| Model | Effective volume (m³) |

Capacity (m³/min) |

Diameter of impeller (mm) |

Impeller revolutions (r/min) |

Stir motor power (kw) |

Scraper motor power (kw) |

Single slot weight (kg) |

| SF-0.37 | 0.37 | 0.2-0.4 | 300 | 352-442 | 1.5 | 0.55 | 468 |

| SF-0.7 | 0.7 | 0.3-1 | 350 | 336-384 | 3 | 1.1 | 629 |

| SF-1.2 | 1.2 | 0.6-1.6 | 450 | 312 | 5.5 | 1.1 | 1373 |

| SF-2 | 2 | 1.5-3 | 550 | 280 | 11 | 1.5 | 1879 |

| SF-2.8 | 2.8 | 1.5-3.5 | 550 | 280 | 11 | 1.5 | 1902 |

| SF-4 | 4 | 2-4 | 650 | 235 | 15 | 1.5 | 2582 |

| SF-6 | 6 | 3-6 | 760 | 191 | 30 | 2.2 | 3540 |

| SF-8 | 8 | 4-8 | 760 | 191 | 30 | 2.2 | 4129 |

| SF-16 | 16 | 5-16 | 850 | 169-193 | 45 | 1.5 | 7415 |

| SF-20 | 20 | 10-12 | 850 | 169-193 | 45 | 1.5 | 9828 |

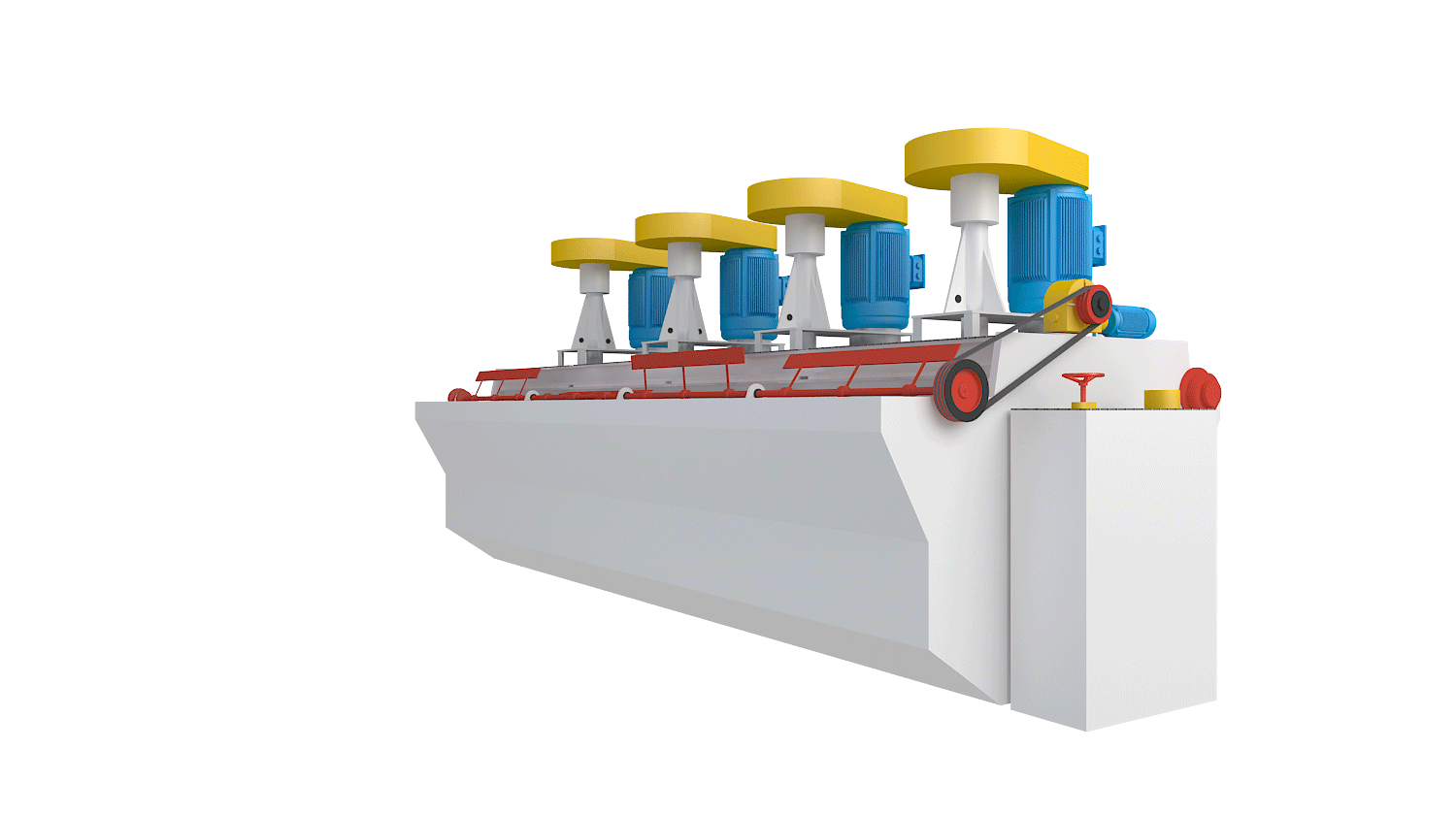

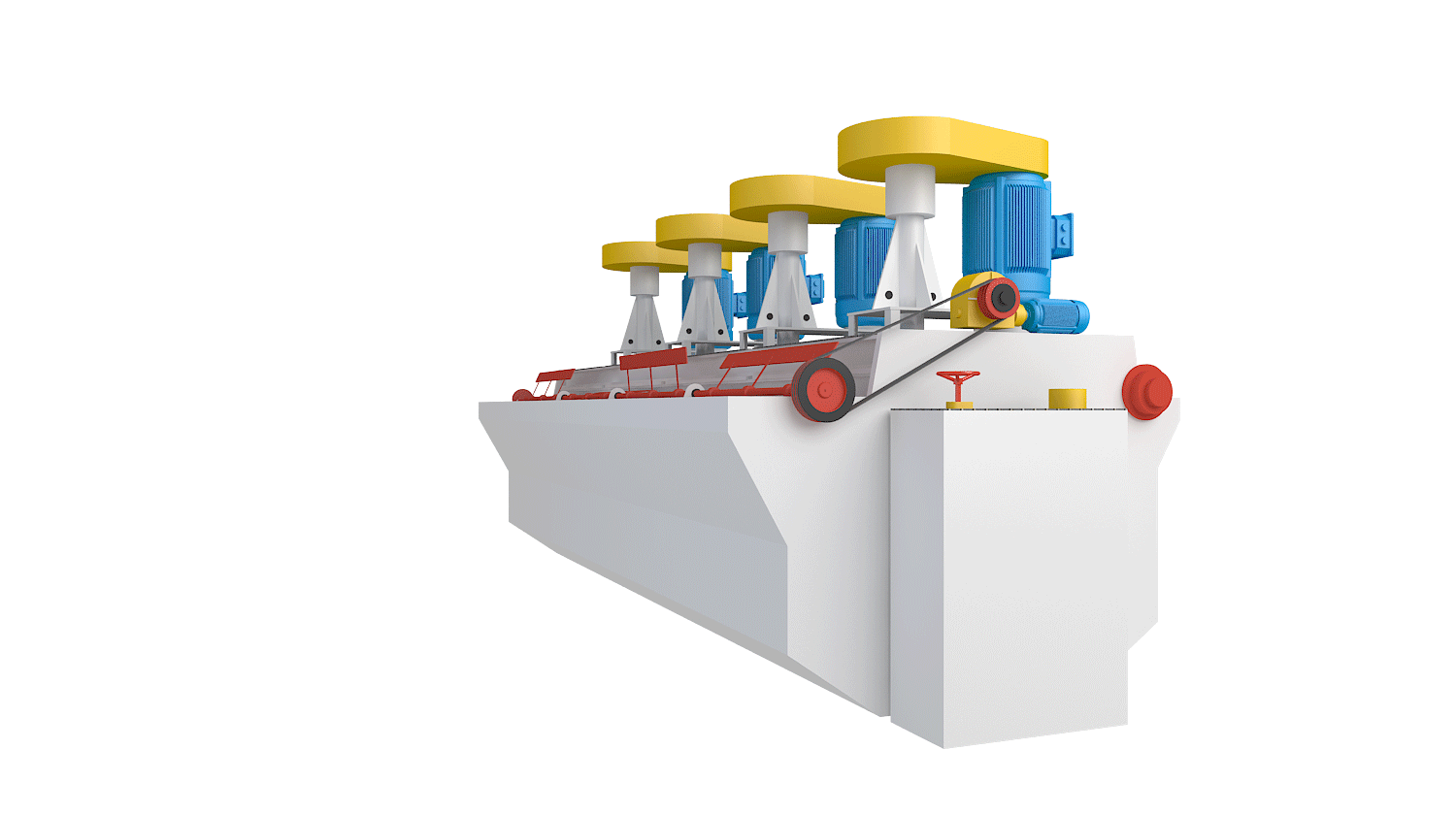

