Introduction

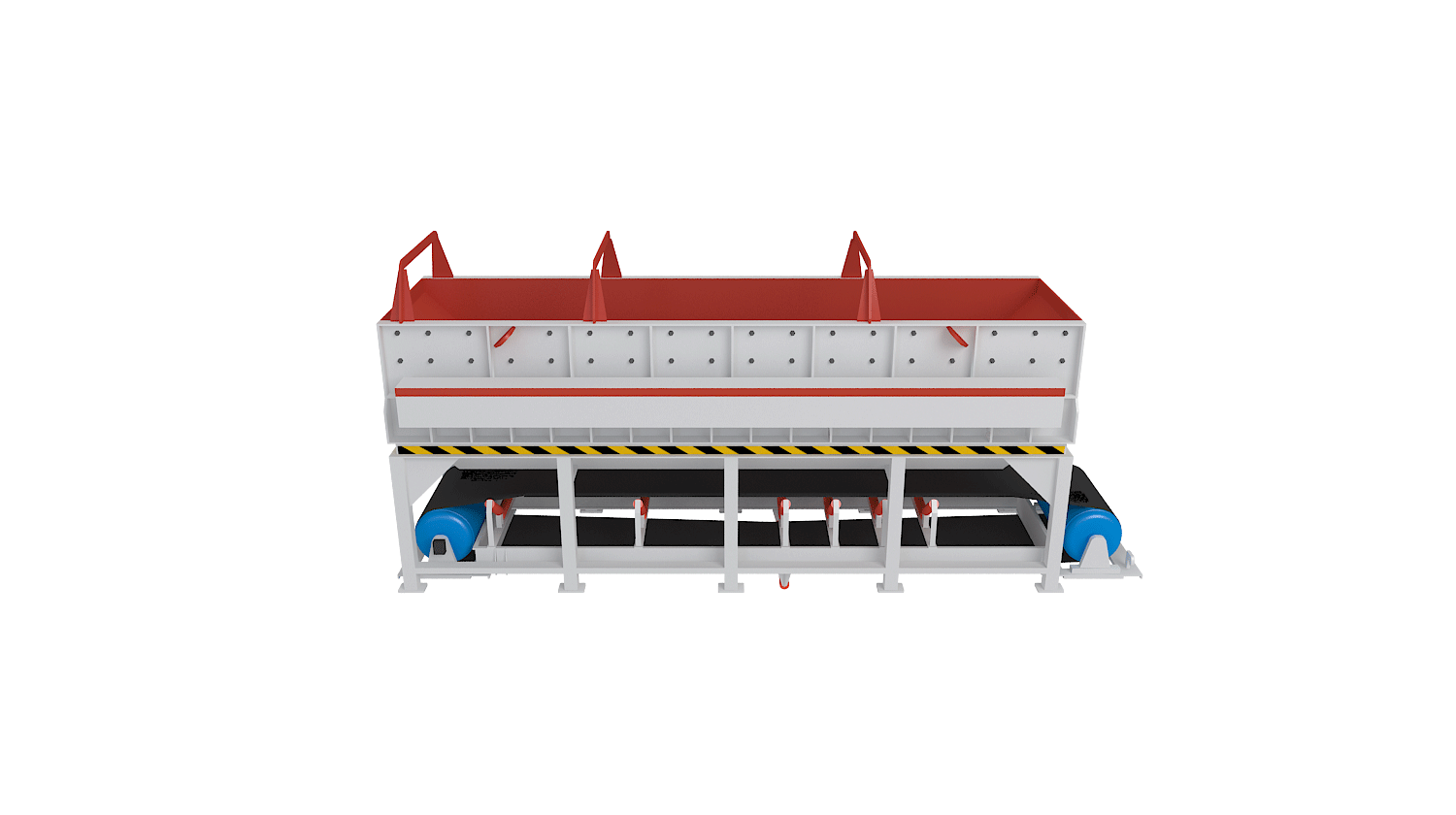

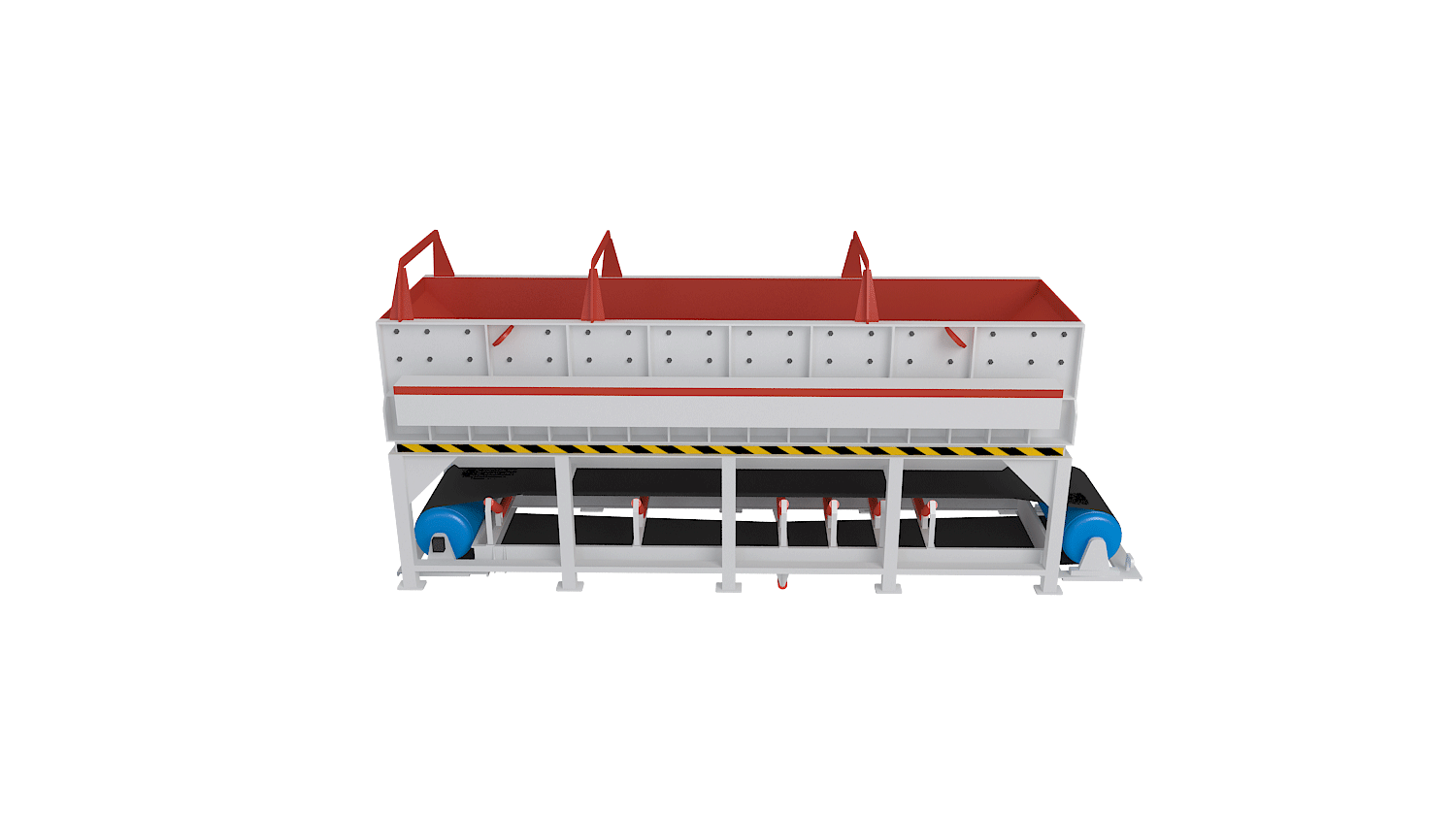

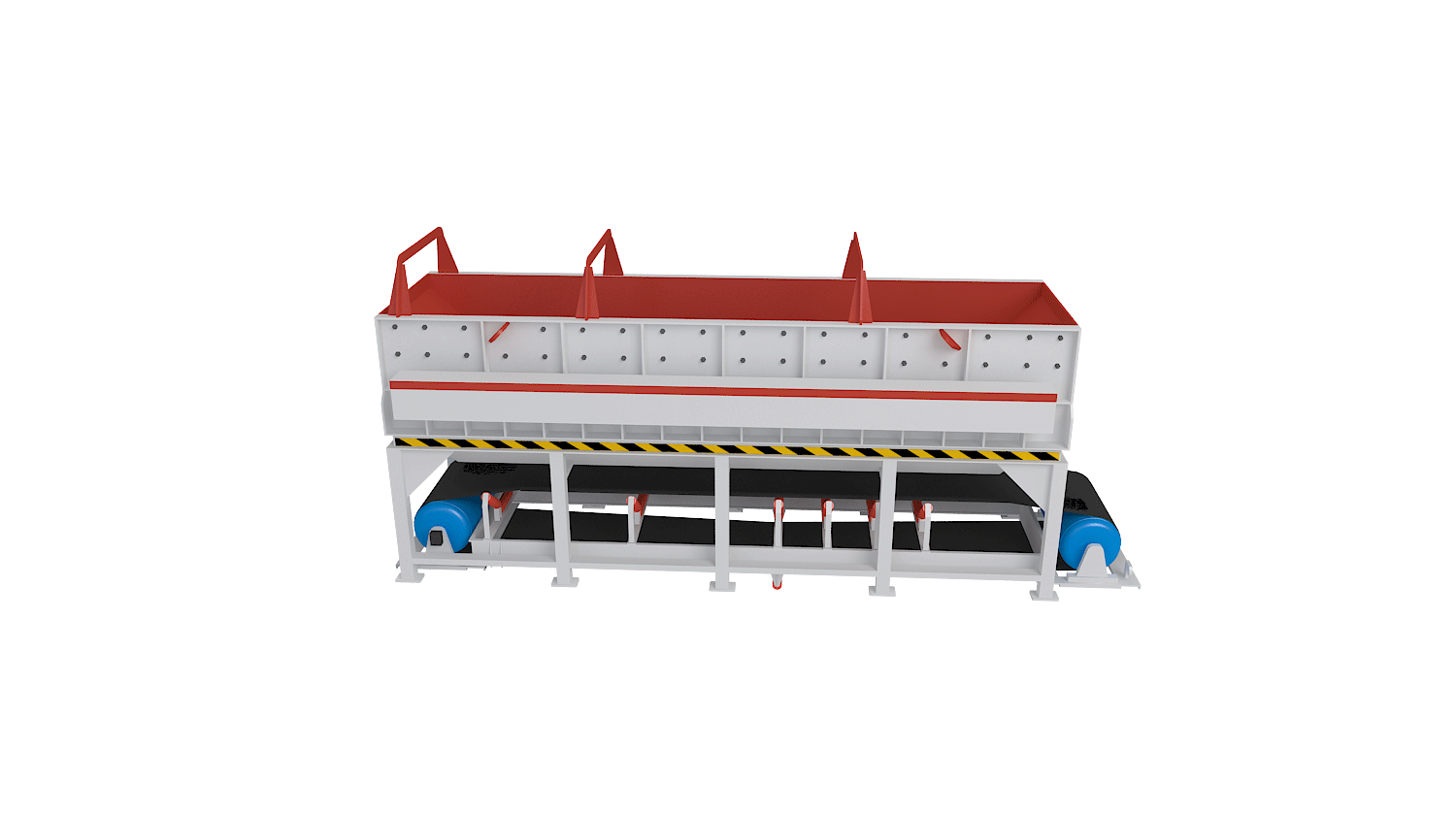

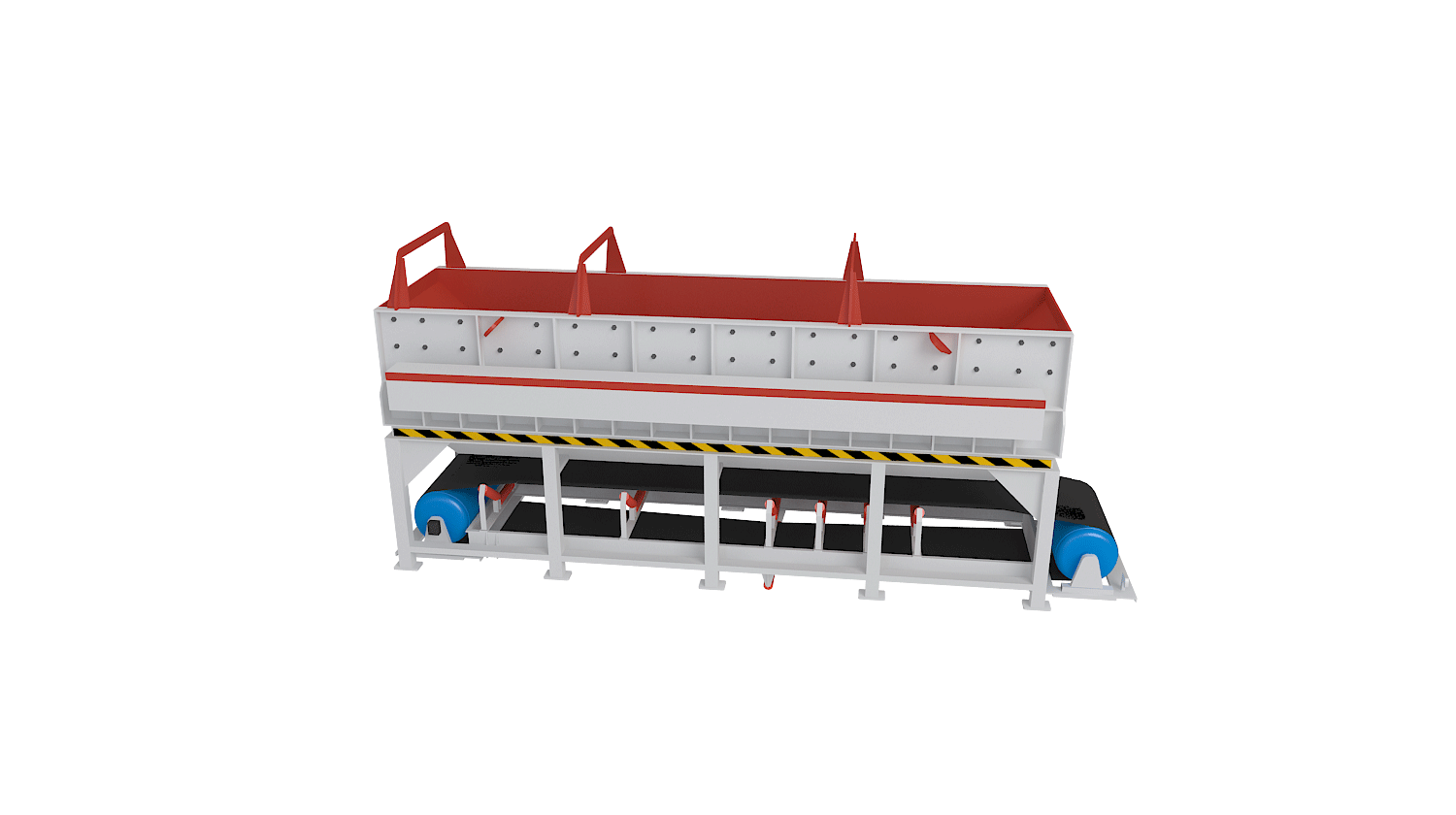

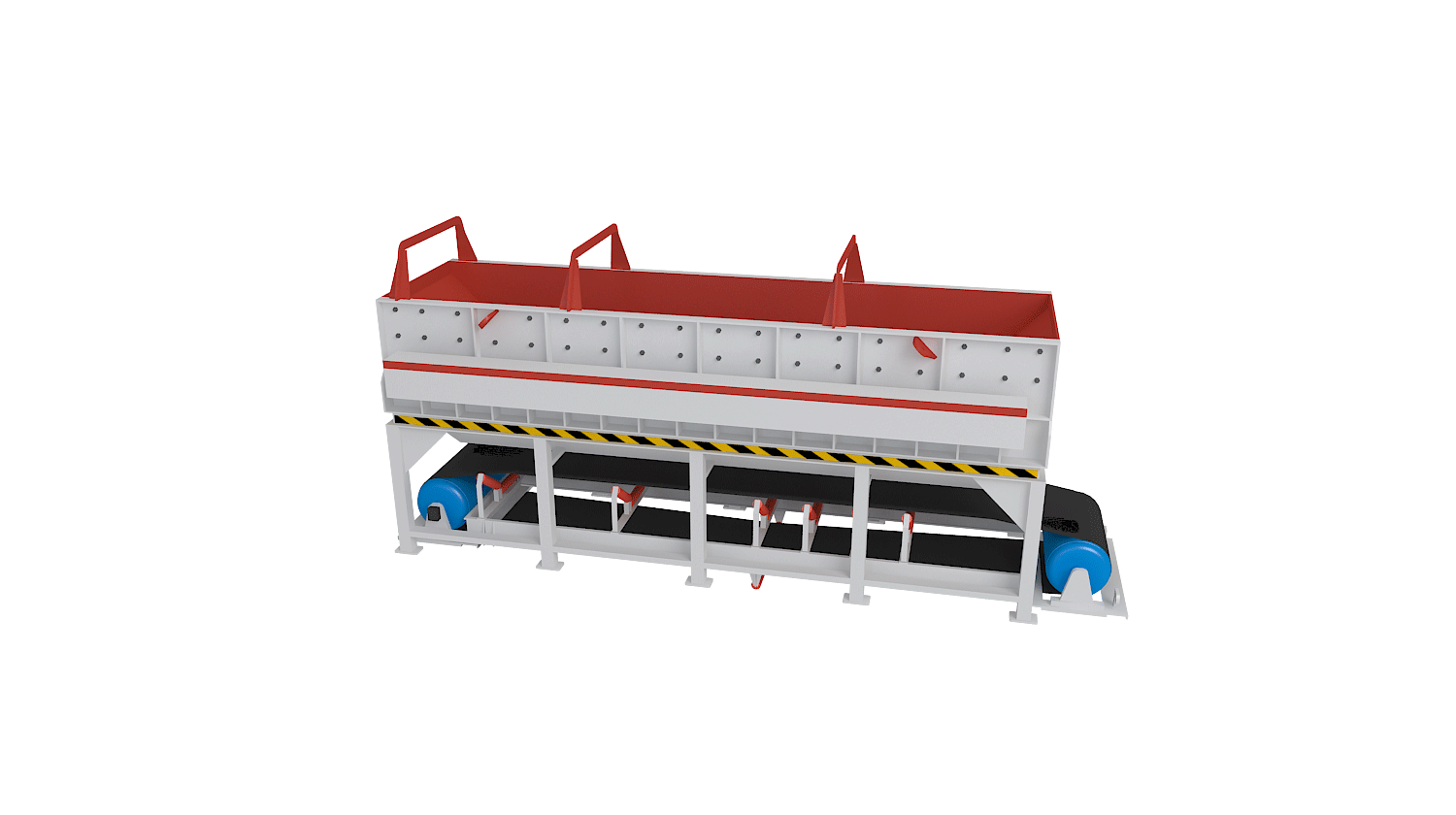

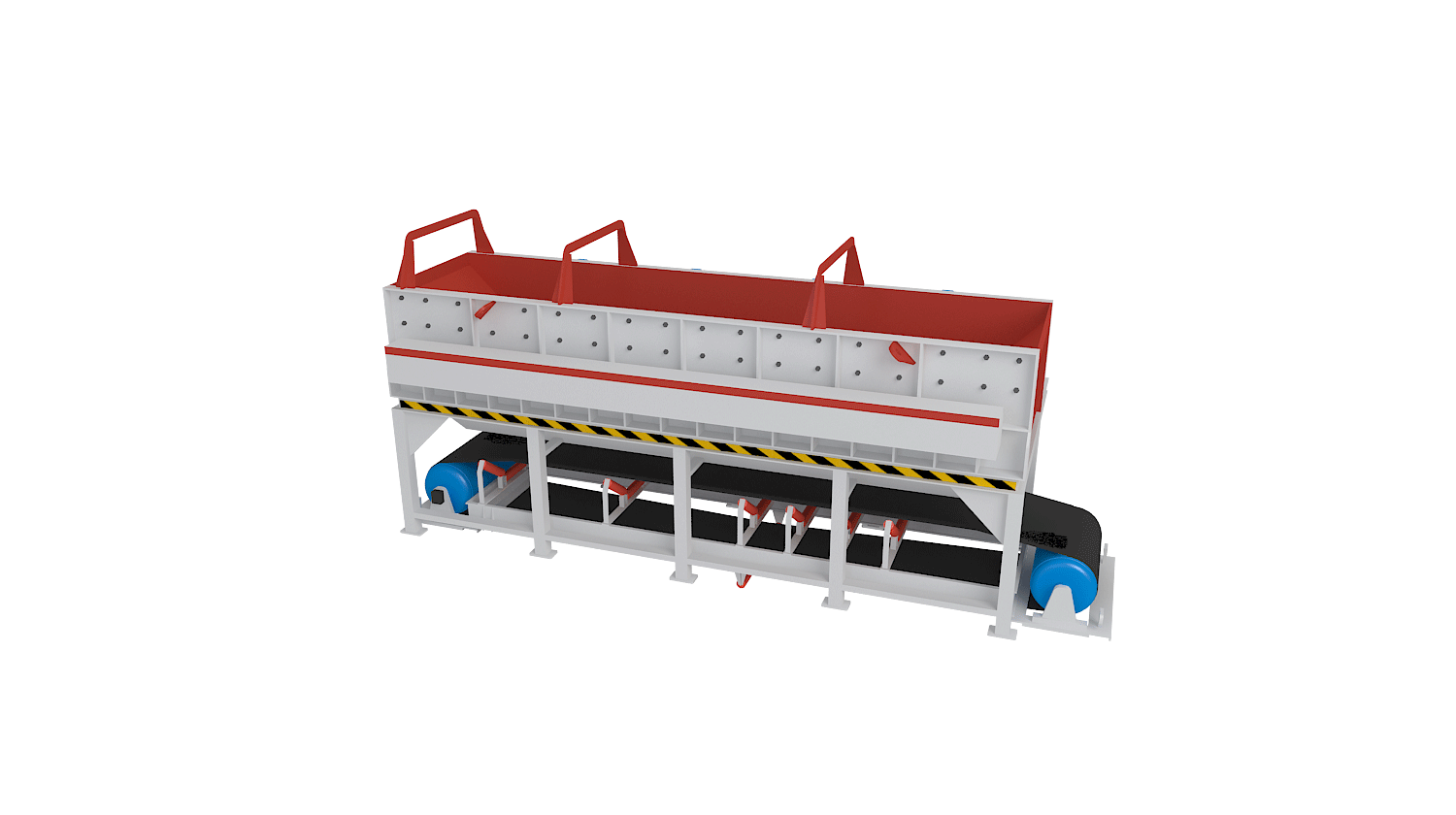

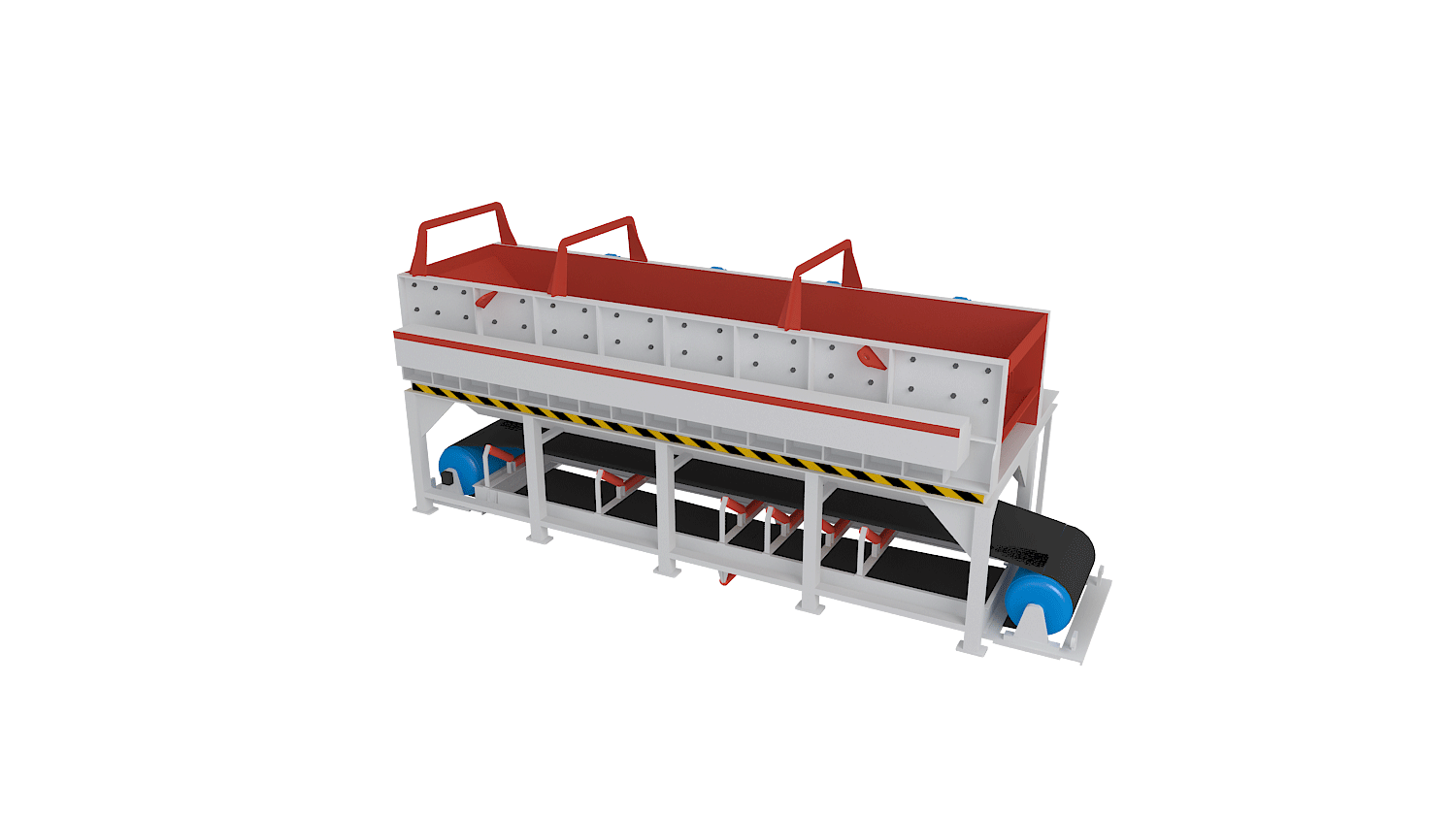

