| Model | Chain plate width (mm) |

Chain plate length (mm) |

Max feed size (mm) |

Motor power (kw) |

Capacity (t/h) |

| BLG-0840 | 800 | 4000 | ≤500 | 7.5 | 200-250 |

| BLG-1040 | 1000 | 4000 | ≤500 | 11 | 250-350 |

| BLG-1240 | 1200 | 4000 | ≤500 | 15 | 400-500 |

| BLG-1540 | 1500 | 4000 | ≤500 | 18.5 | 600-800 |

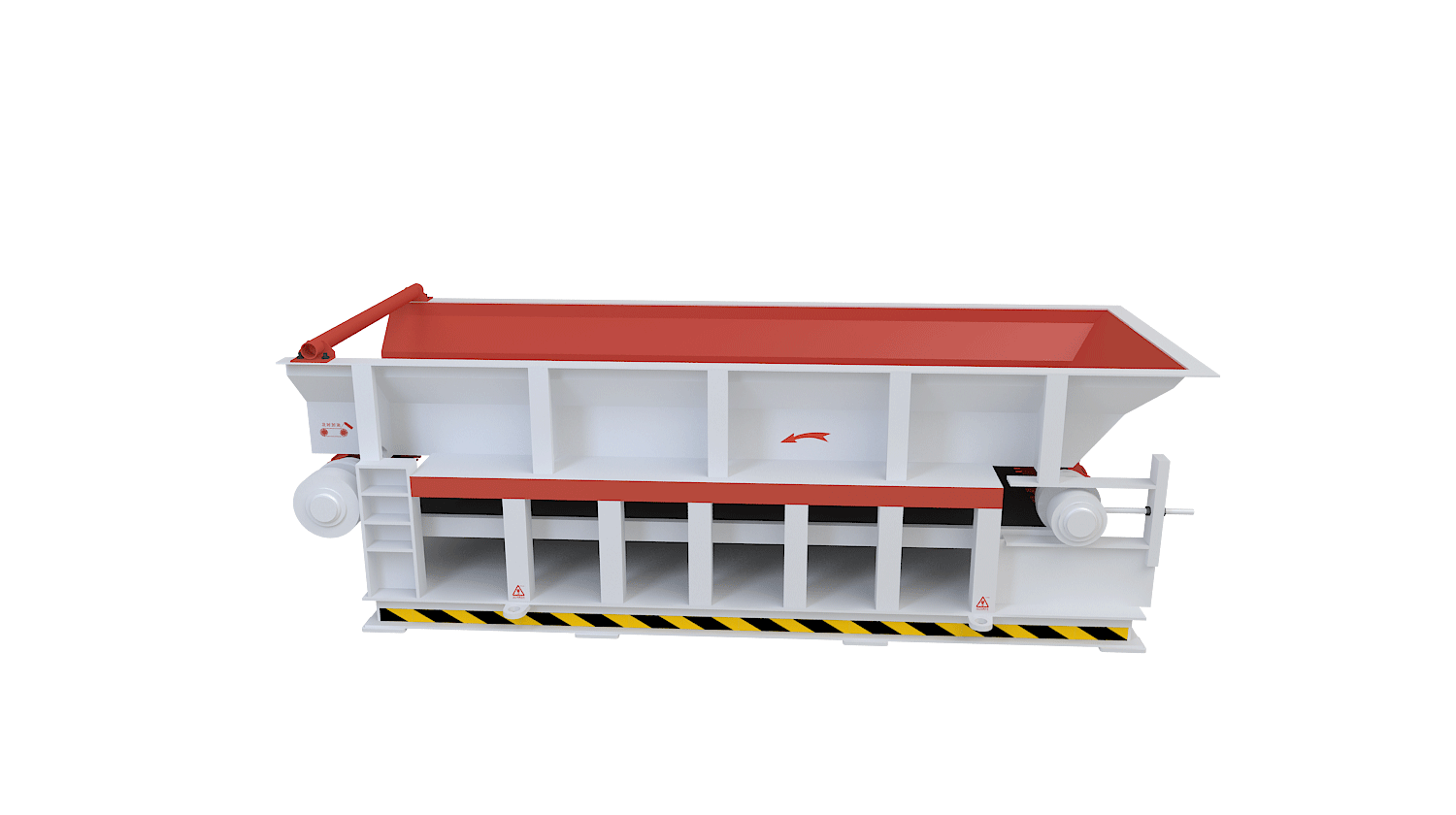

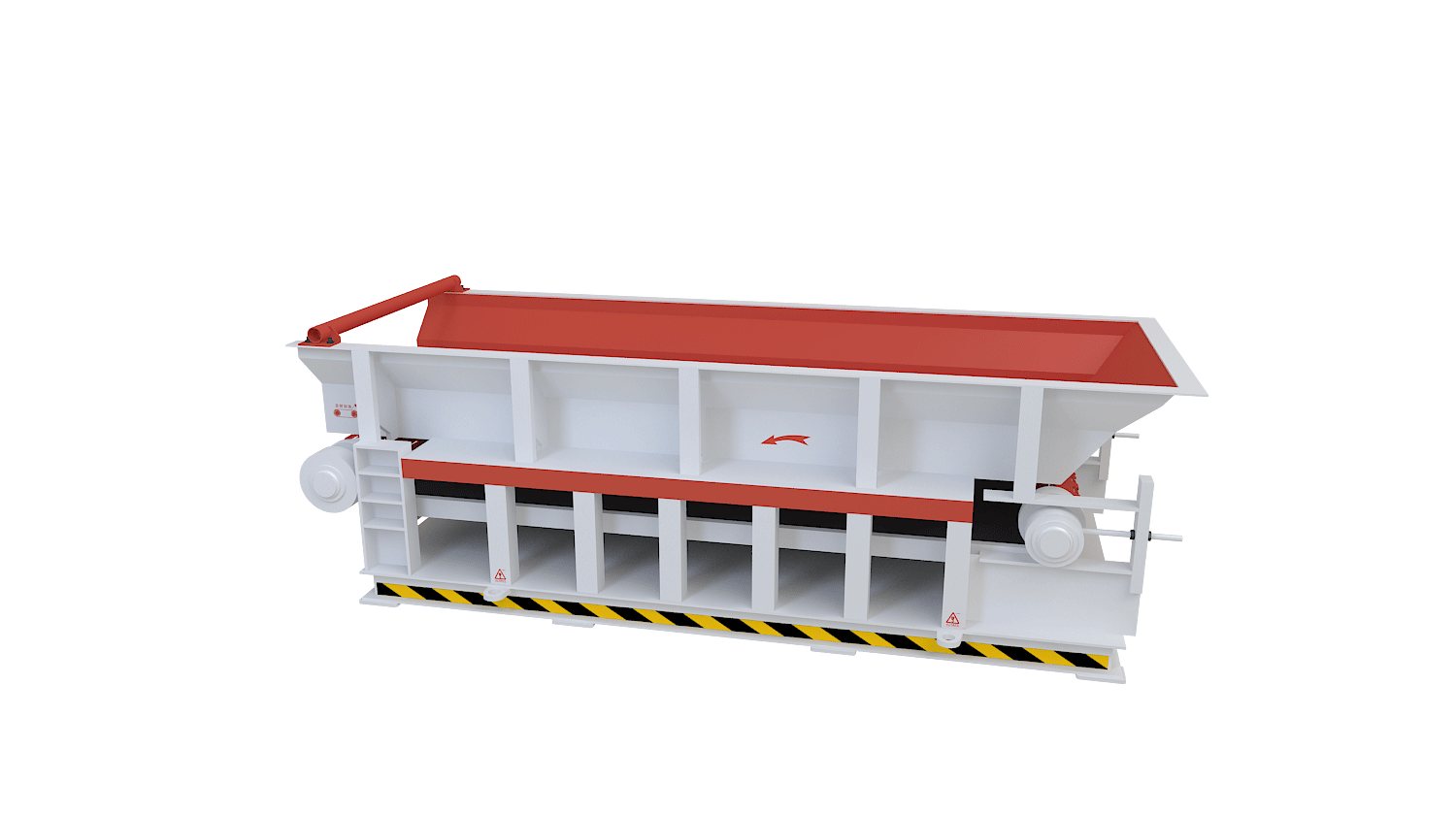

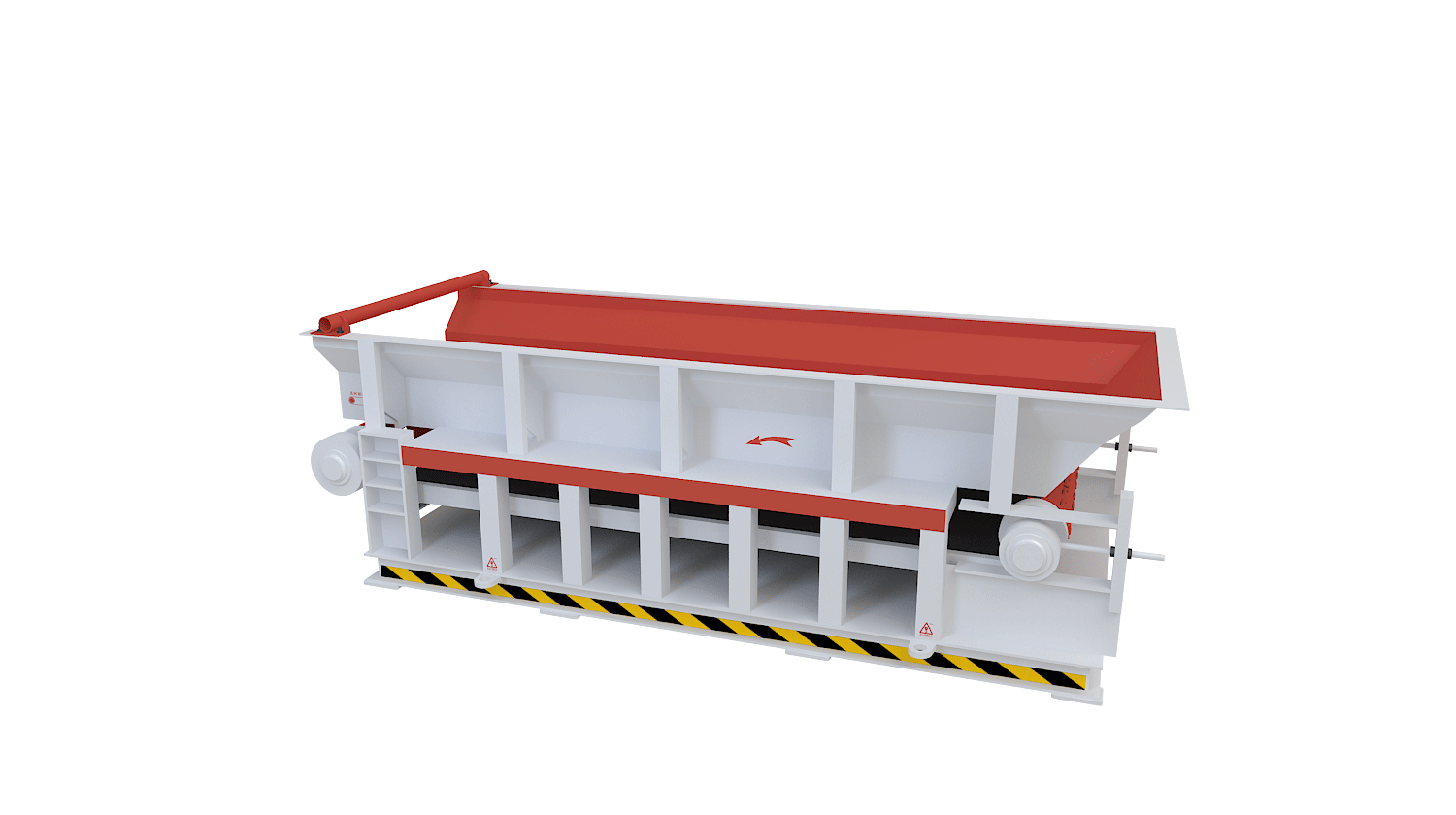

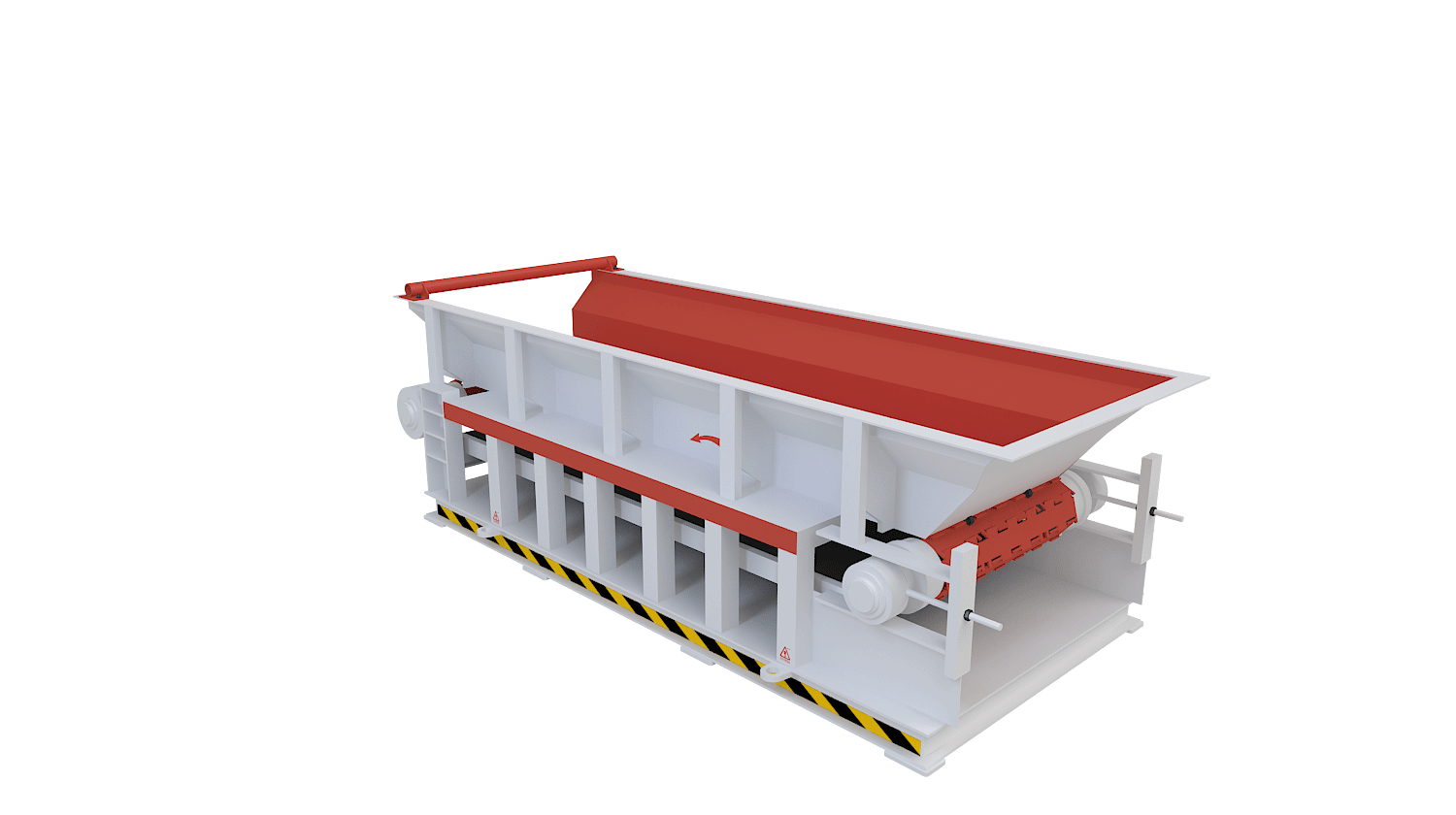

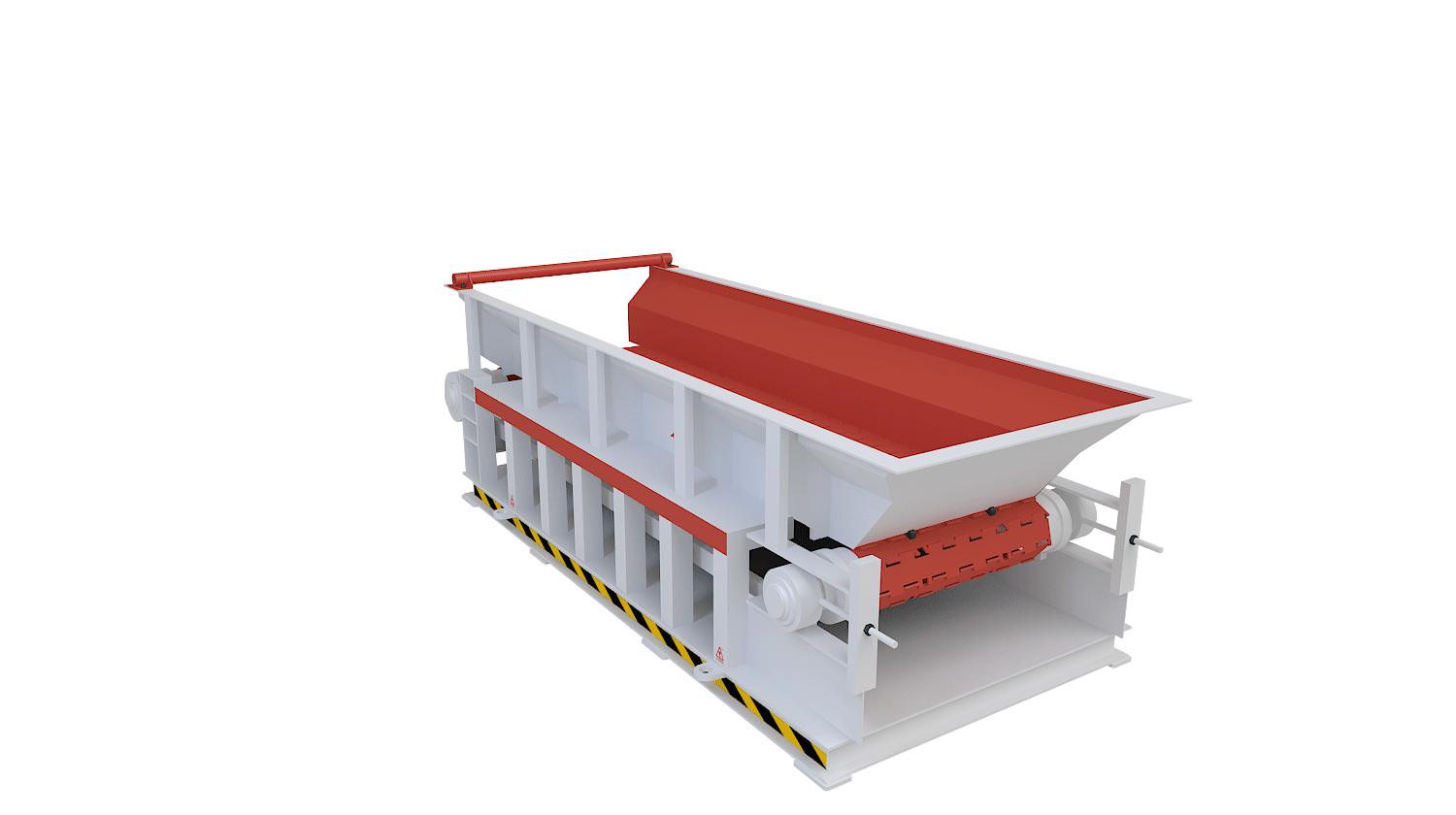