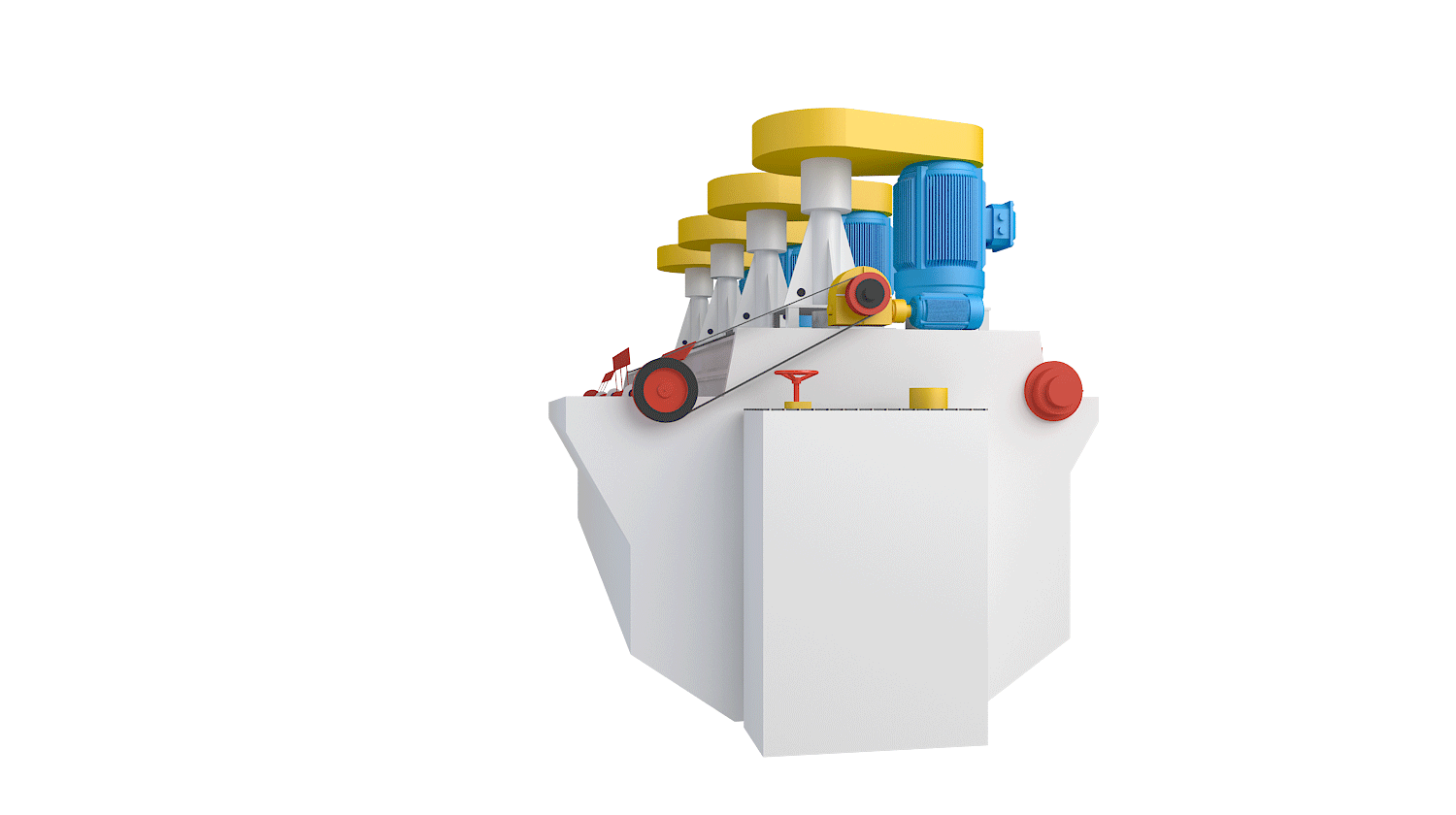

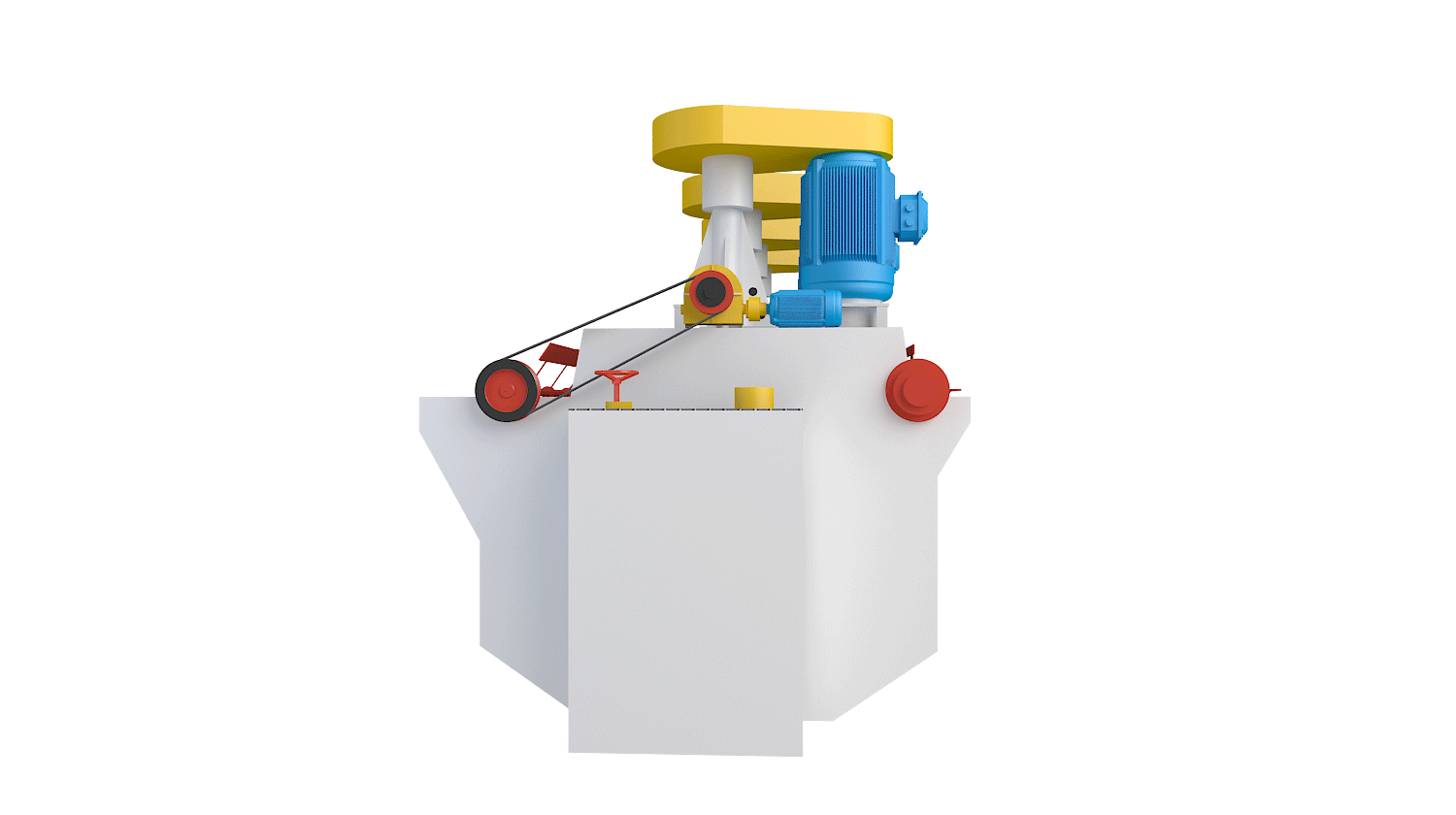

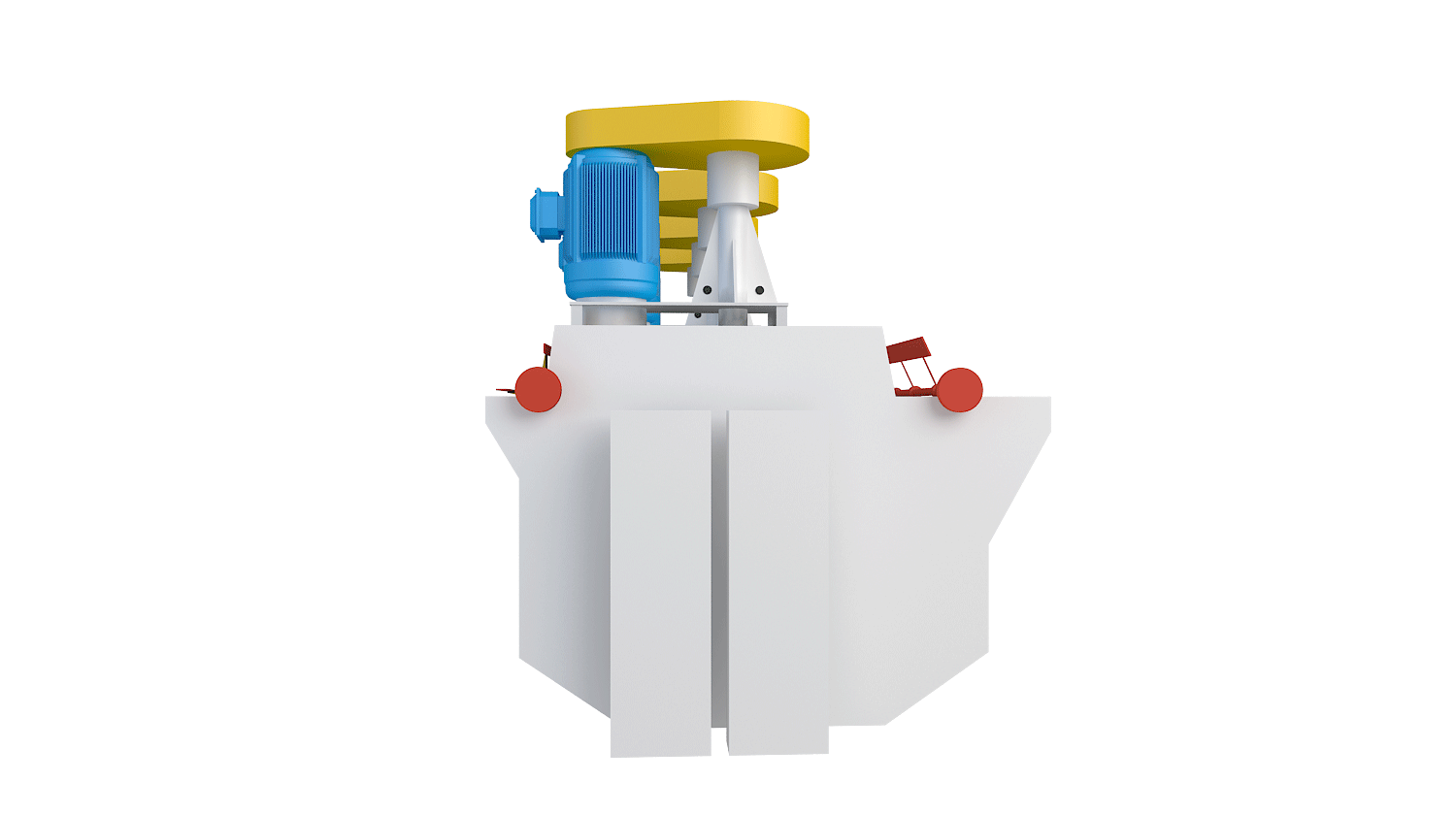

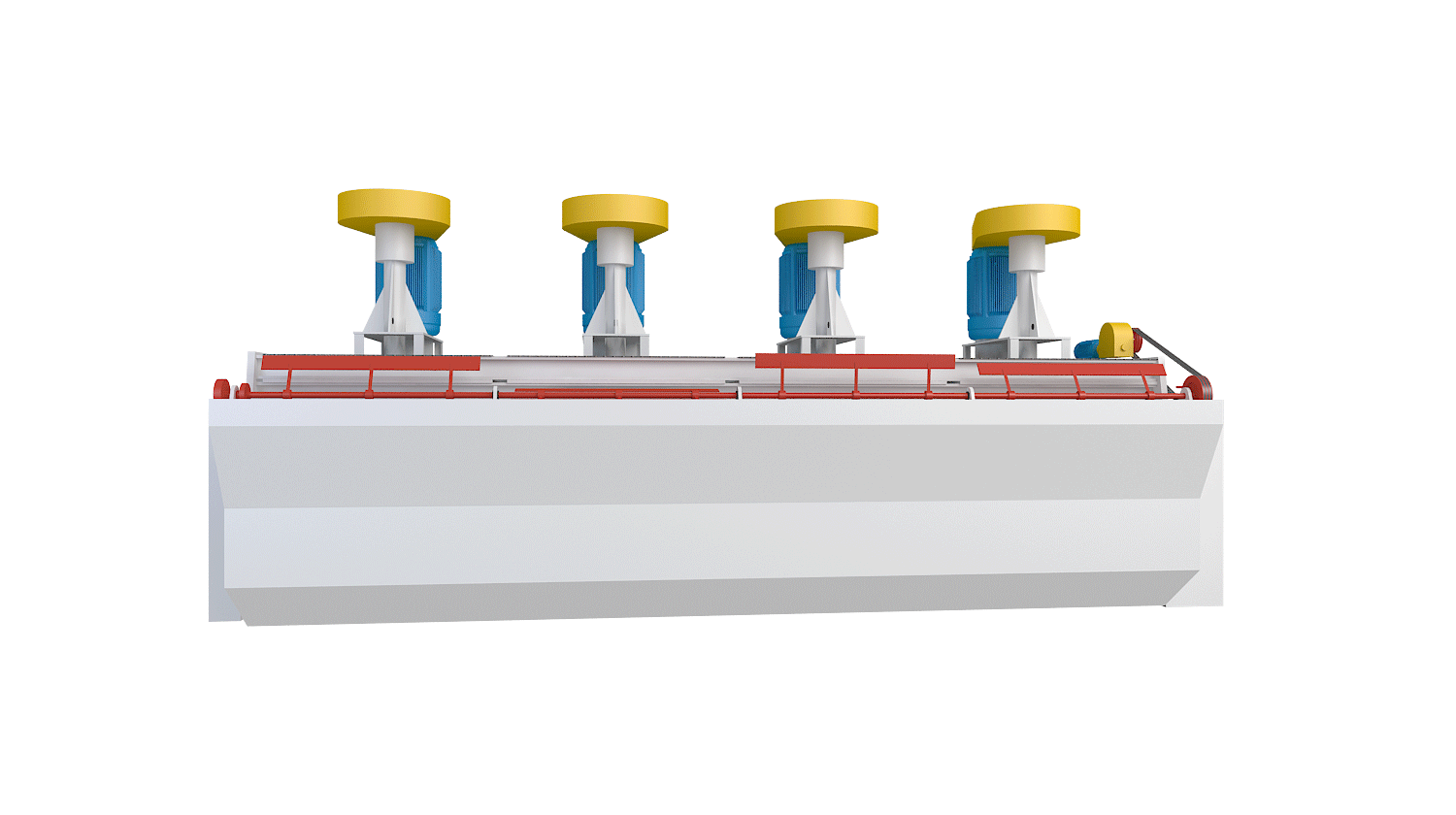

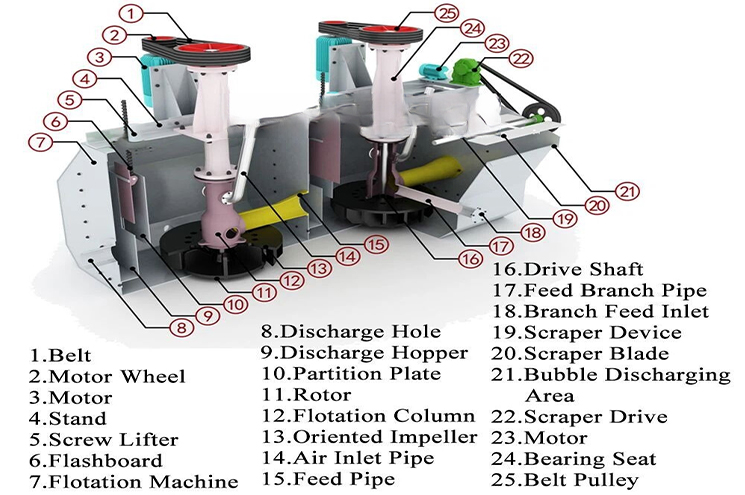

Flotation Machine operates on the principle of selective adhesion of mineral particles to air bubbles. When ore pulp is fed into the tank, it is agitated by the rotating impeller and mixed with air. Reagents are added to increase the hydrophobicity of target minerals. The air bubbles generated rise through the slurry, attracting and lifting hydrophobic mineral particles to the surface to form a froth layer. The froth, enriched with valuable minerals, is then scraped off, while hydrophilic gangue remains in the slurry and is discharged from the bottom. This continuous process ensures effective mineral separation.