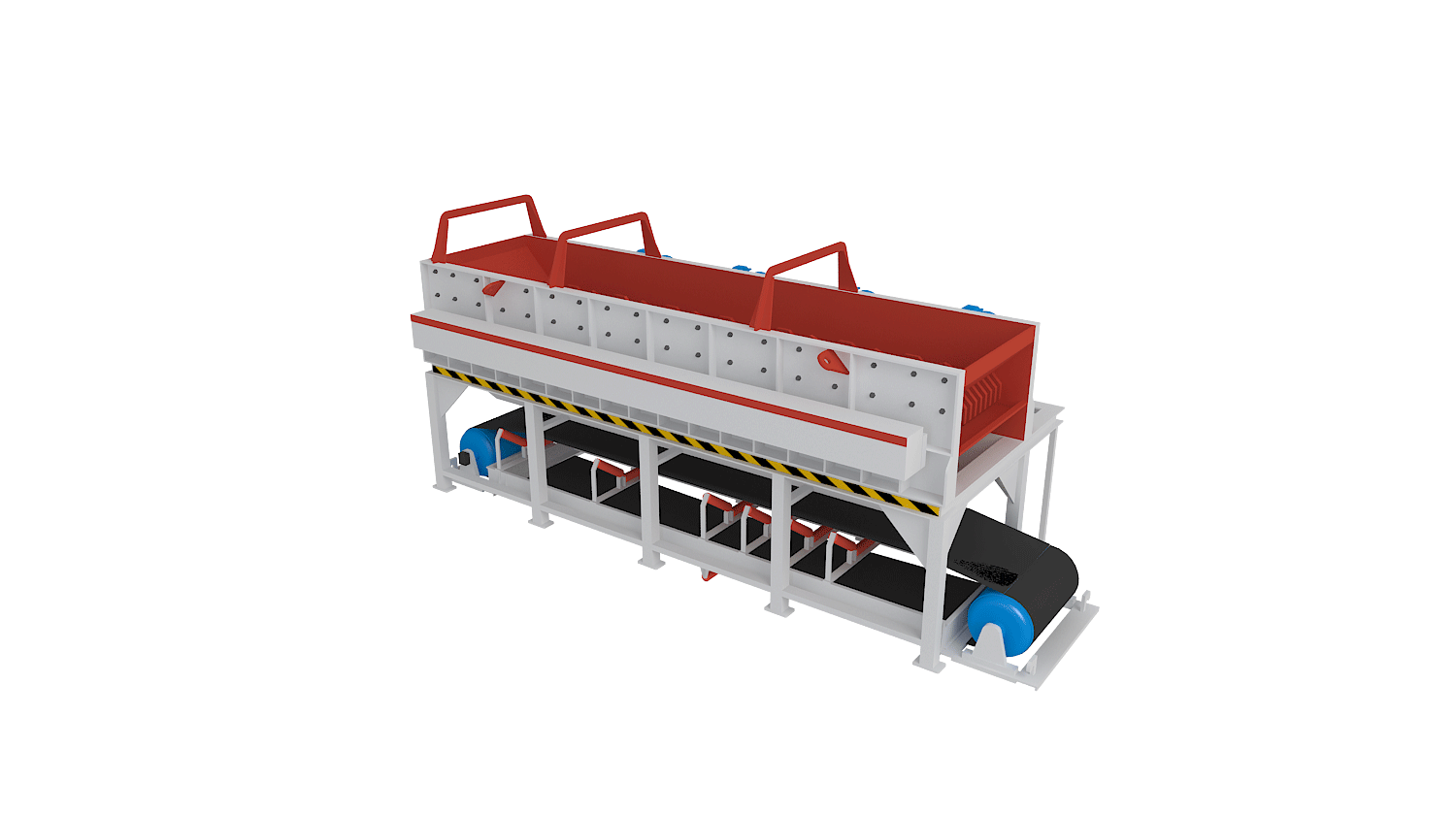

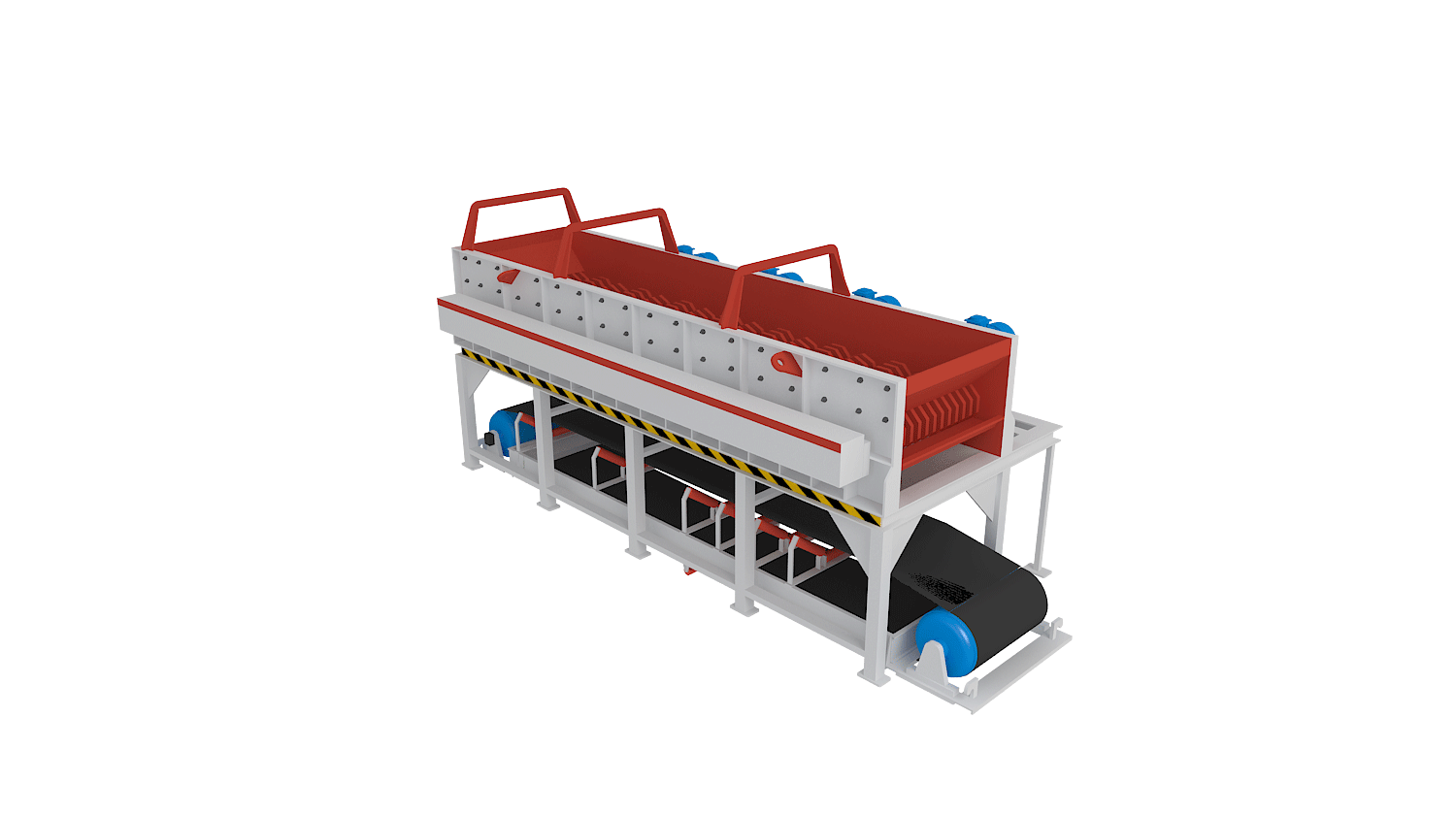

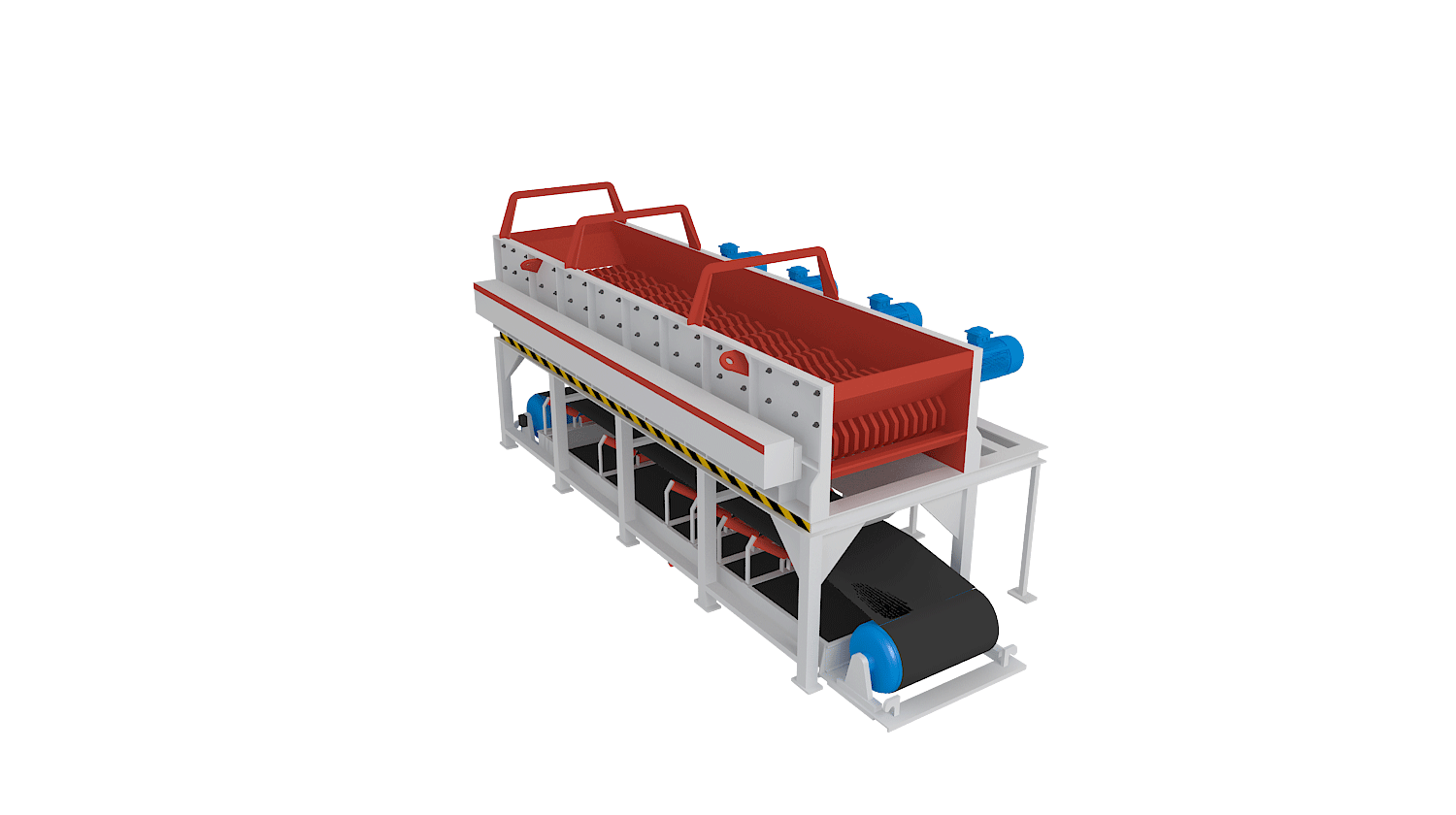

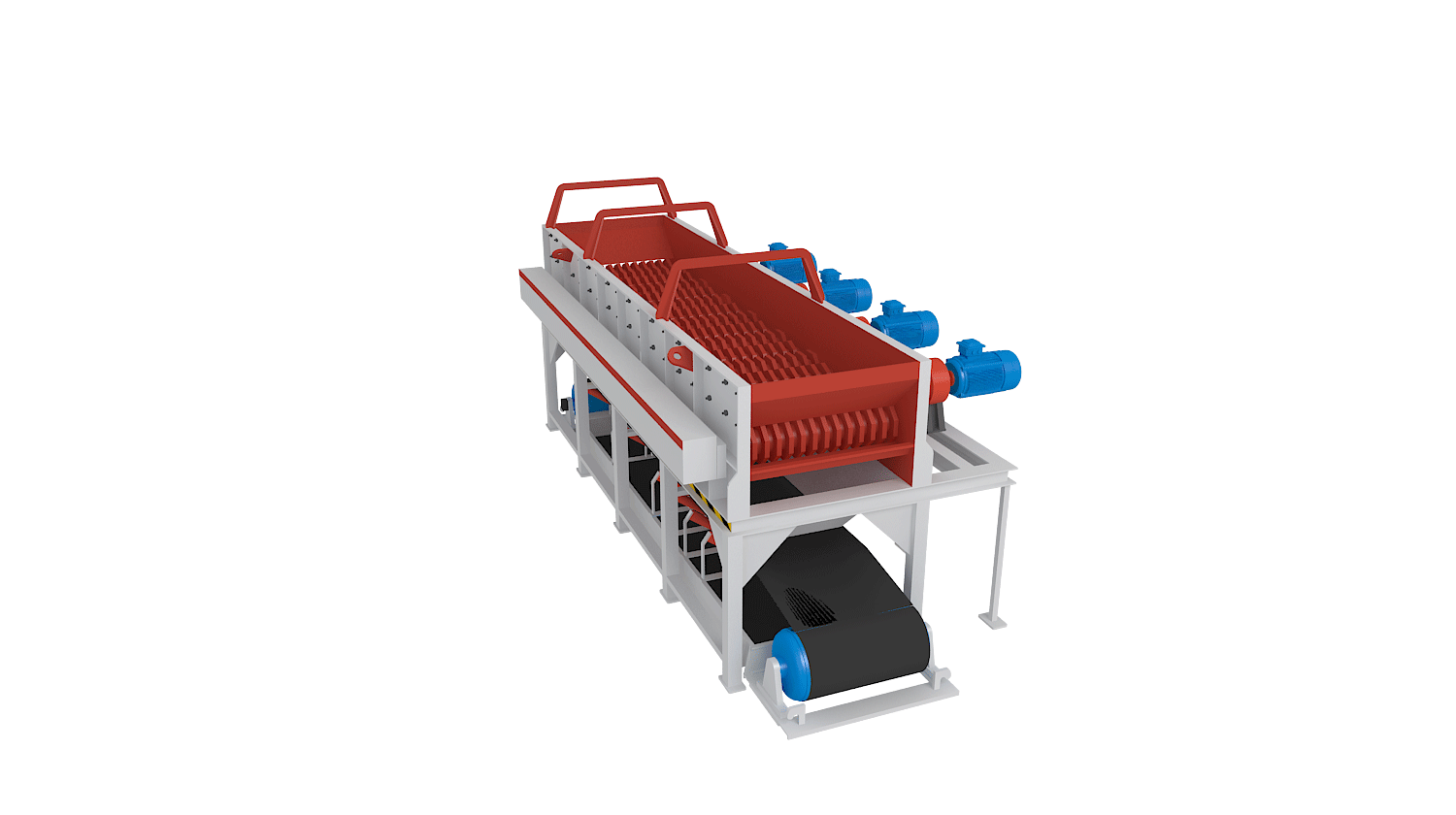

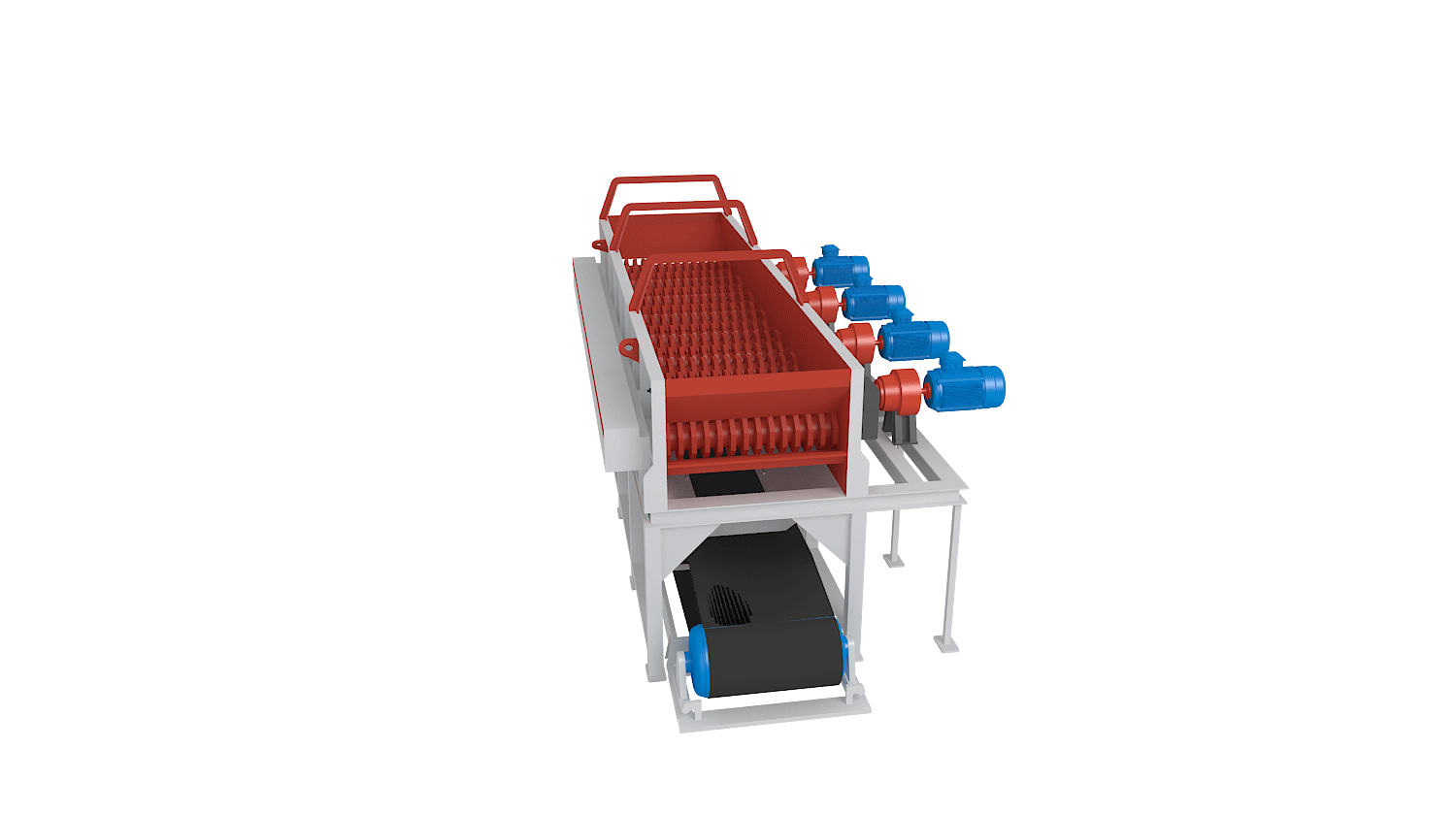

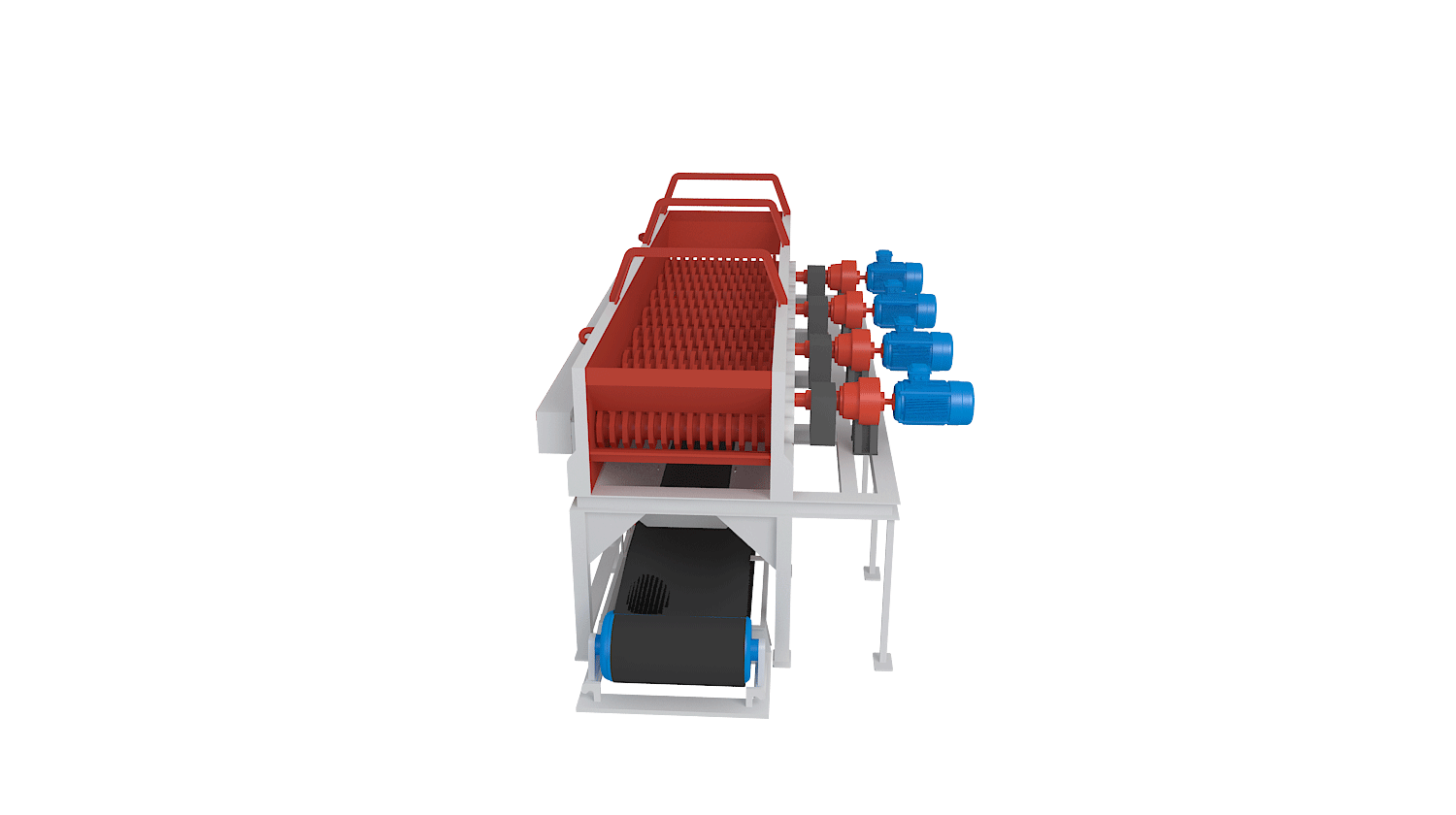

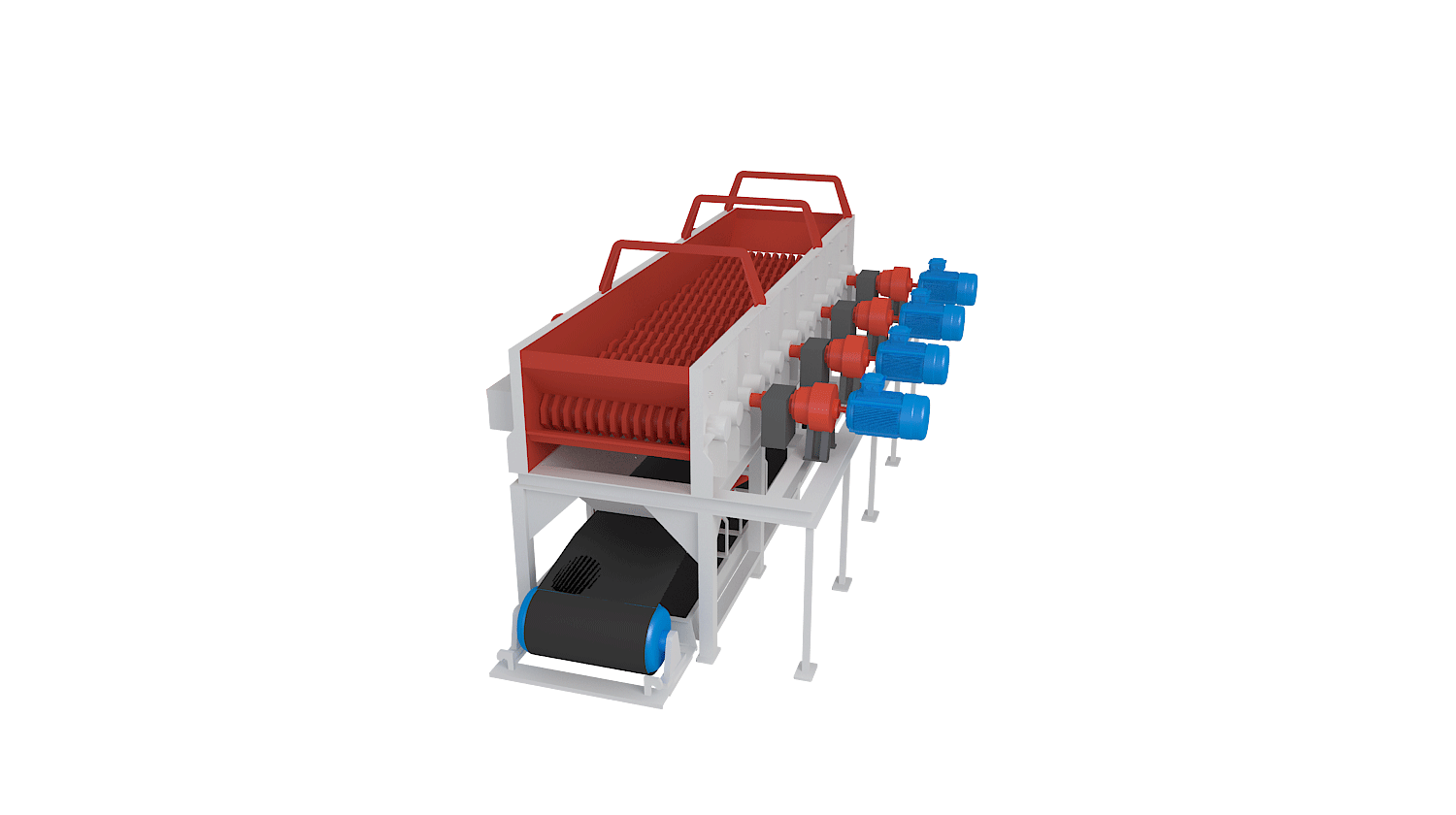

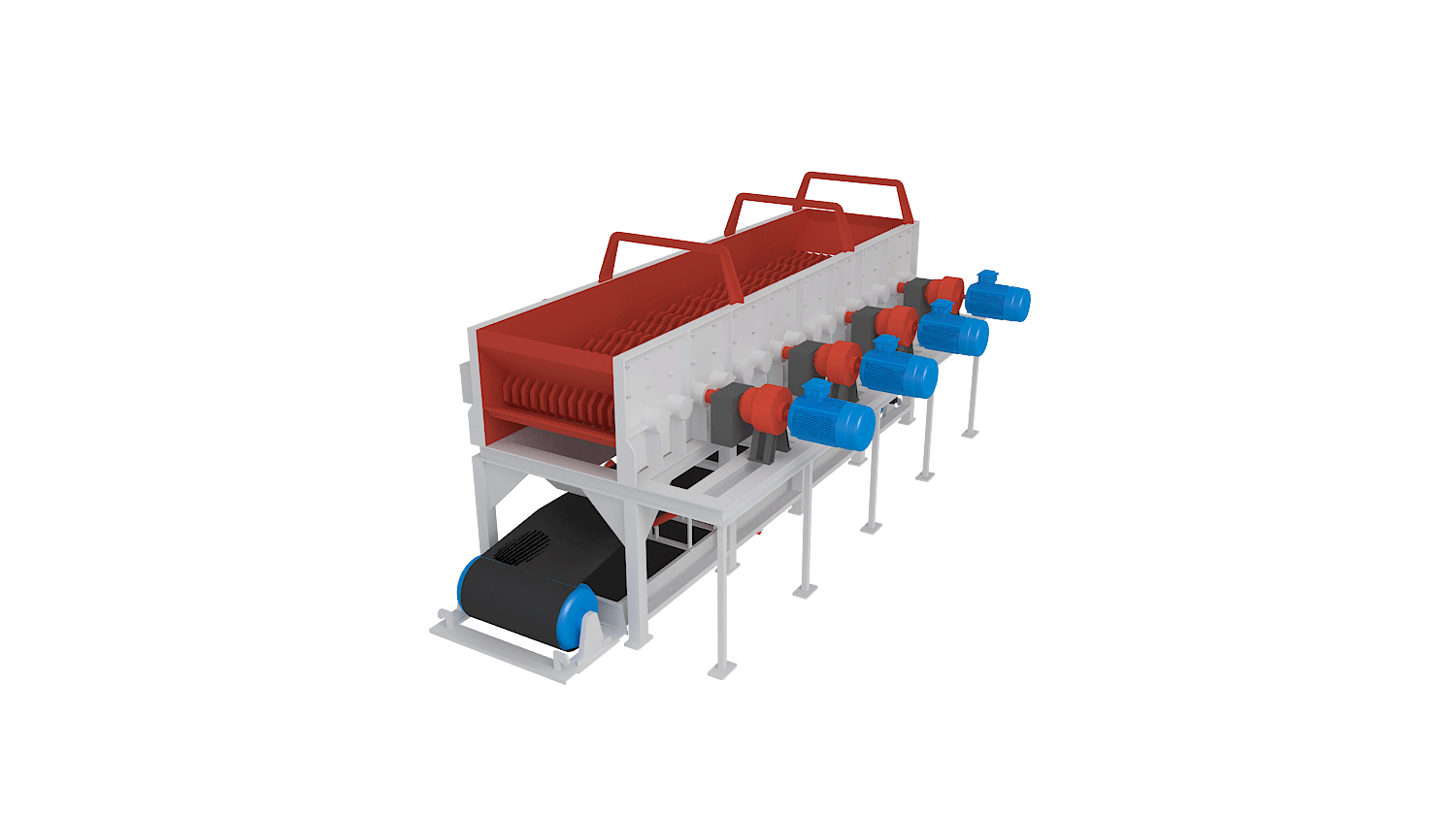