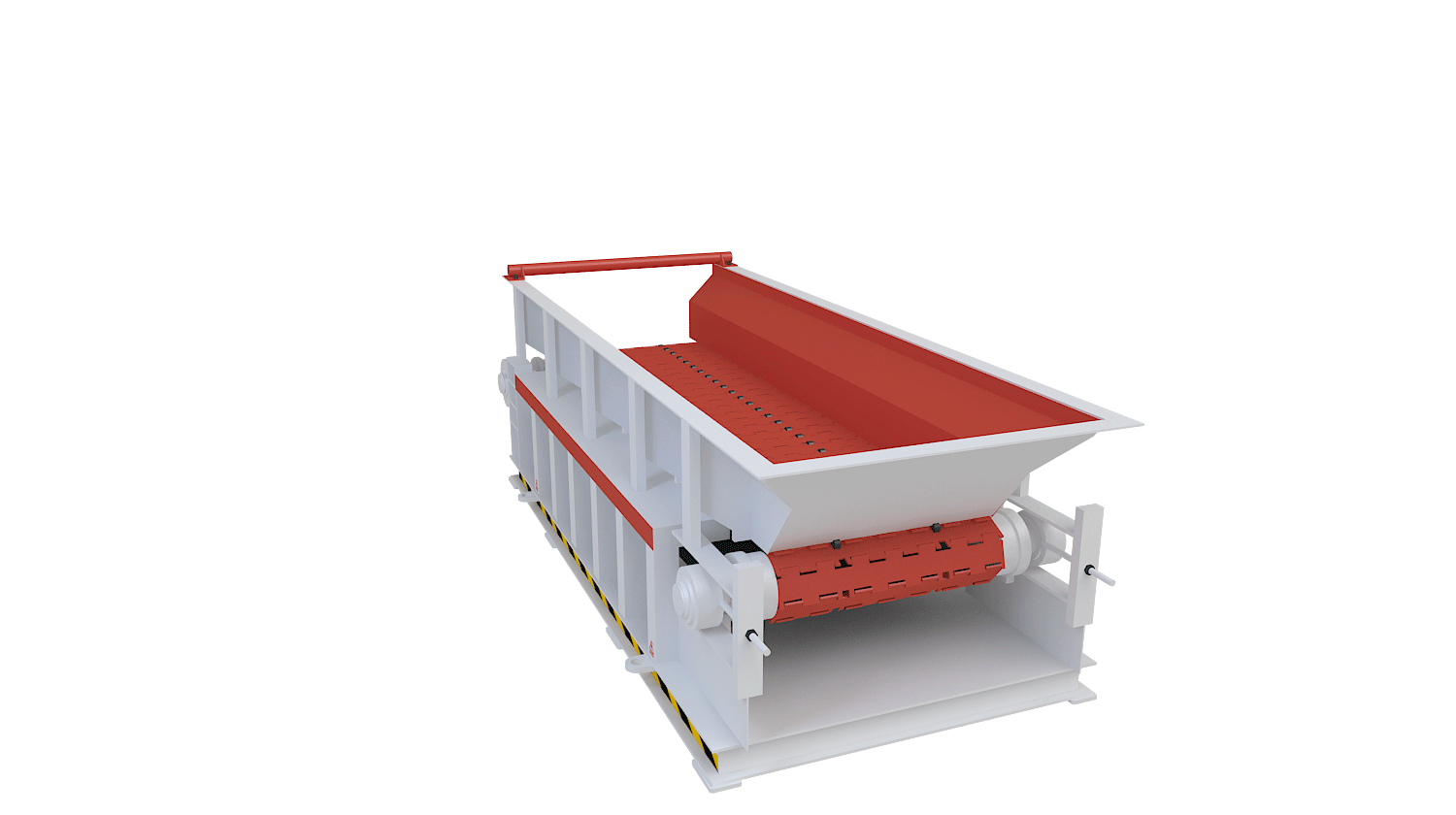

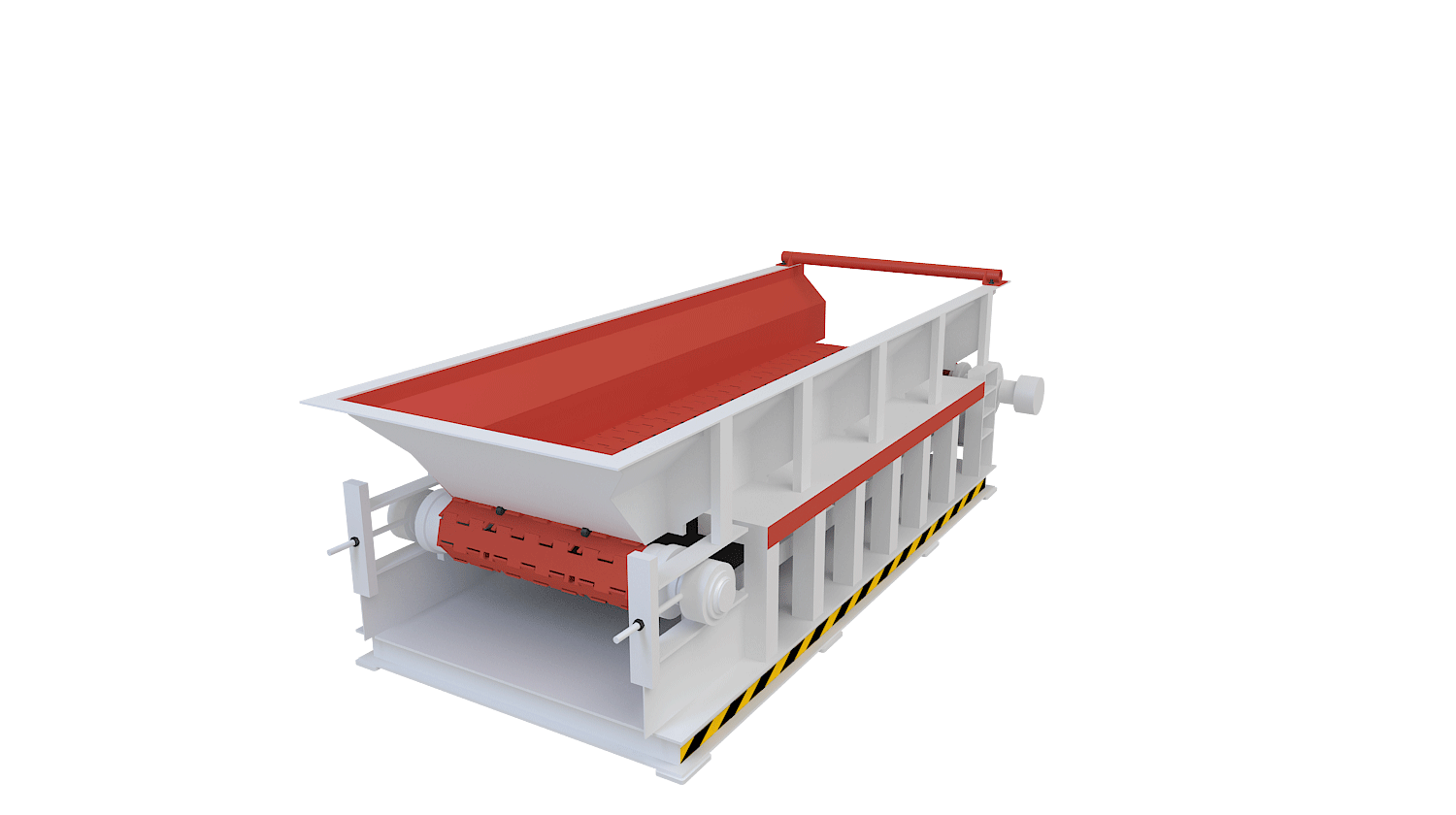

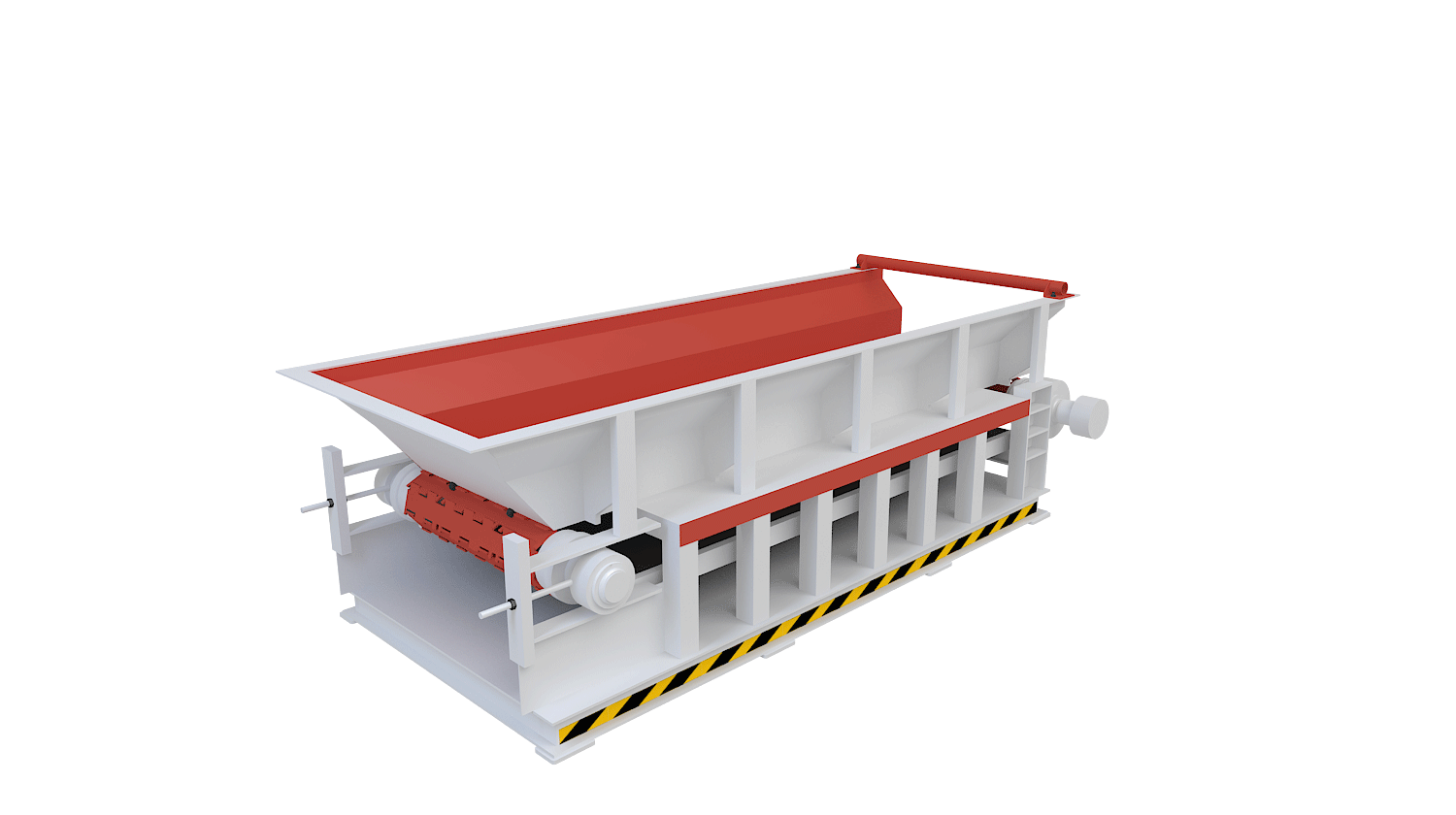

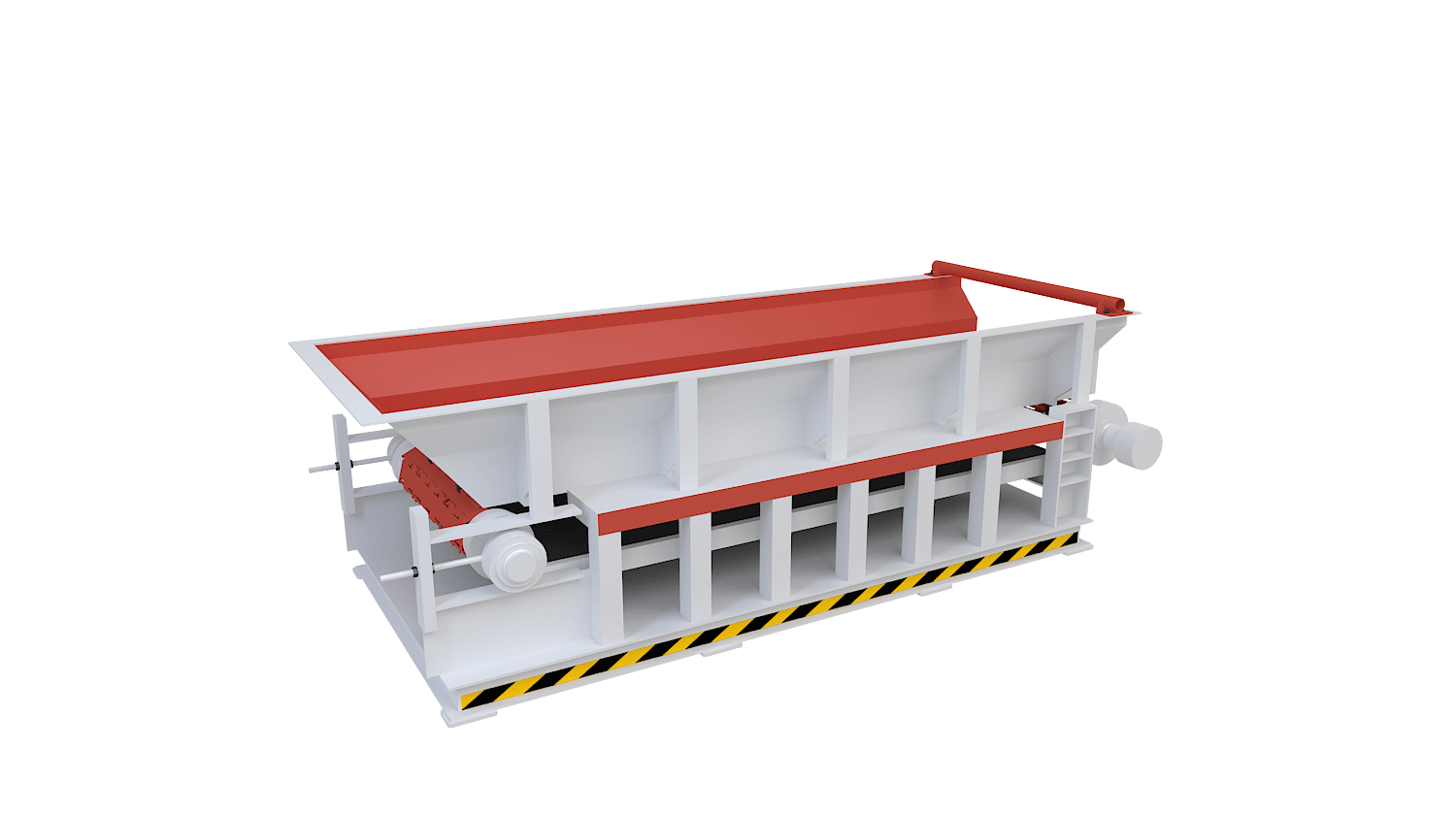

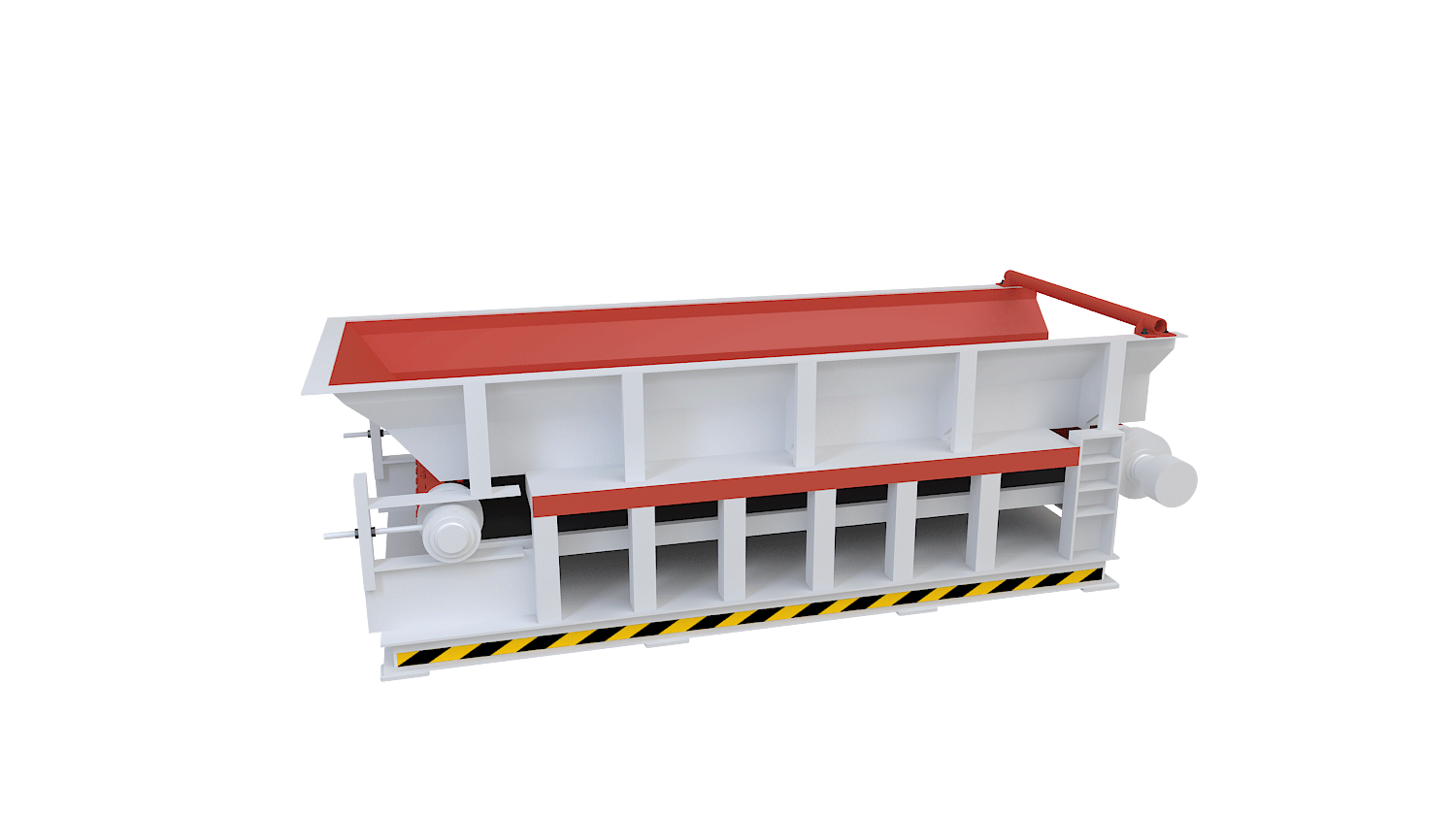

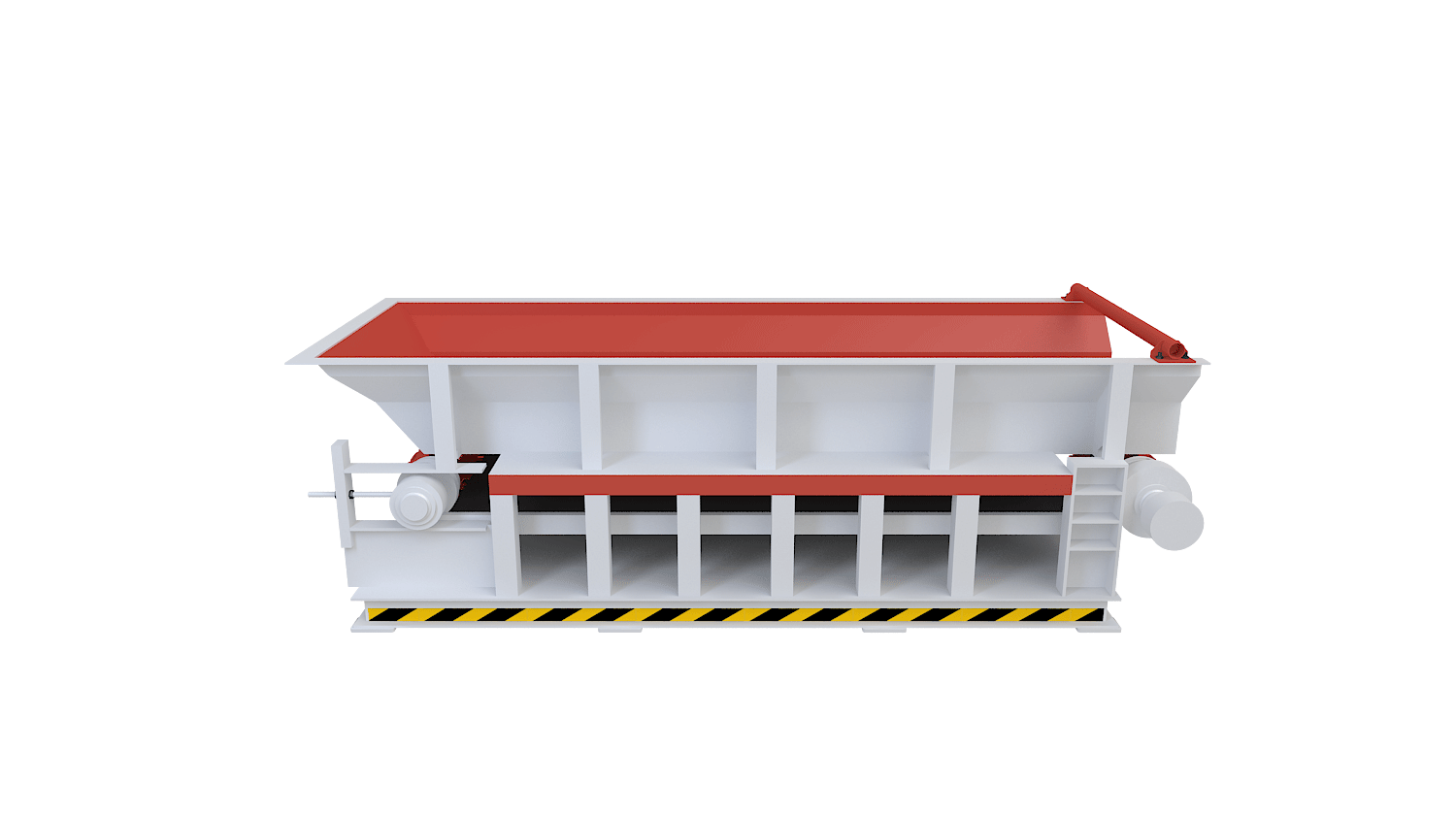

