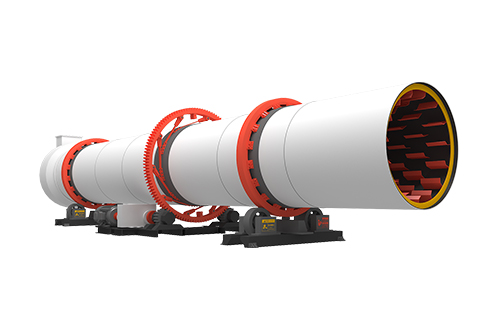

Rotary Dryer

Rotary Dryer is a widely used drying equipment designed for reducing moisture content in bulk materials. With a rotating cylindrical shell and efficient heat transfer system, it is suitable for drying metal and non-metal ores, coal slurry, clay, sand, and other granular materials. Known for its simple structure, large capacity, and reliable performance, Rotary Dryer is widely applied in mining, construction, chemical, and cement industries.