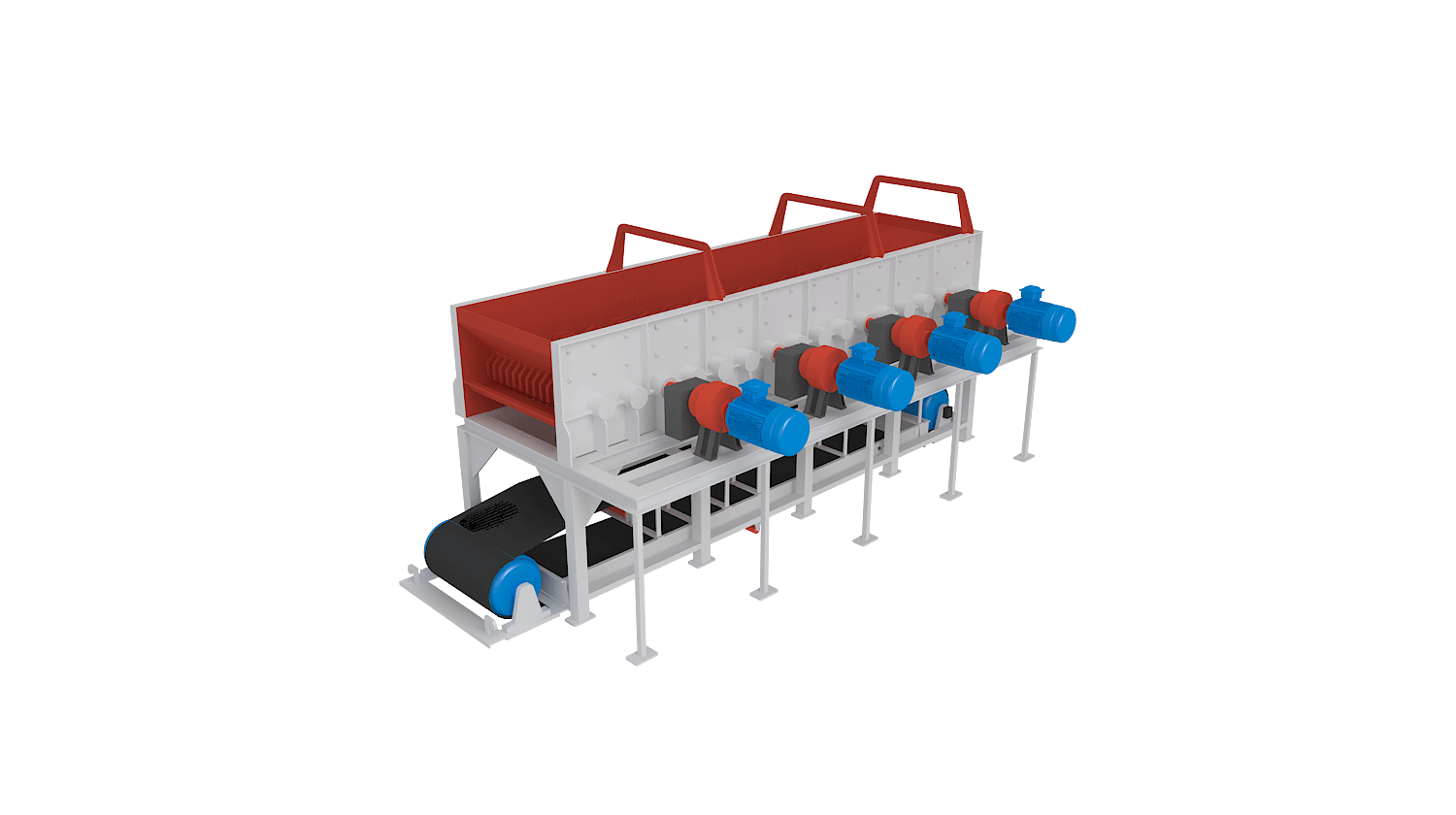

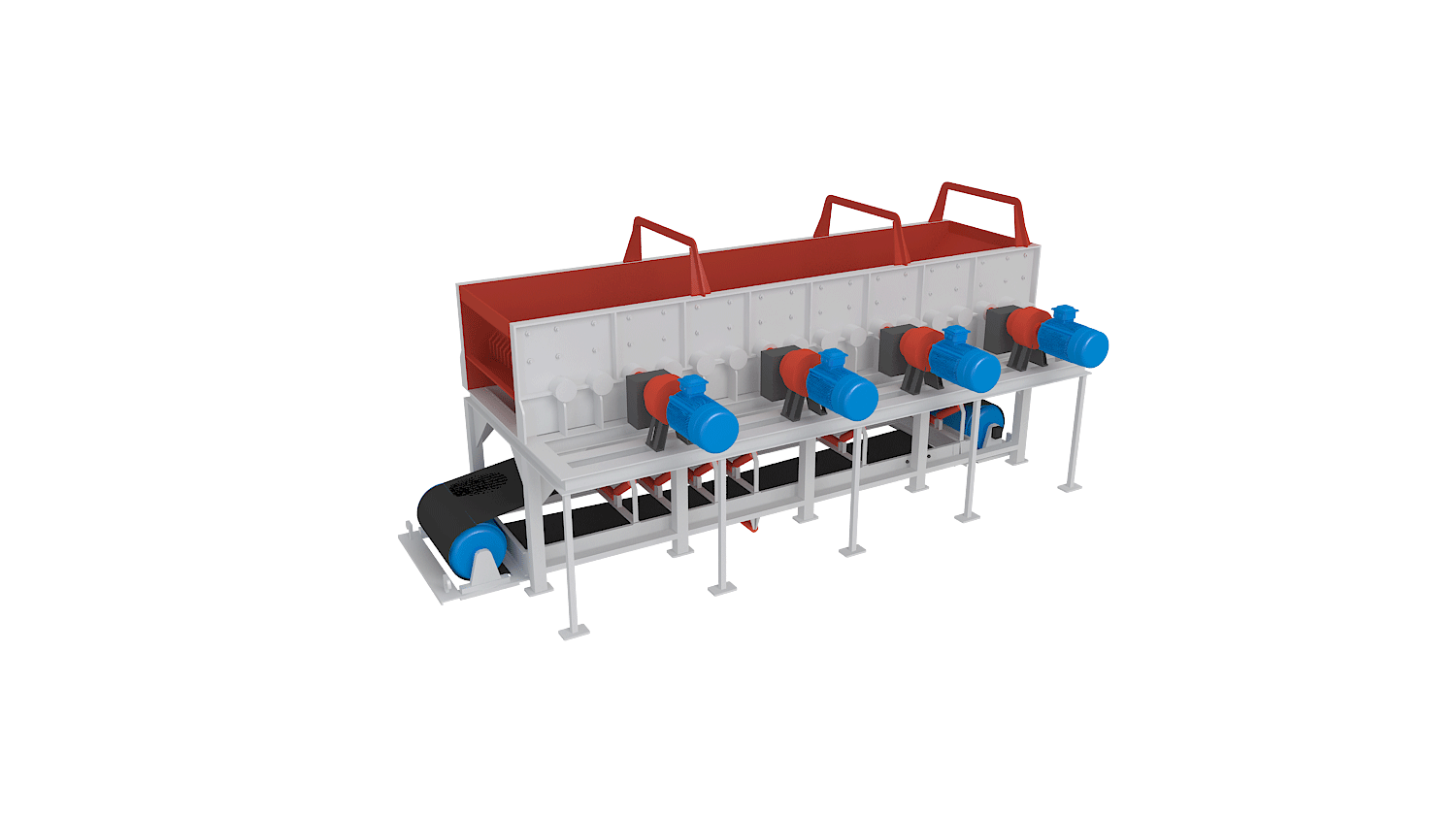

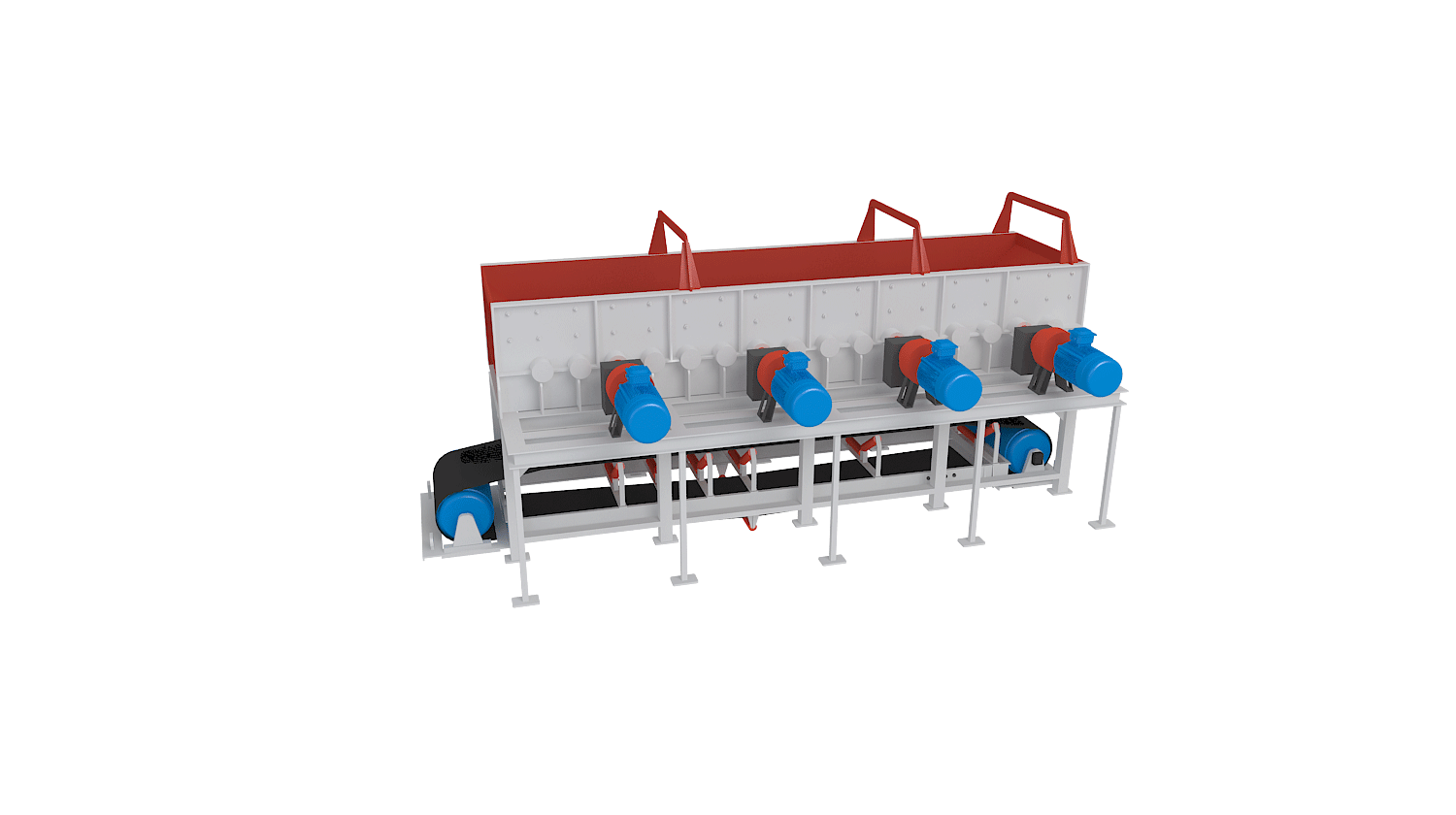

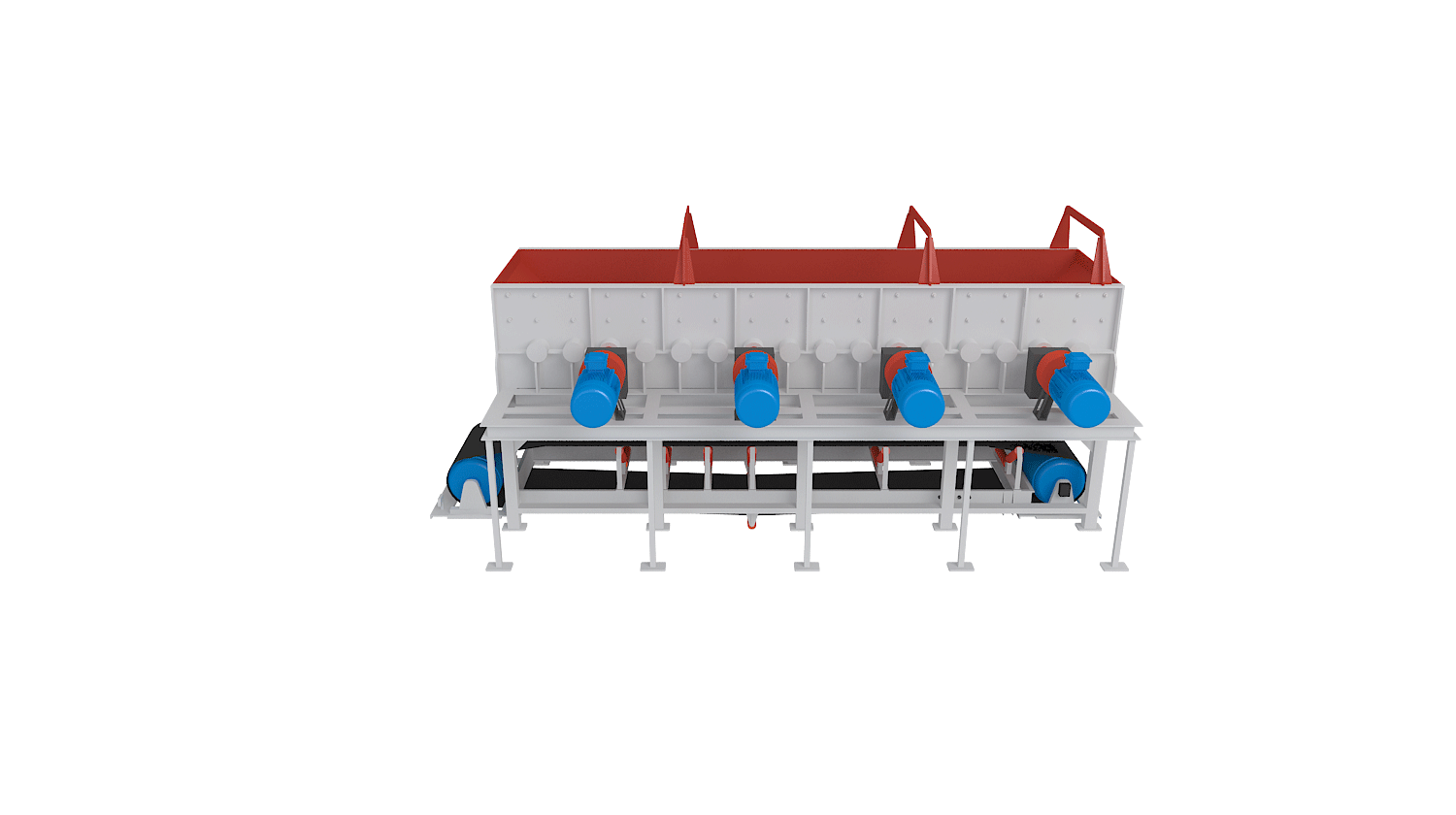

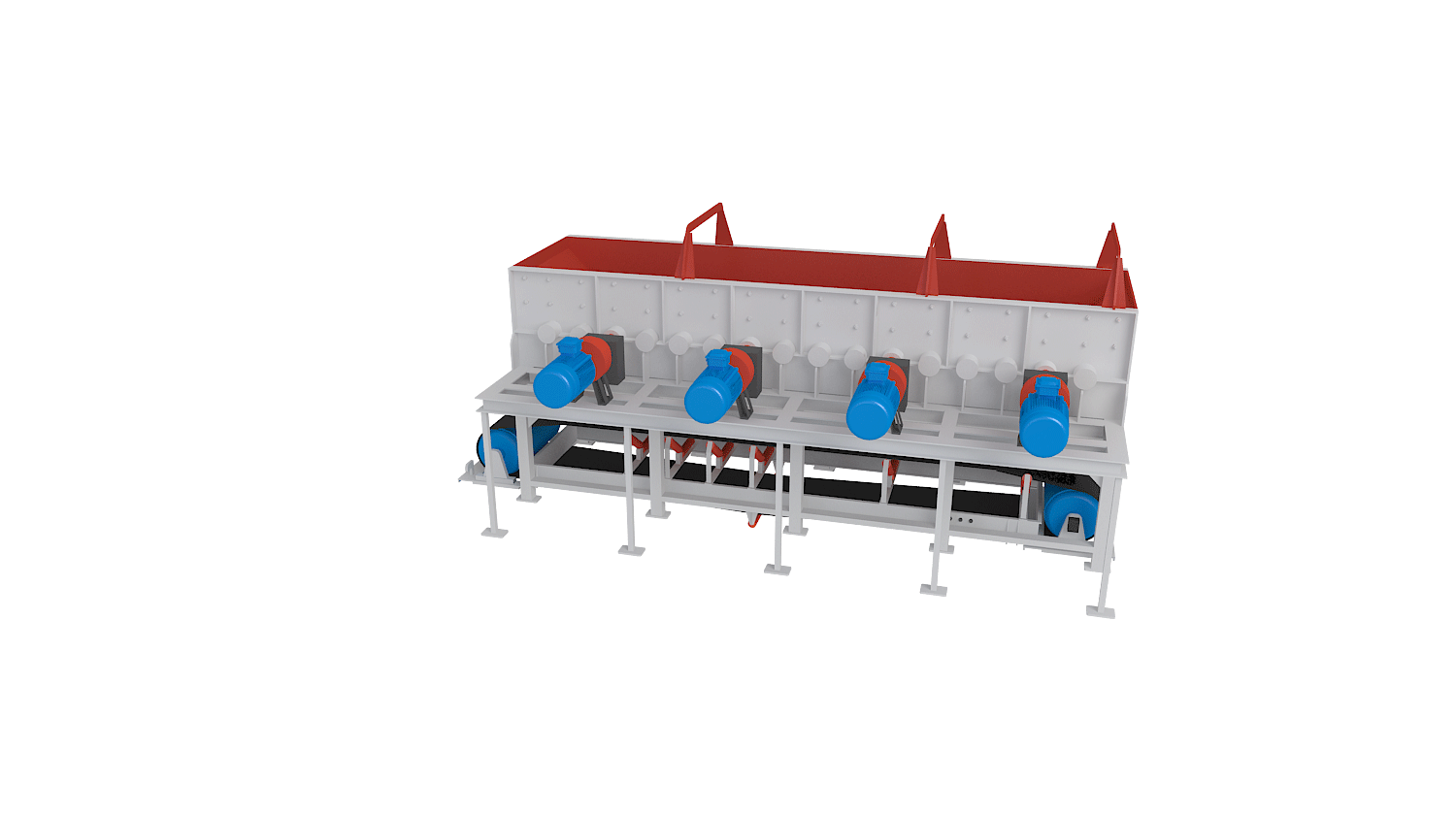

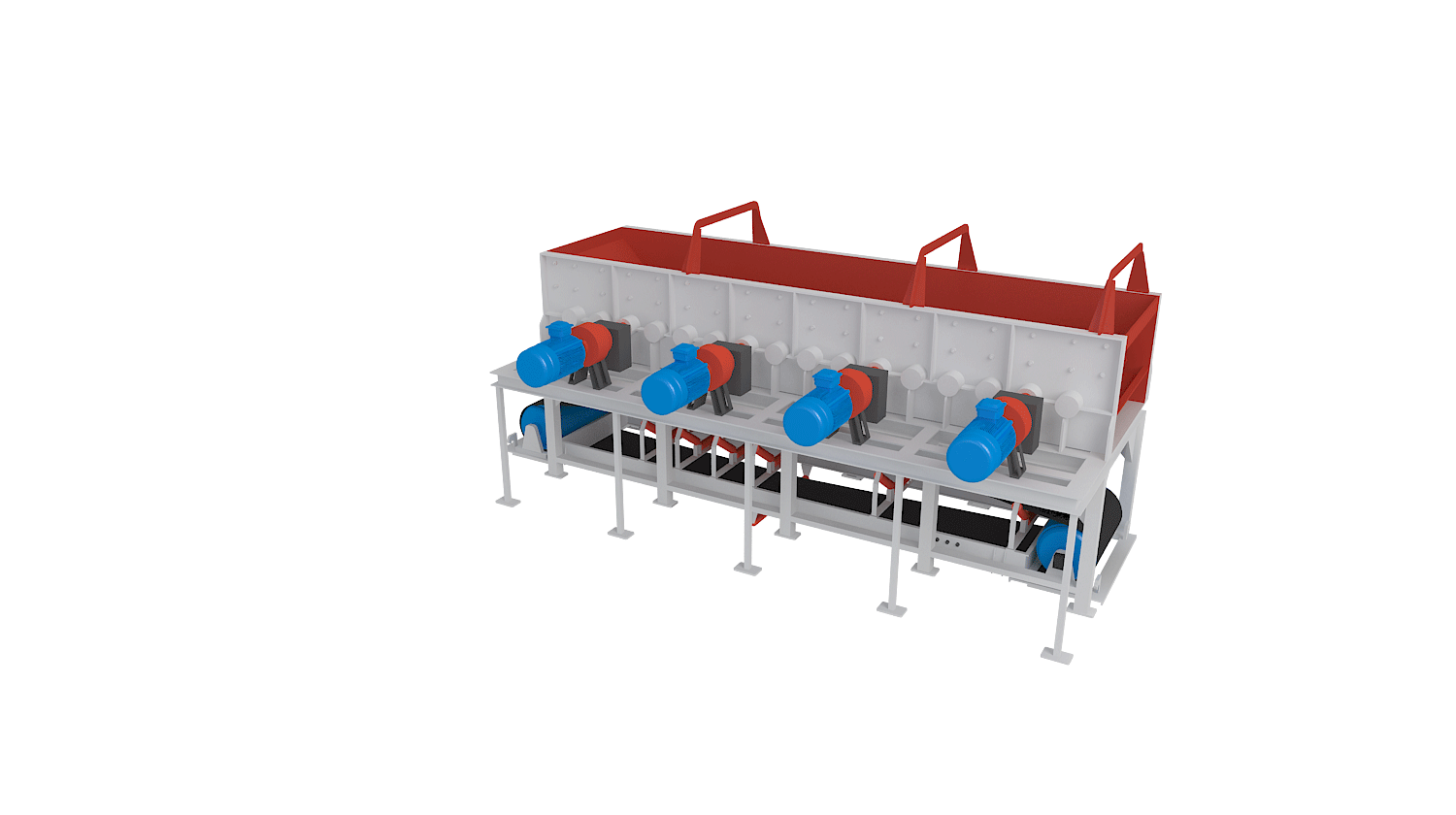

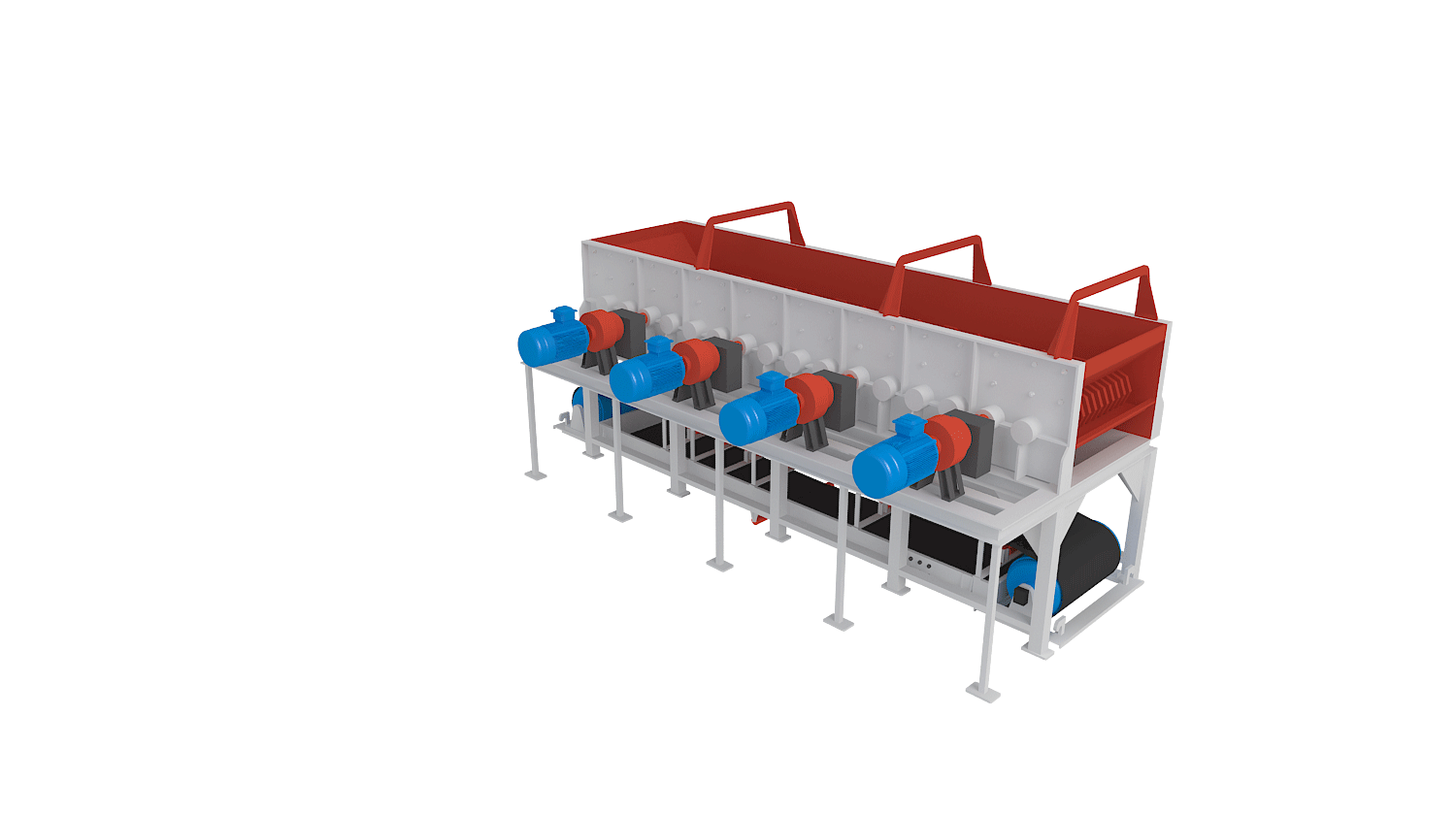

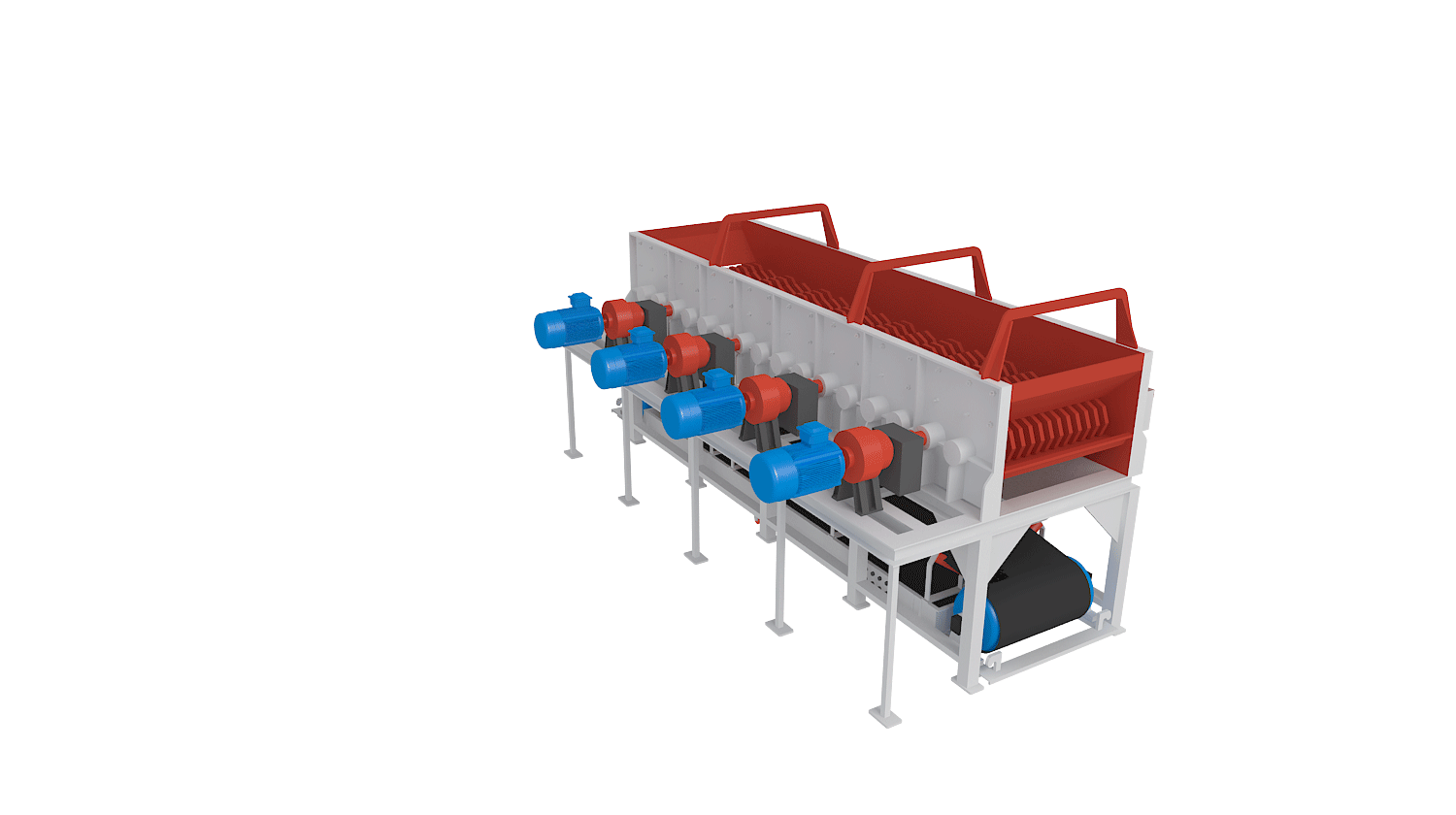

