| Model | Cylinder diameter (mm) |

Cylinder length (mm) |

Cylinder field strength (mT) |

Cylinder rotating speed (r/min) |

Dry ore processing capacity (t/h) |

Feed particle size (mm) |

Pulp concentration (%) |

Motor Power (kw) |

Gross weight (t) |

Length×Width×Height (mm) |

| CTBC1018 | 1000 | 1800 | 300-500 | 23 | 36-54 | 0-4 | 20-50 | 5.5 | 5.2 | 3160×2250×1750 |

| CTBC1024 | 1000 | 2400 | 300-500 | 23 | 44-75 | 0-4 | 20-50 | 7.5 | 6.4 | 3790×2250×1750 |

| CTBC1030 | 1000 | 3000 | 300-500 | 23 | 66-103 | 0-4 | 20-50 | 7.5 | 7.1 | 4460×2250×1750 |

| CTBC1218 | 1000 | 1800 | 300-500 | 20 | 47-82 | 0-4 | 20-50 | 7.5 | 6.7 | 3380×2460×2000 |

| CTBC1224 | 1000 | 2400 | 300-500 | 20 | 62-105 | 0-4 | 20-50 | 11 | 7.2 | 4190×2460×2000 |

| CTBC1230 | 1000 | 3000 | 300-500 | 20 | 83-129 | 0-4 | 20-50 | 11 | 8.9 | 4770×2460×2000 |

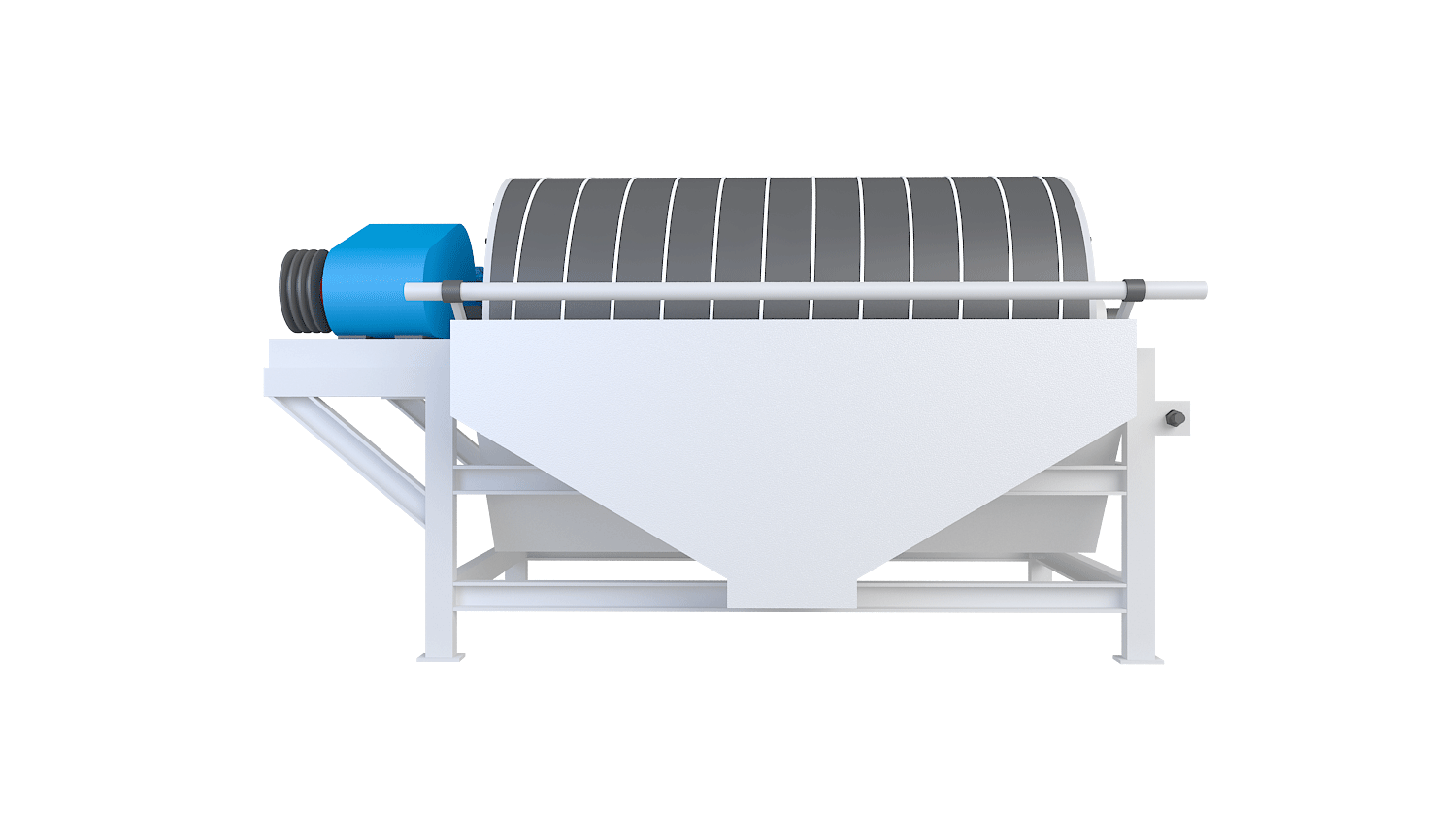

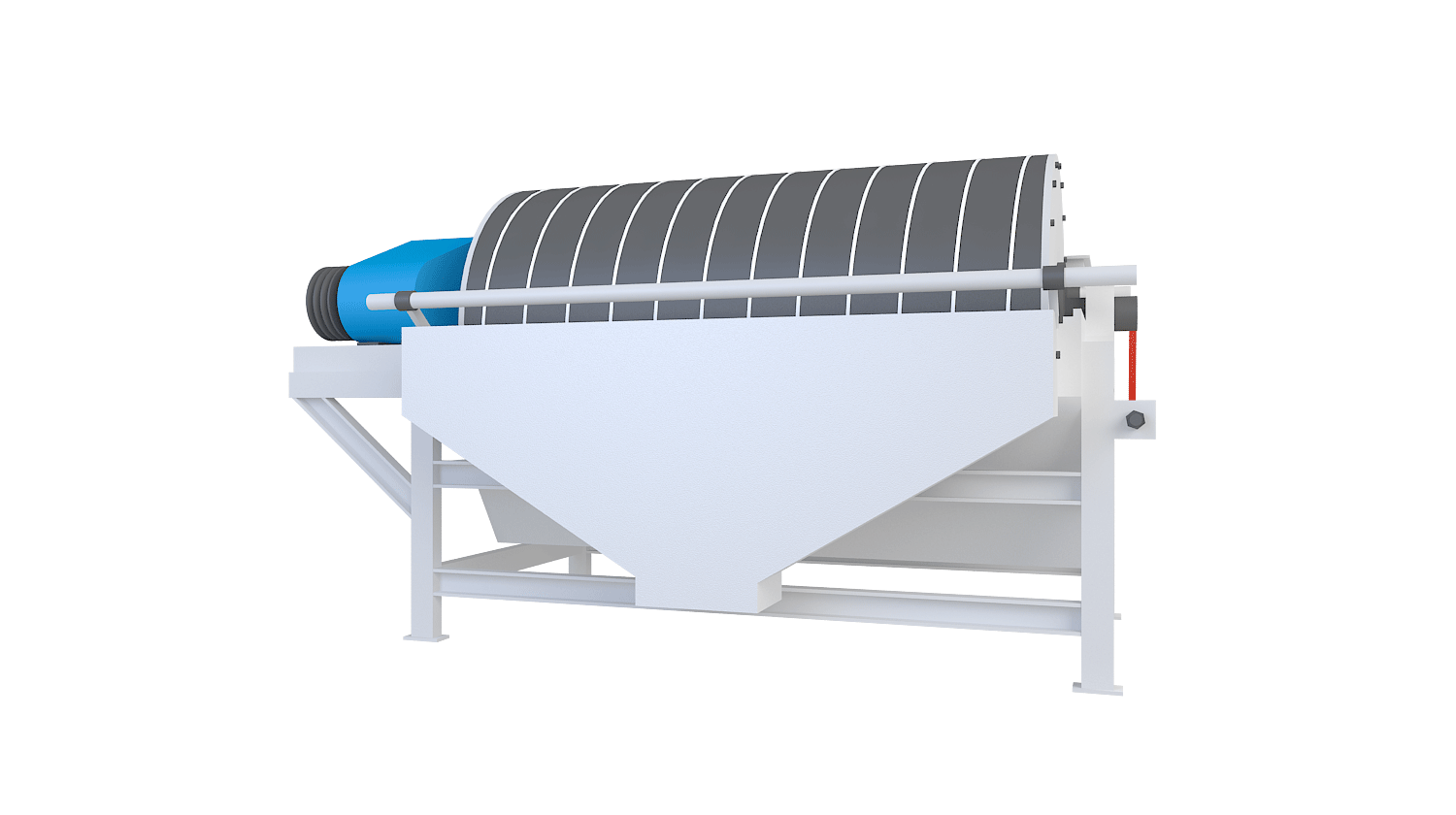

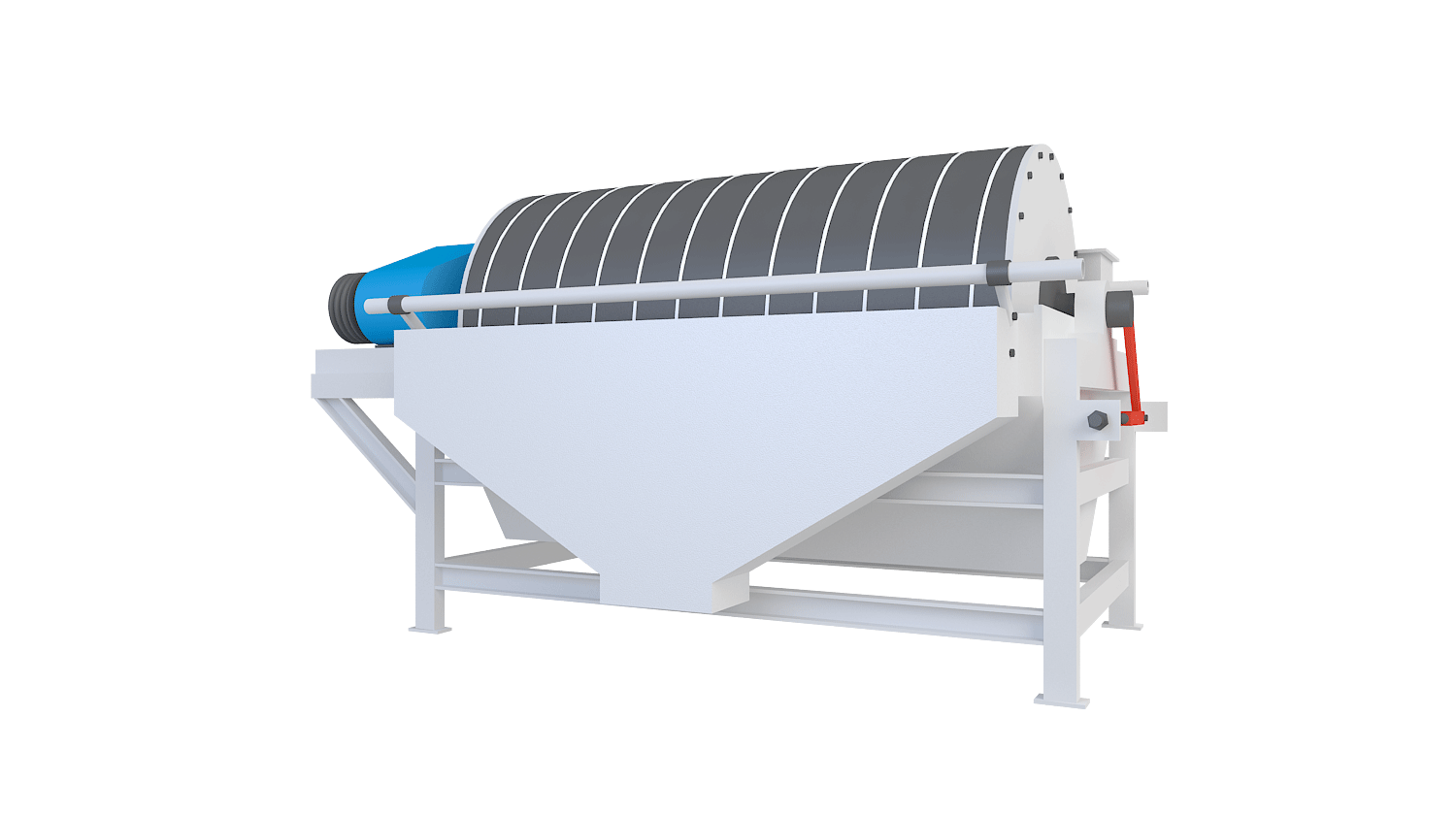

