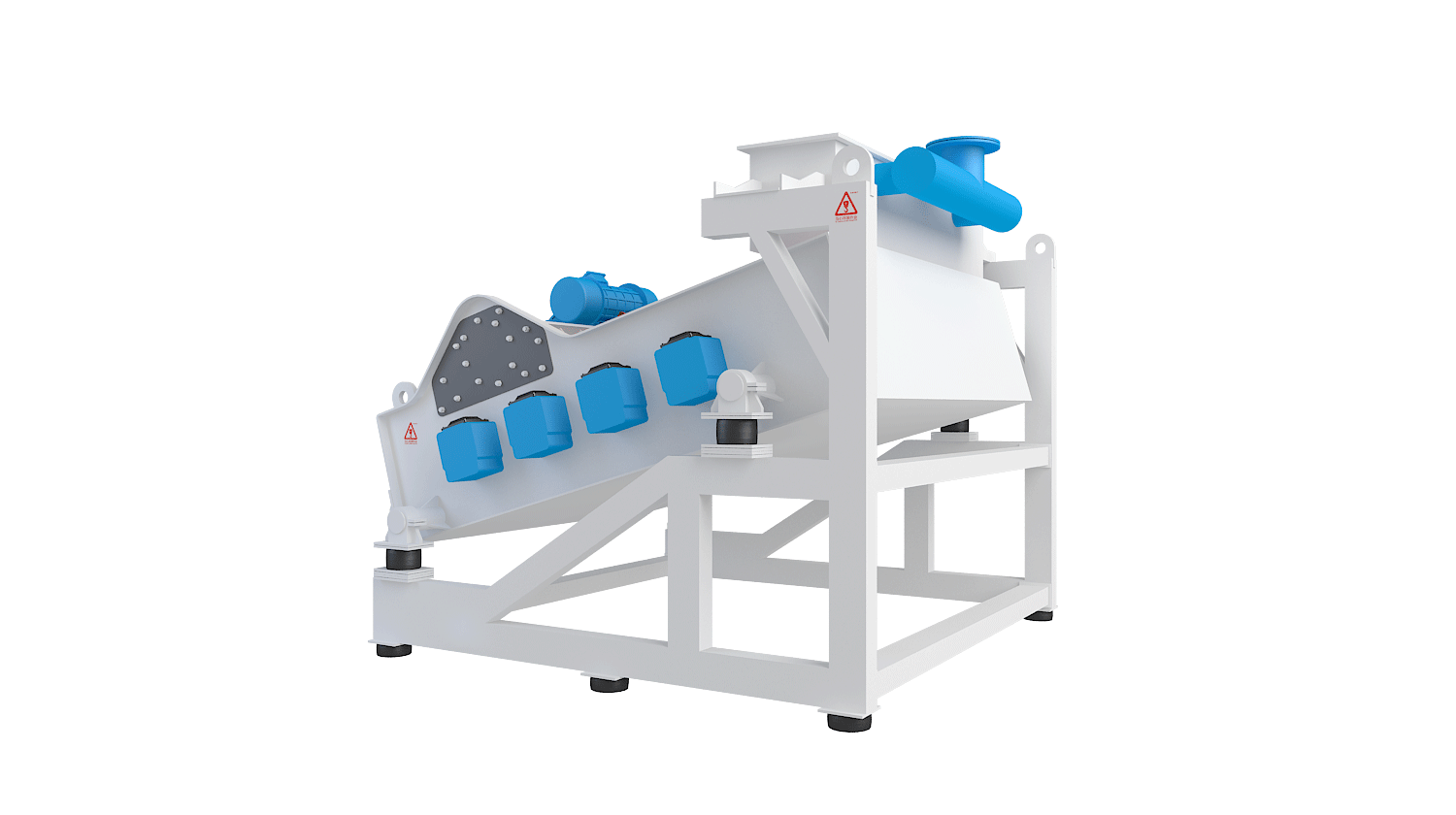

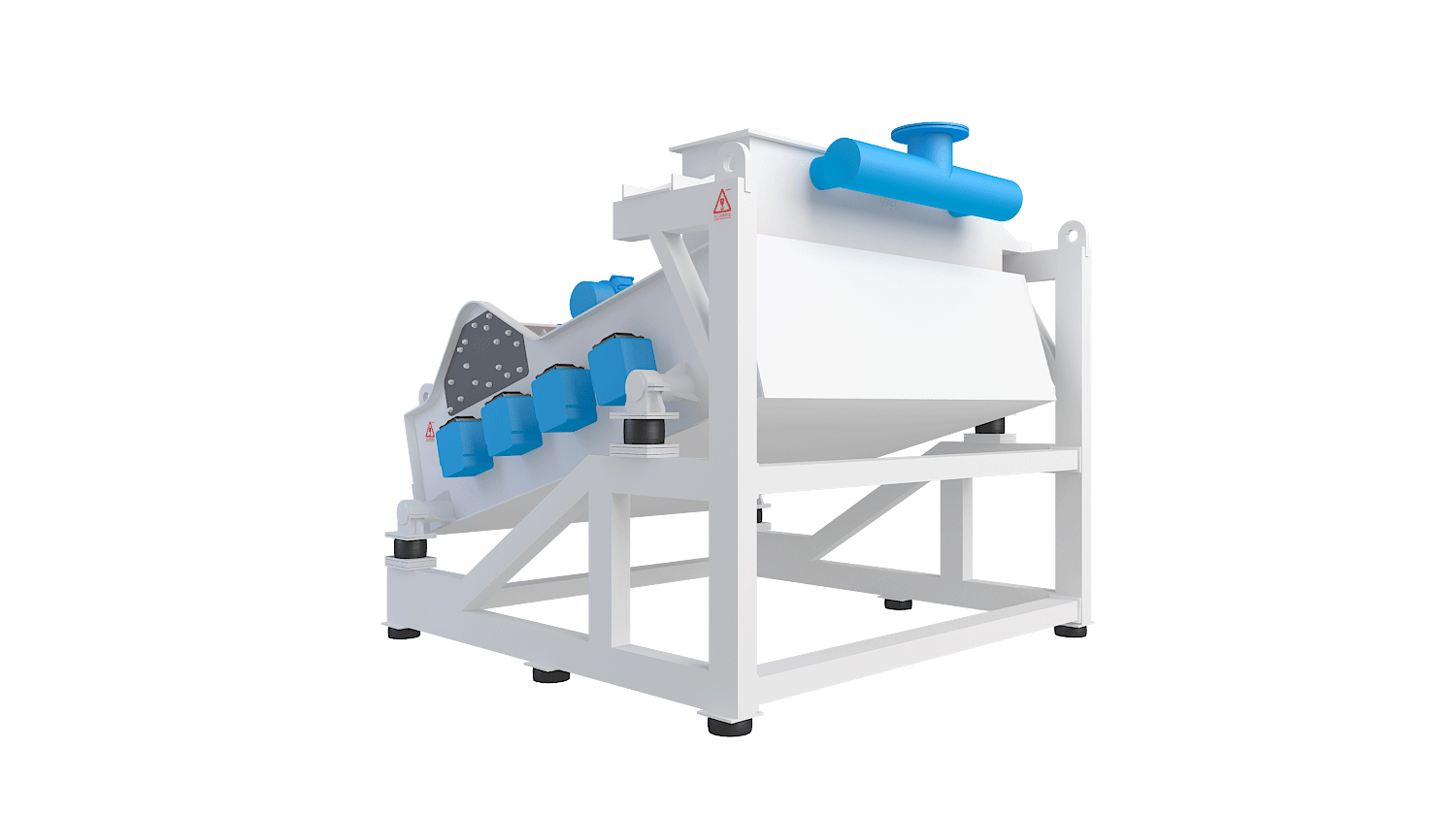

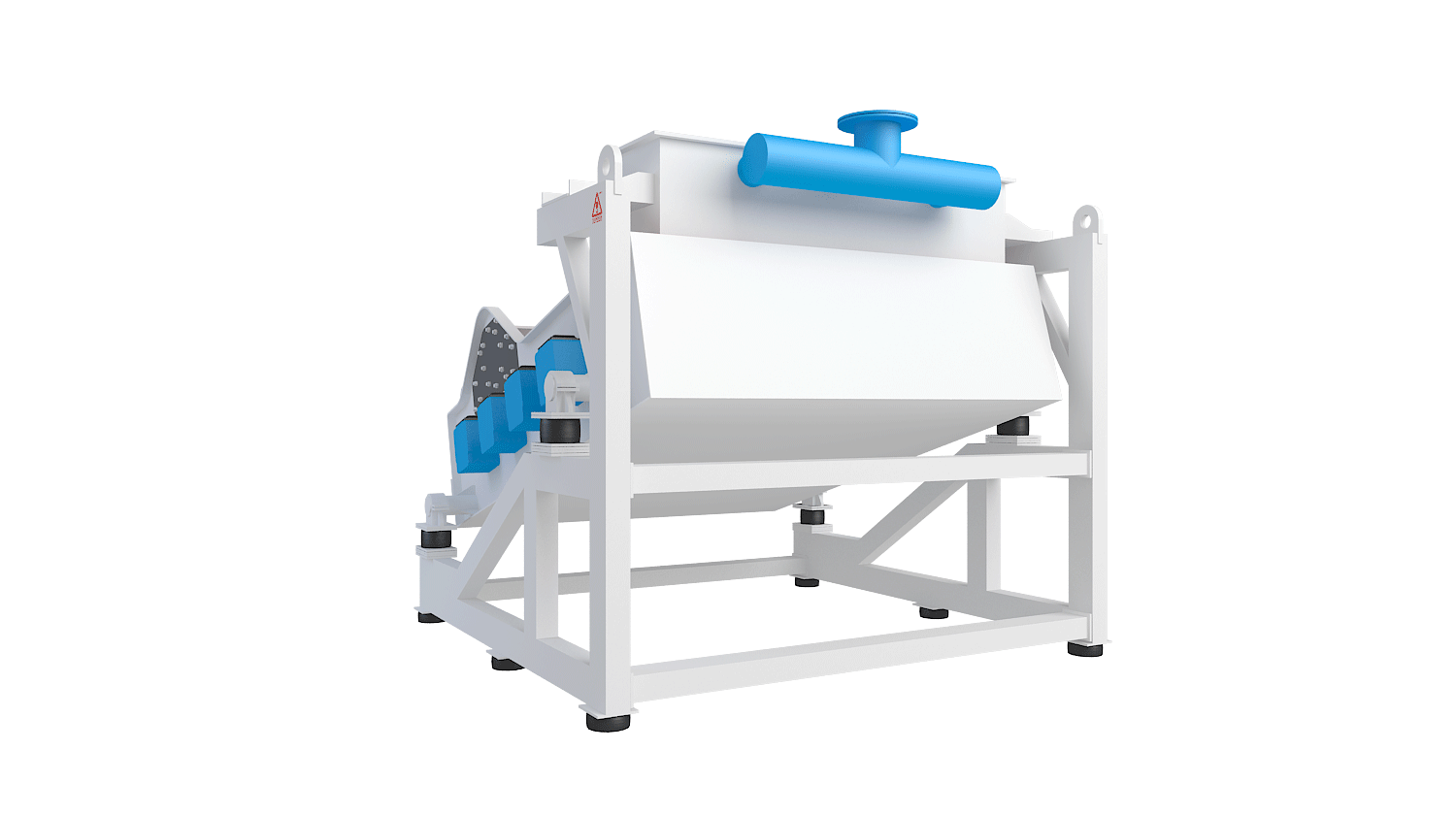

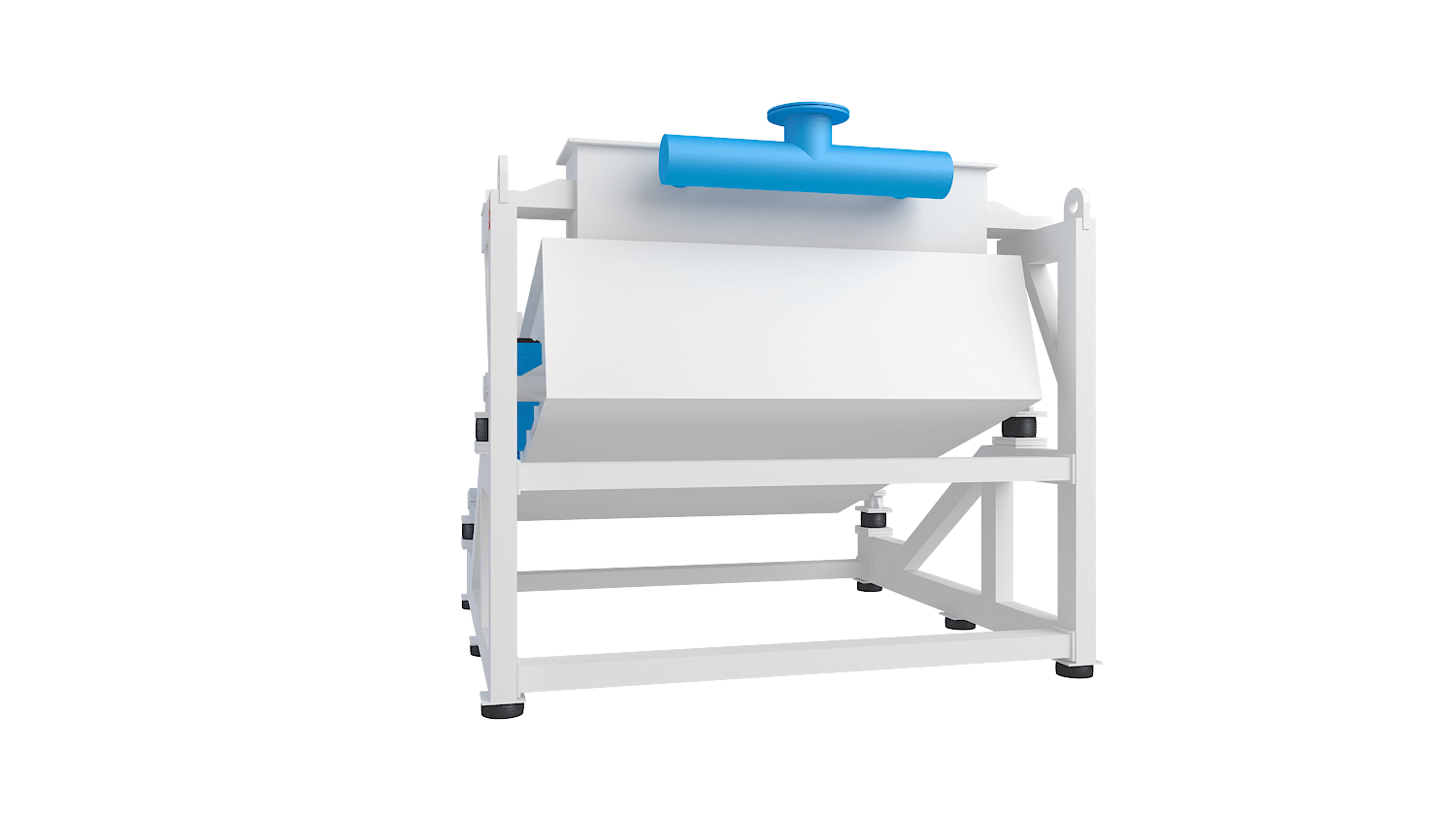

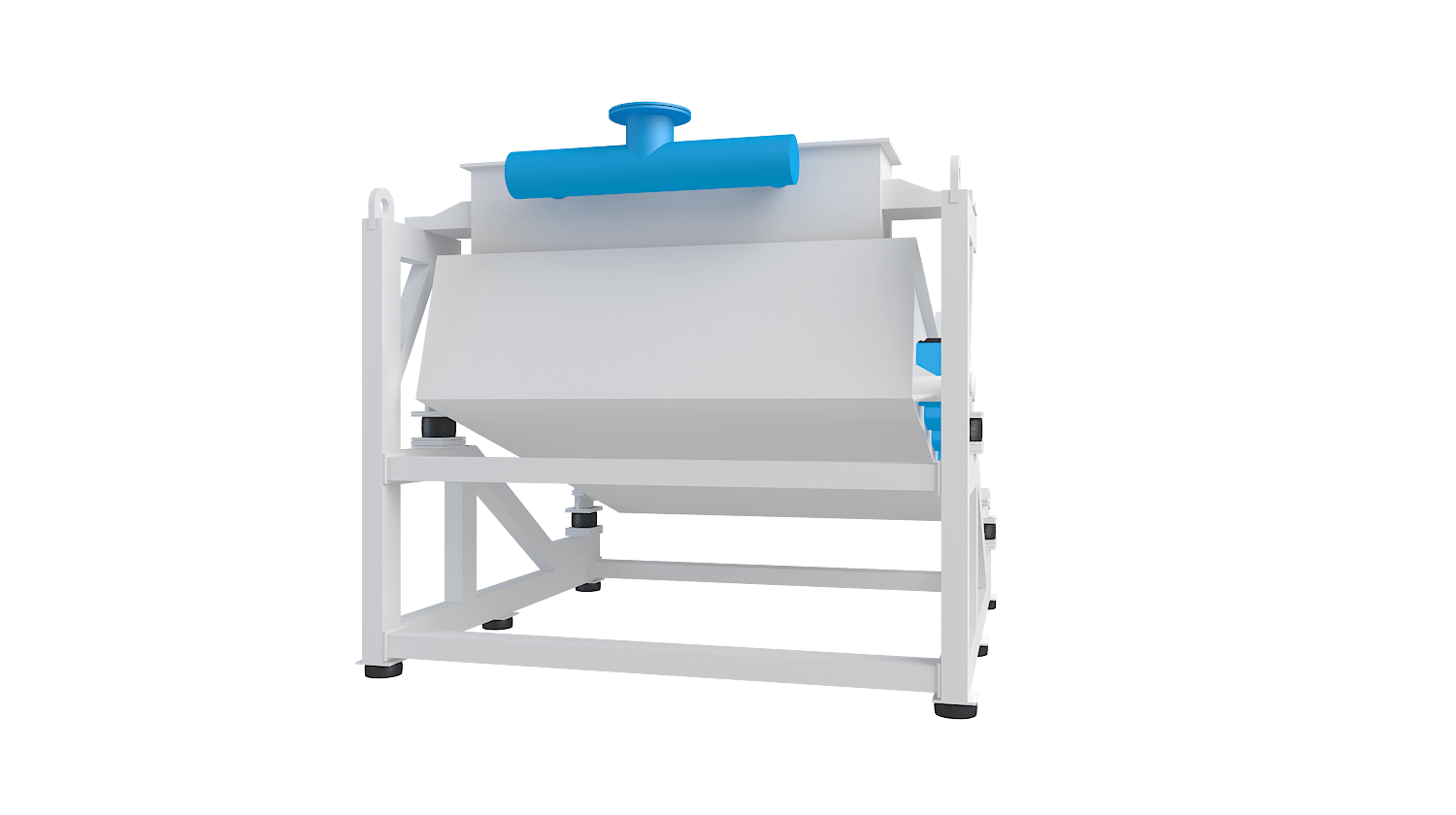

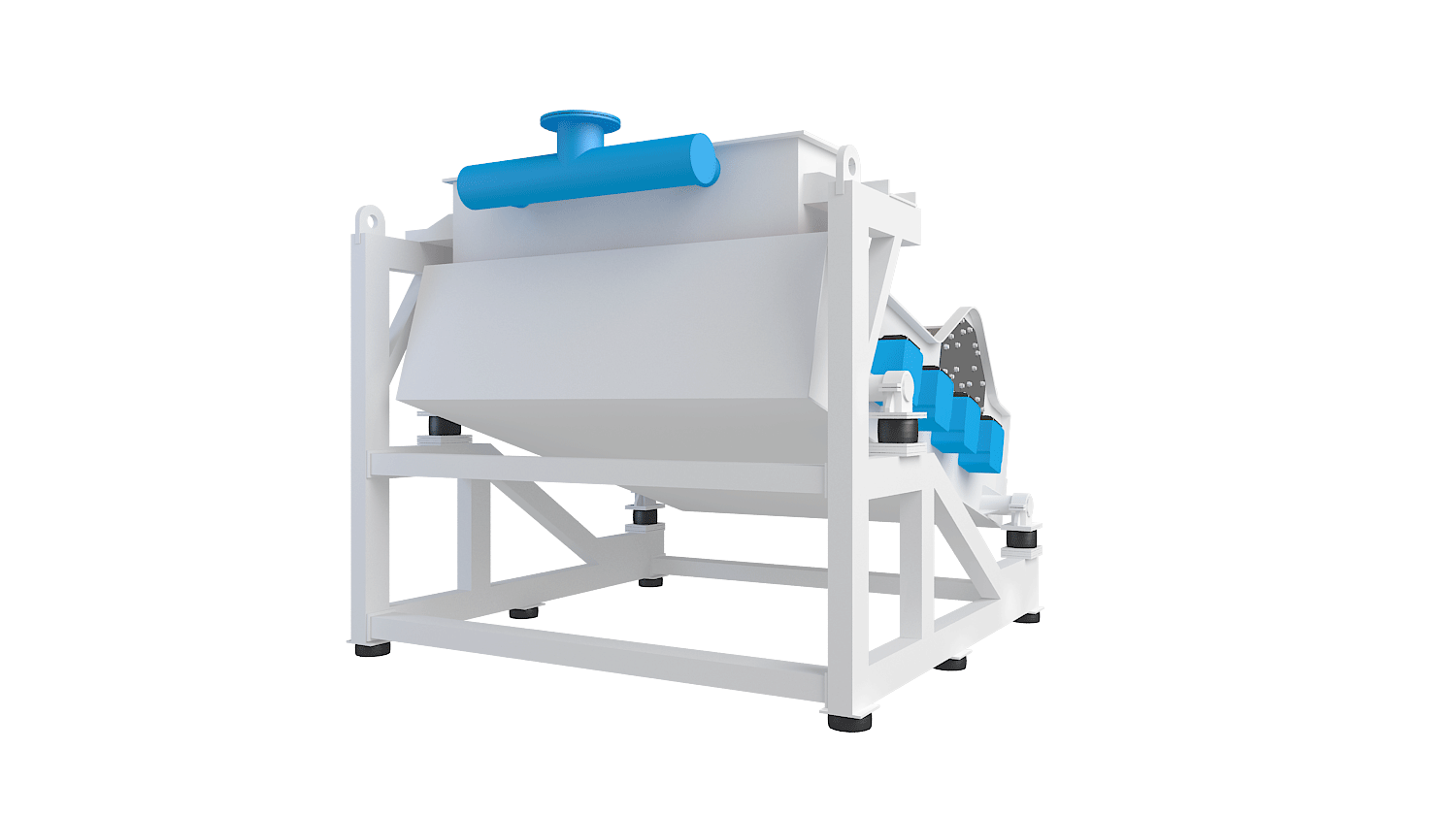