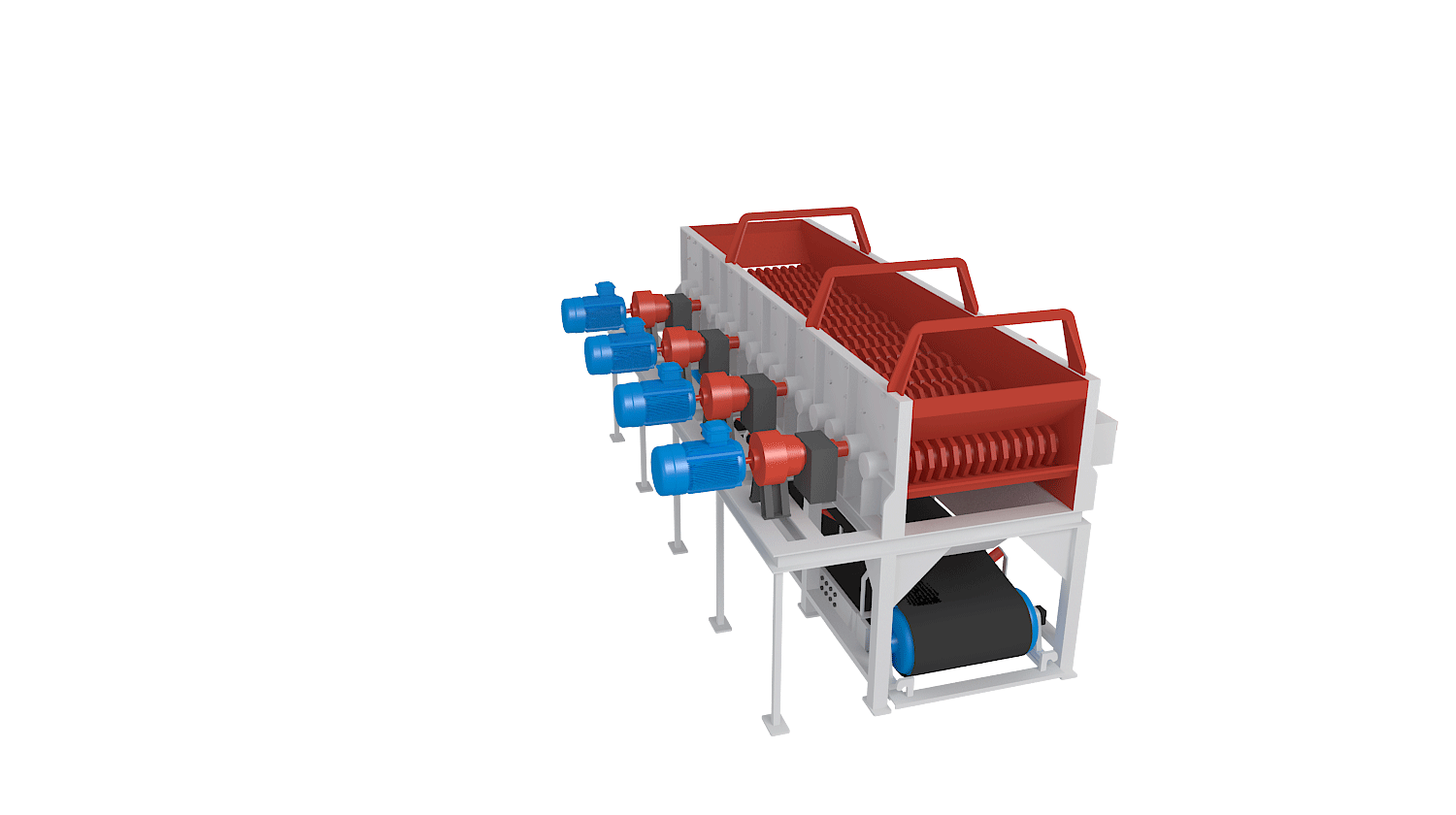

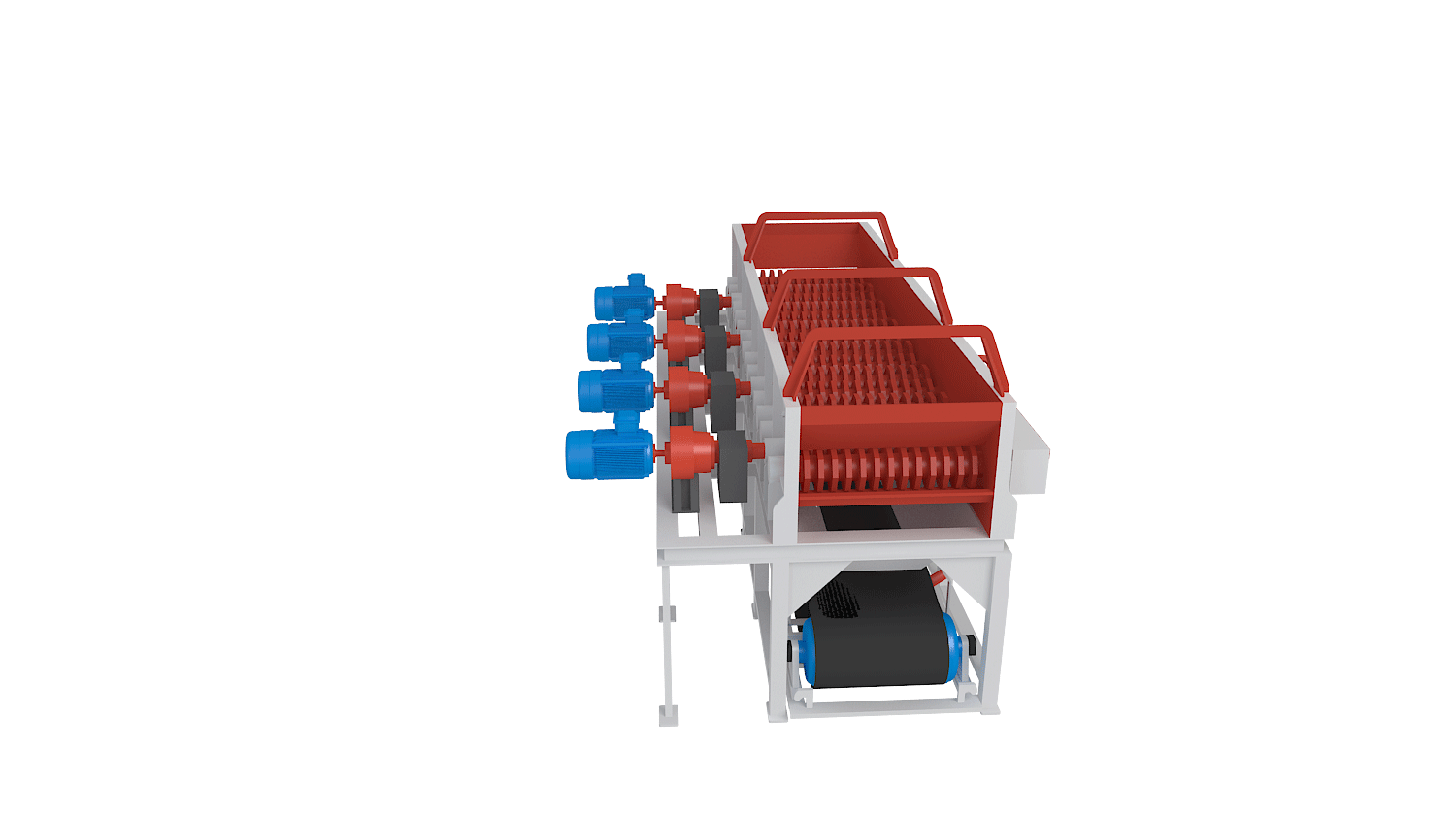

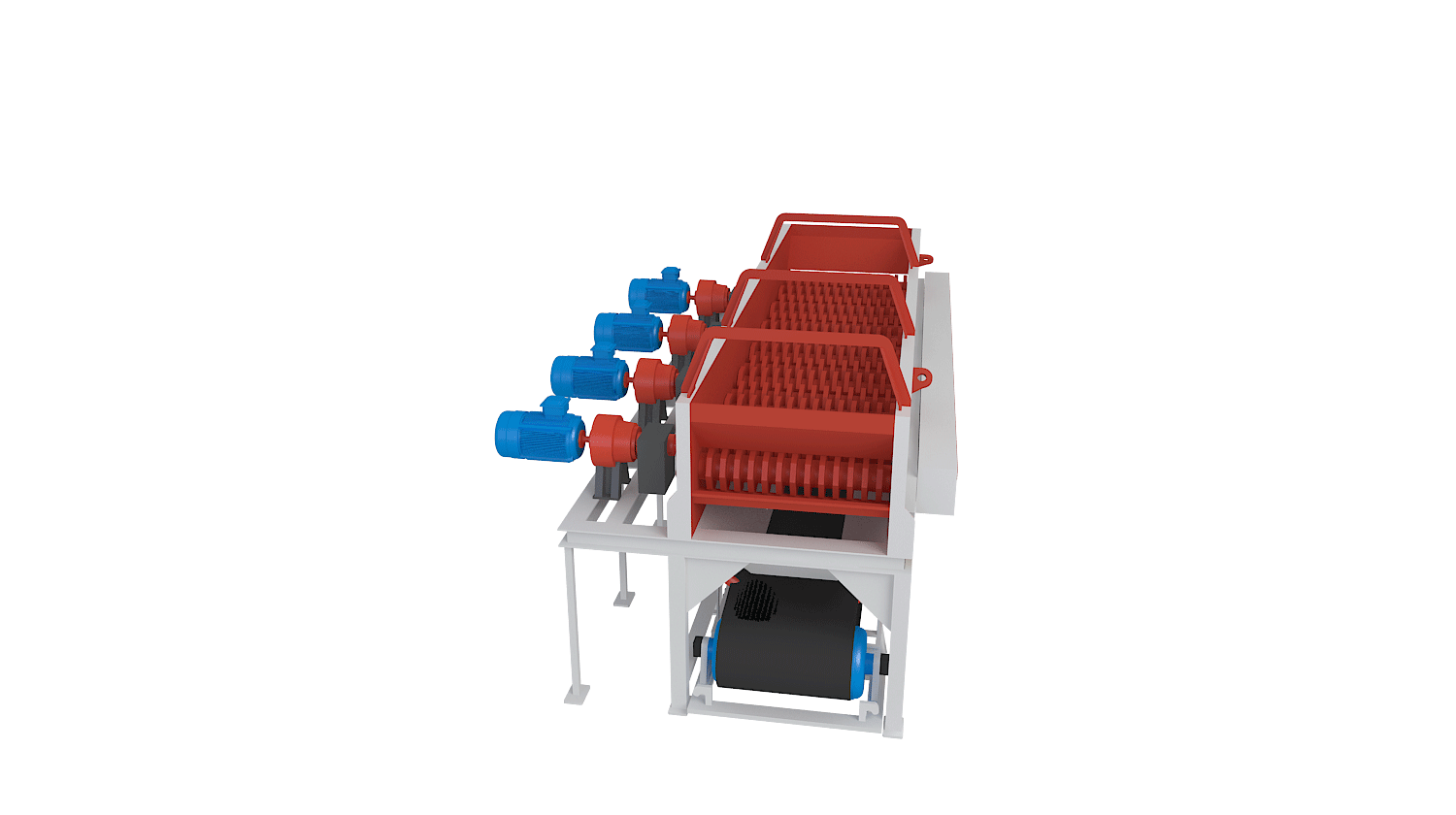

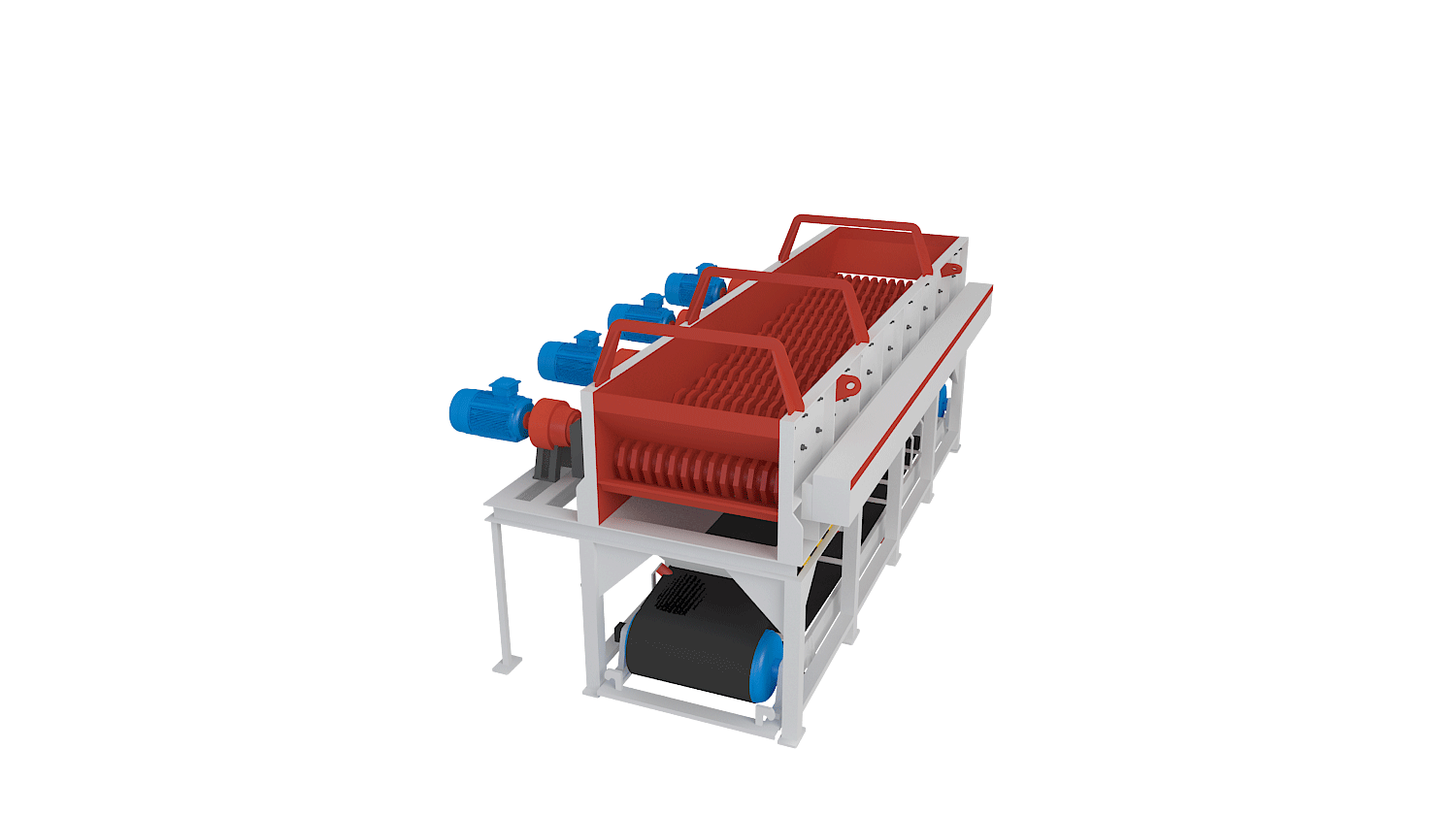

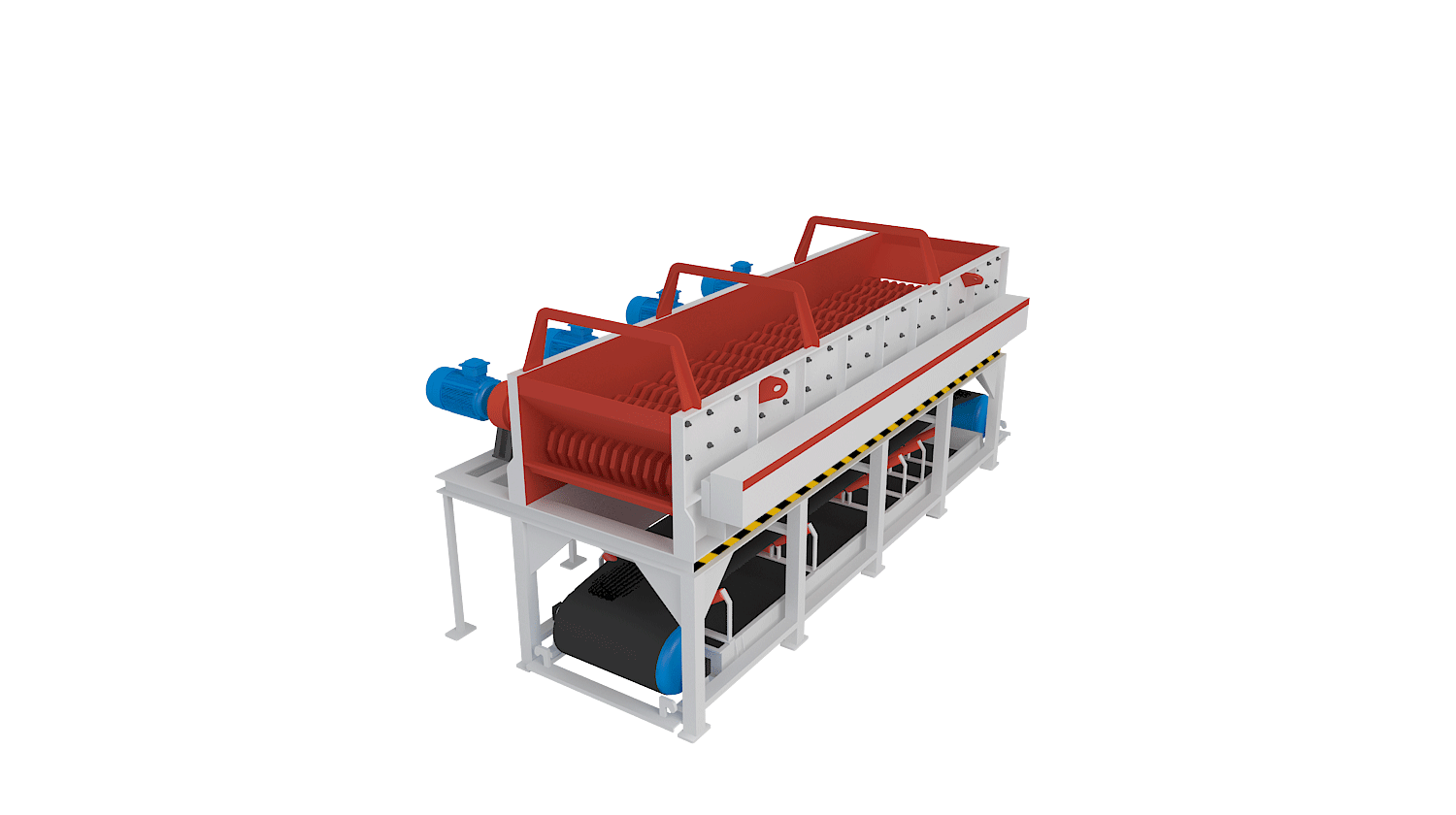

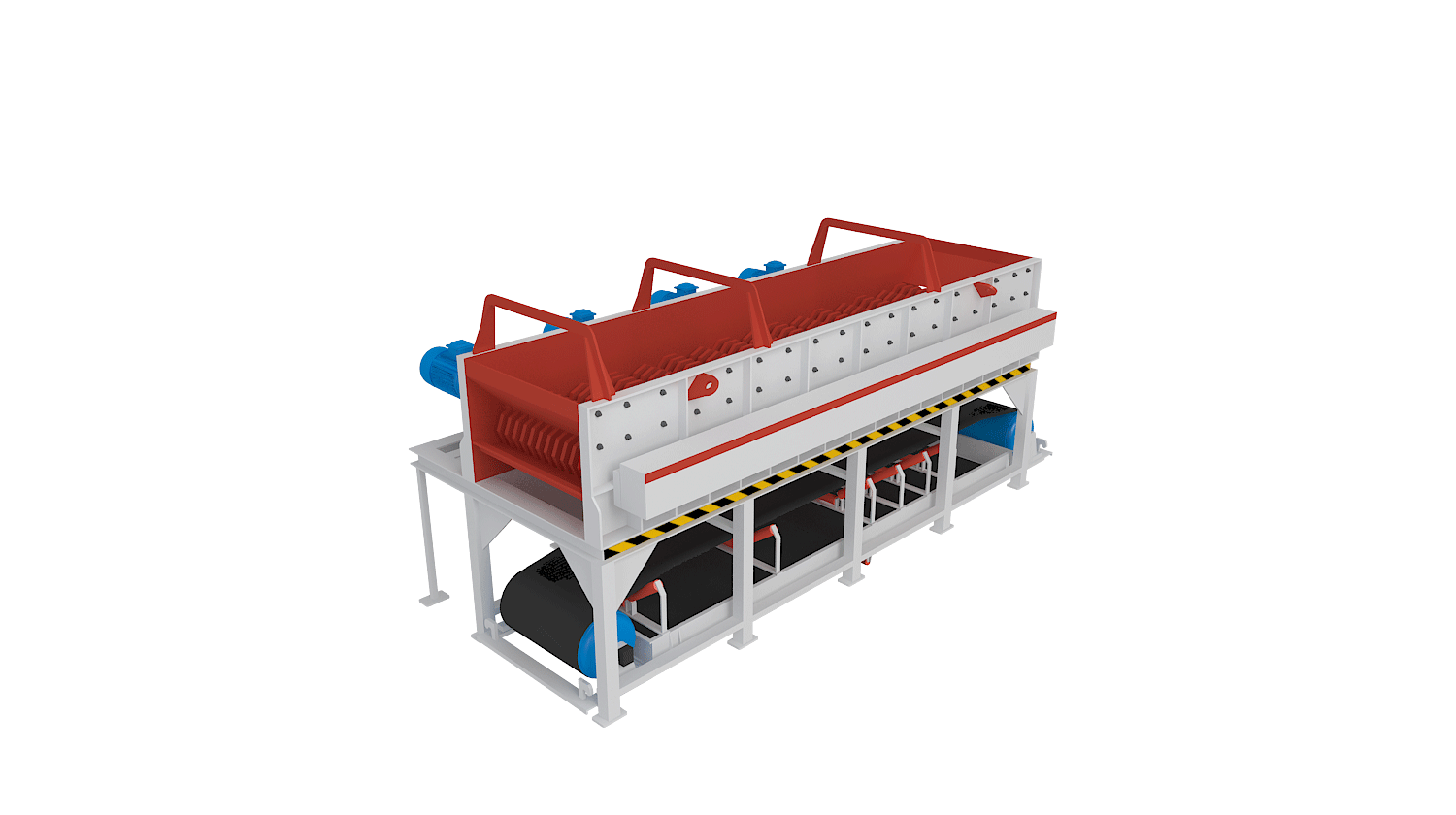

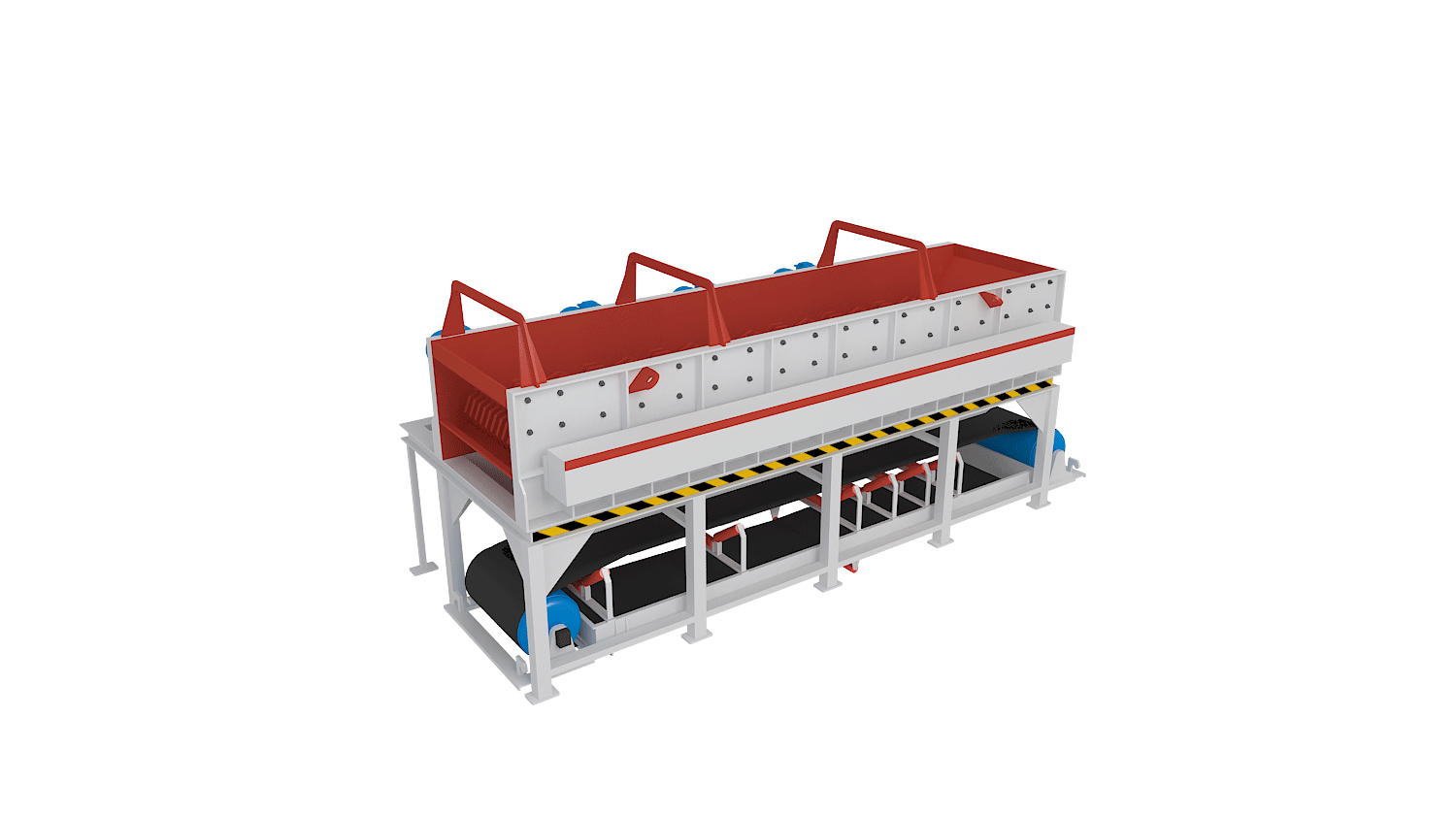