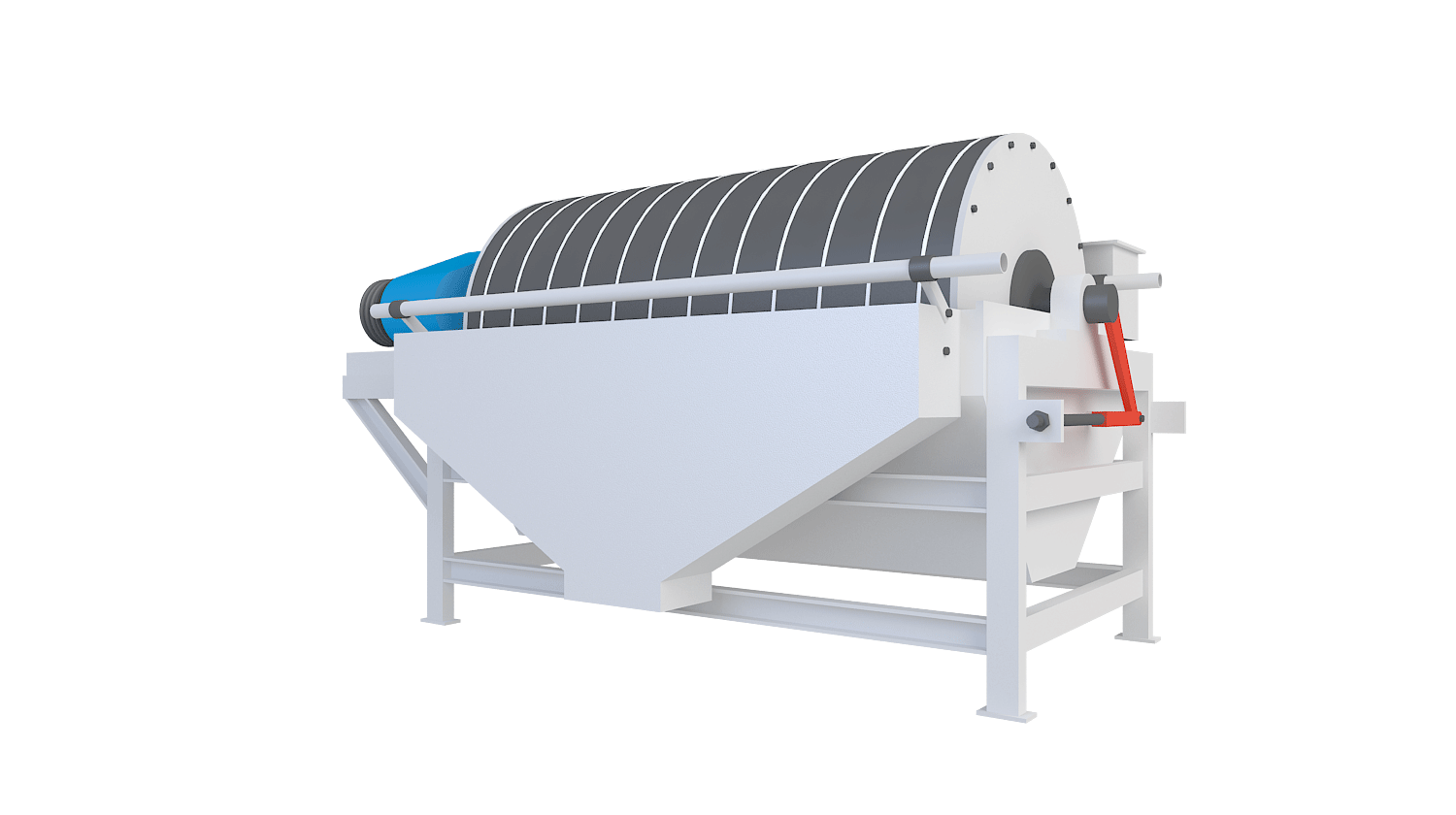

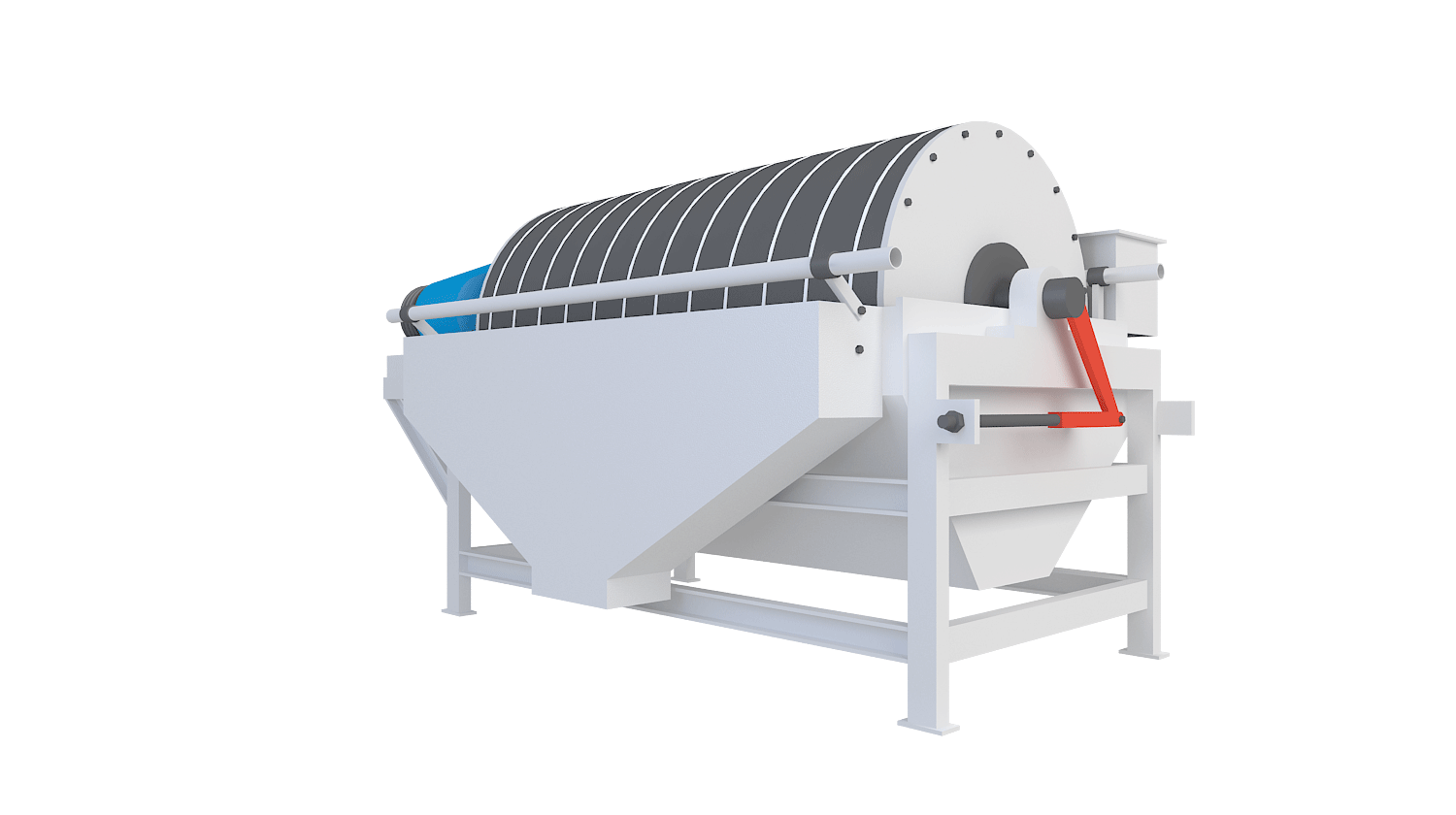

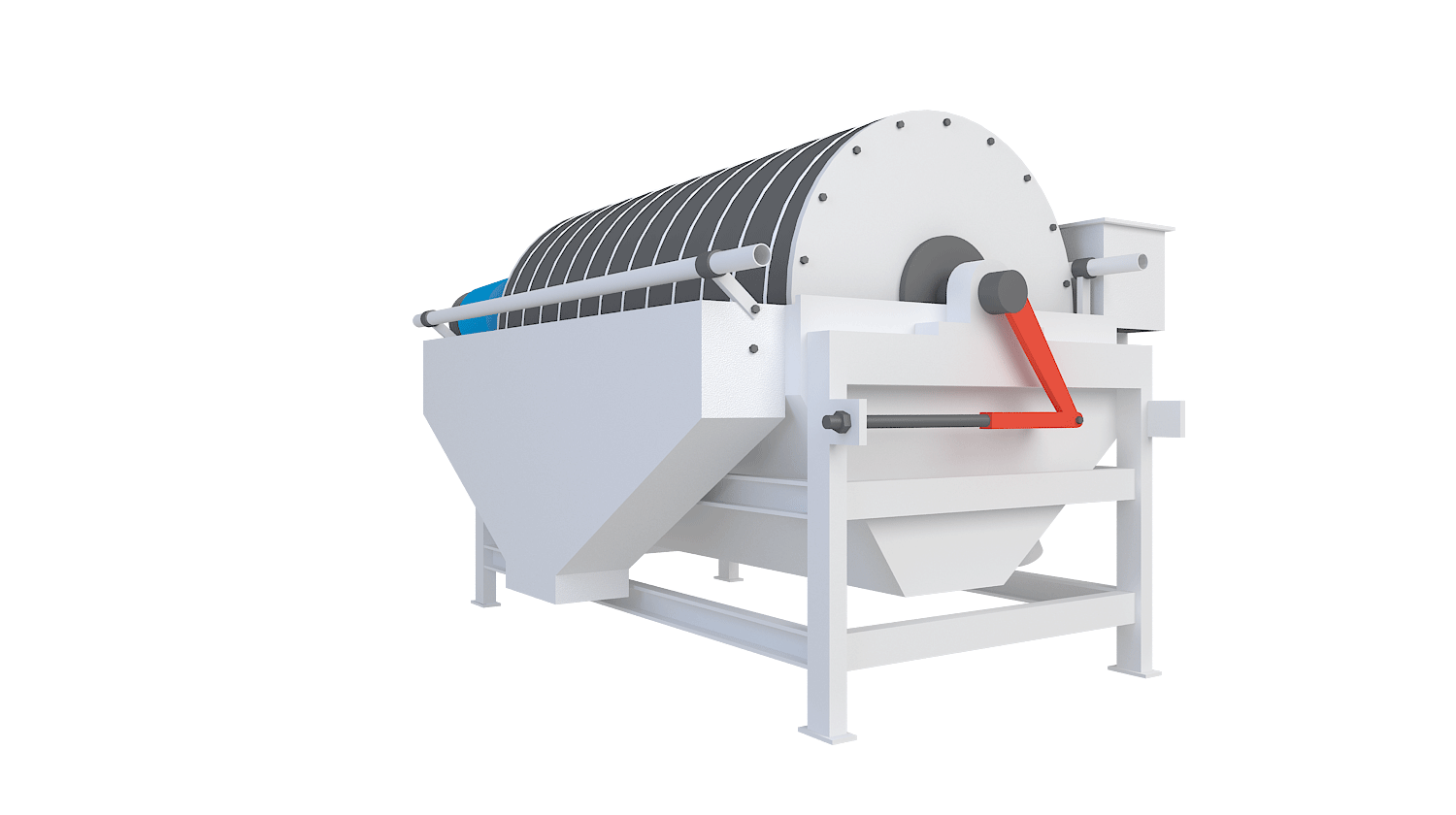

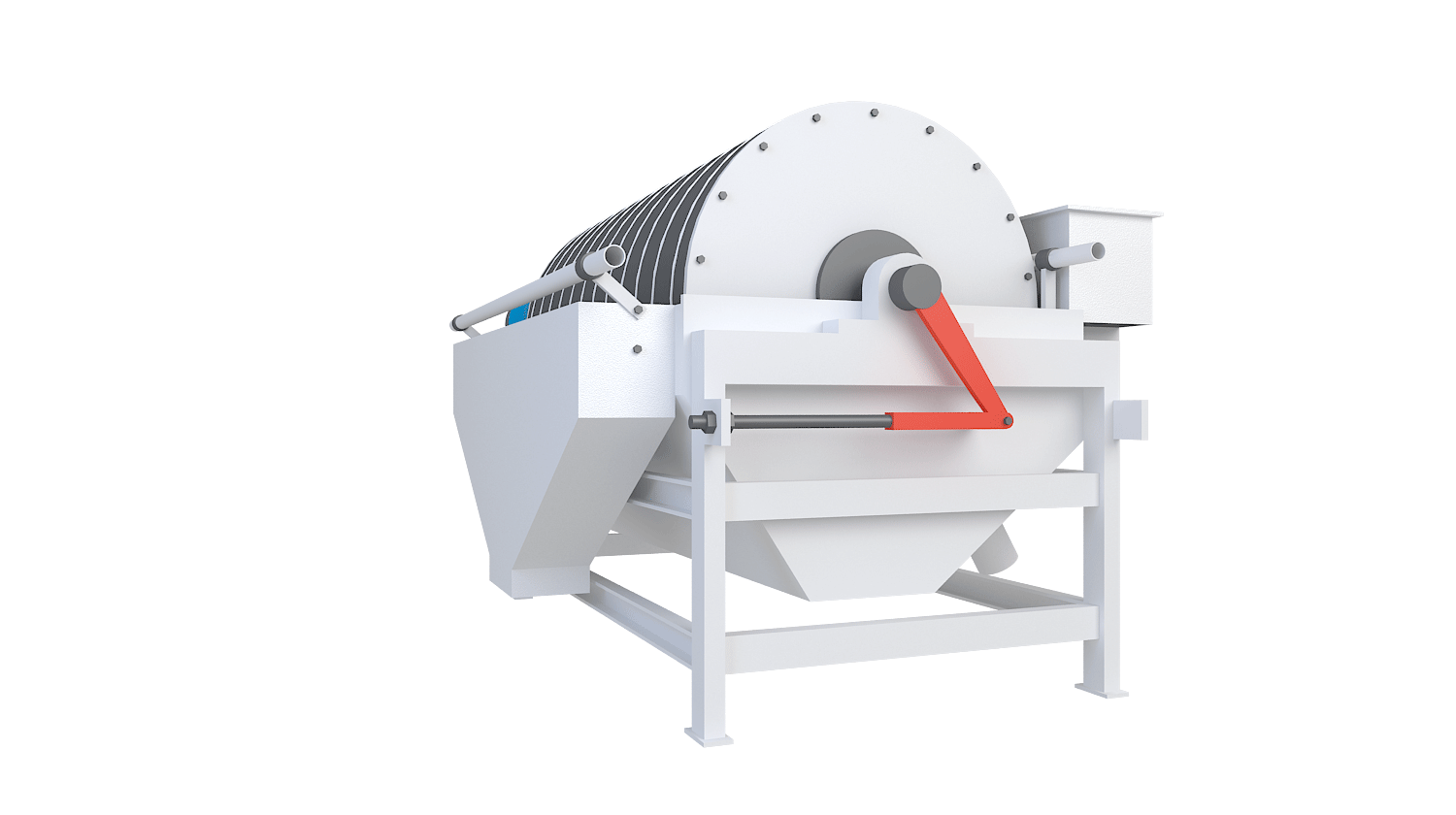

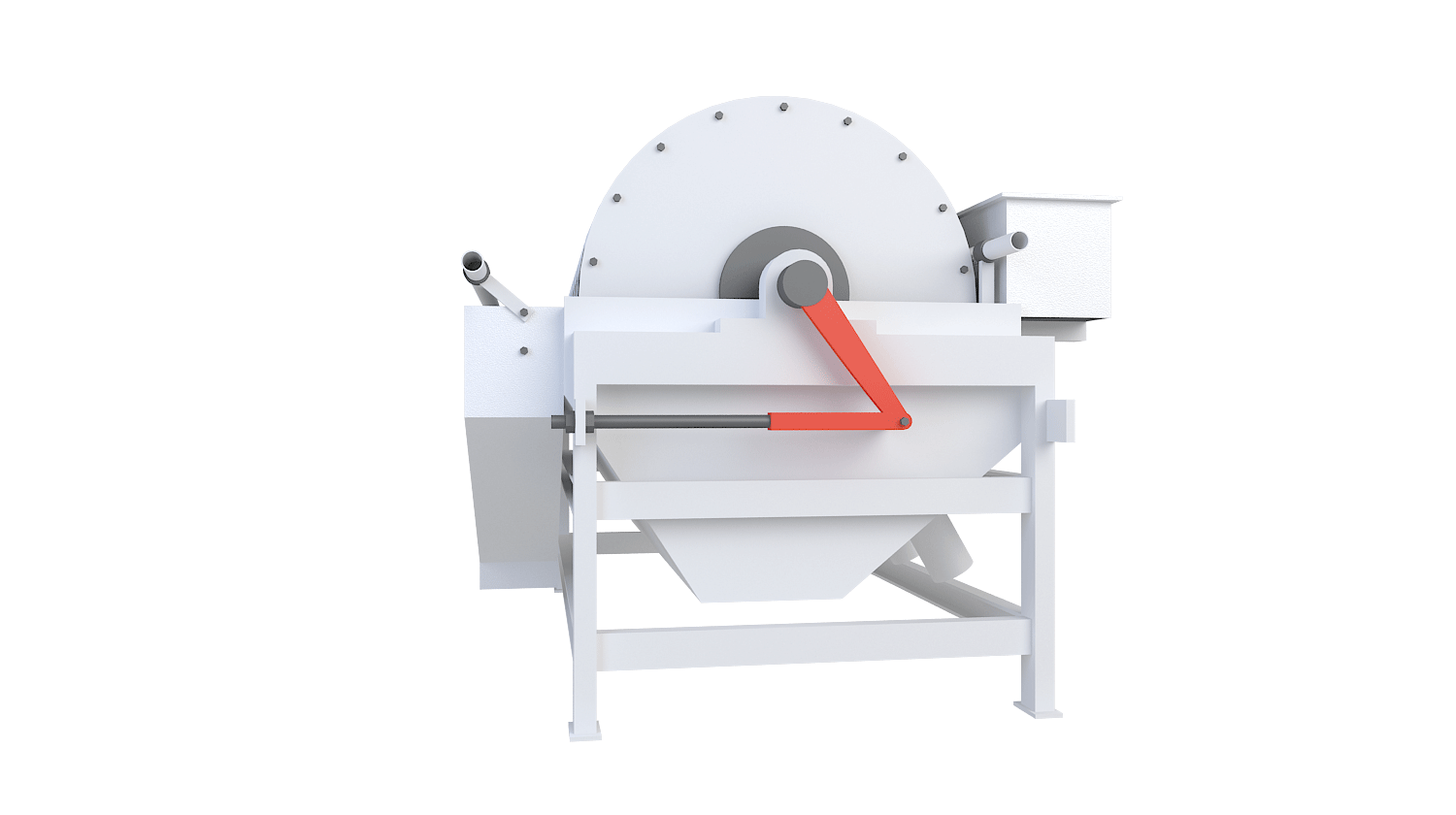

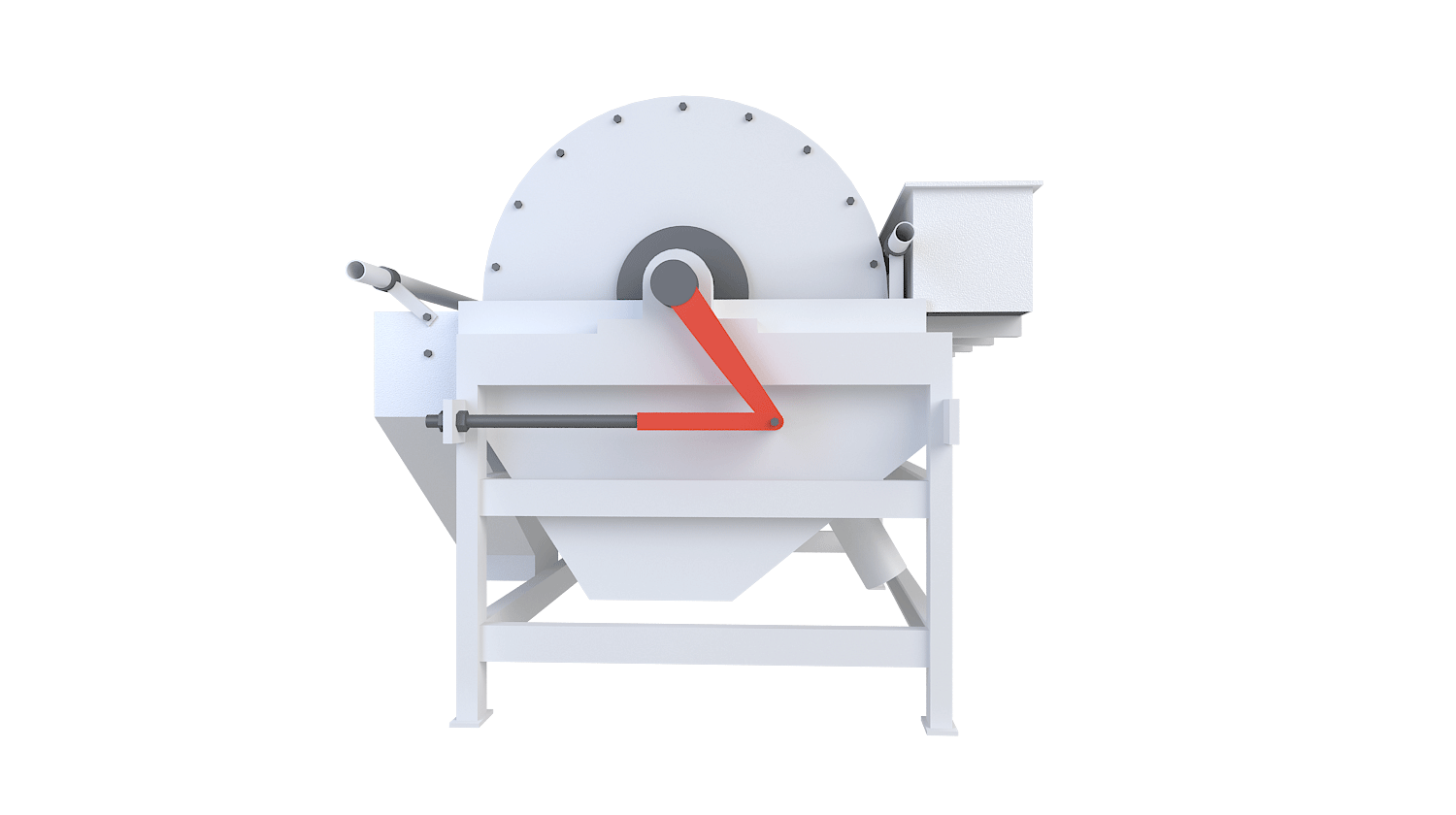

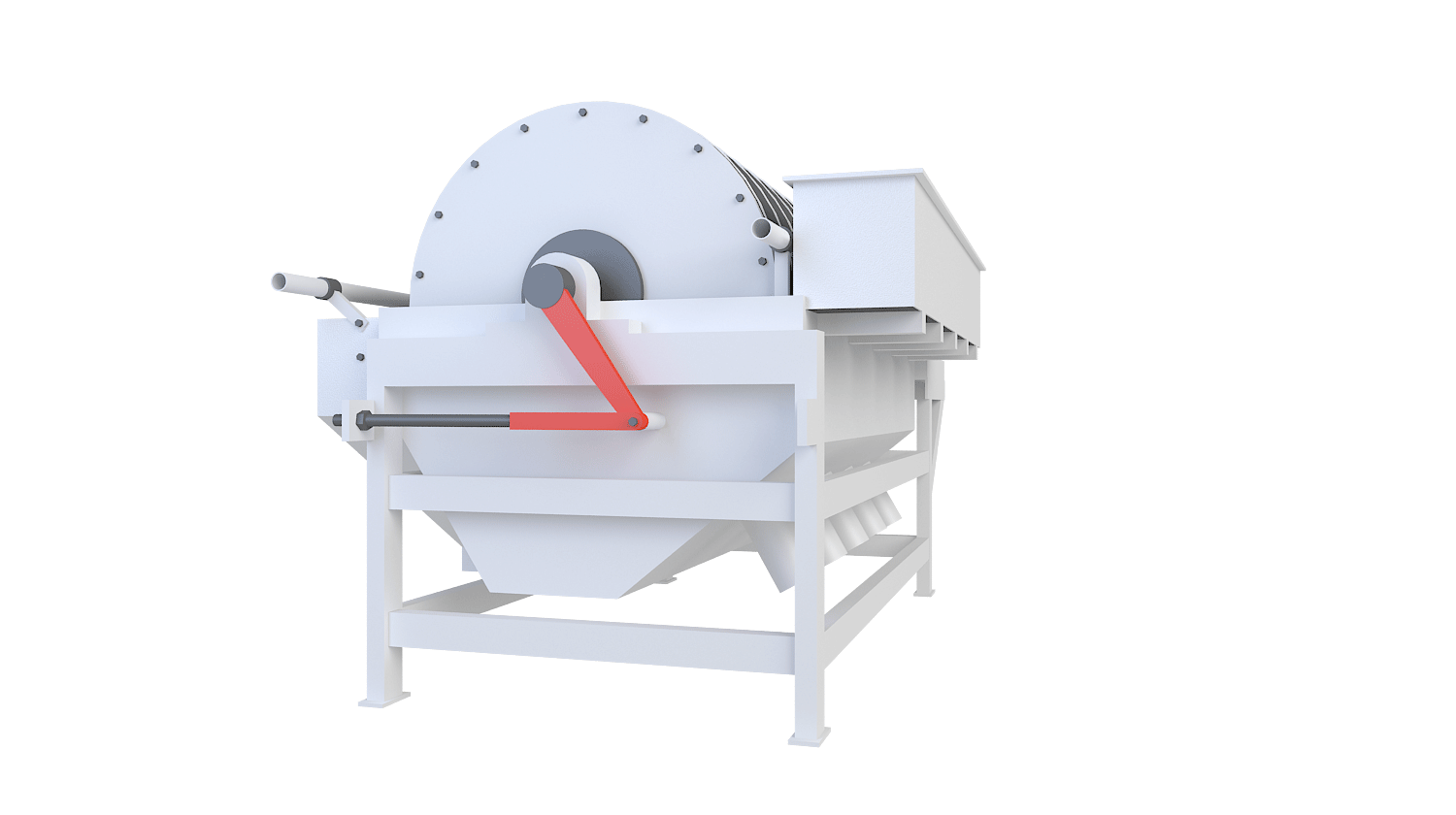

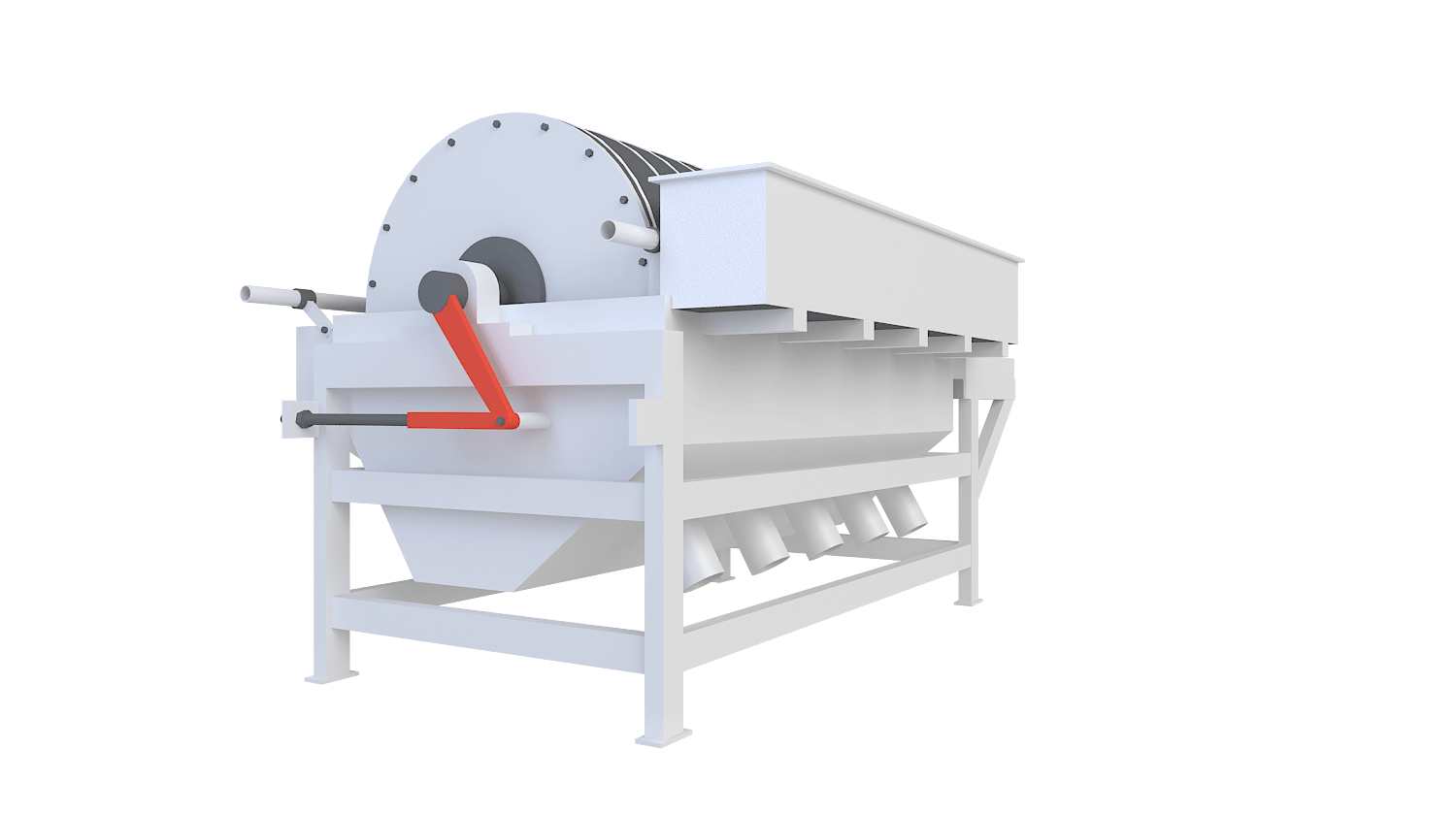