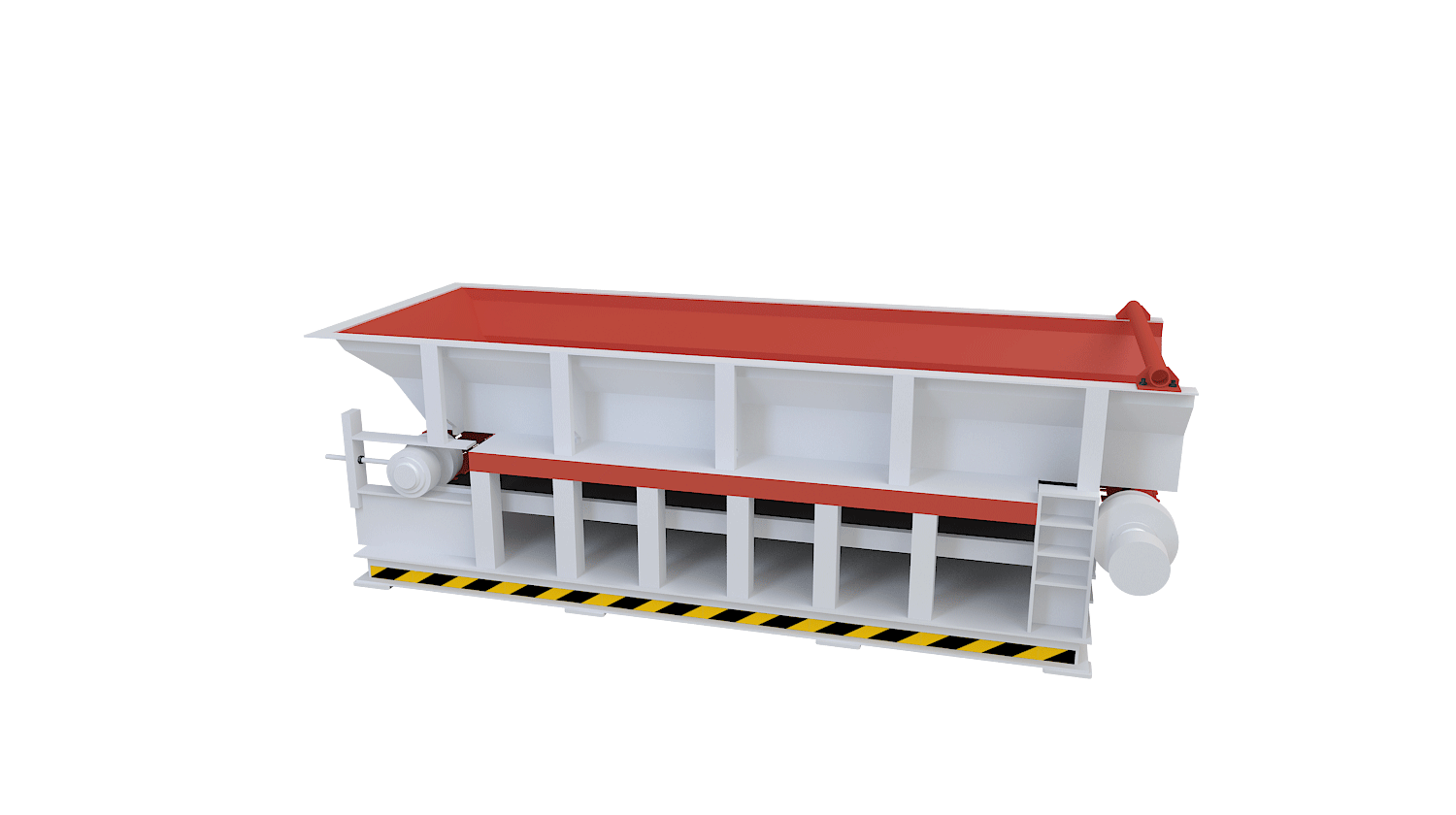

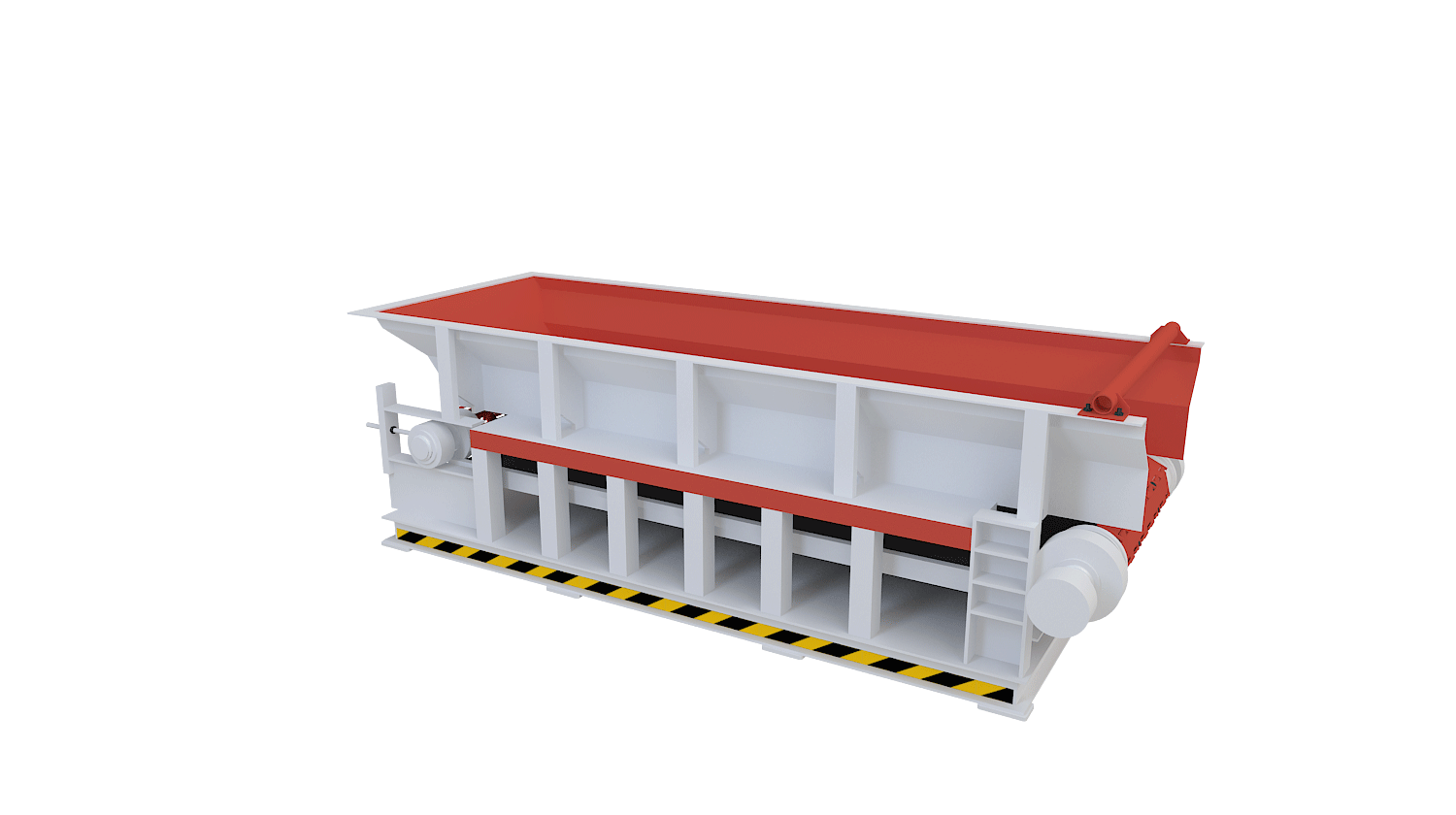

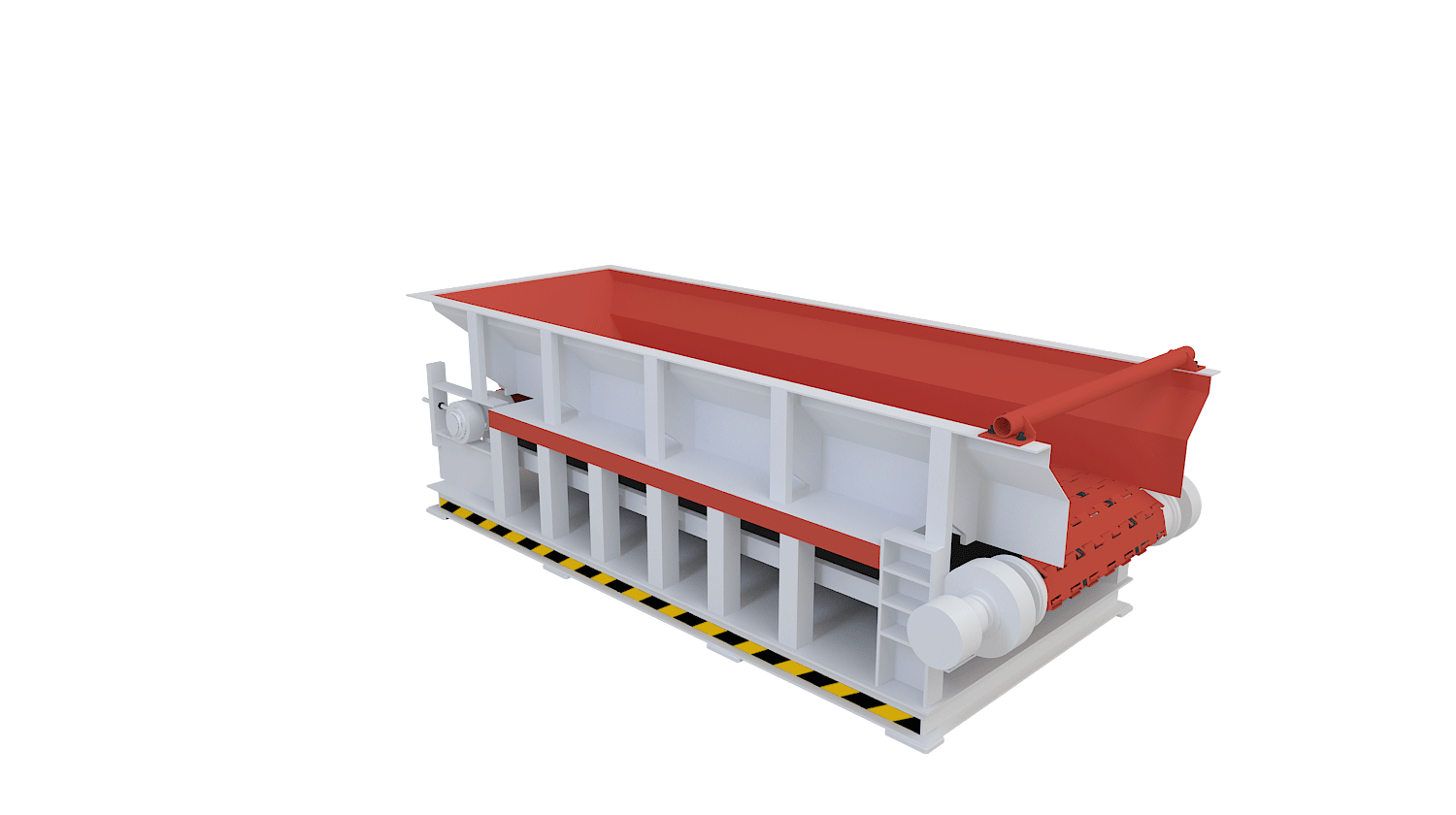

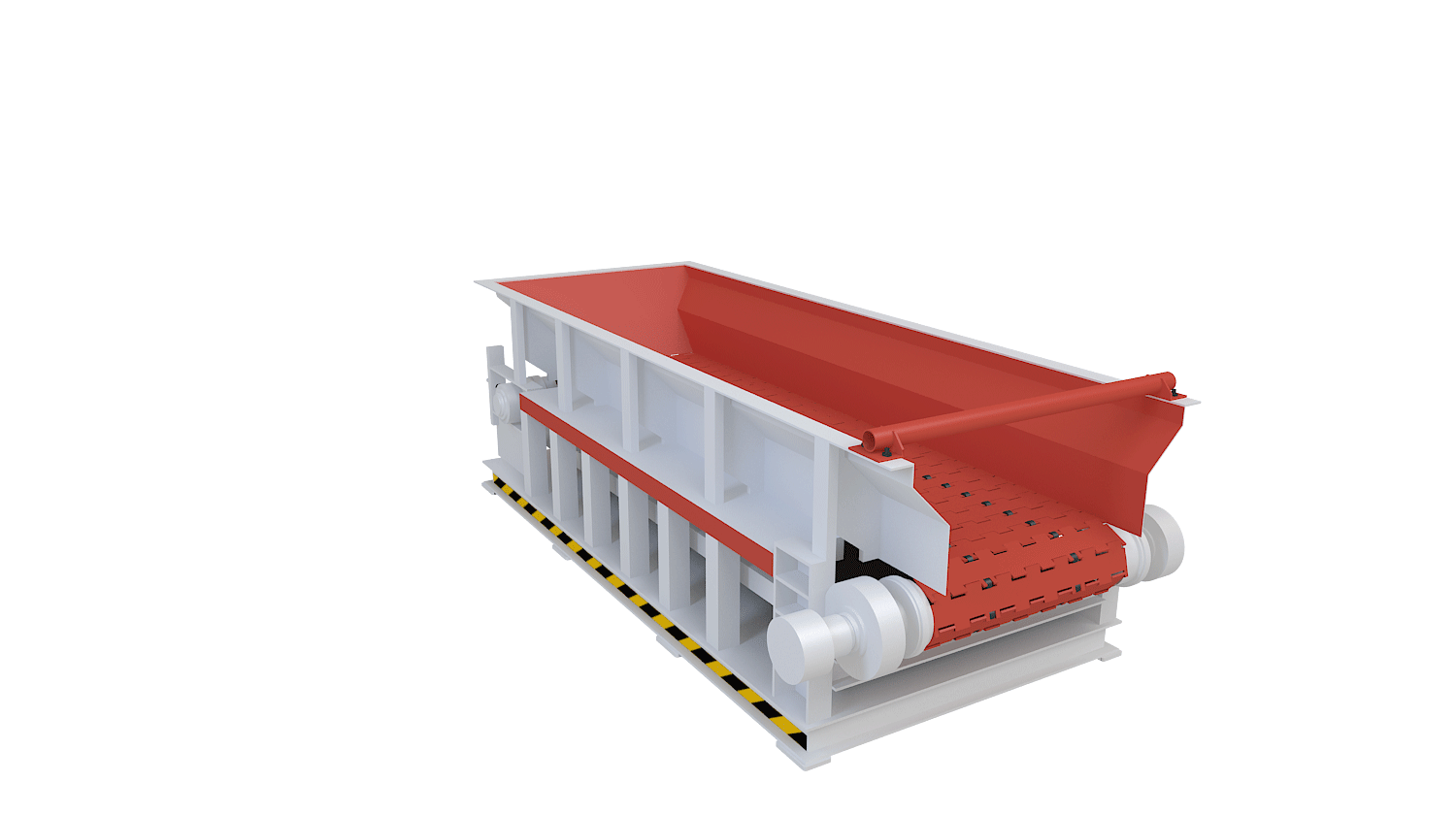

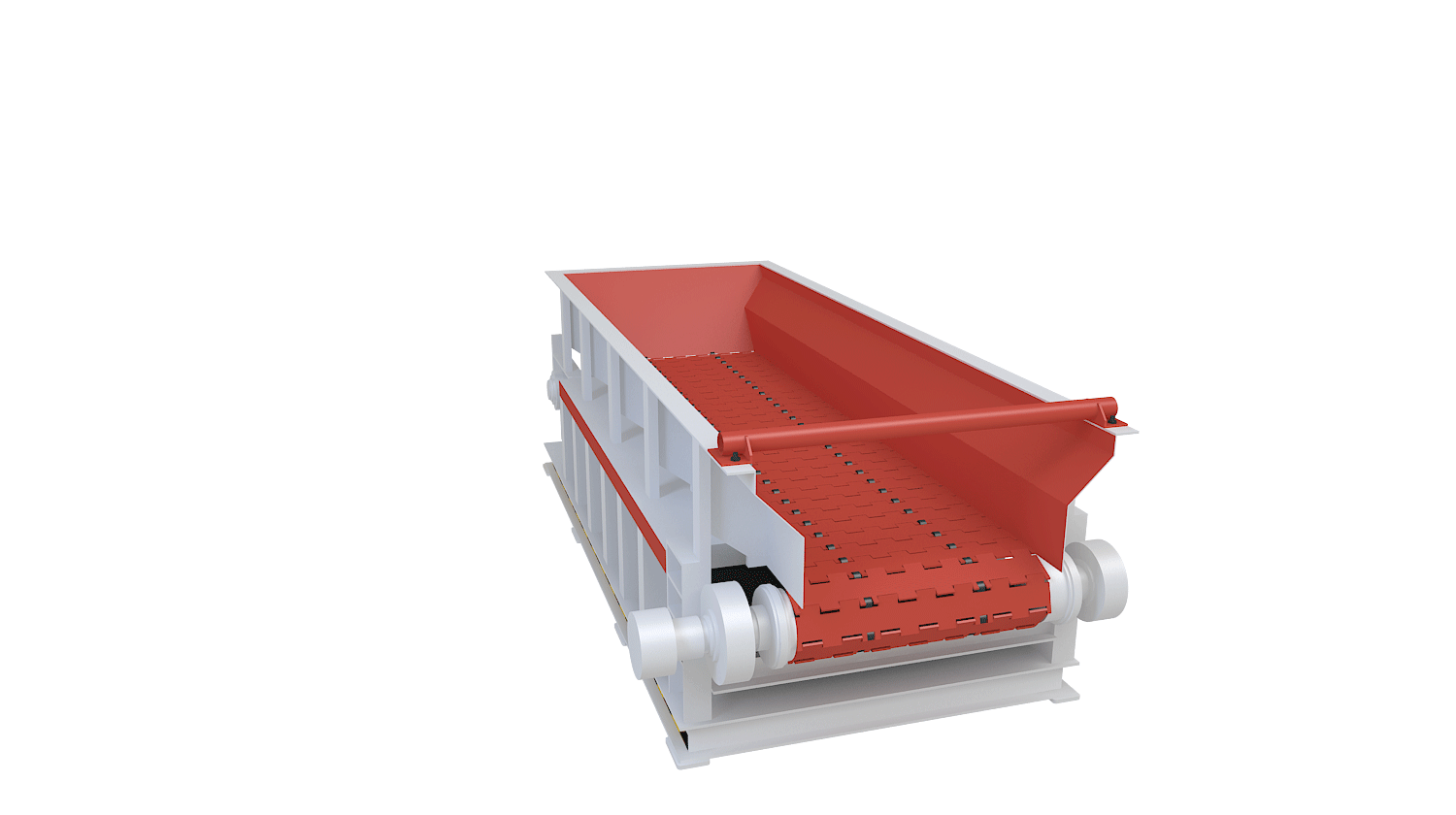

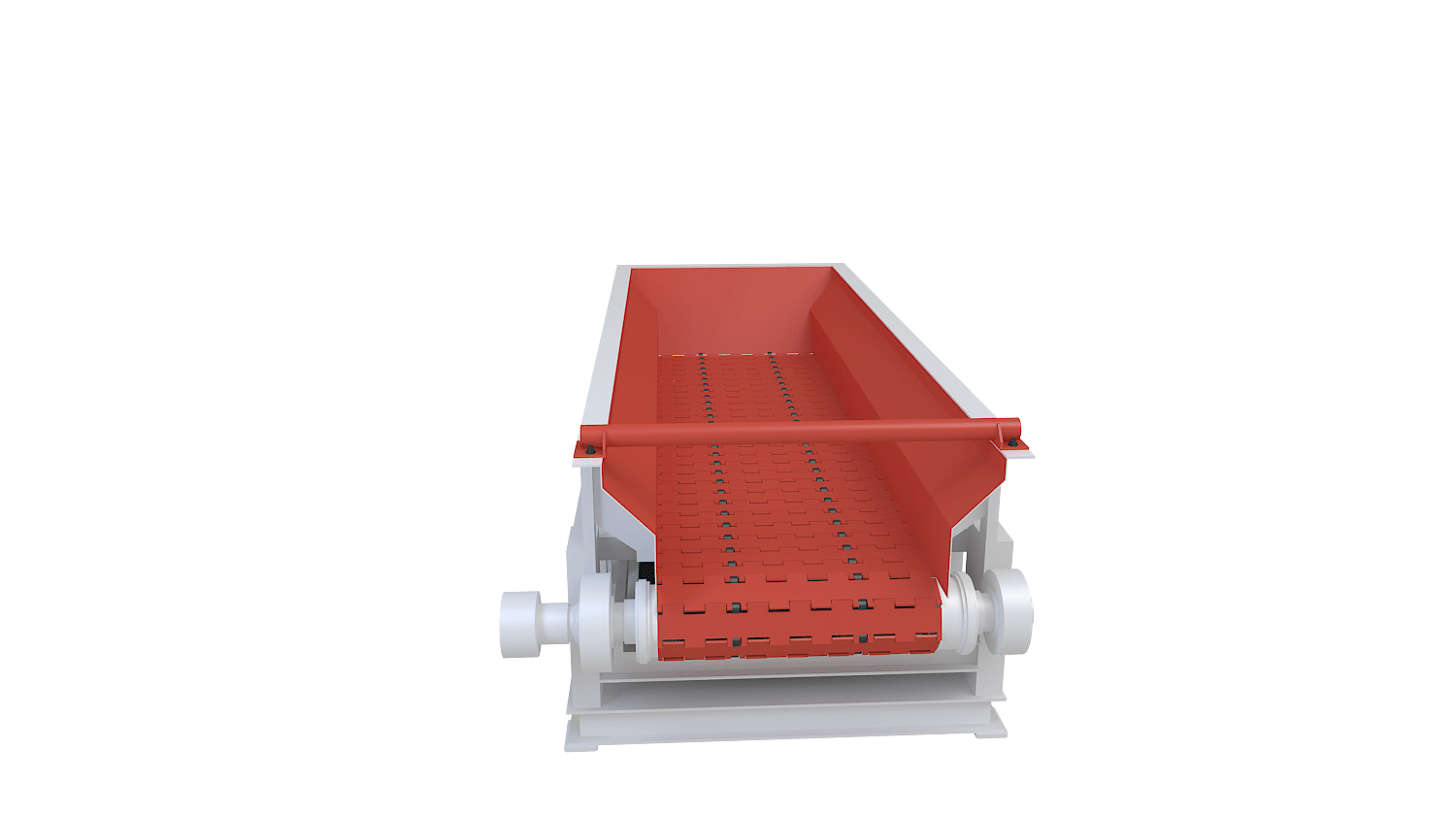