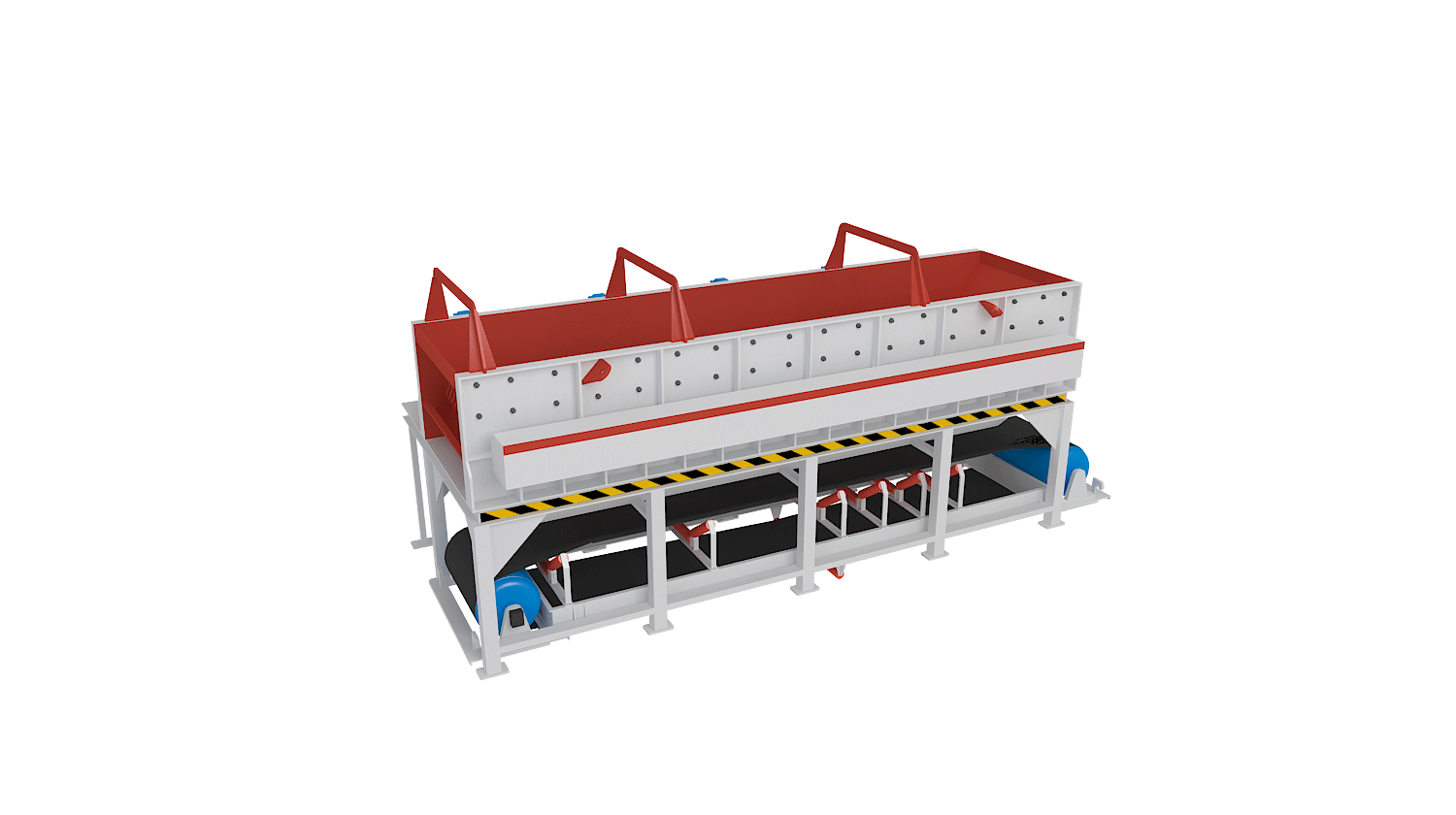

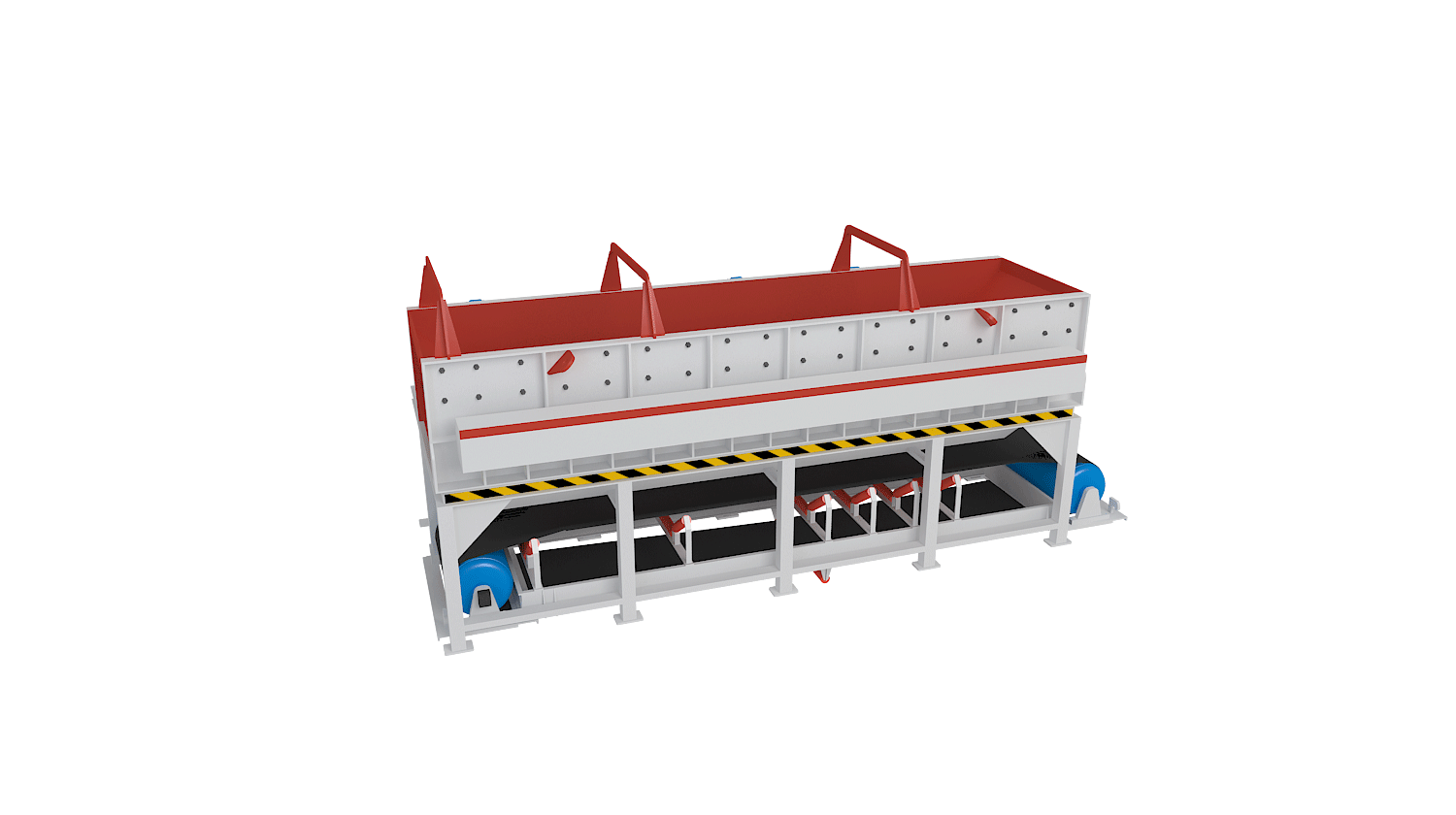

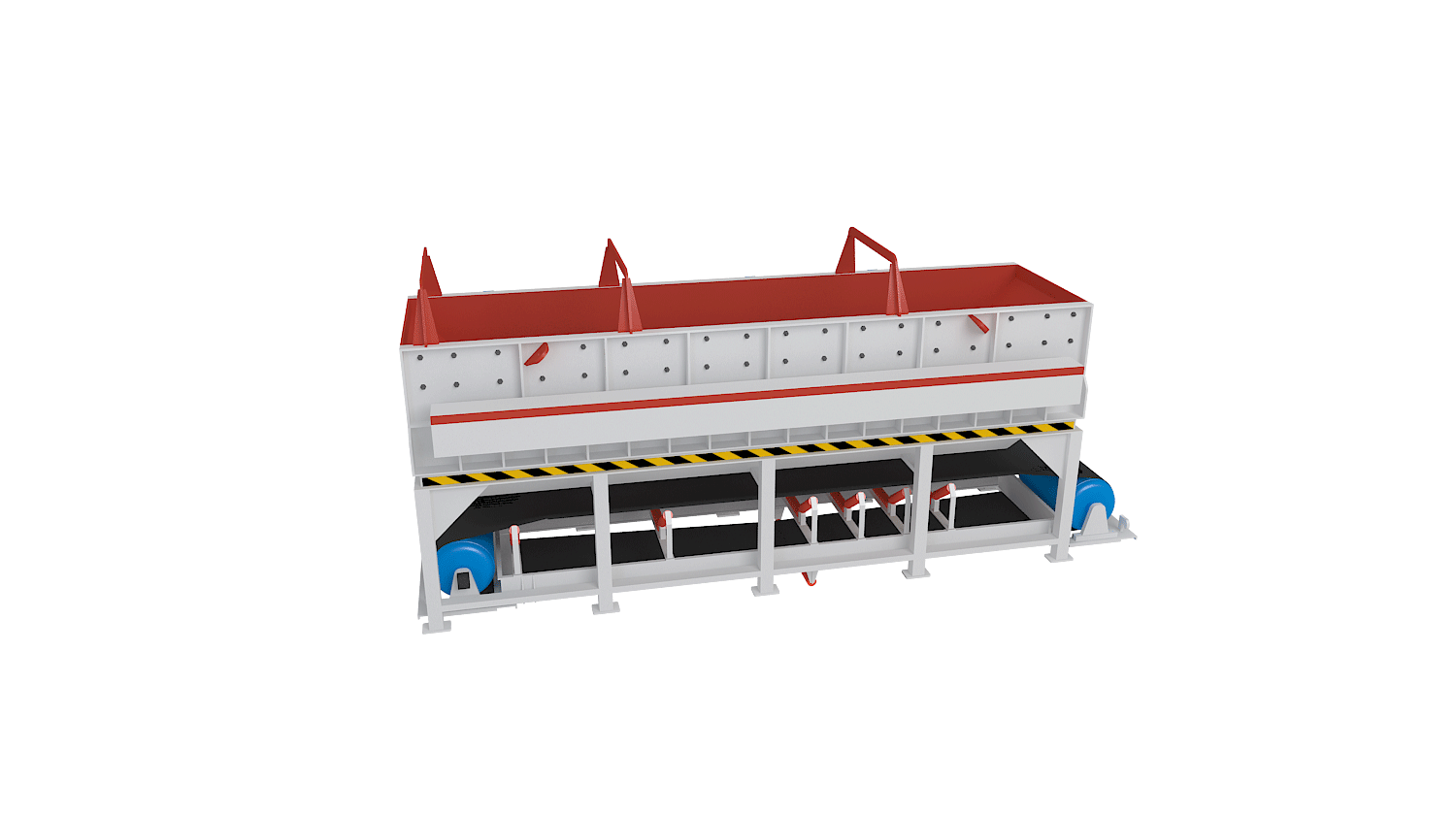

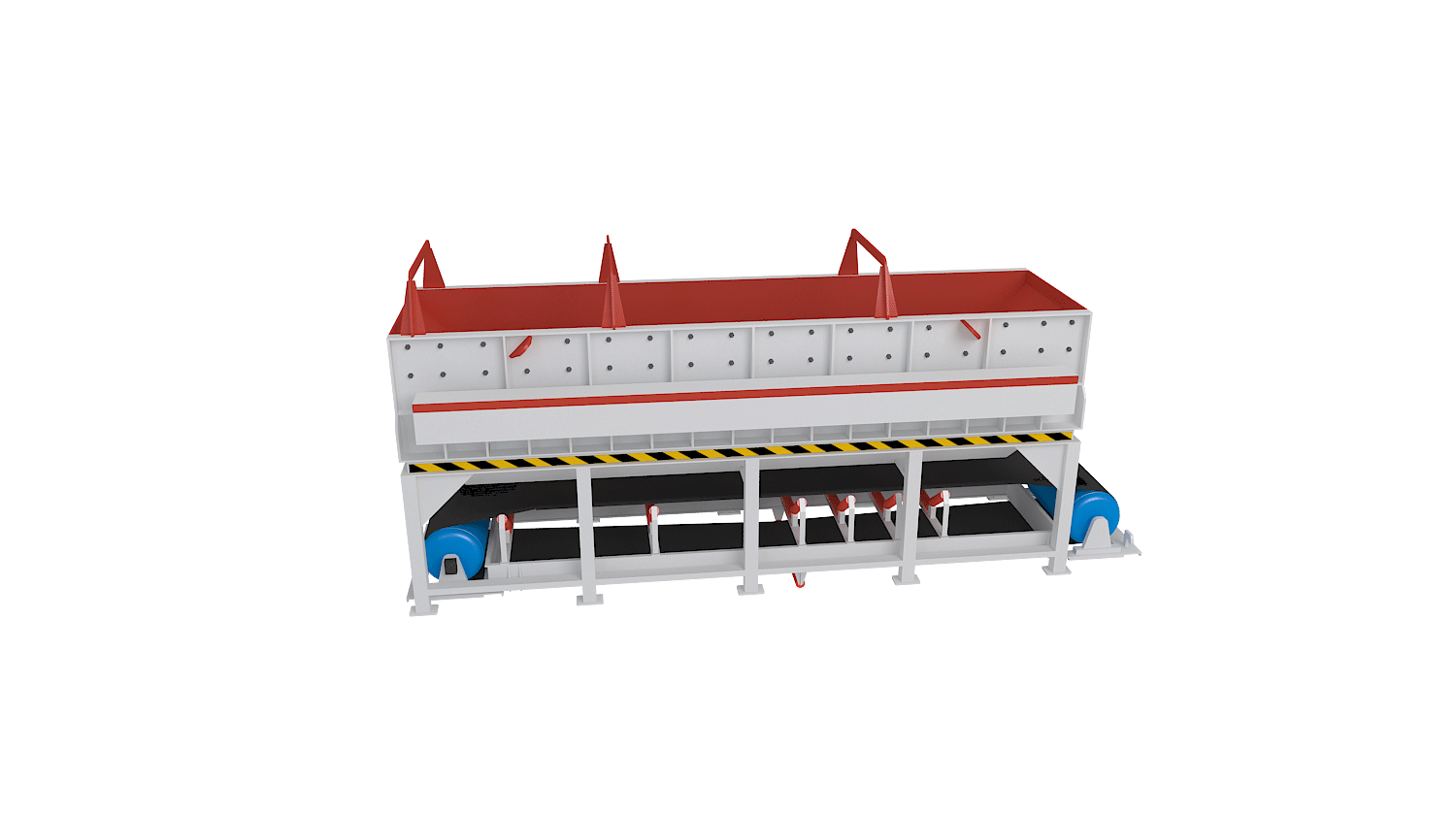

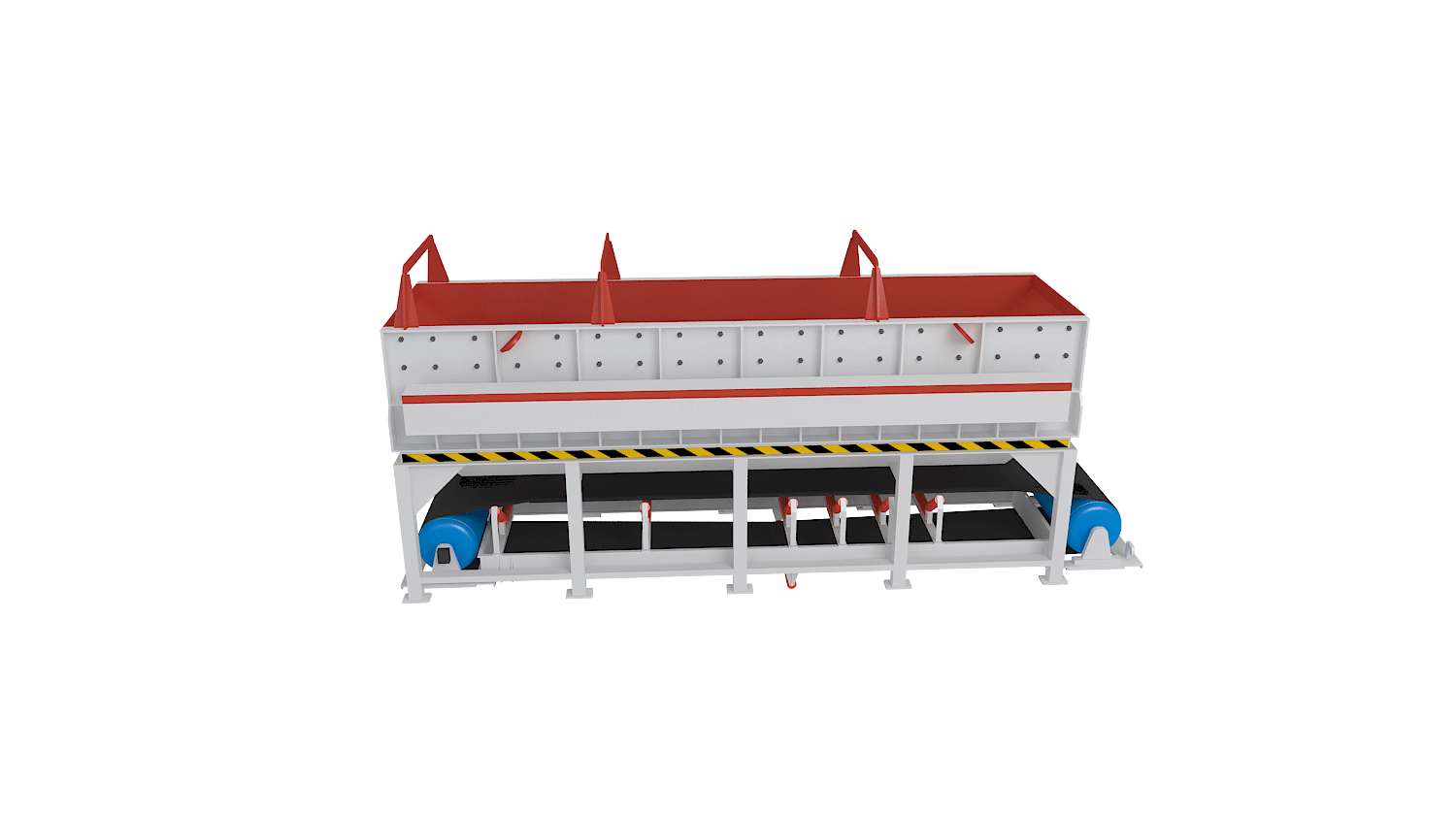

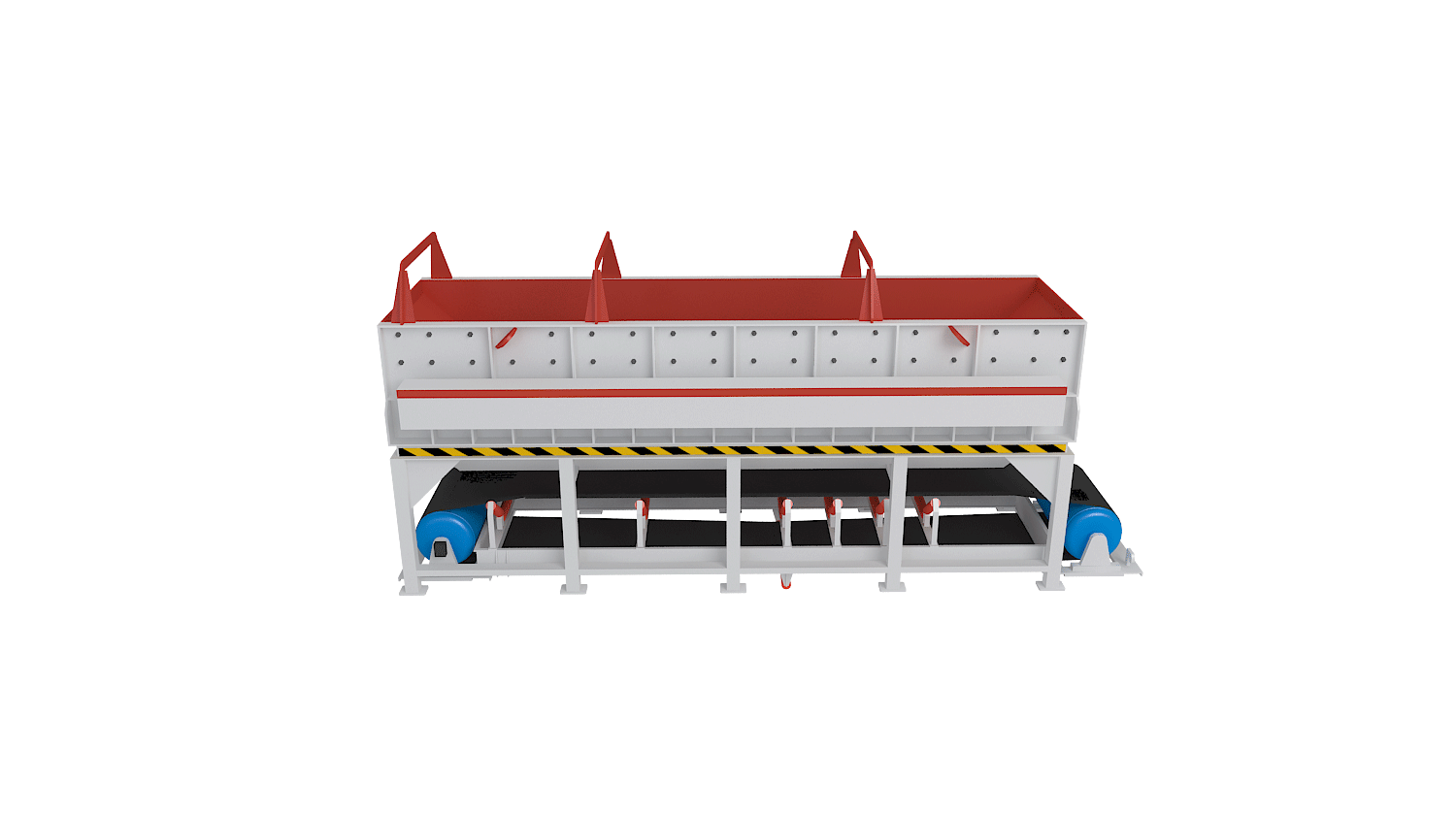

Mudstone Separation Equipment

Mudstone Separation Equipment is engineered to handle complex raw materials containing a mixture of soil, clay, and stones. It plays a crucial role in preliminary screening and cleaning of raw aggregates before crushing or washing. By removing fine mud and sticky clay, it prevents clogging and wear in crushers and conveyors, improving the overall efficiency and lifespan of the production line.

This equipment typically features heavy-duty construction and adopts either vibrating screen decks, rotary drums (trommel screens), or grizzly bars, depending on the specific separation needs. The robust structure ensures stability under heavy loading and continuous operation. Its design allows effective screening of wet, viscous, and high-moisture materials without material blocking or overflow.

Widely used in sand and gravel plants, construction waste treatment systems, open-pit mines, and tunnel excavation sites, Mudstone Separation Equipment significantly reduces manual cleaning and enhances the purity of output materials.