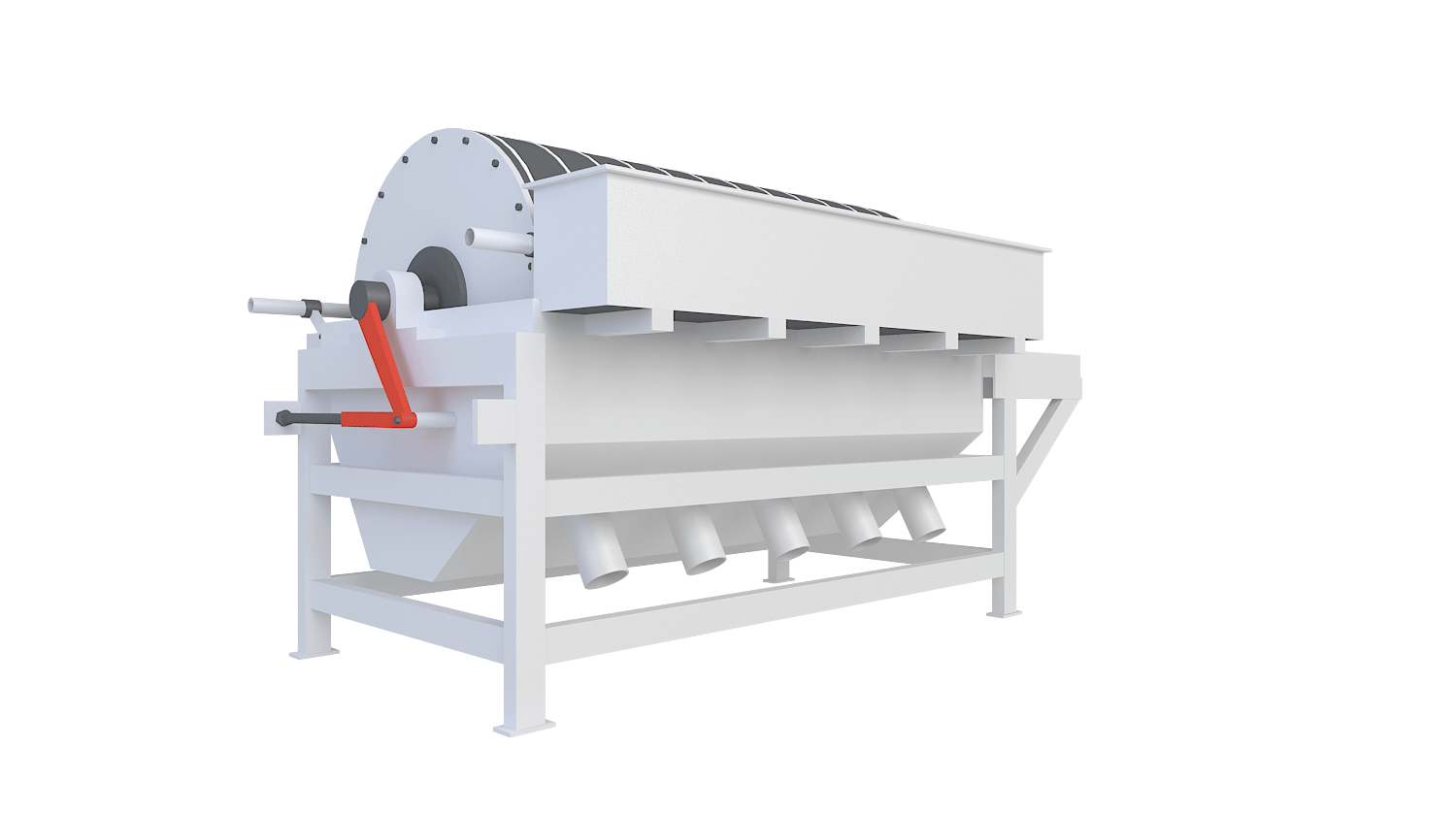

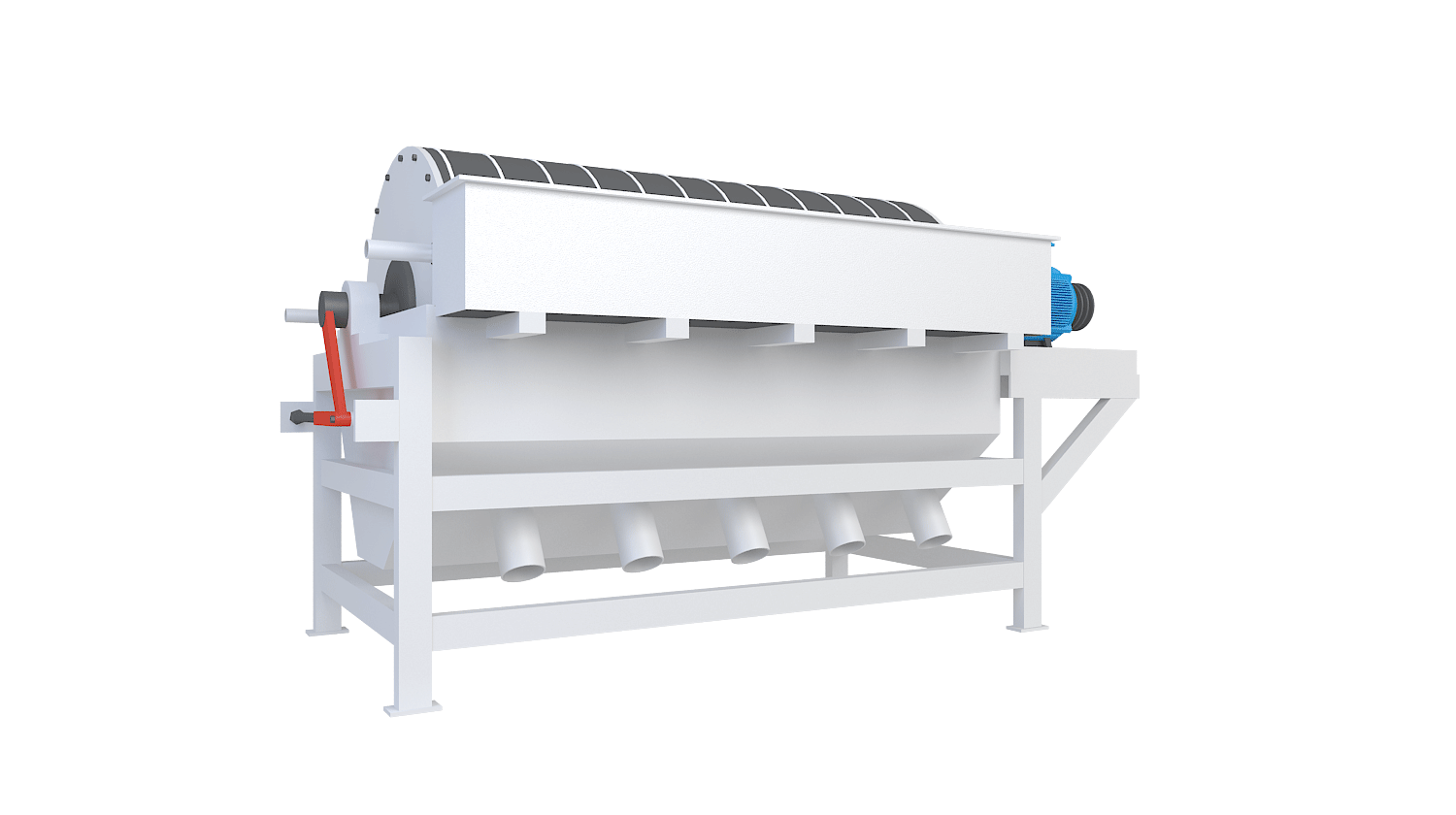

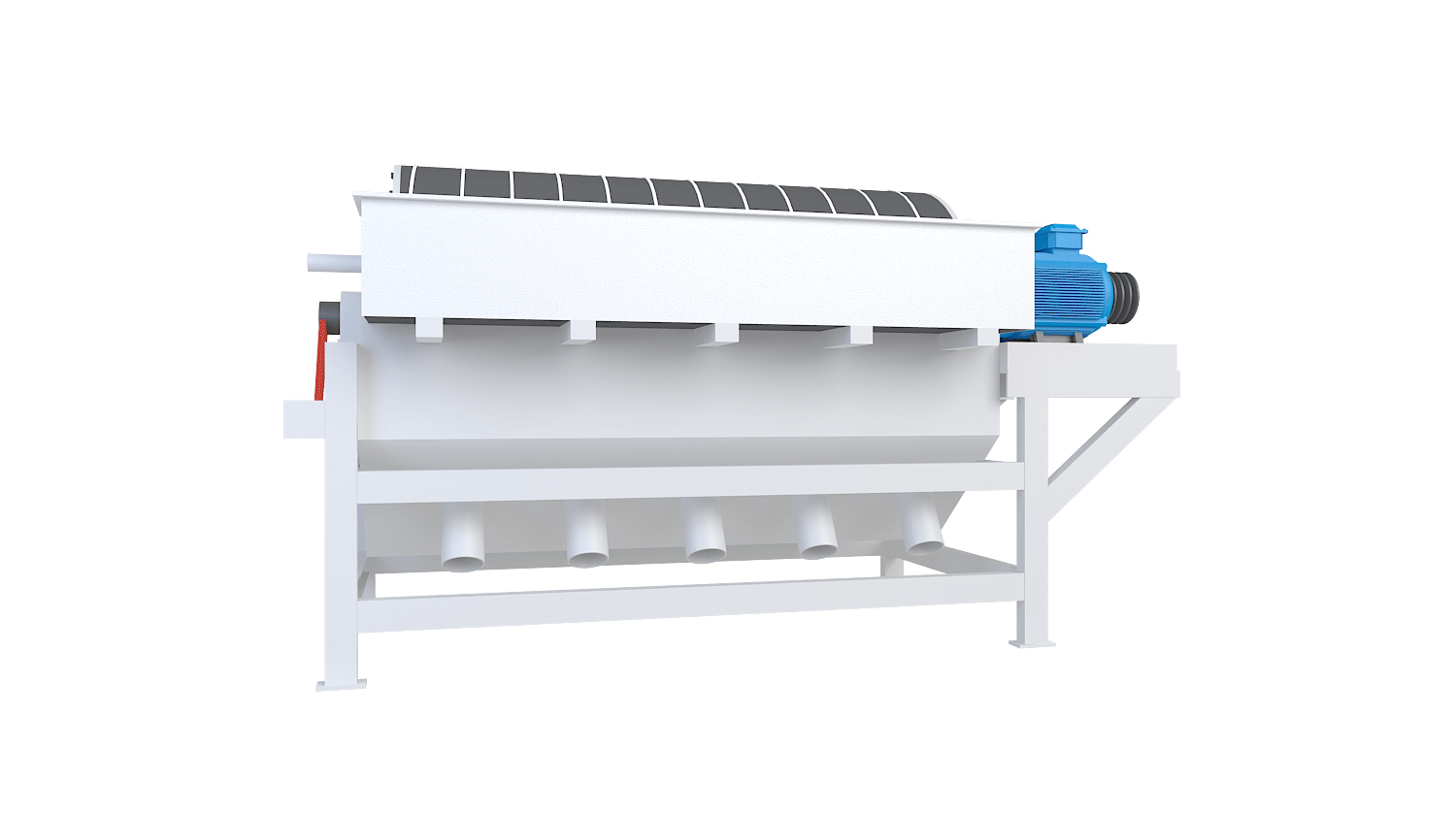

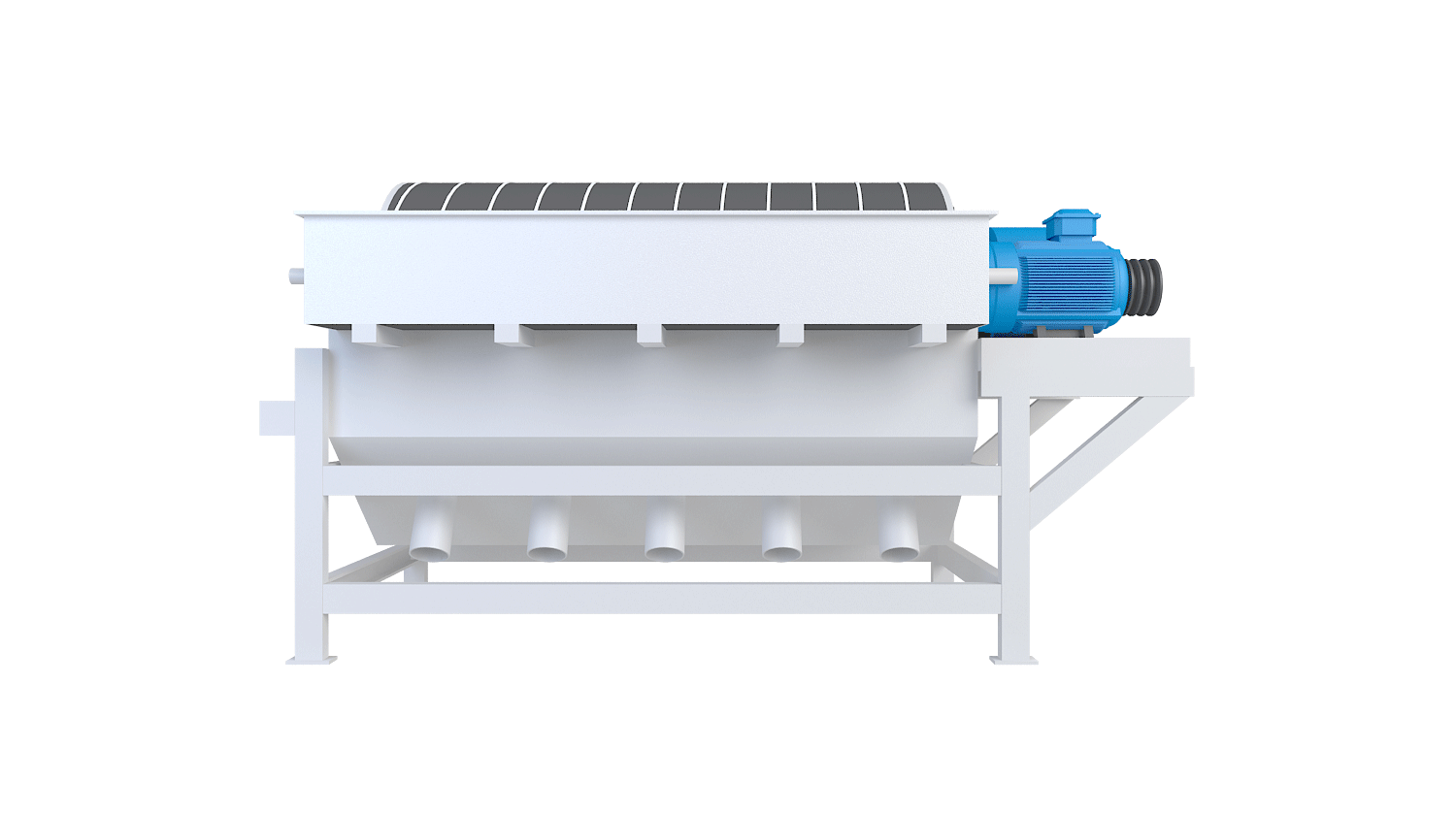

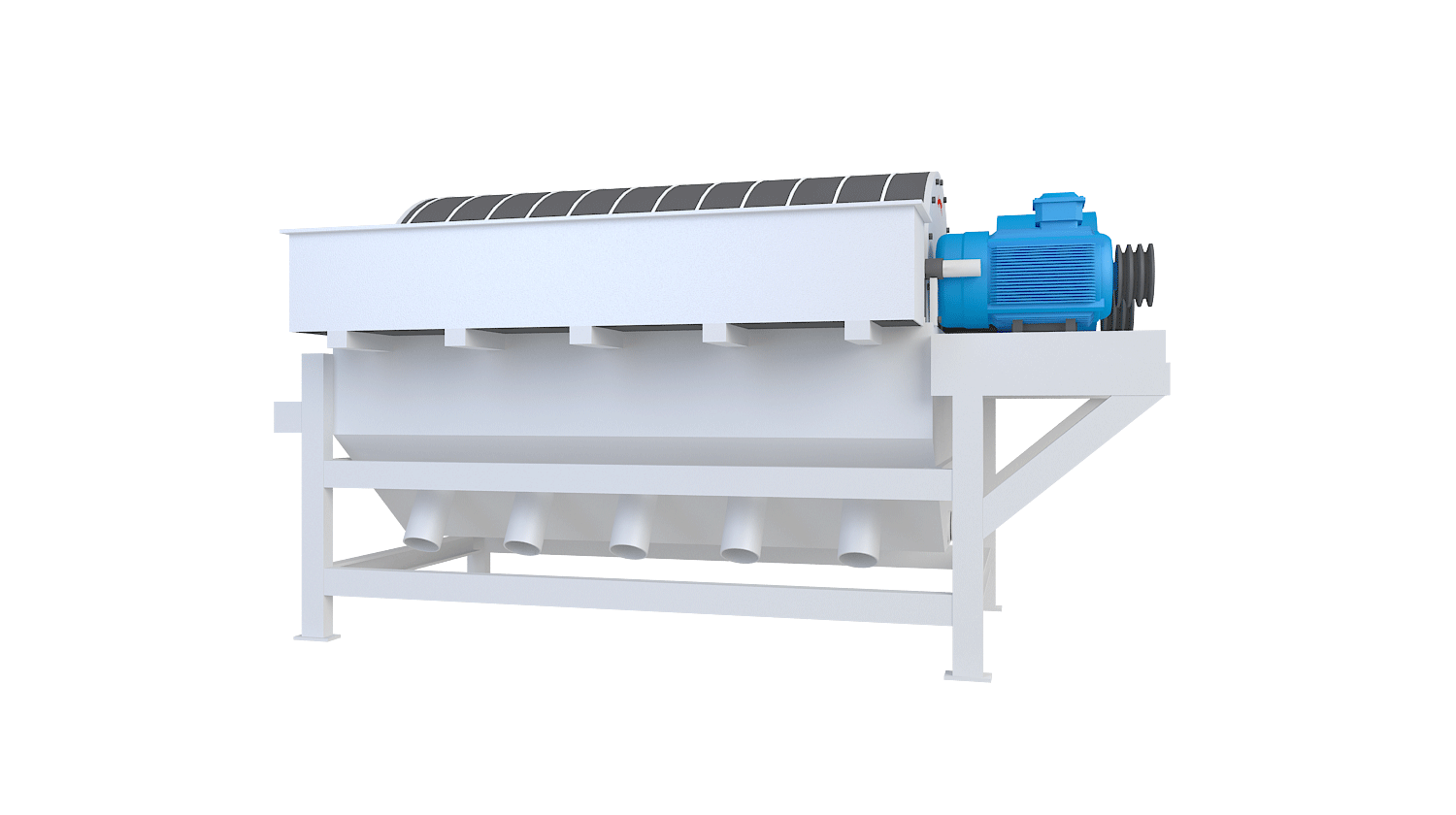

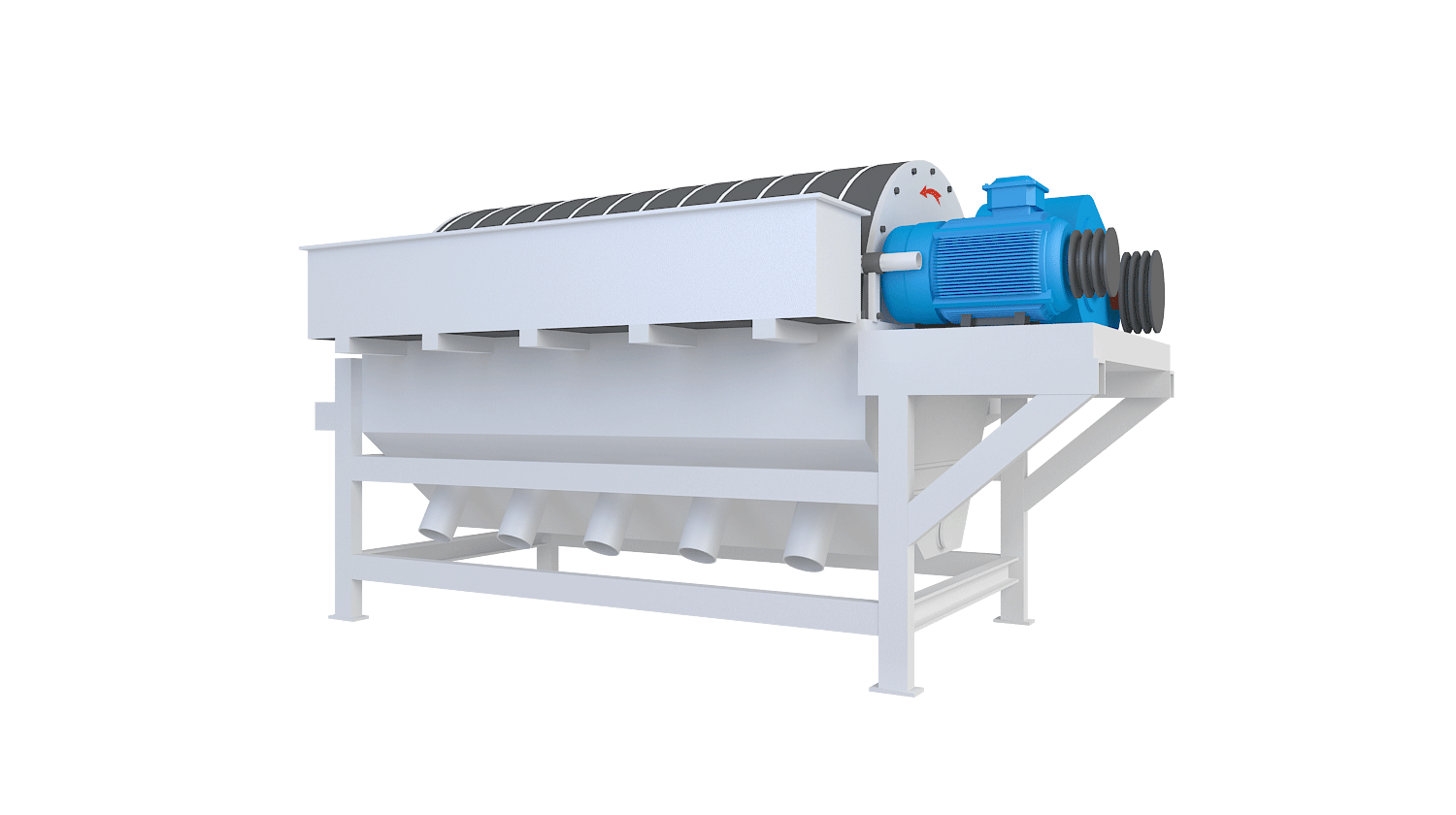

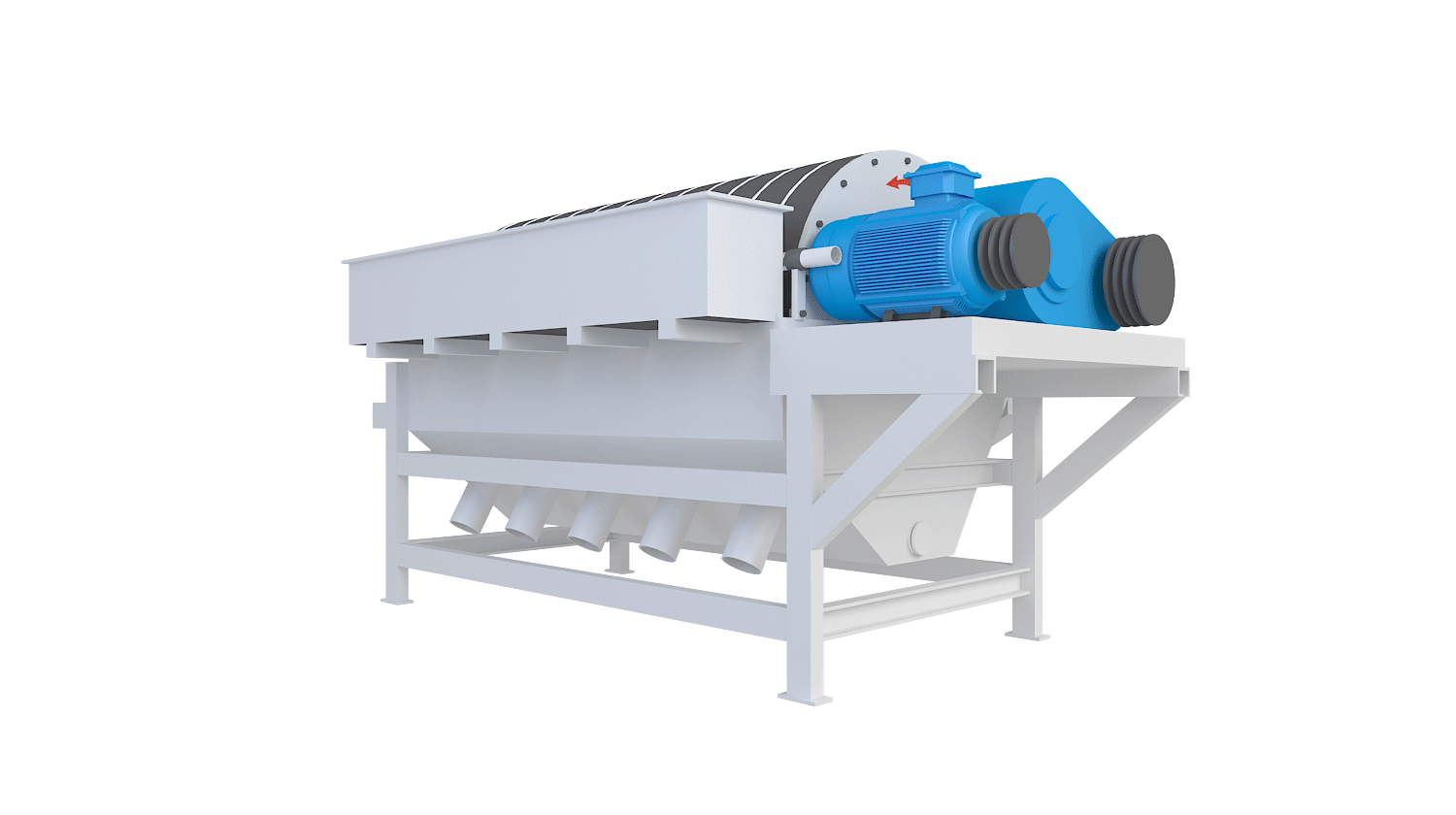

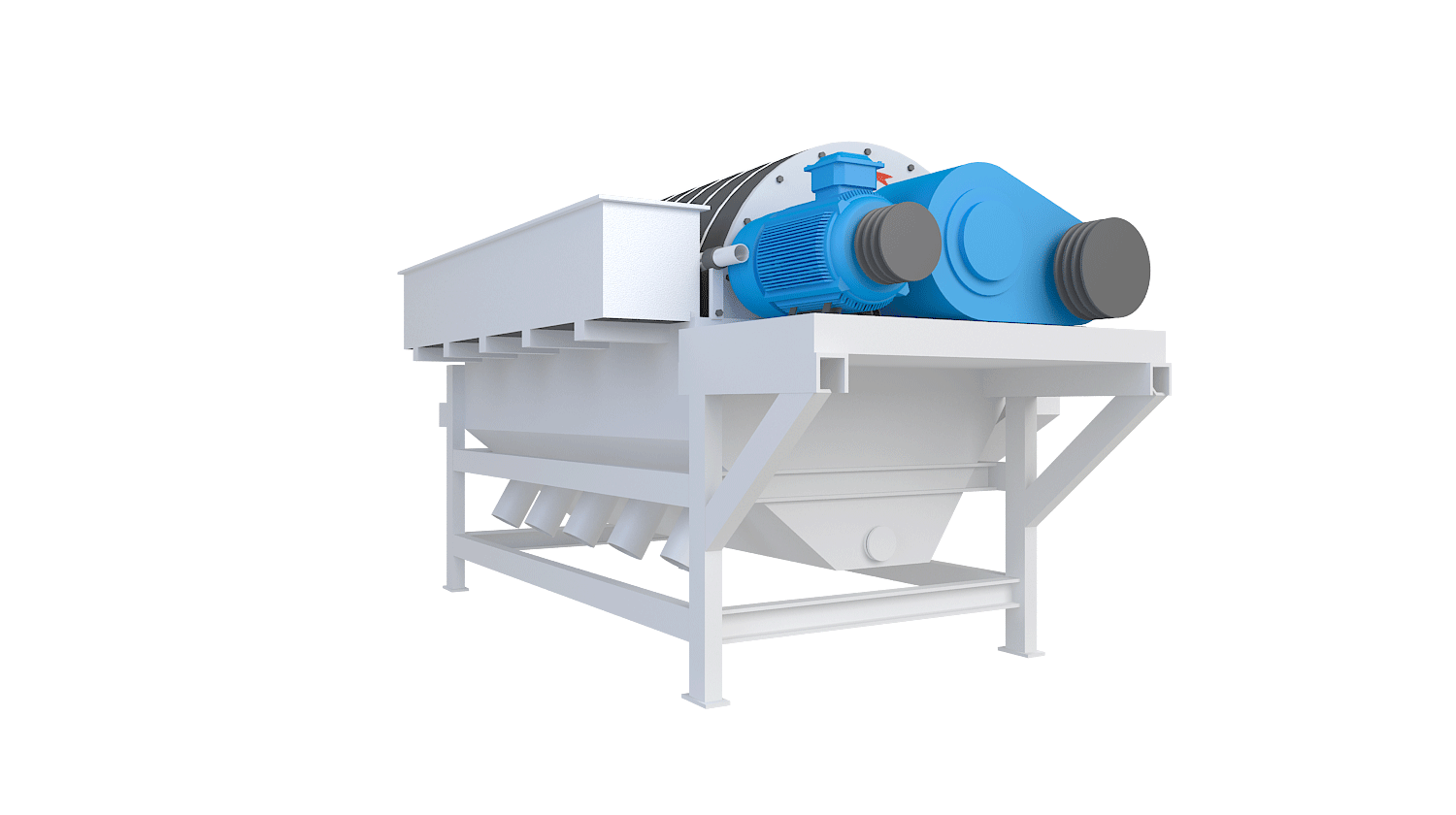