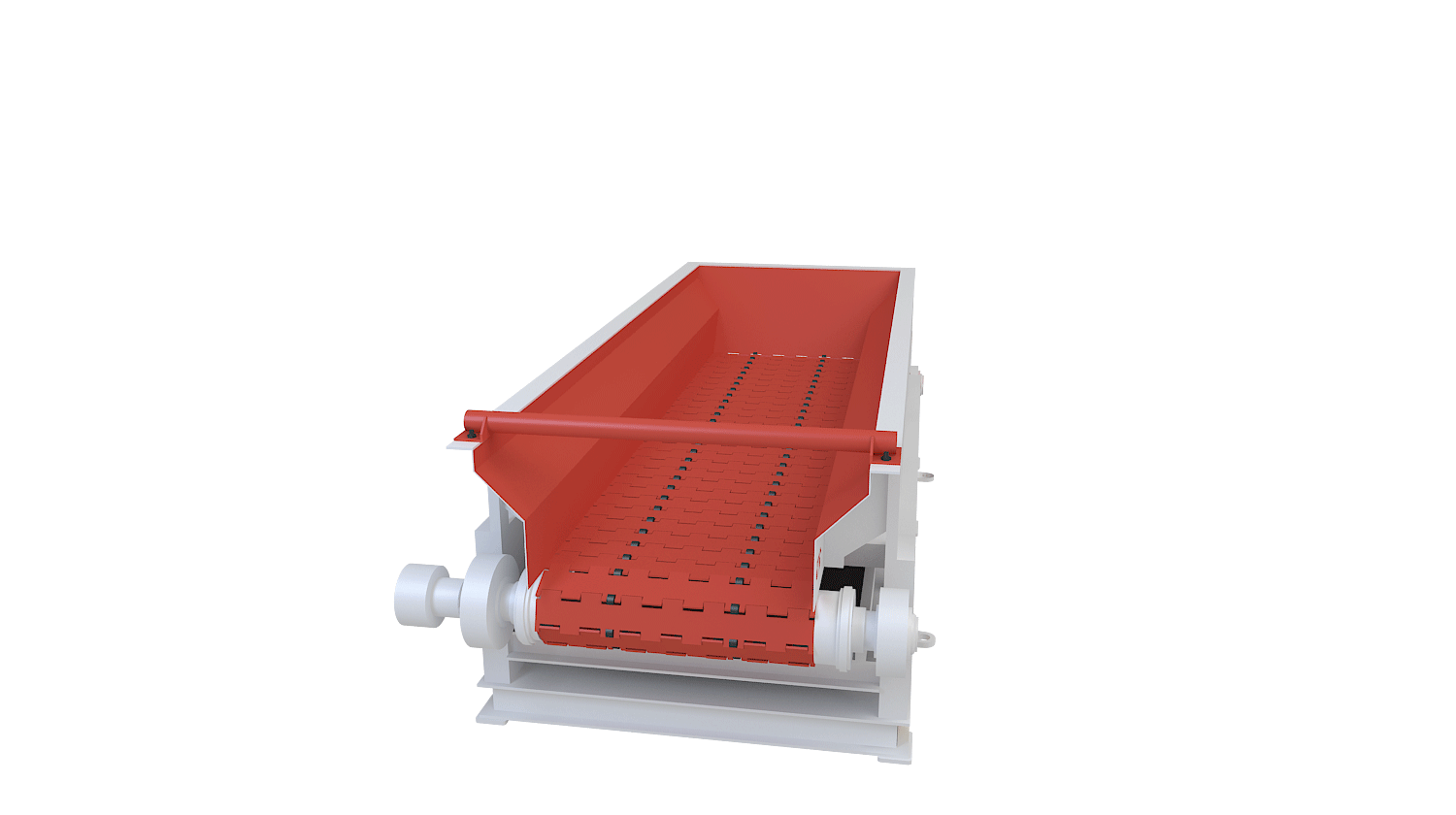

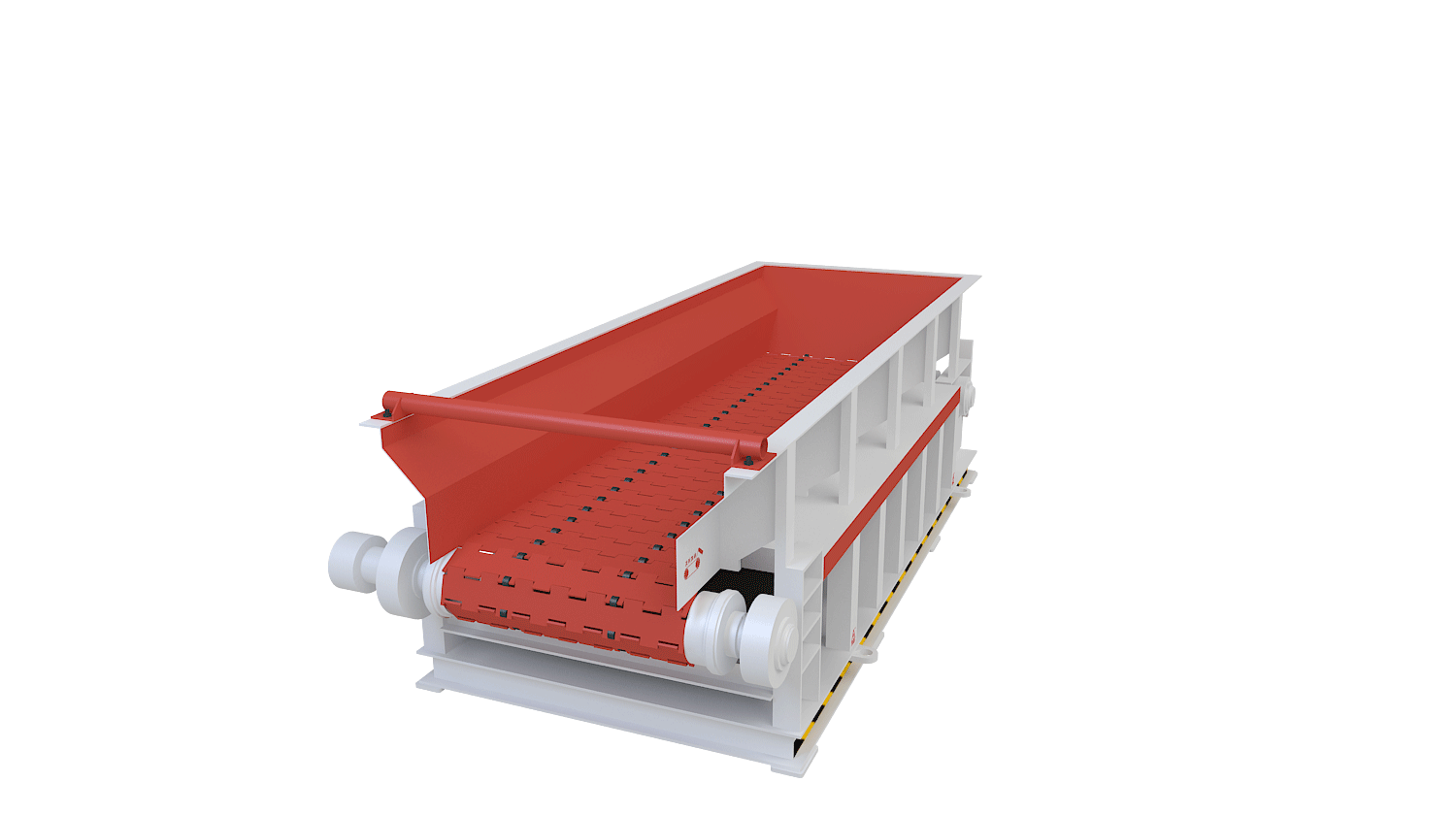

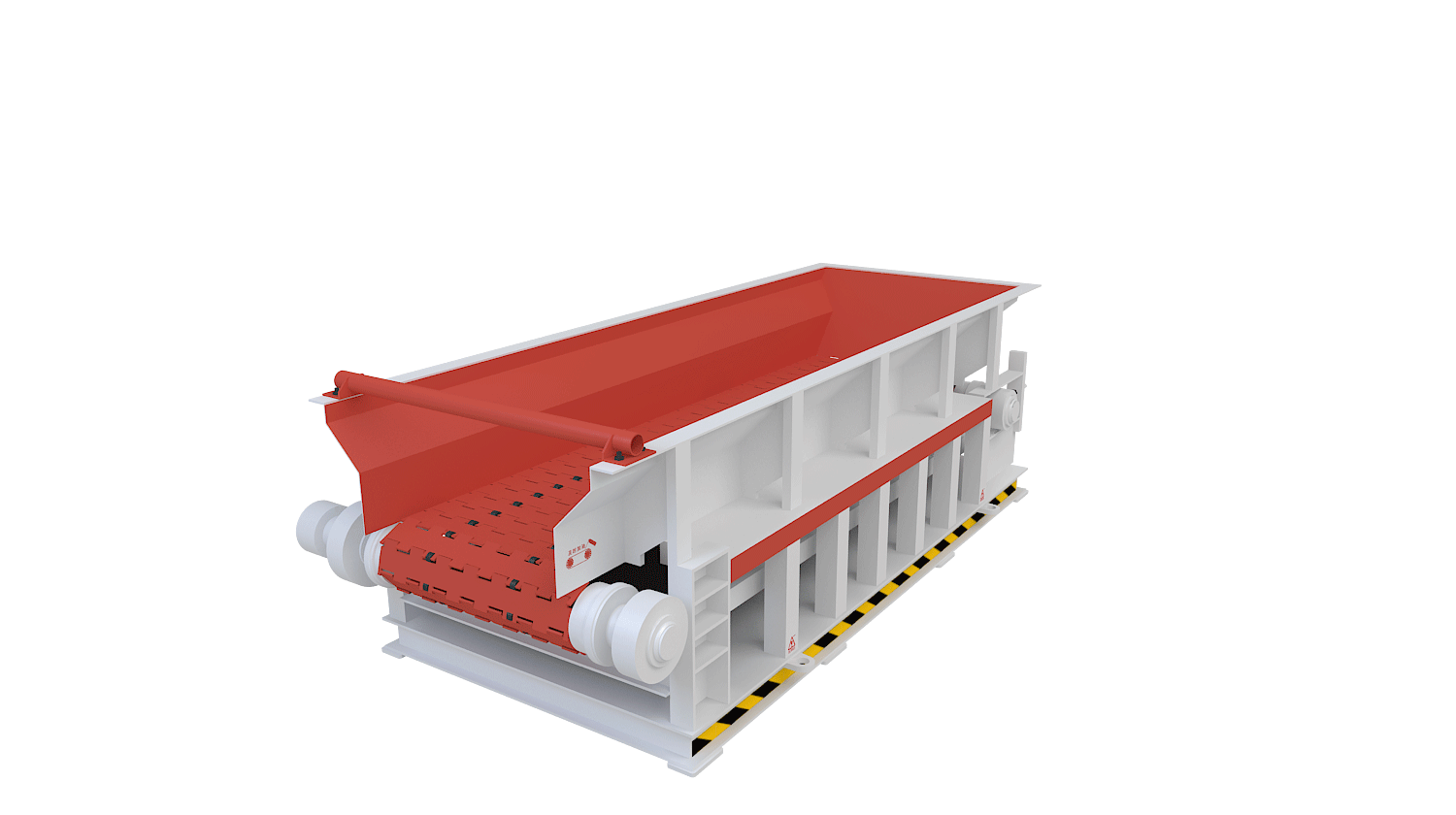

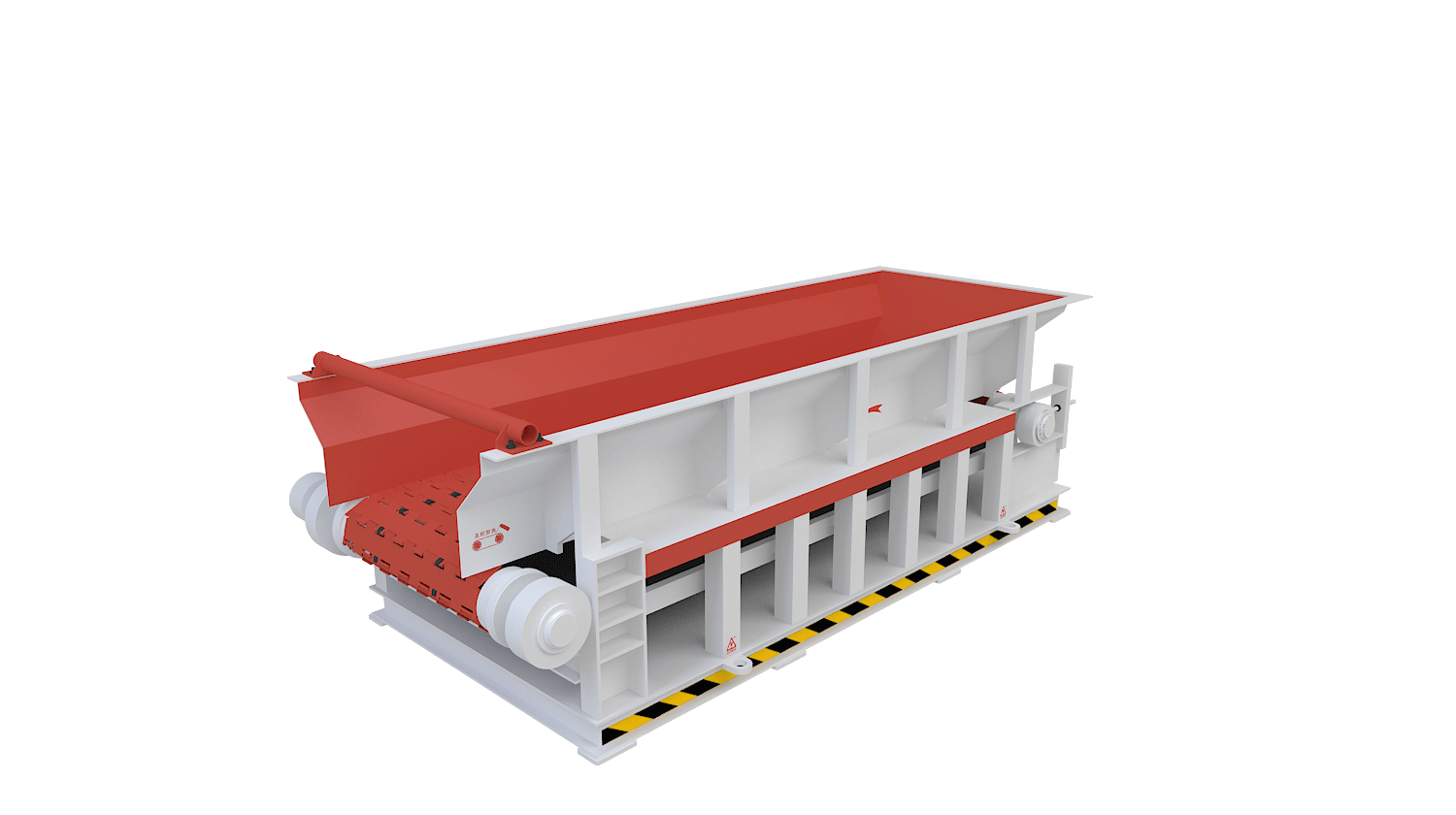

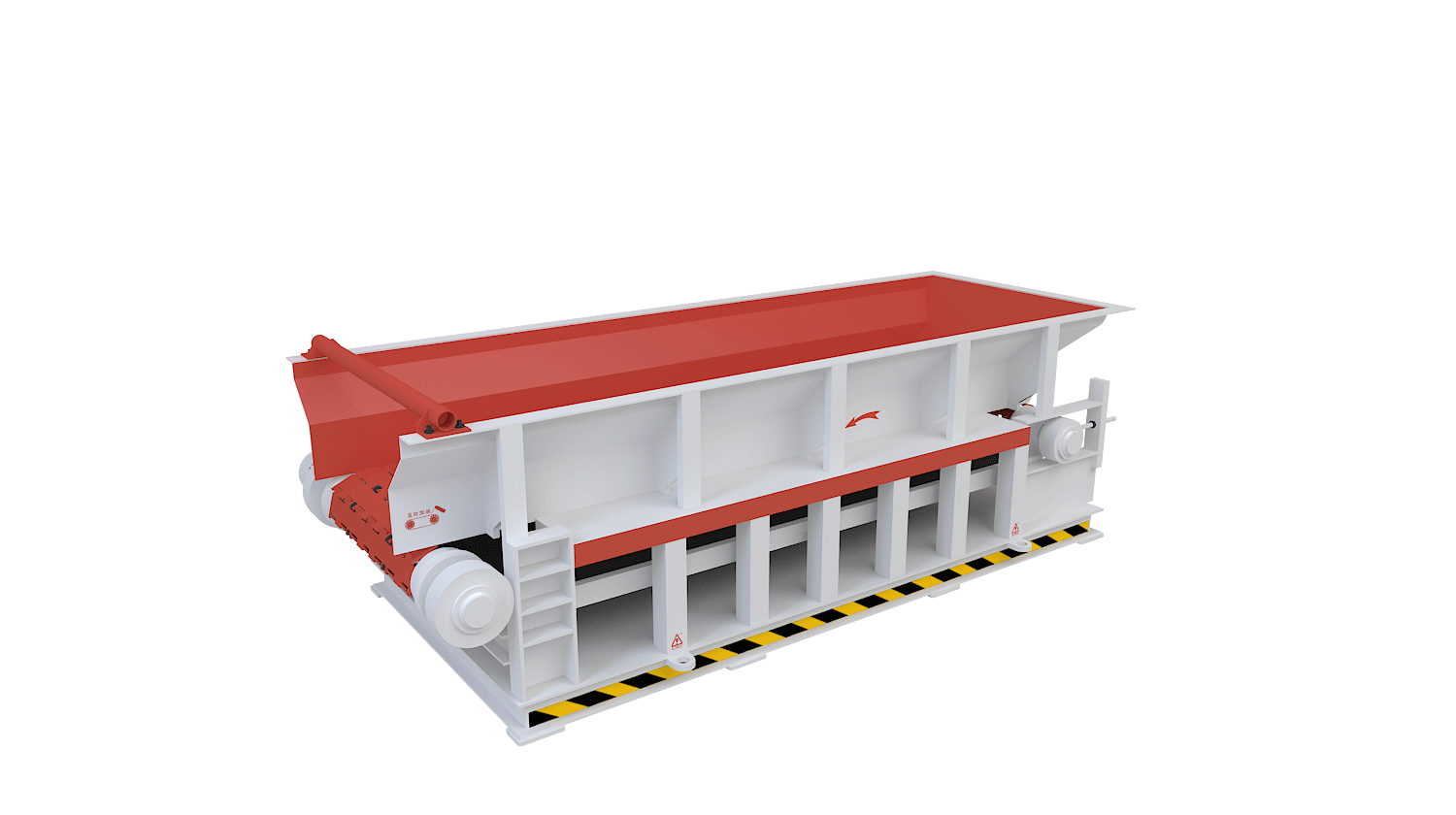

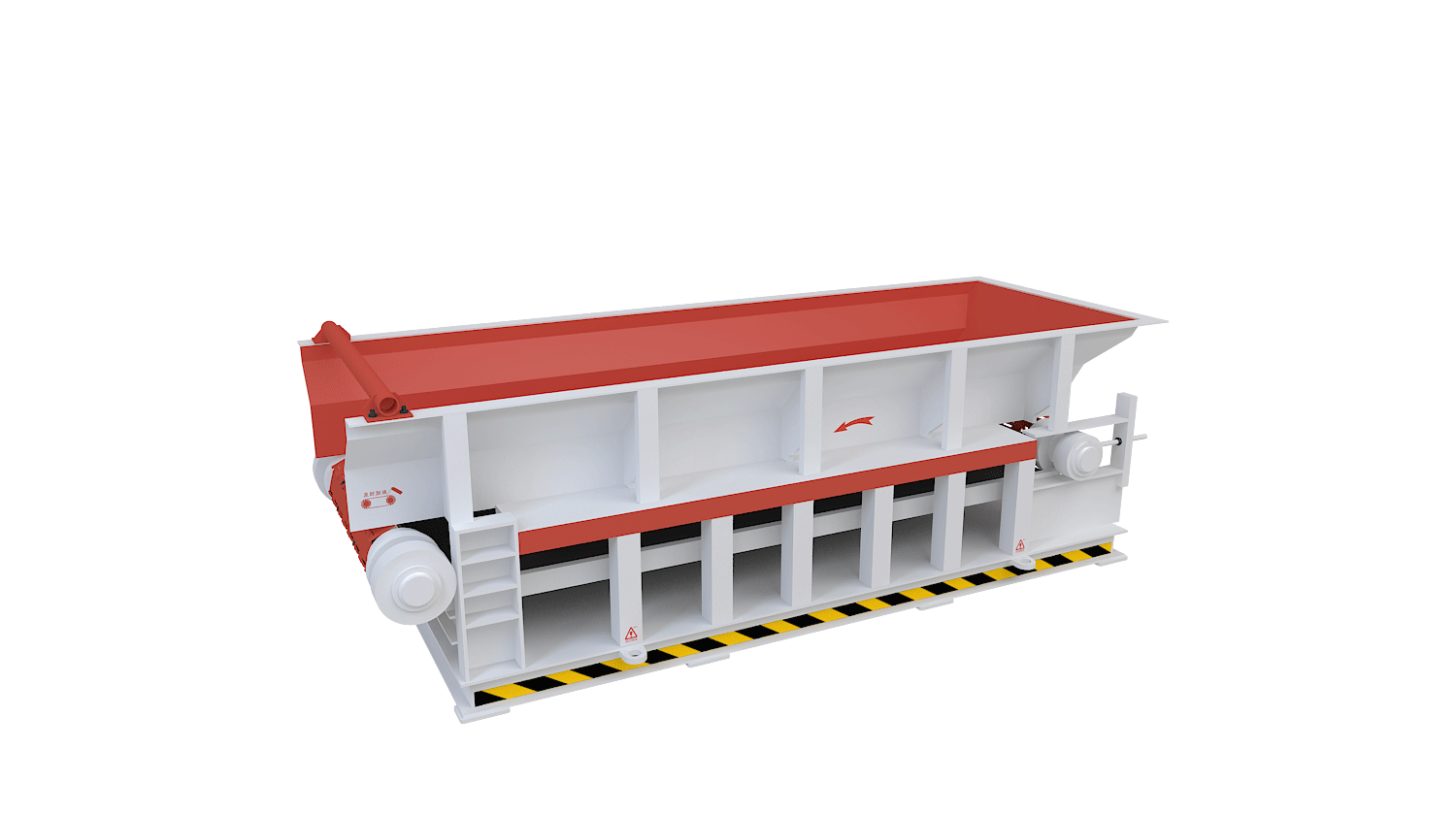

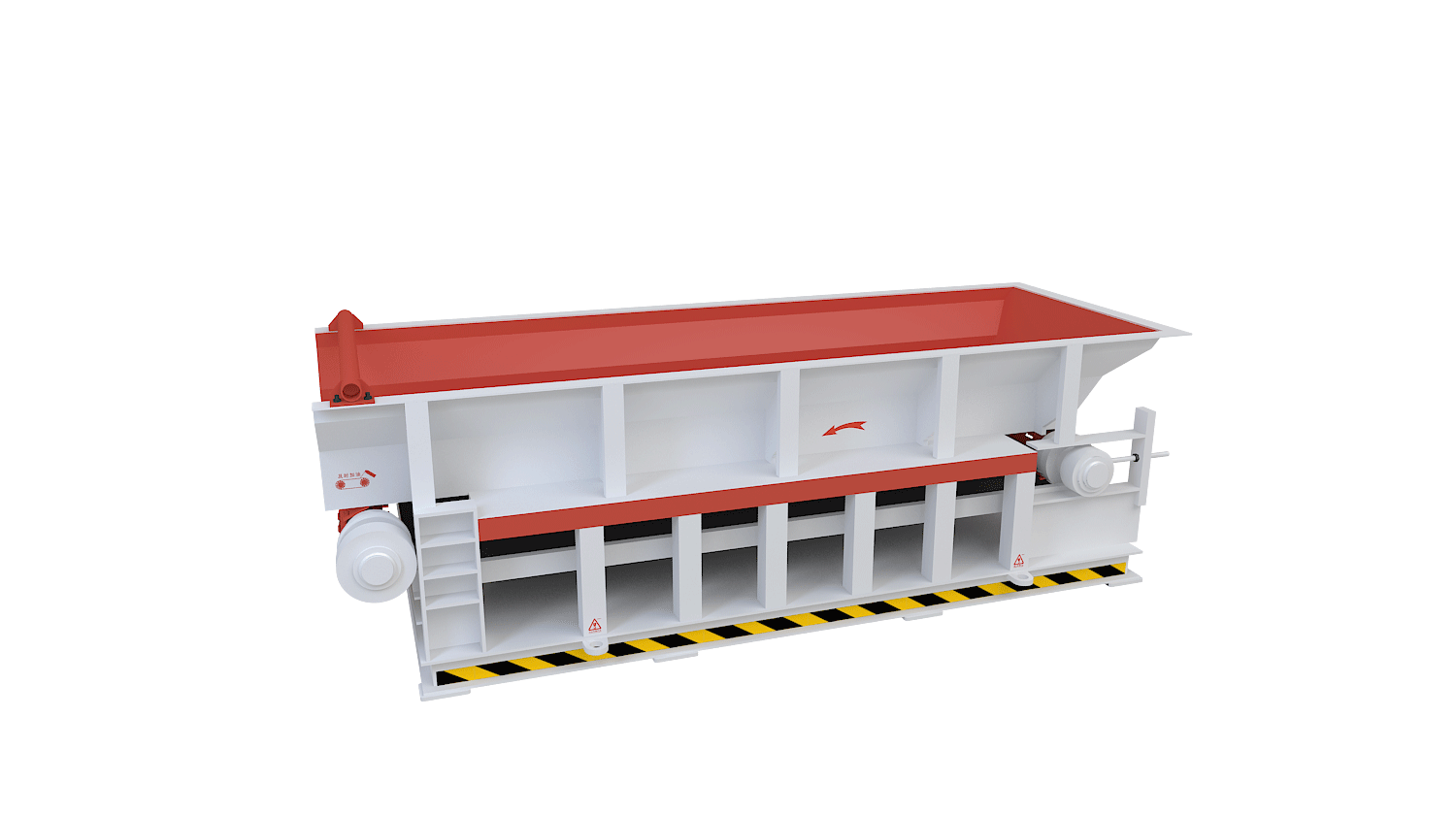