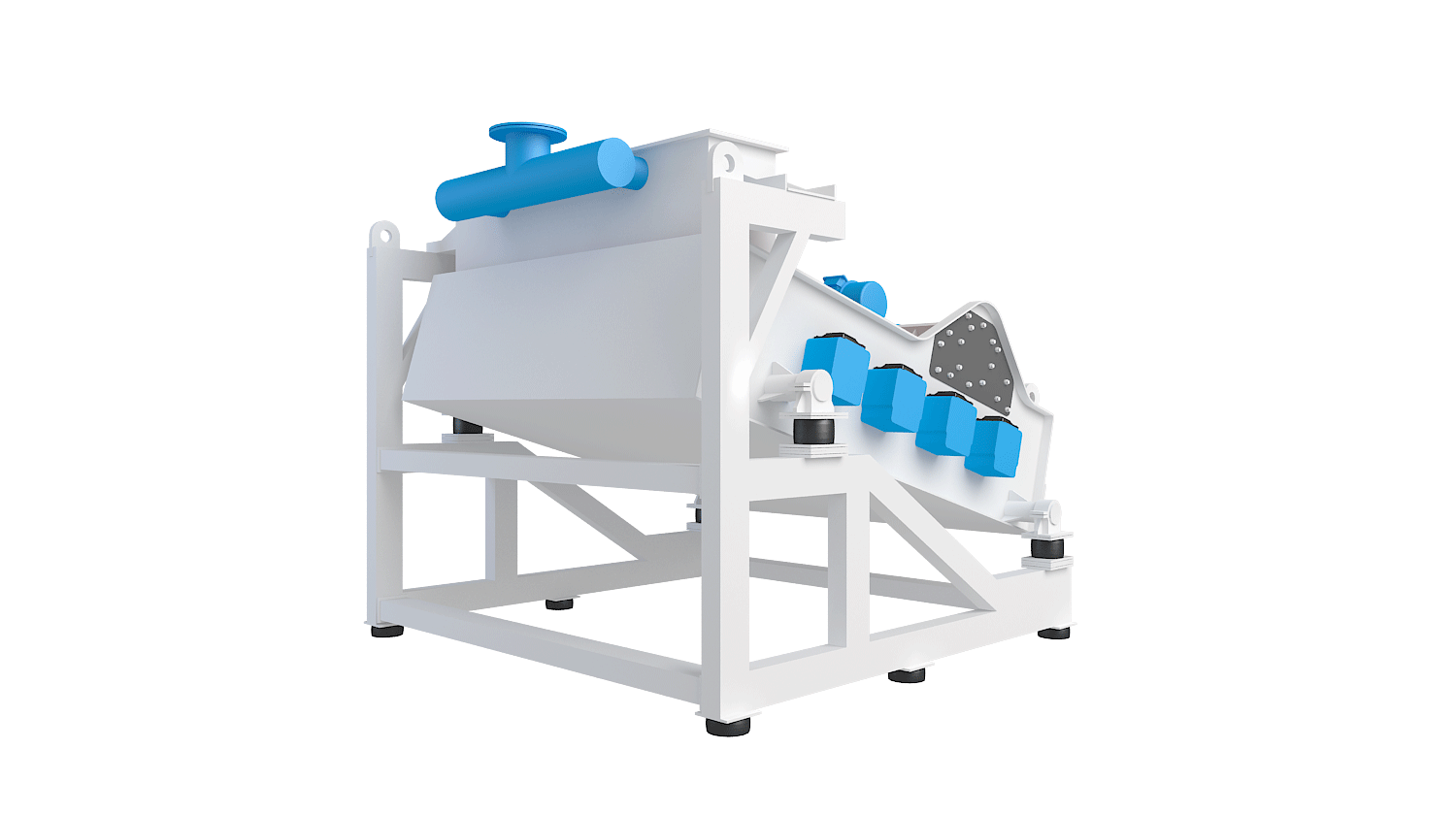

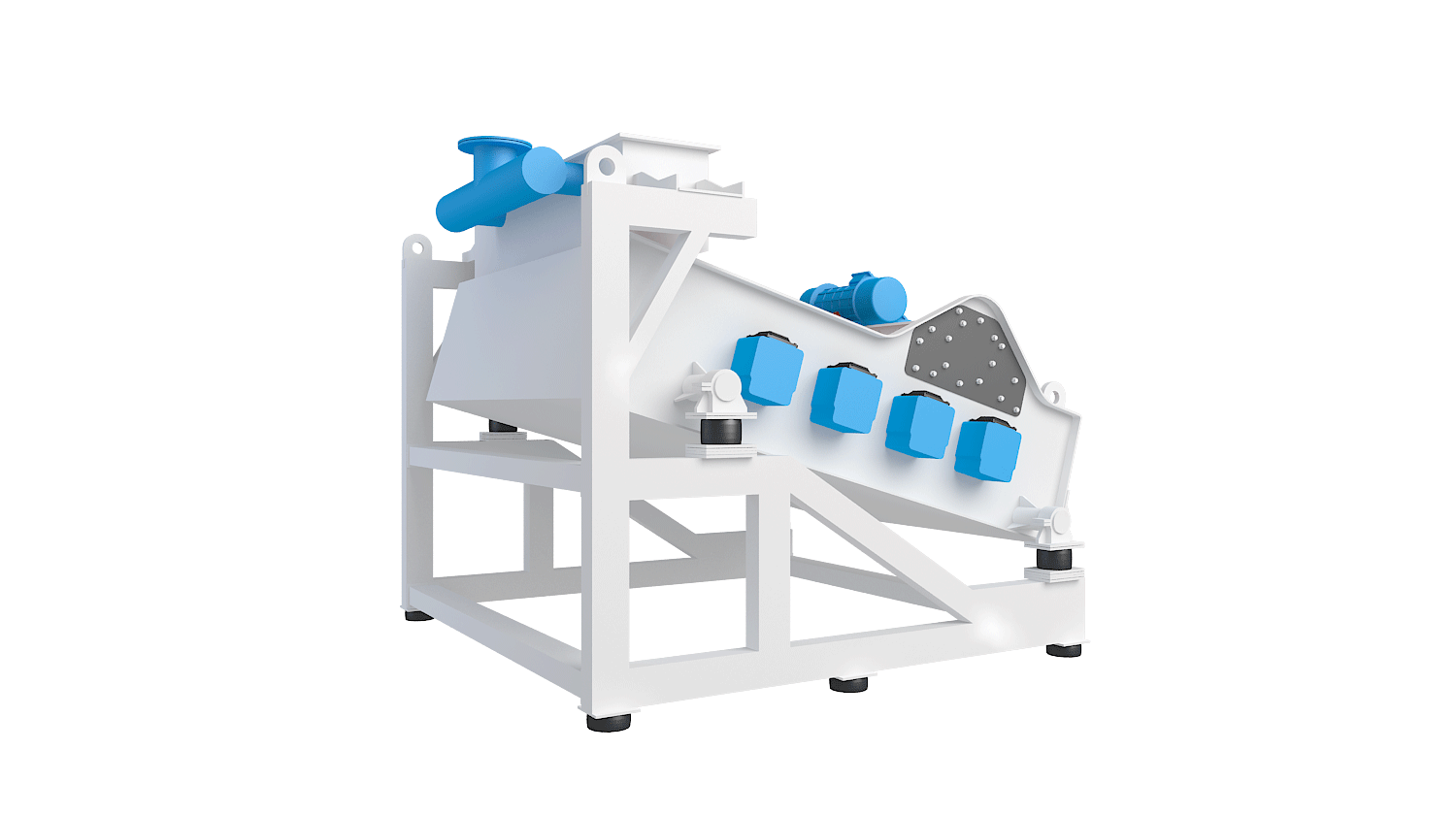

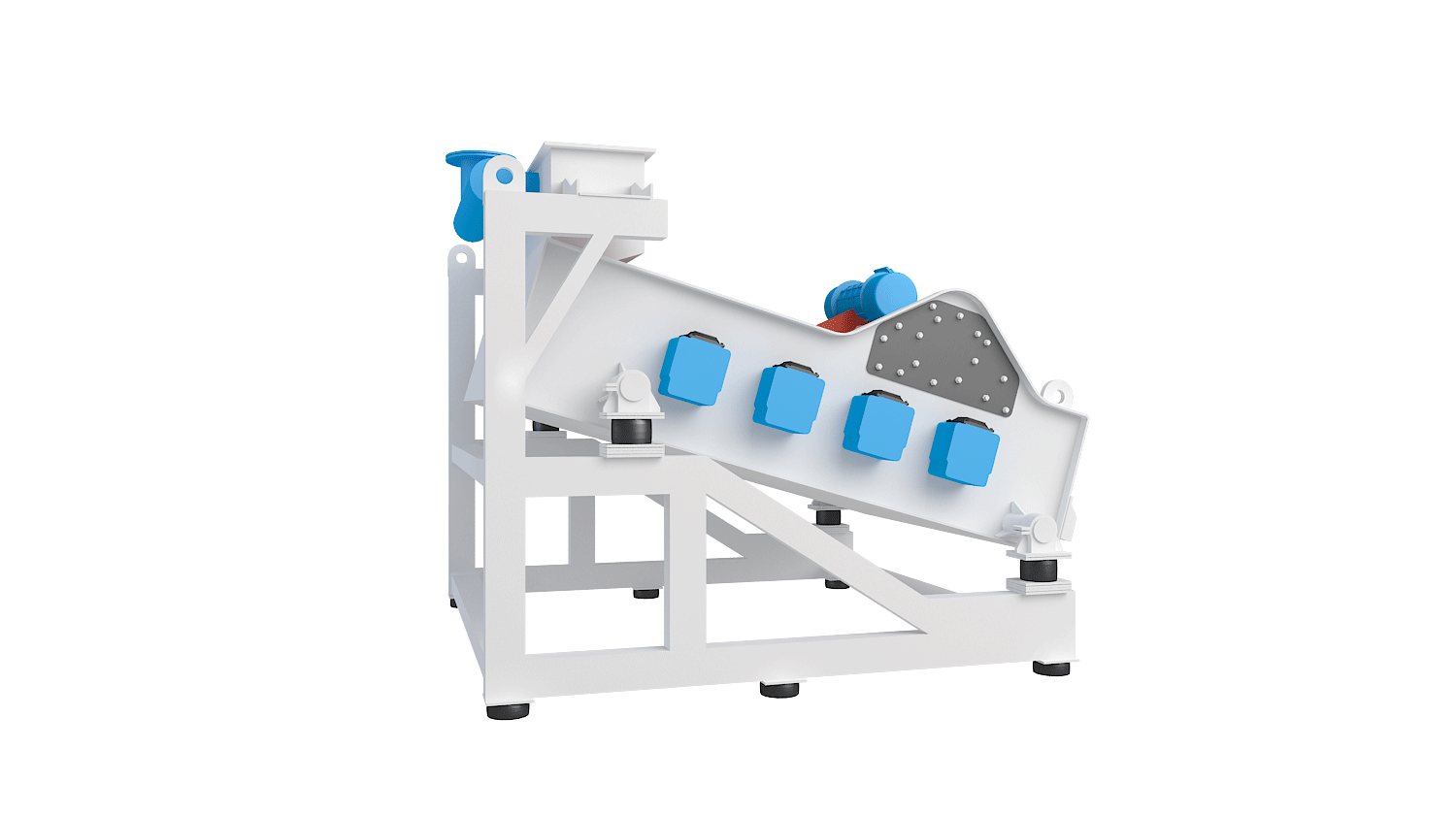

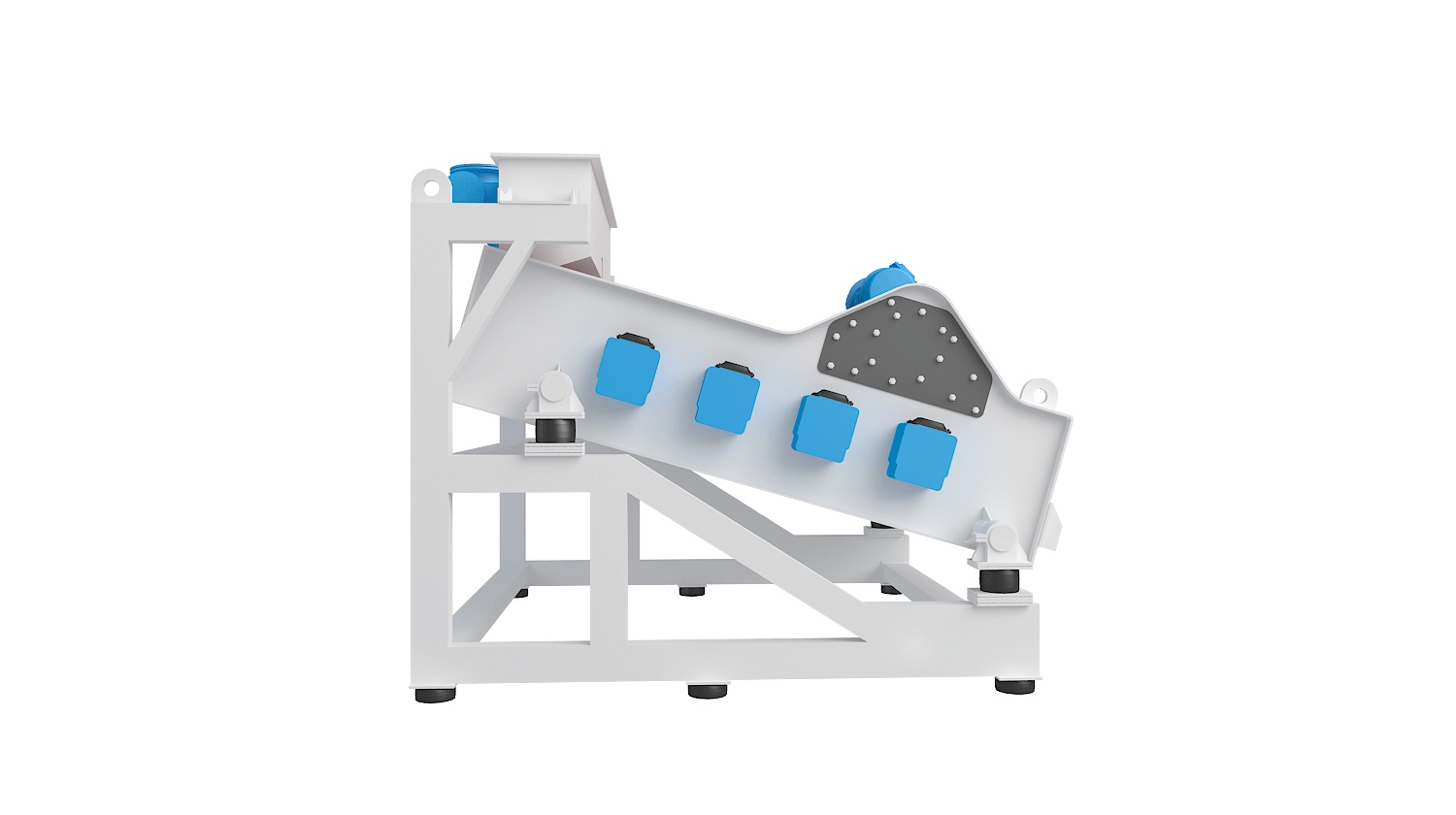

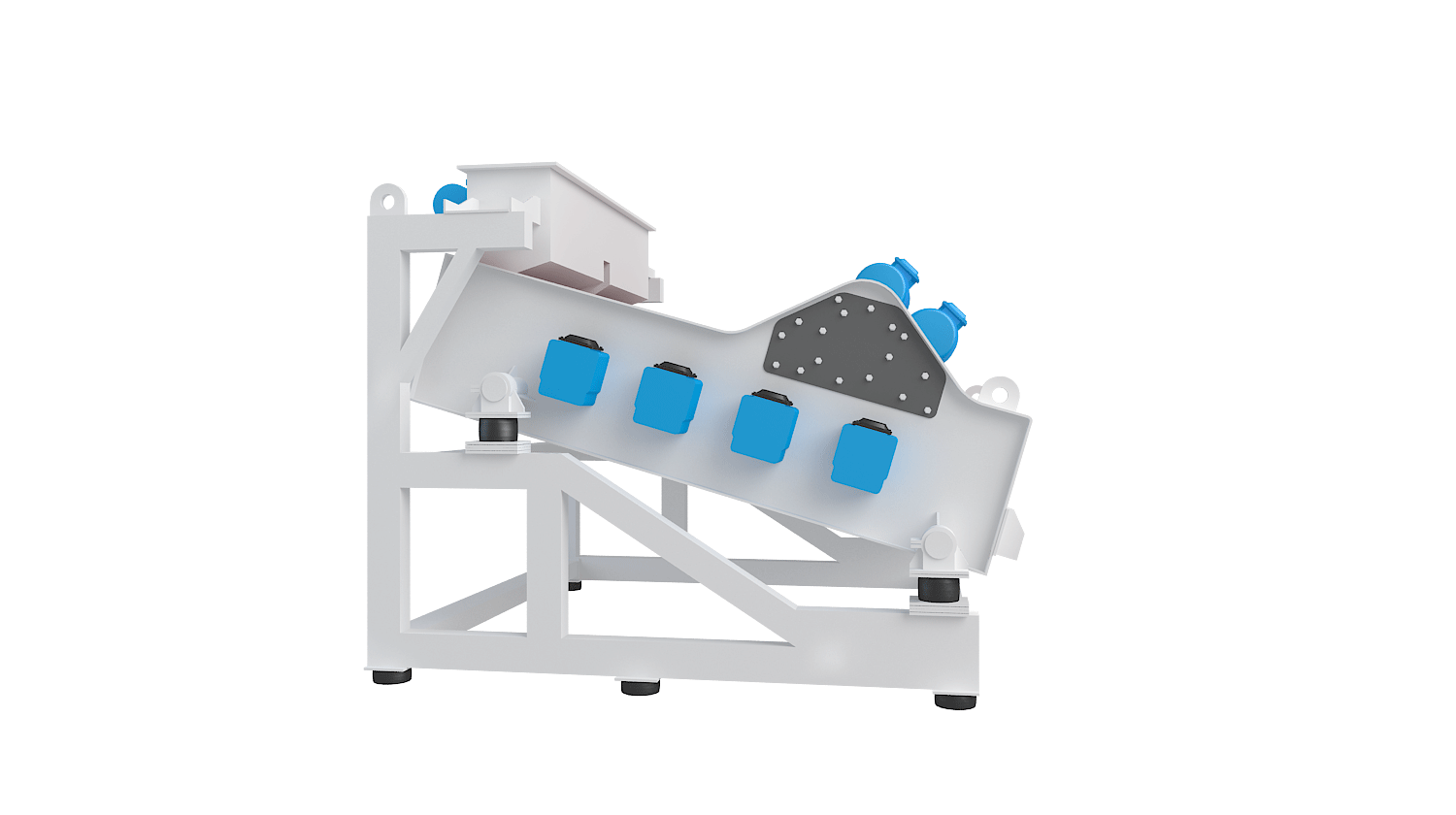

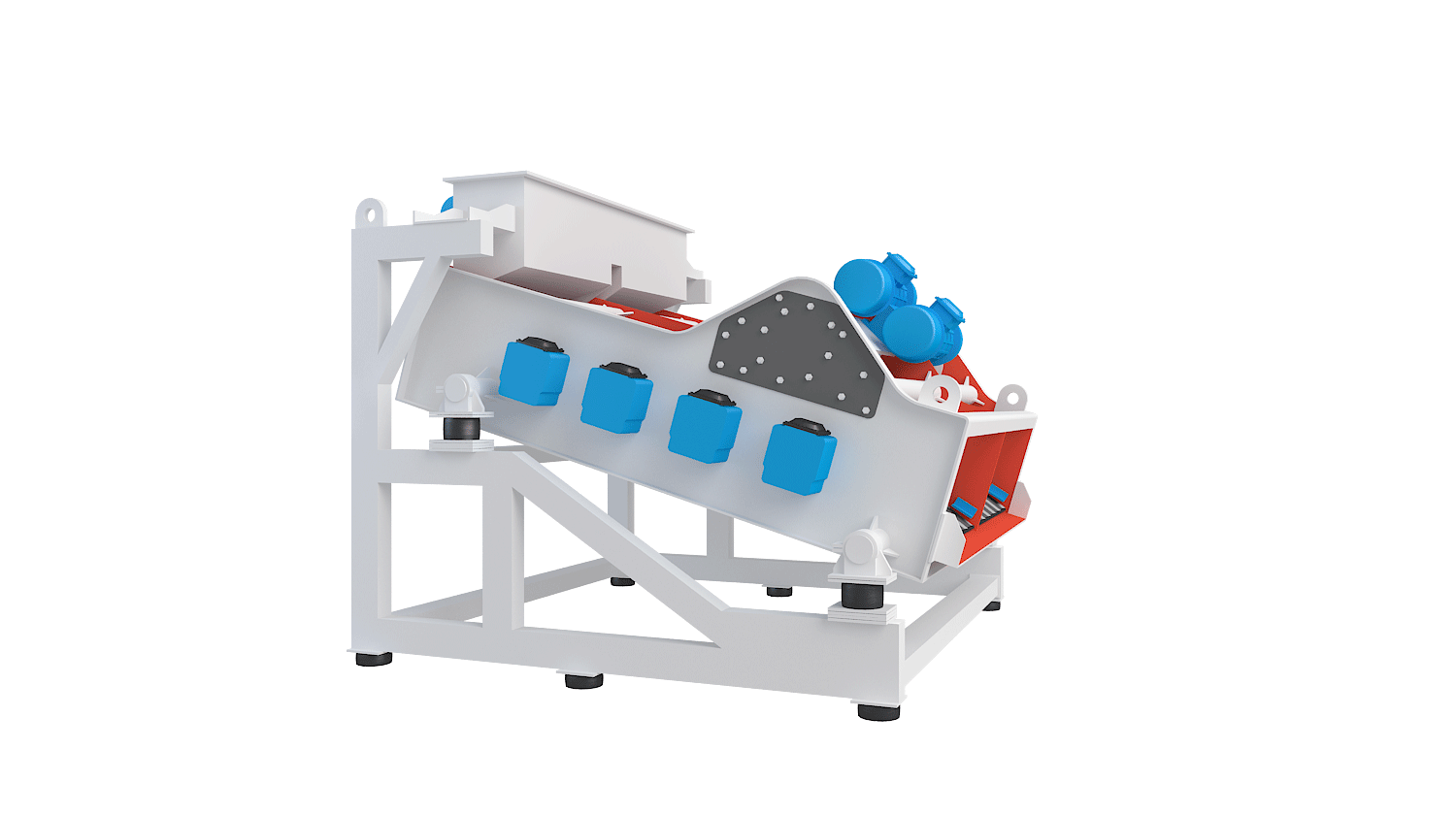

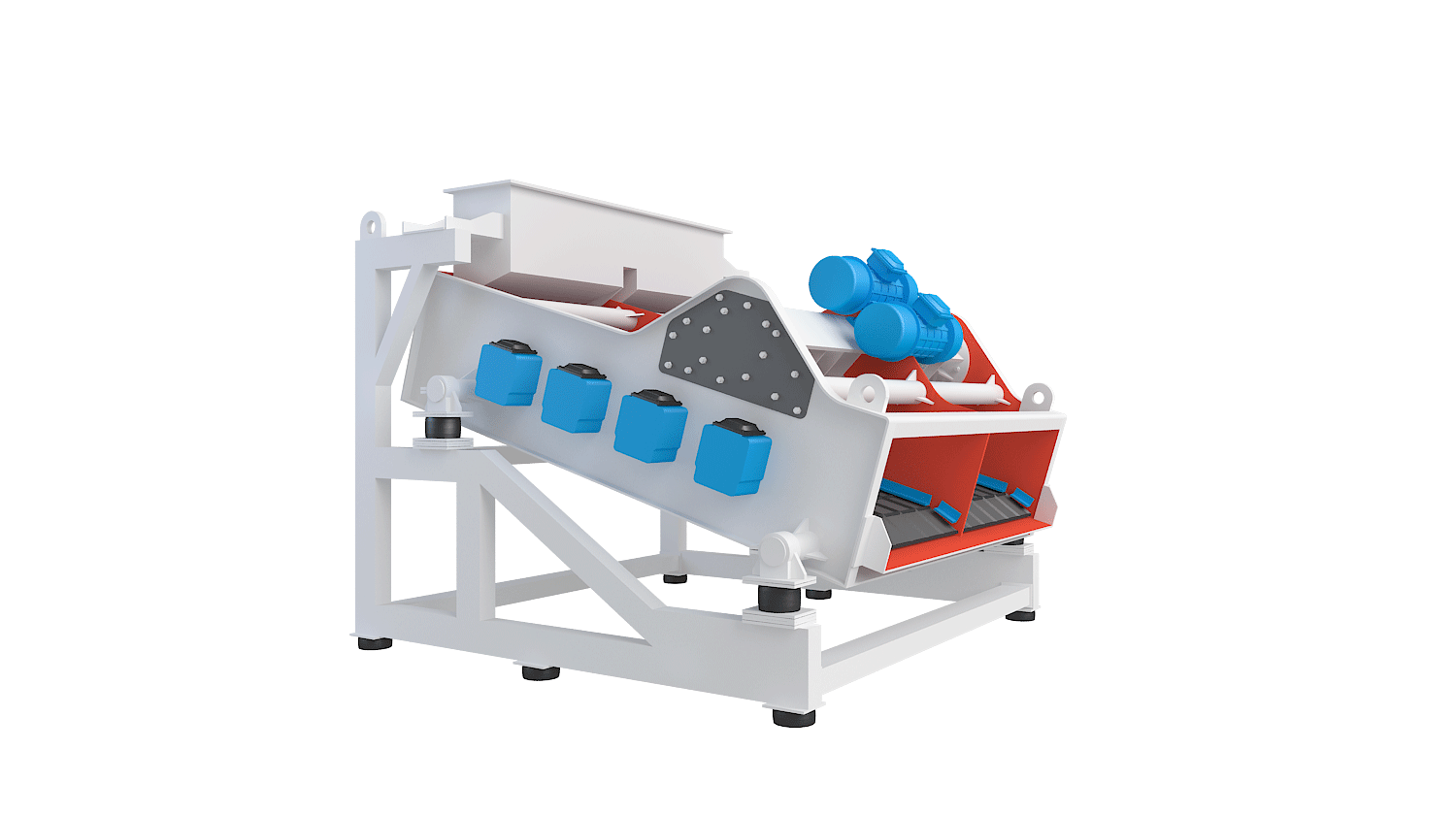