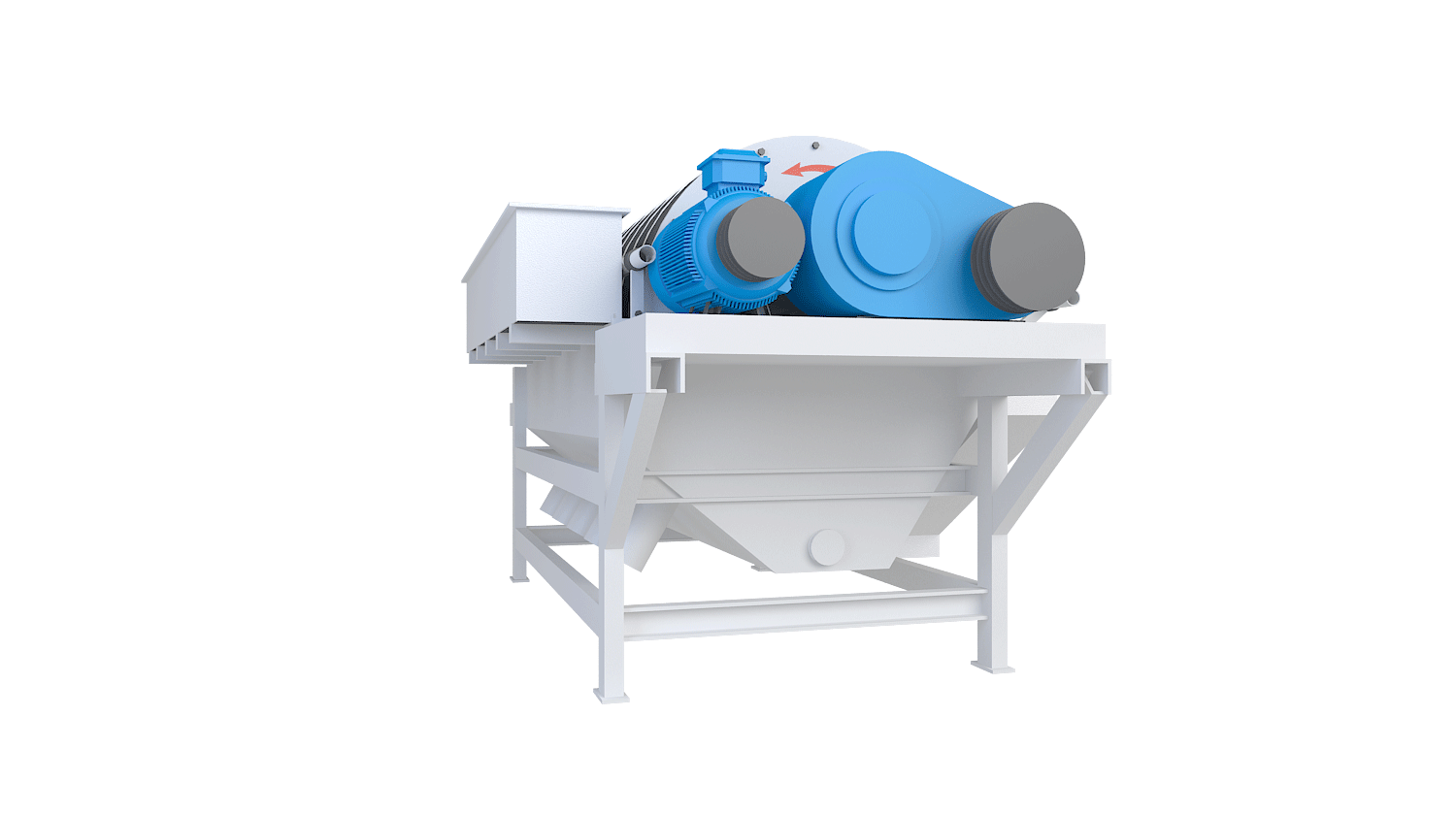

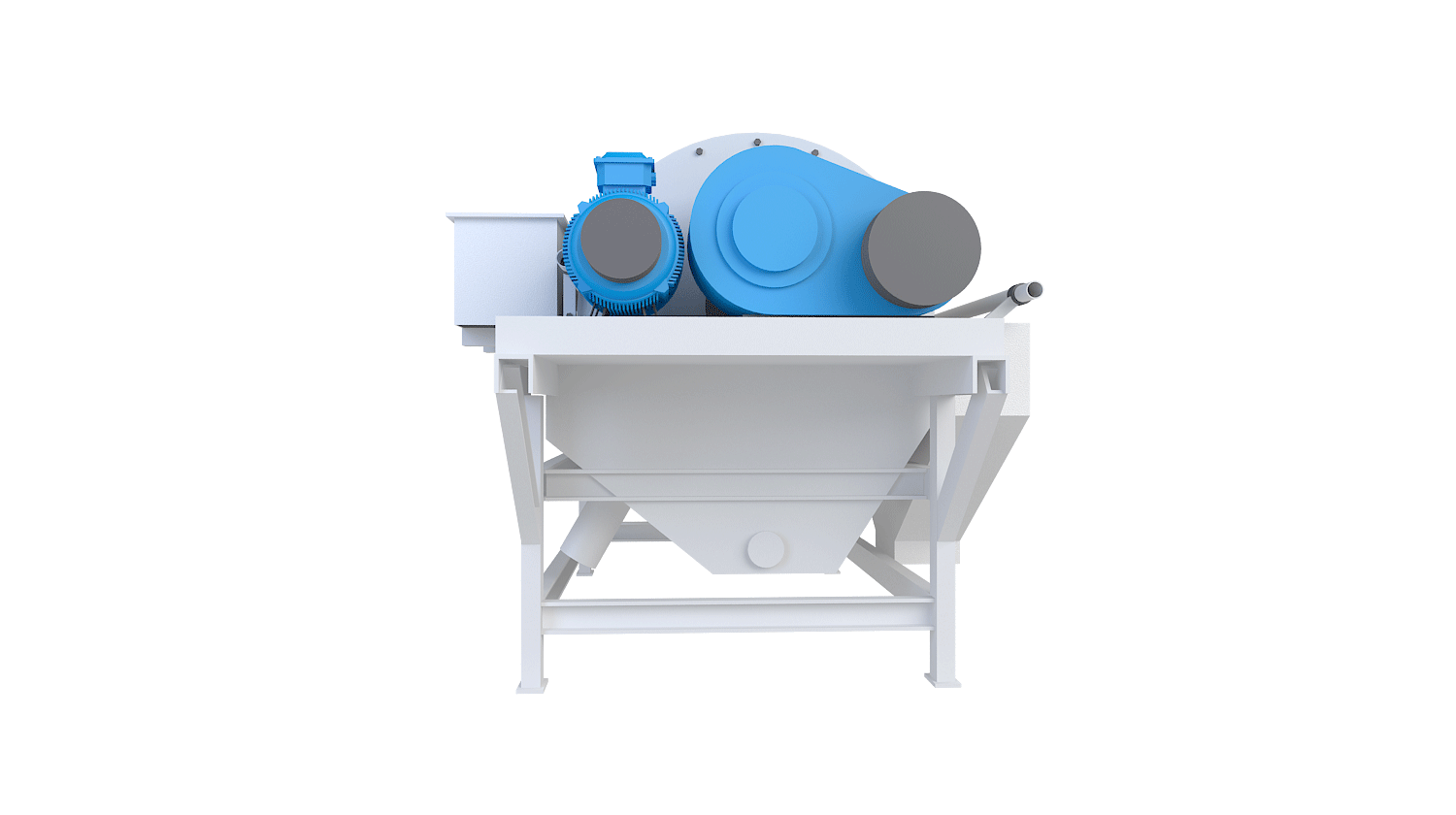

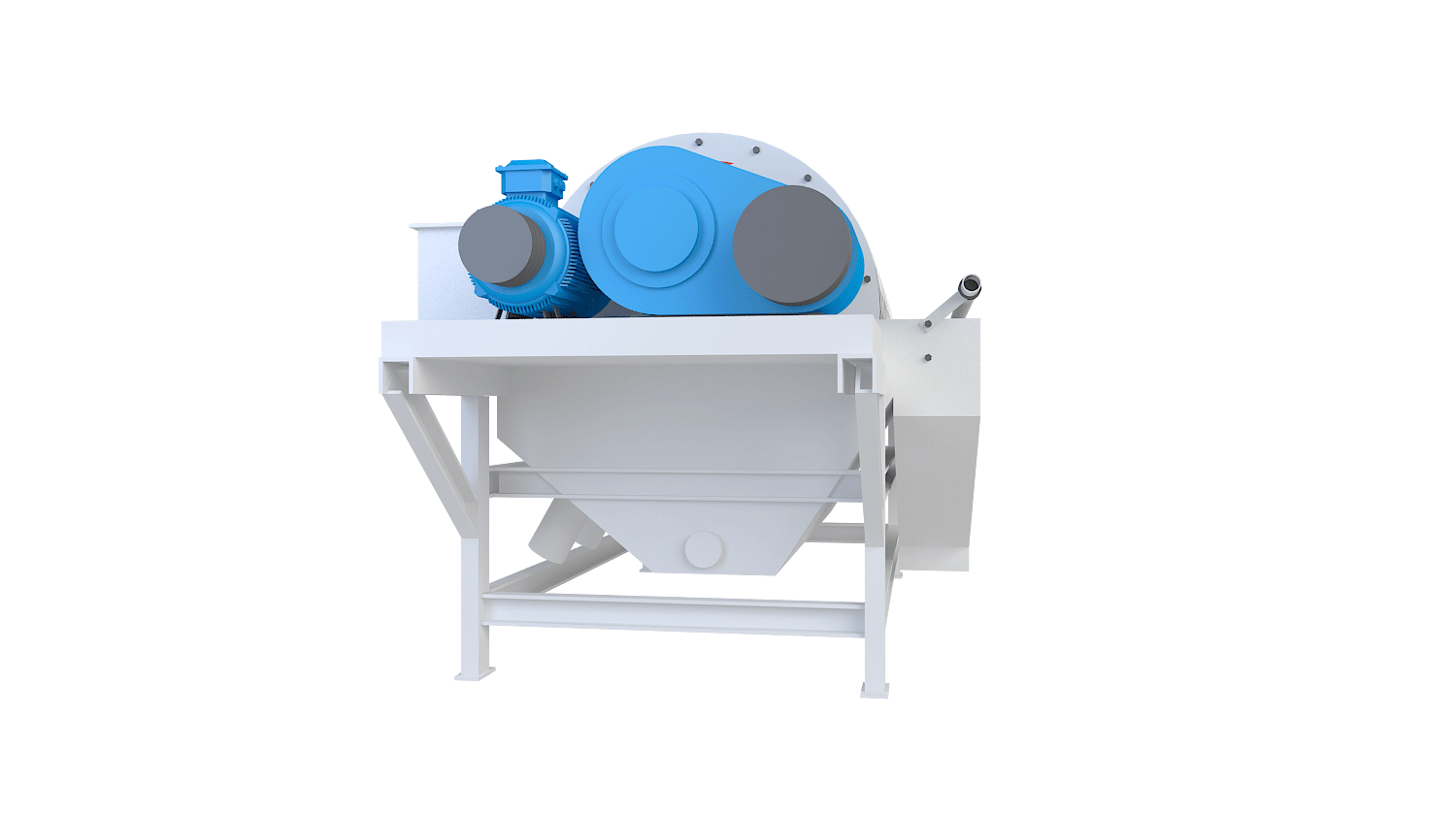

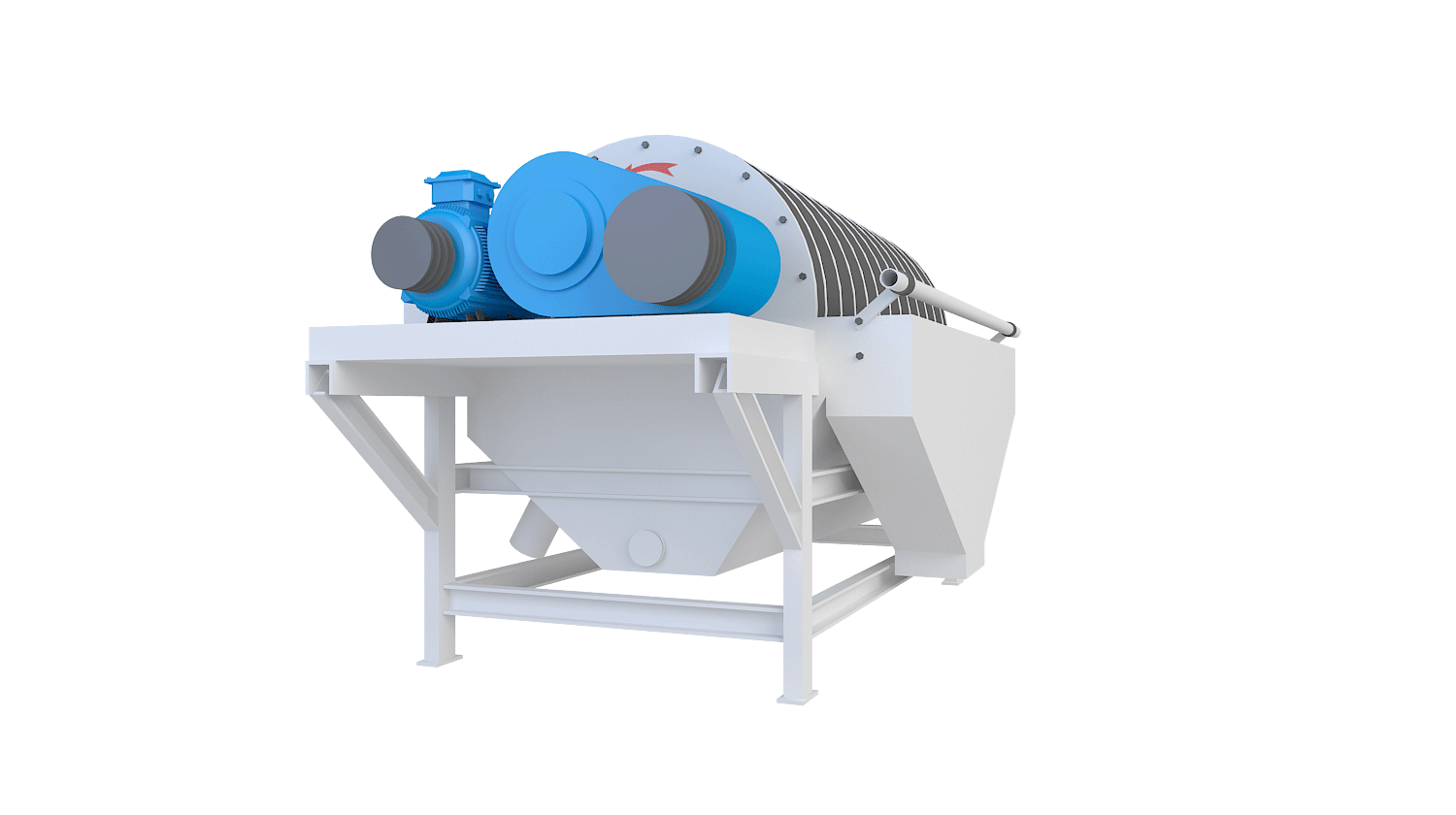

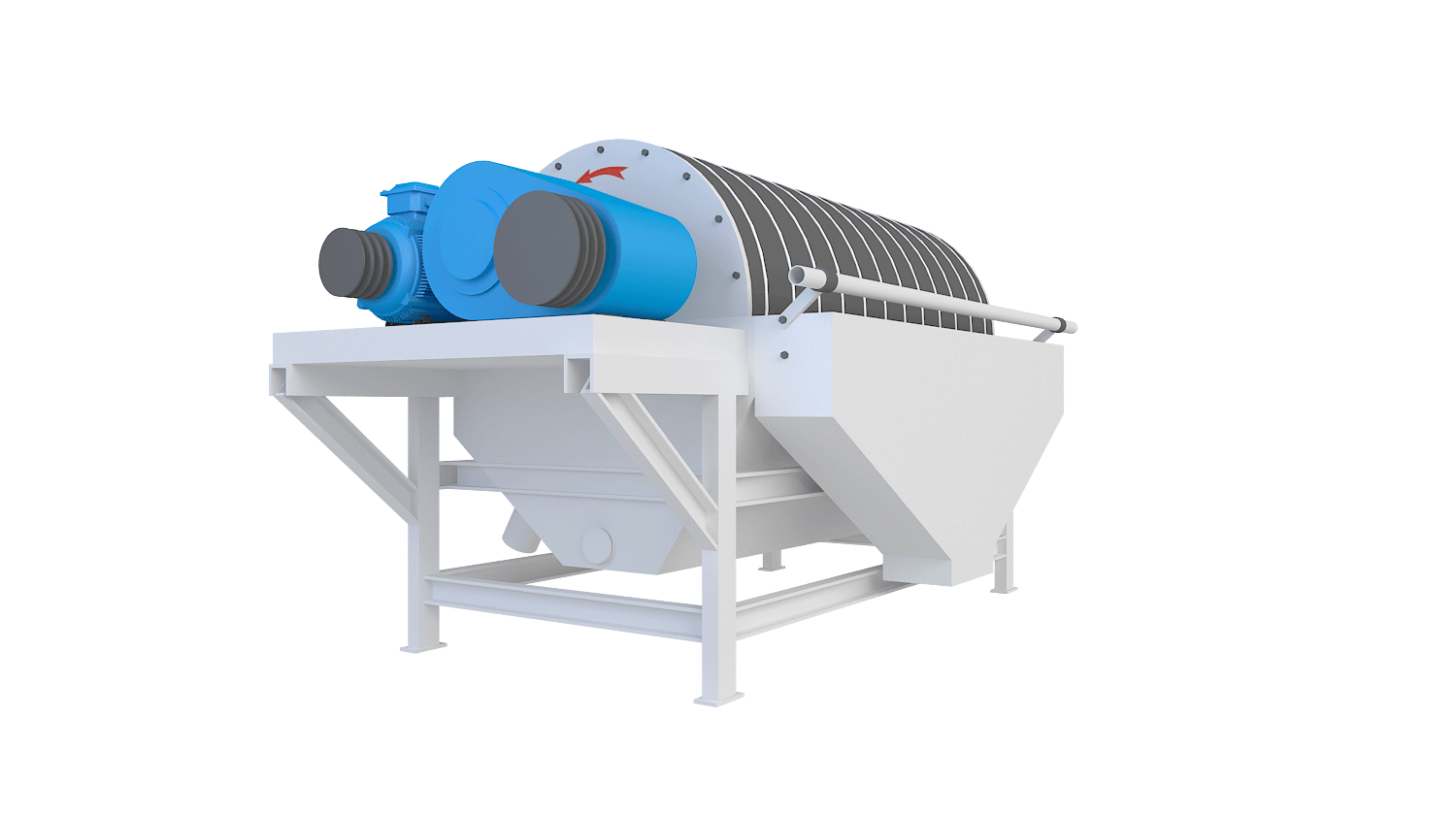

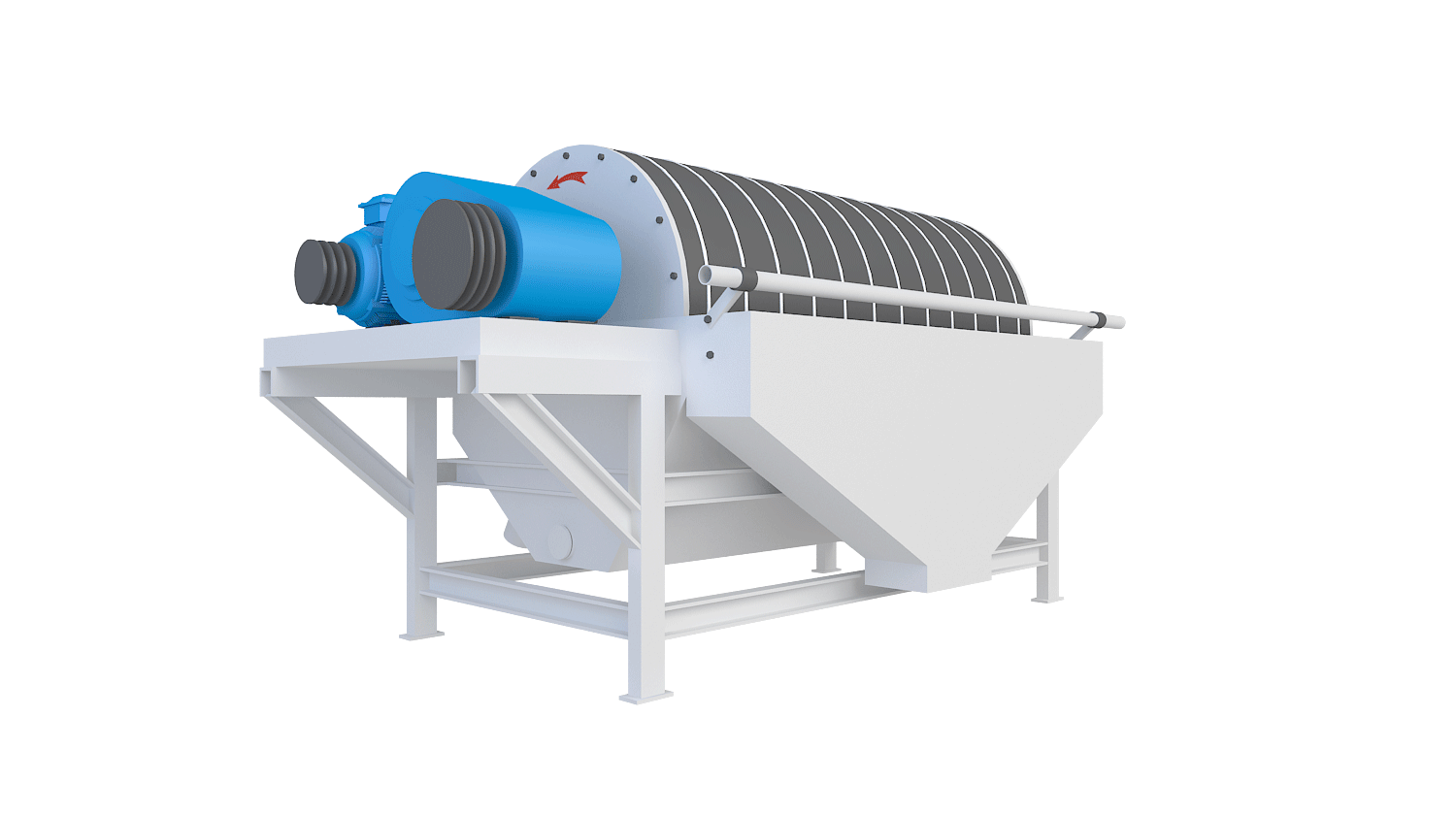

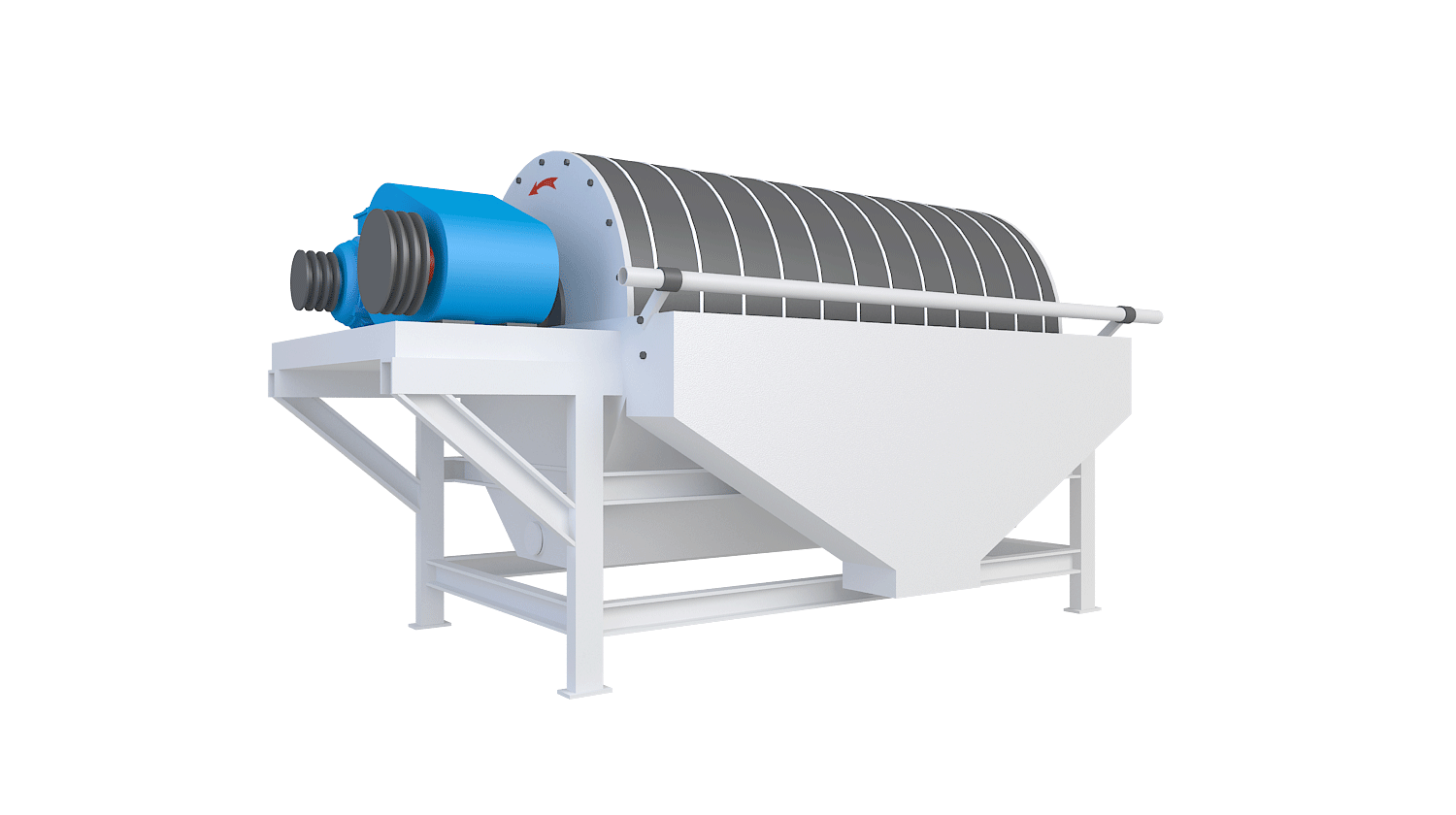

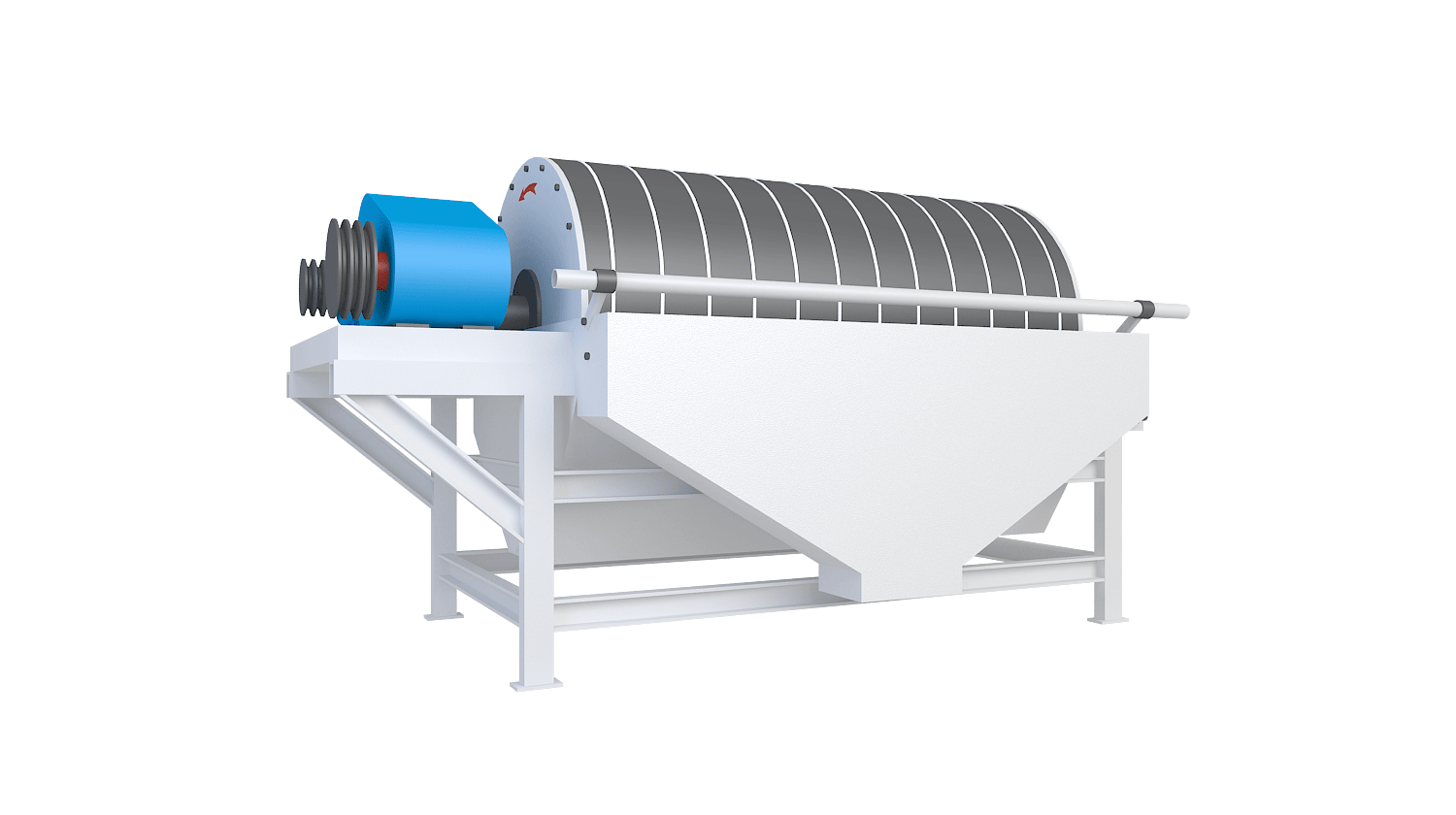