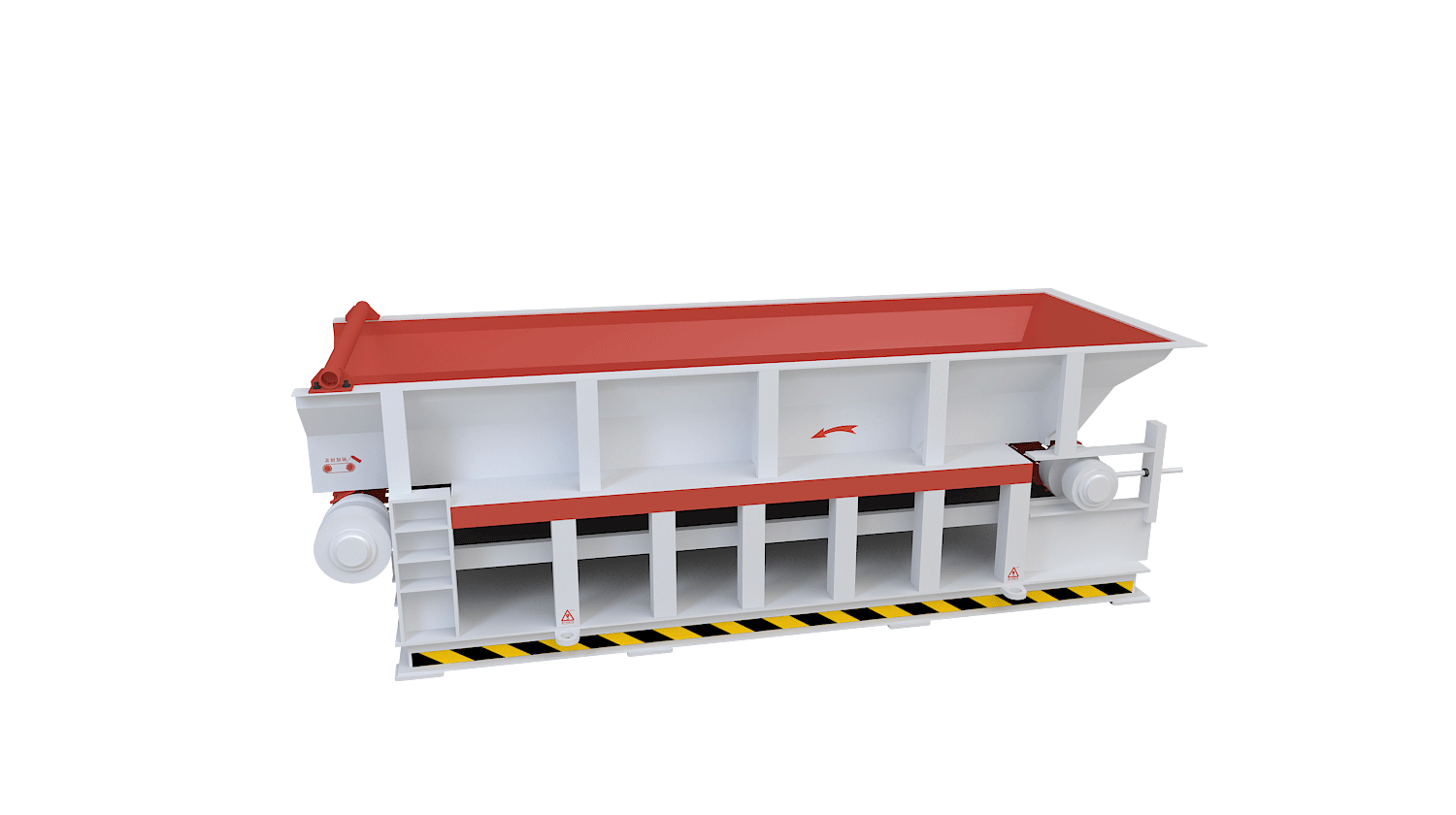

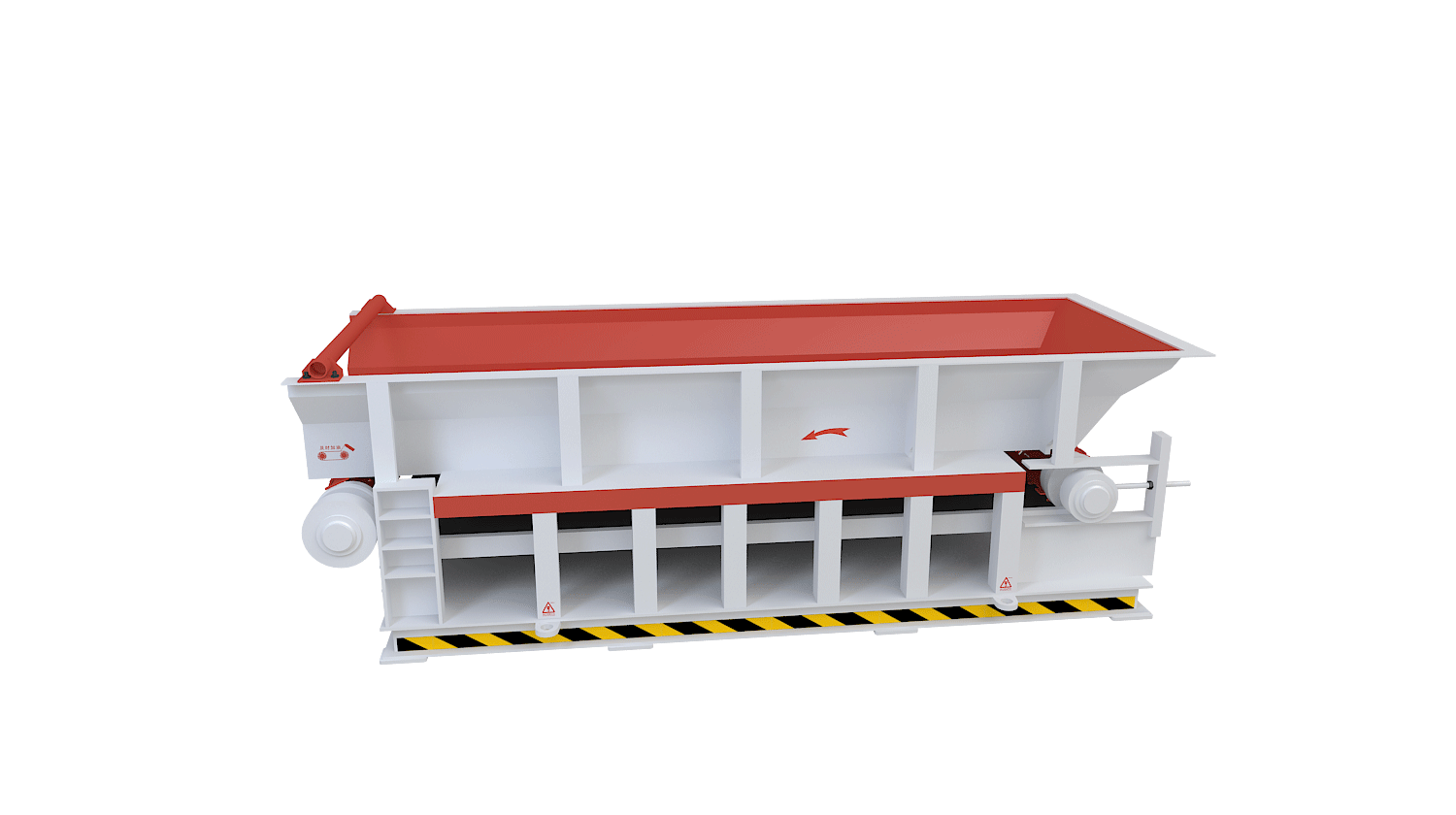

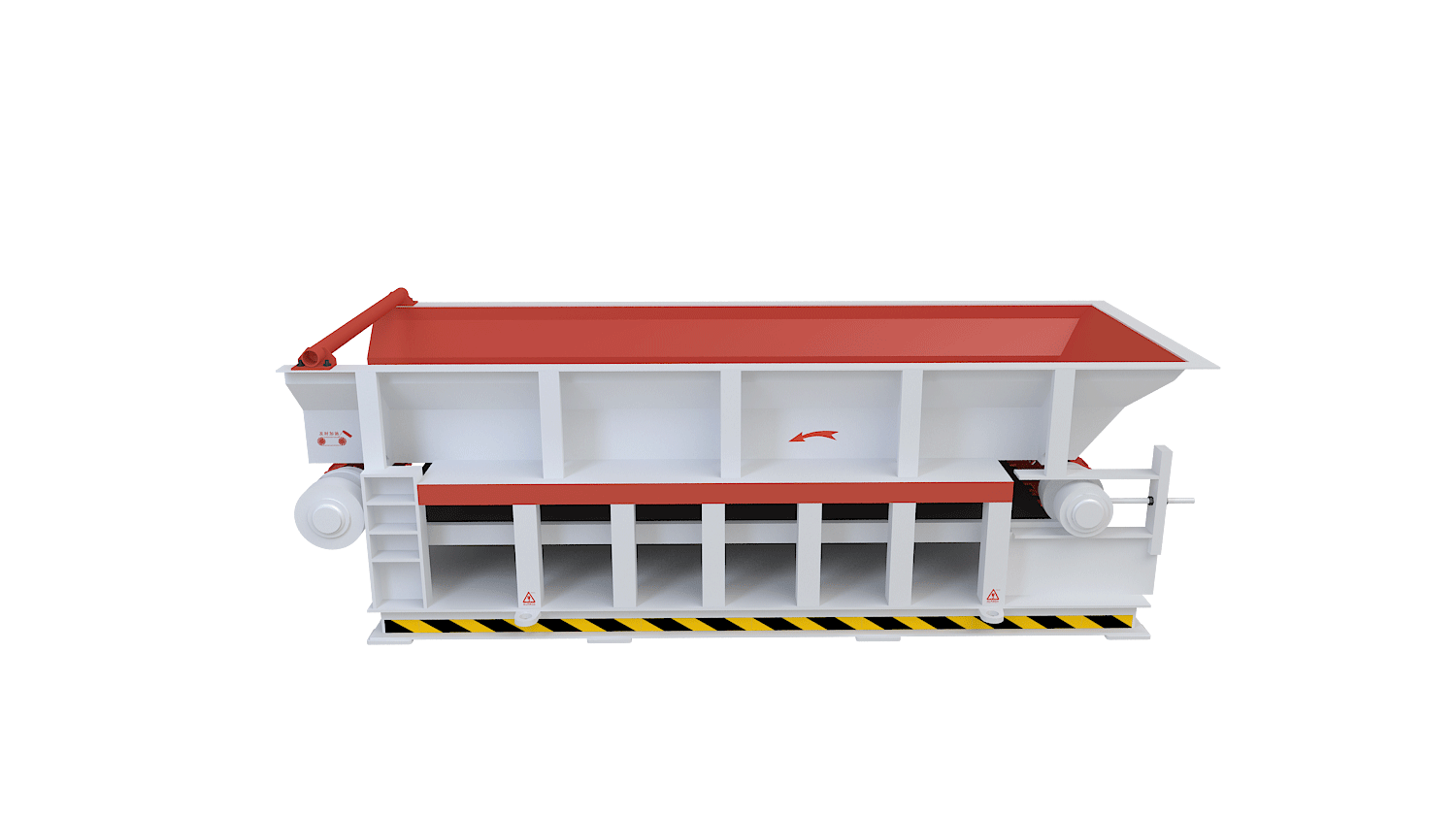

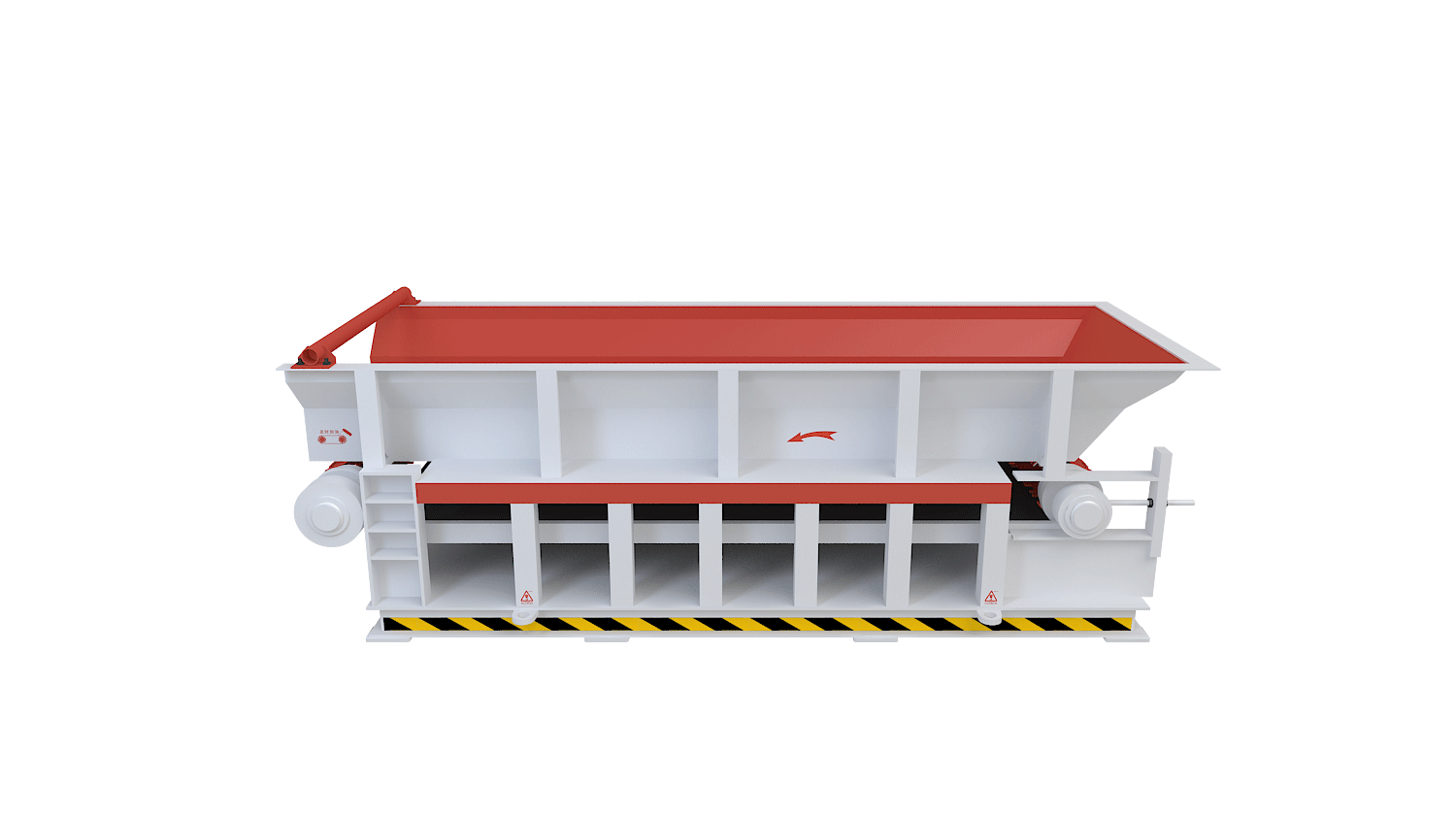

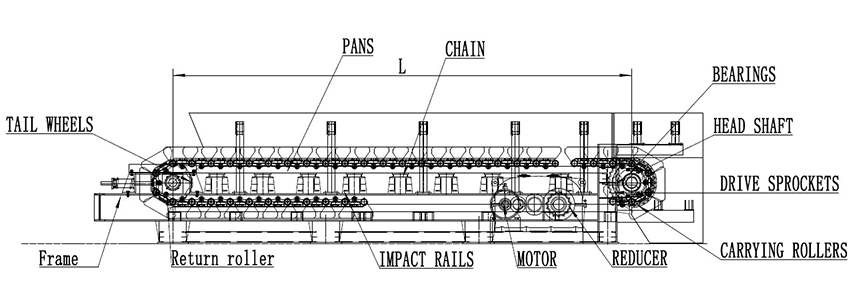

Apron Feeder works by driving a series of steel pans mounted on roller-supported chains. As the chain moves, the pans carry material forward at a controlled rate. Material is loaded onto the feeder from above (typically by a dump truck or loader) and moves steadily along the horizontal or inclined path toward the discharge point. The heavy-duty design ensures the feeder can absorb large impacts, resist wear, and transport massive loads. By adjusting the drive speed or regulating the feed gate, operators can control the output flow to match downstream equipment capacity.