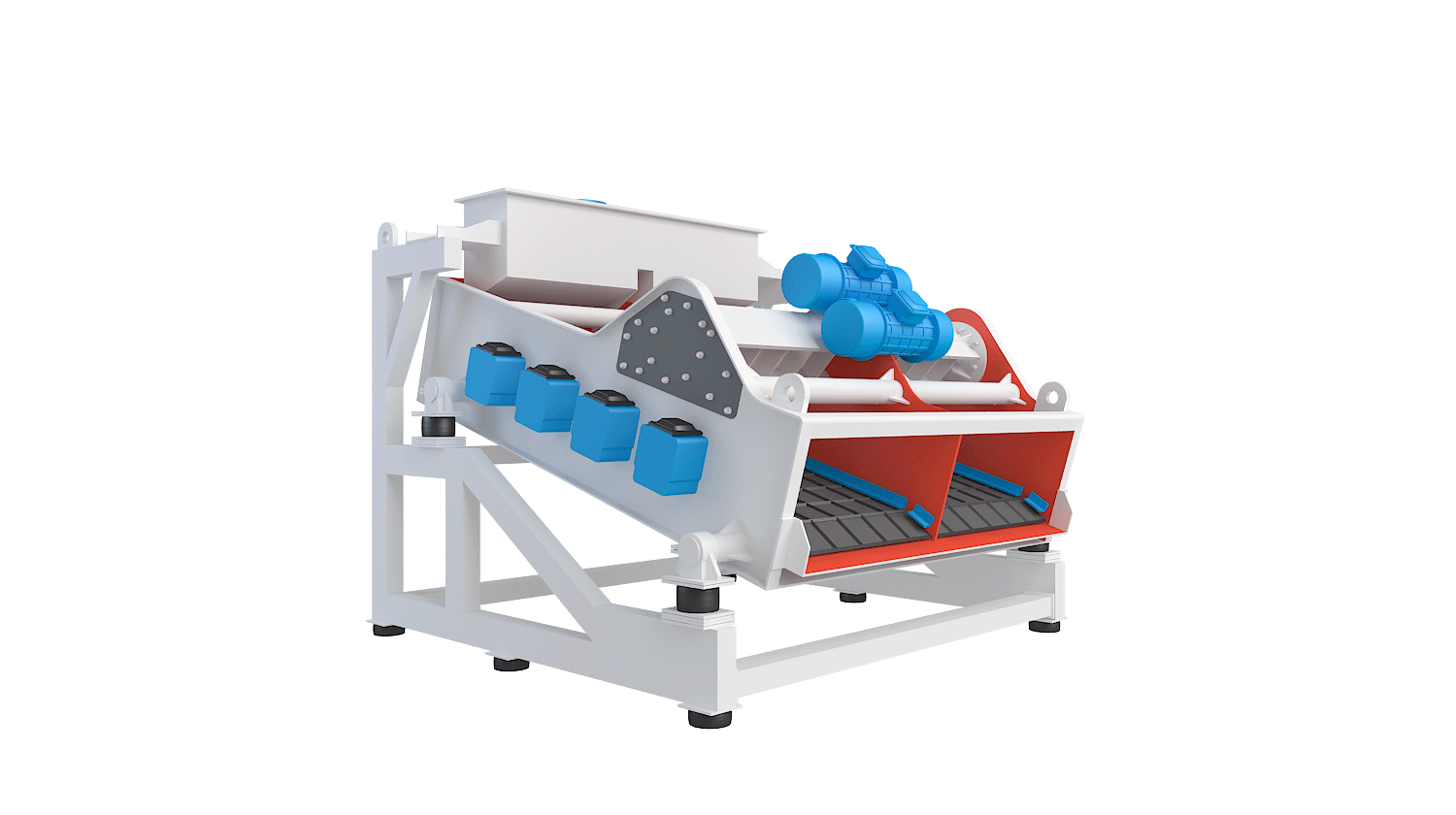

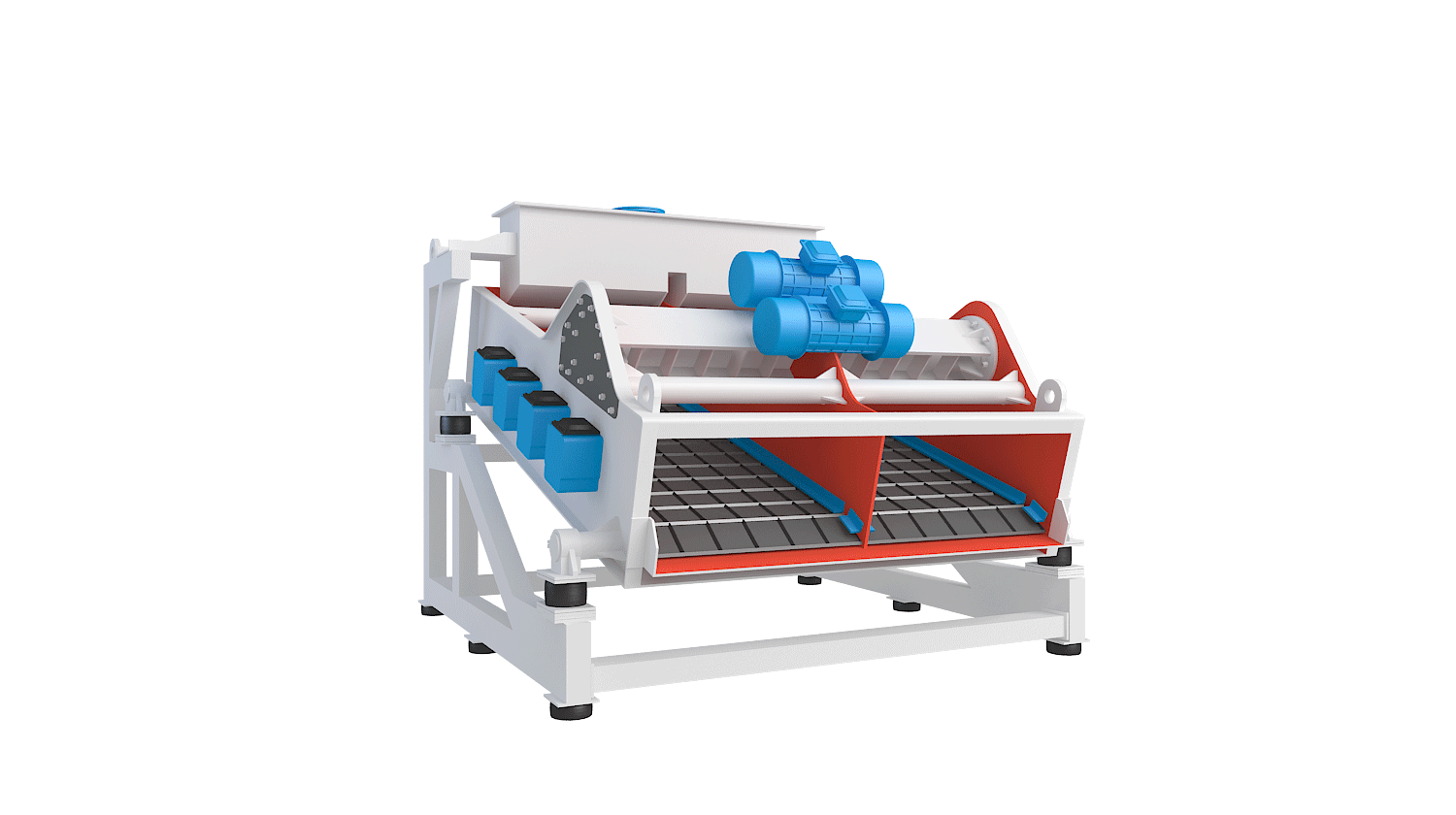

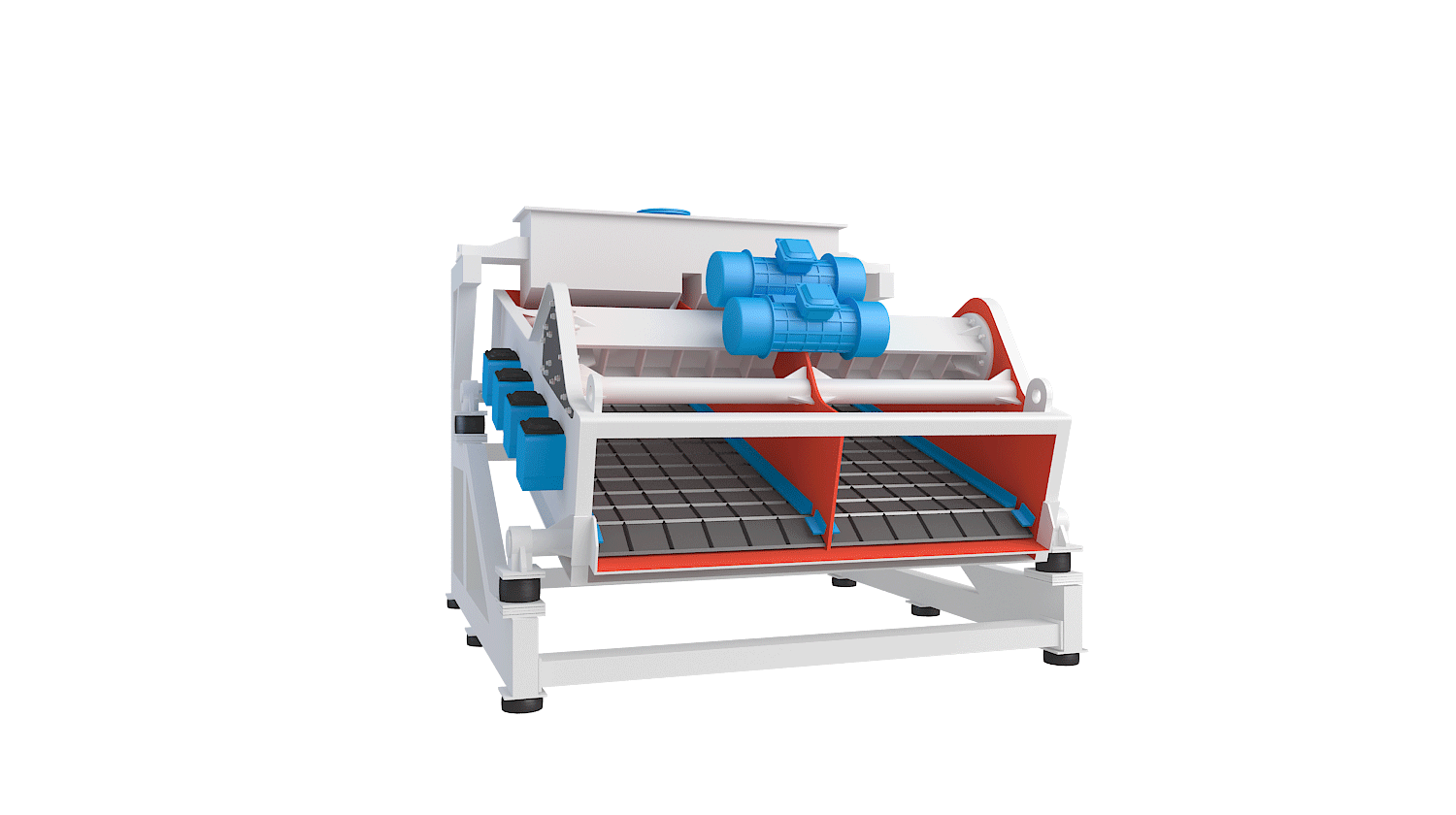

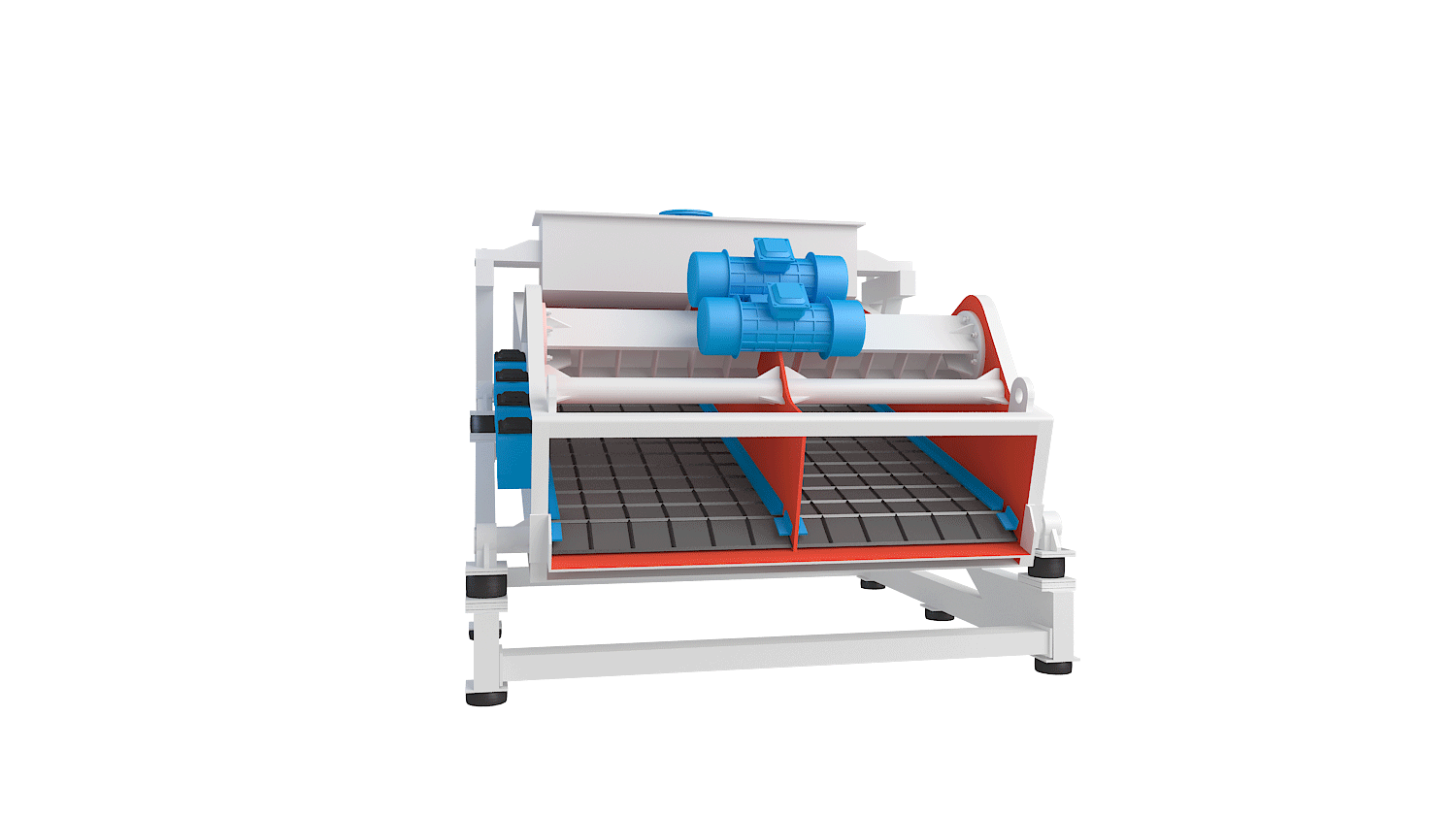

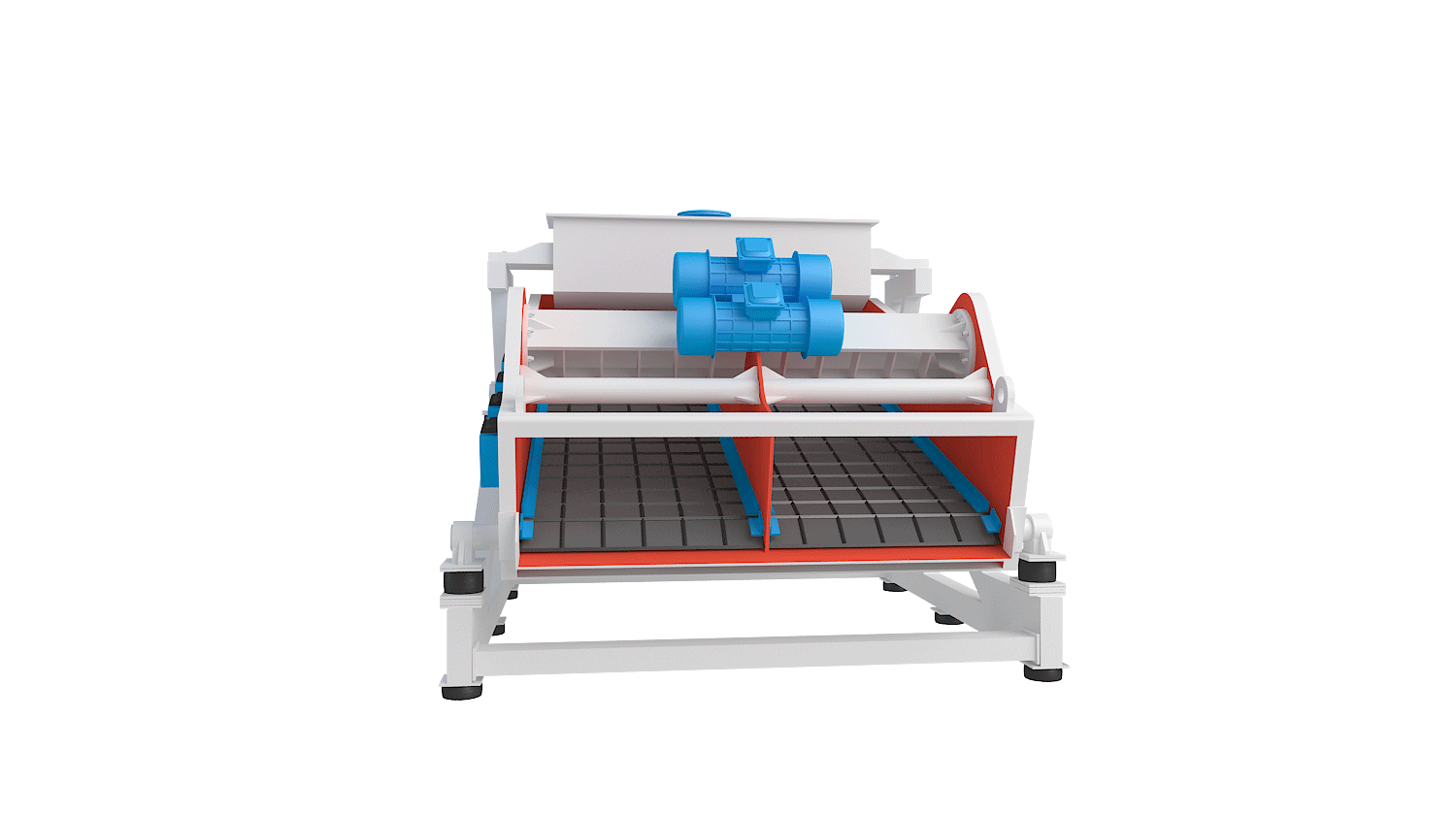

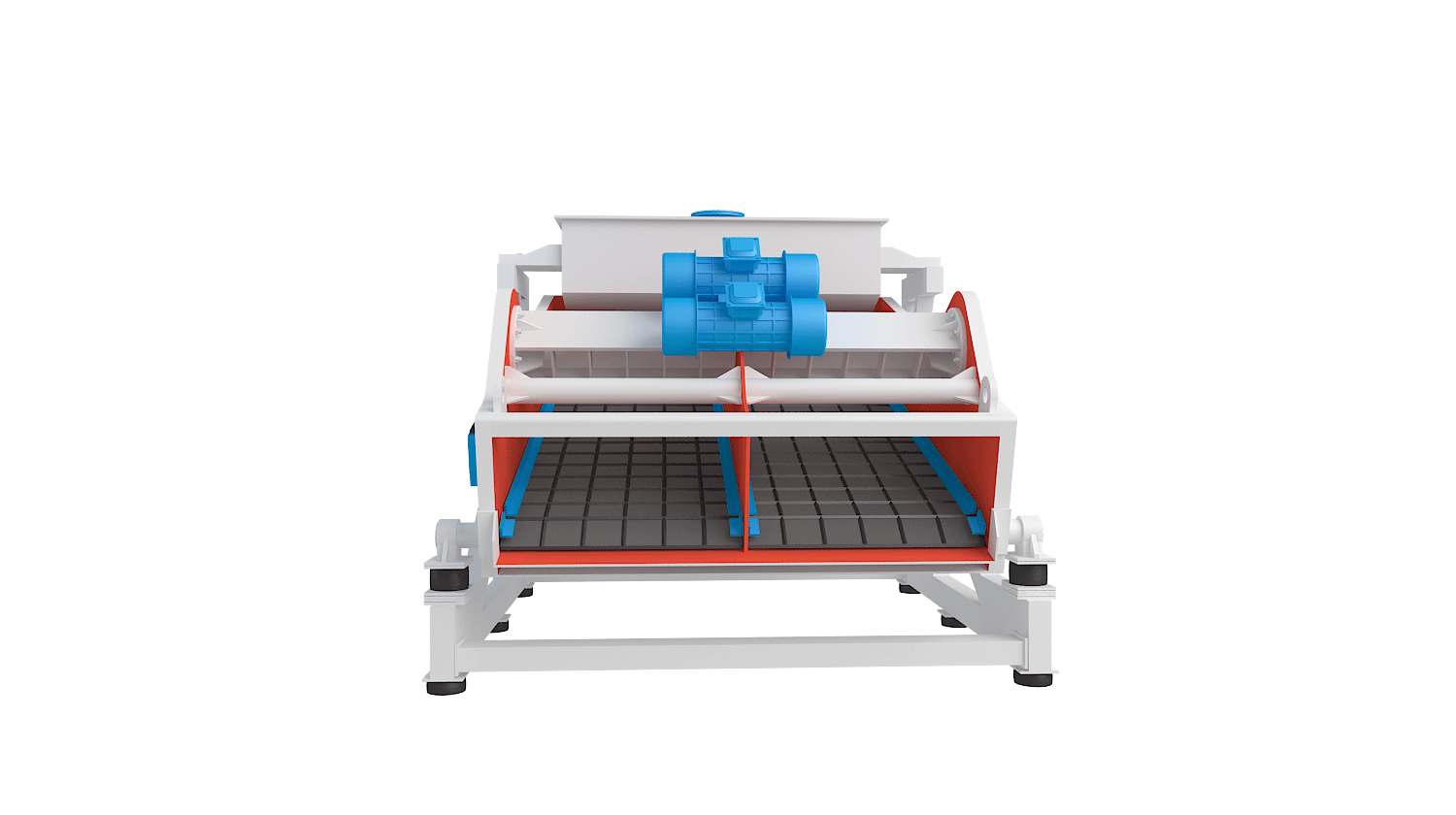