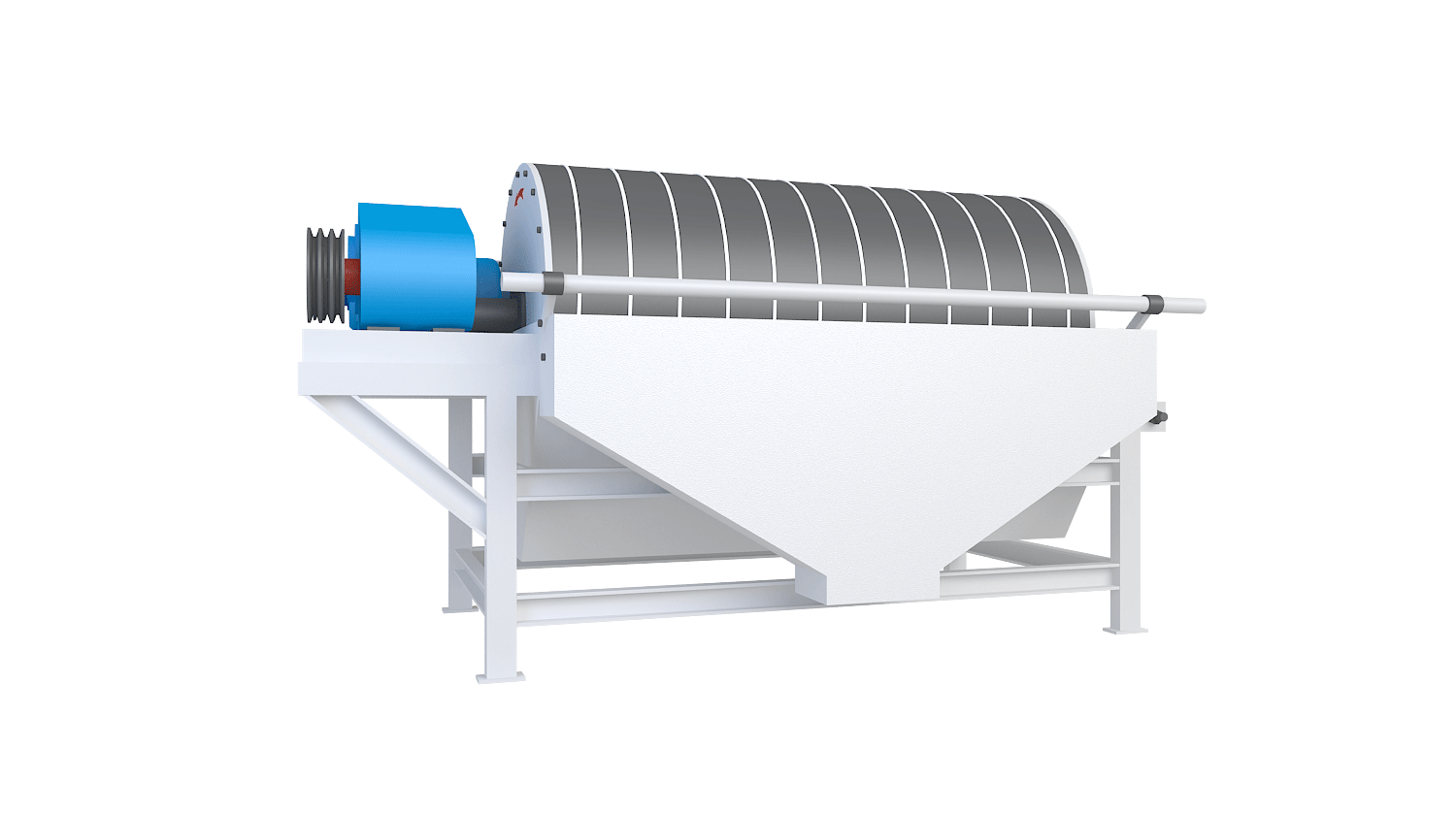

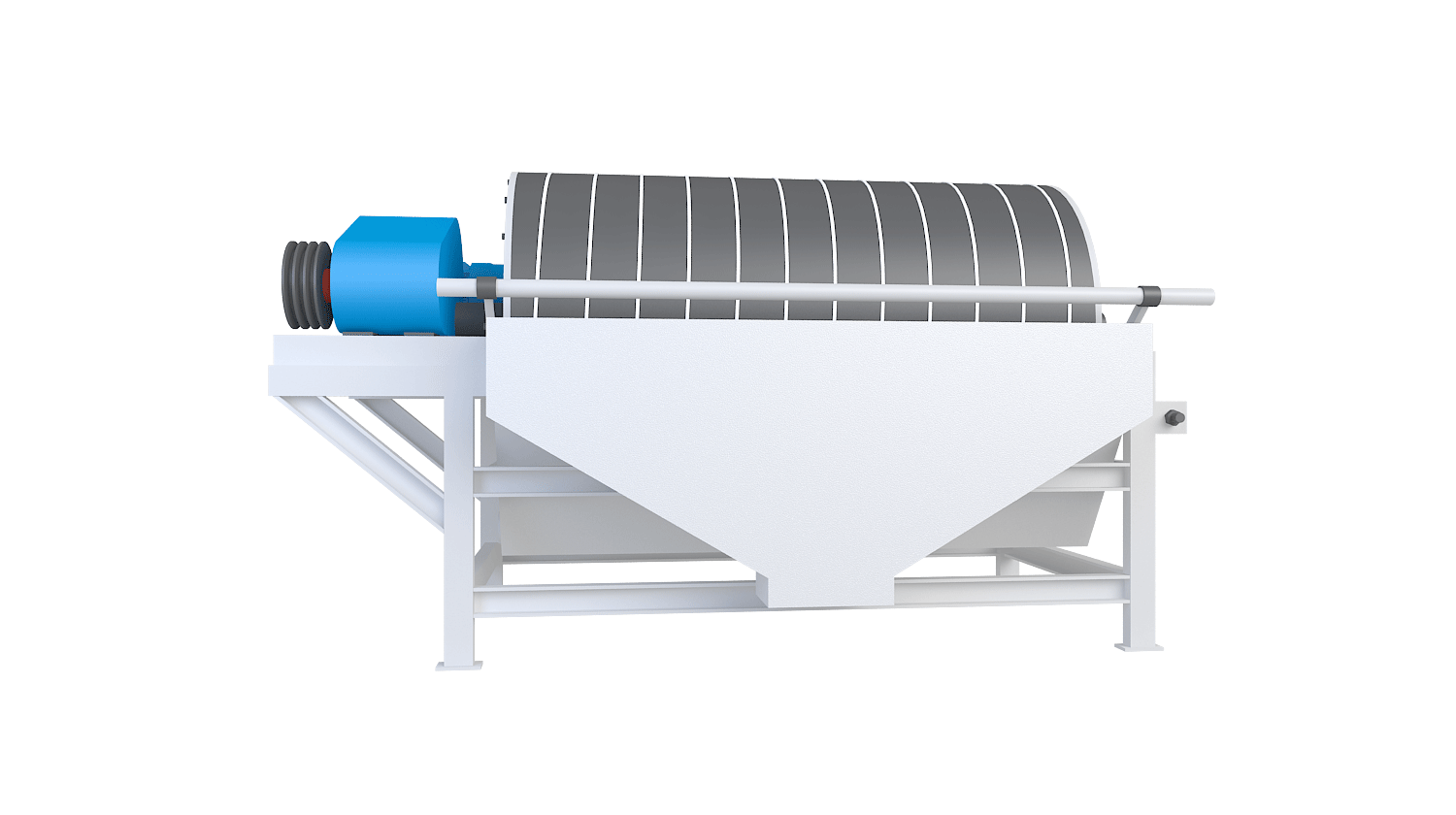

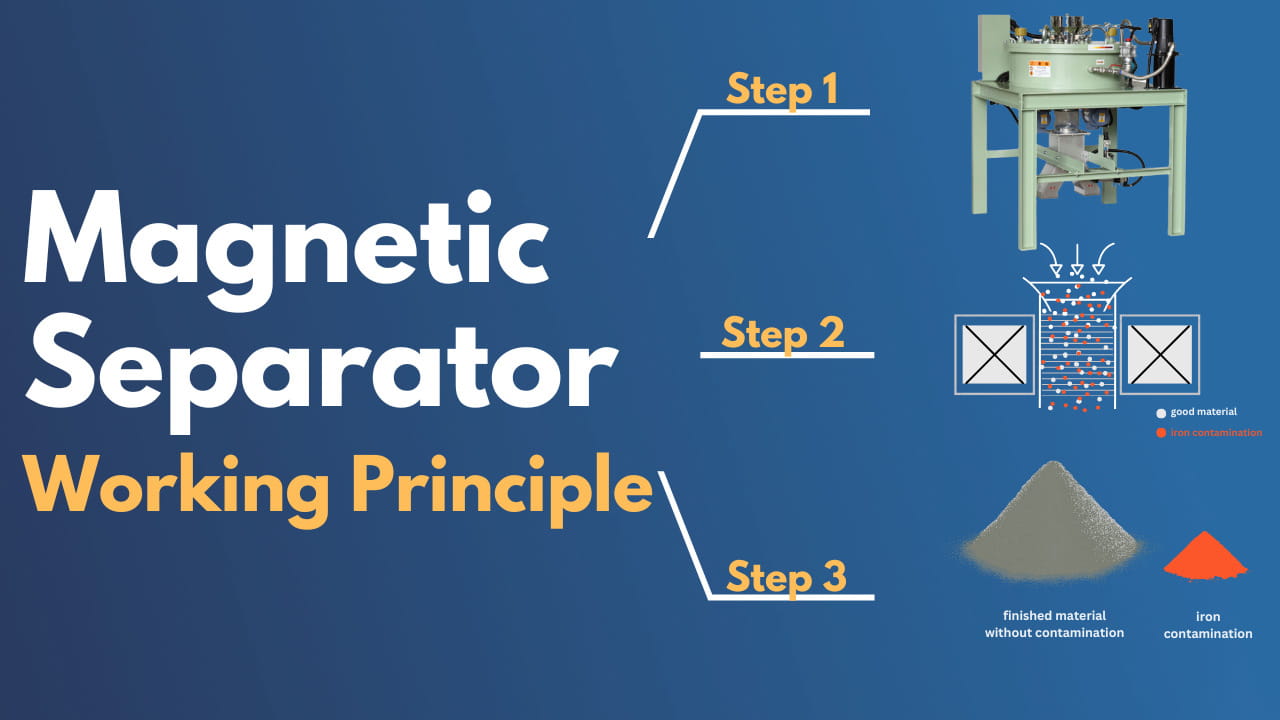

Magnetic Separator operates based on principle of magnetic attraction. When mineral slurry is fed into tank, it flows around rotating drum that contains fixed array of high-intensity permanent magnets. Magnetic particles in slurry are attracted to drum surface and rotate with it, while non-magnetic materials pass freely and are discharged separately. As drum rotates past magnetic field, captured magnetic materials are released by scraper into separate discharge chute, completing separation process efficiently and continuously.