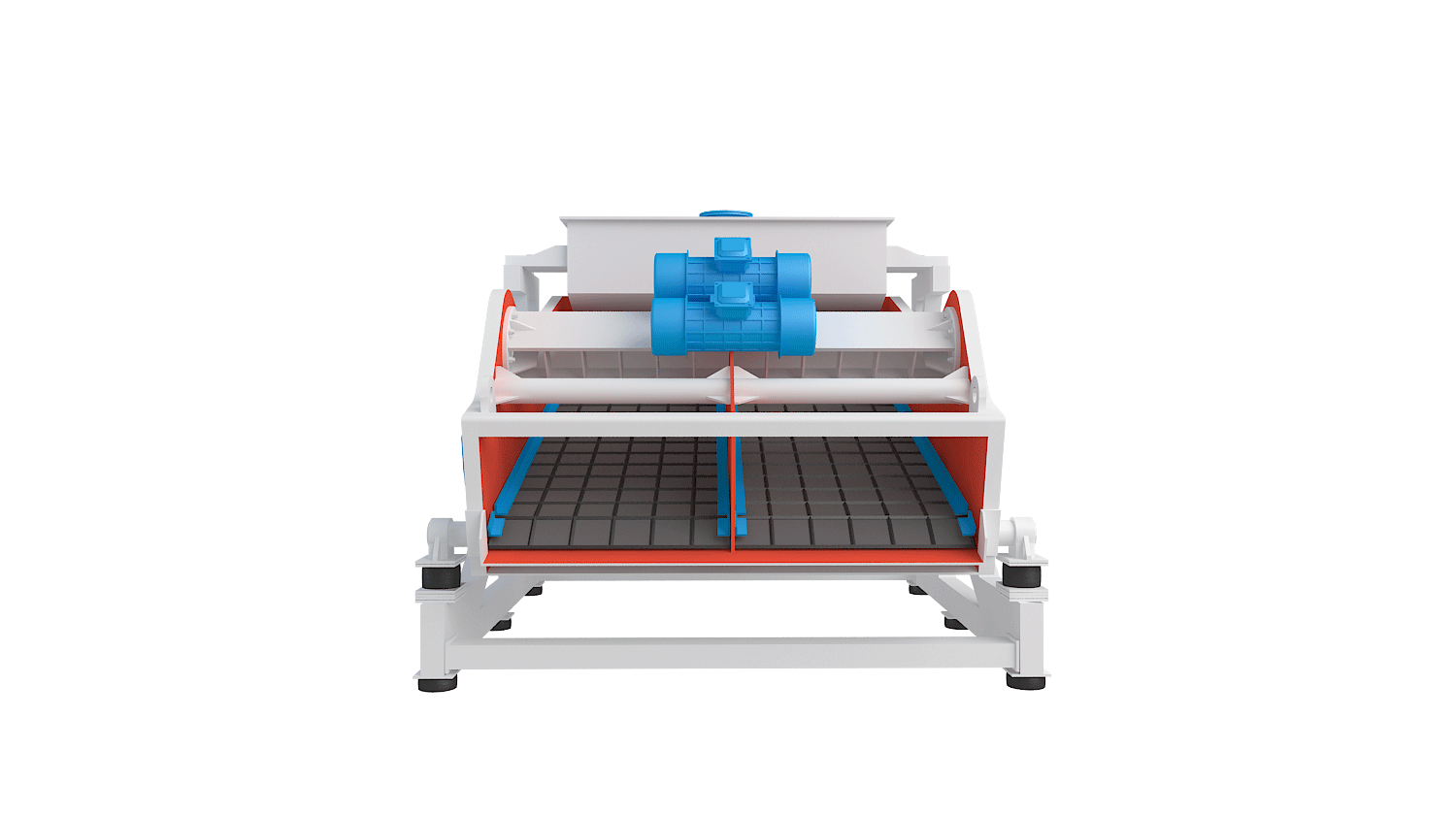

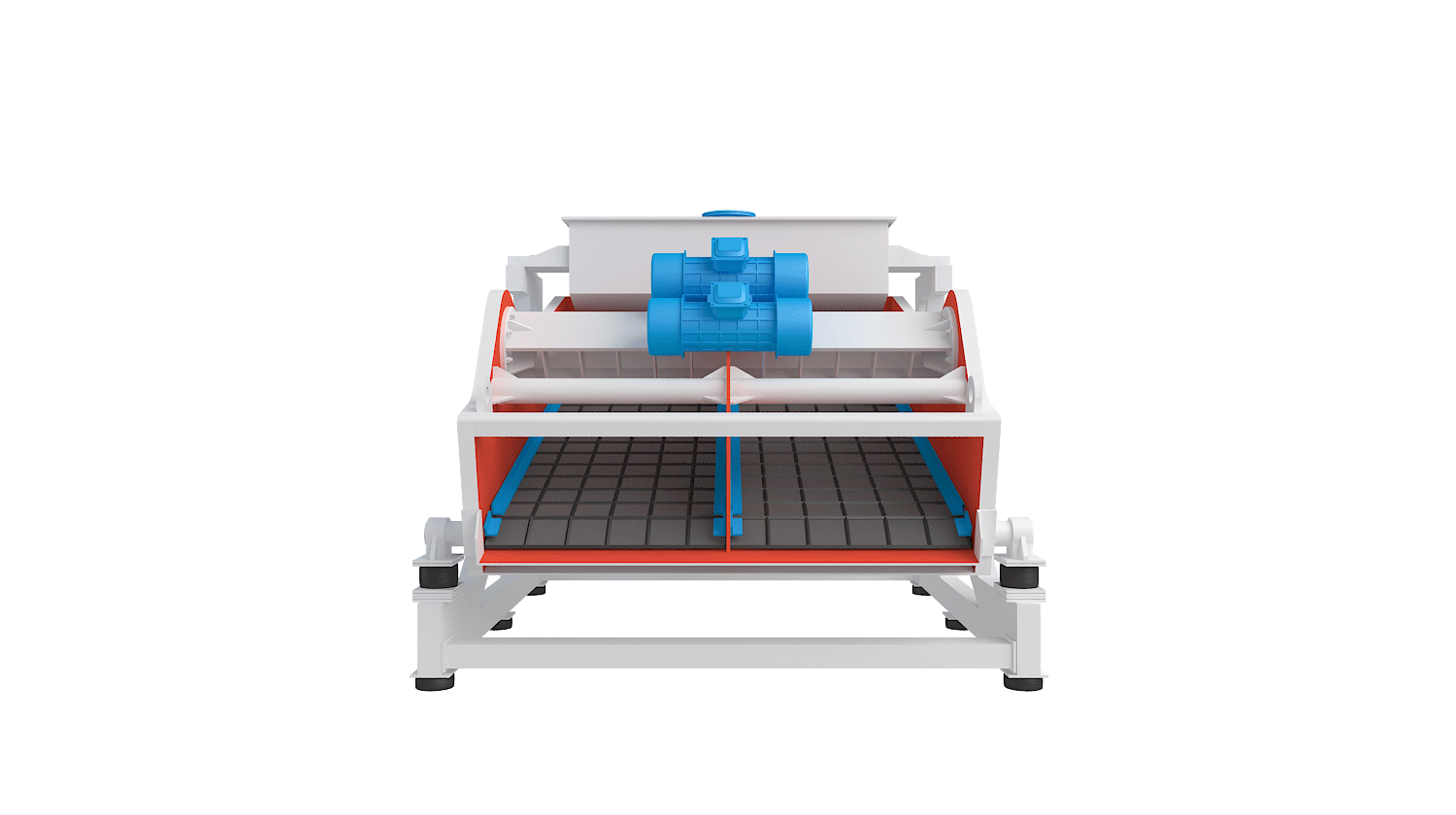

Electromagnetic High Frequency Screen

Electromagnetic High Frequency Screen is a high-precision screening machine that utilizes electromagnetic drive technology to achieve stable, high-frequency vibrations. Unlike conventional vibrating screens, it produces ultra-fine and uniform oscillations with small amplitude, which greatly enhances stratification and separation efficiency of fine particles, especially in wet processing.

This equipment is especially suitable for classifying materials with particle sizes below 1 mm, such as iron ore concentrate, kaolin, silica sand, feldspar, and tailings. The screen operates at frequencies of 3000 RPM or higher, promoting effective separation, desliming, and dewatering processes.

With features such as energy-saving electromagnetic excitation, compact design, low noise, and minimal blinding, the screen supports multiple layers and can be integrated into closed-circuit grinding and fine screening systems. Its modular design ensures easy maintenance and long service life.

Electromagnetic High Frequency Screen is widely applied in industries like mining, metallurgy, chemical engineering, and non-metallic mineral processing, where it significantly improves product quality and operational efficiency.