| Model | Spiral speed (r/min) |

Return sand volume (t/d) |

Overflow handling capacity (t/d) |

Spiral diameter (mm) |

Spiral length (mm) |

Slope of sink | Drive motor model | Power (kw) |

Lifting motor model | Power (kw) |

Weight (kg) |

| FLG-300 | 7.7 | 30-80 | 10-30 | Φ300 | 3900 | 14-18 | Y100L1-4 | 2.2 | manual | - | 668 |

| FLG-500 | 8 | 145-260 | 21-75 | Φ500 | 4390 | Y112M-6 | 2.2 | manual | - | 1600 | |

| FLG-750 | 7.8 | 100-455 | 31-165 | Φ750 | 5500 | Y132S-6 | 3 | manual | - | 2716 | |

| FLG-1000 | 6.7 | 473-1026 | 85 | Φ1000 | 6556 | Y132M2-6 | 5.5 | manual | - | 4000 | |

| FLG-1200 | 5,6,7 | 1145-1600 | 150 | Φ1200 | 6500 | Y132M2-6 | 5.5 | Y90L-4 | 1.5 | 7943 | |

| FLG-1500 | 2.5,4,6 | 1140-2730 | 235 | Φ1500 | 8265 | Y160M-6 | 7.5 | Y100L1-4 | 2.2 | 11827 | |

| FLG-2000 | 3.6,5.5 | 3240-5940 | 400 | Φ2000 | 8700 | Y160L-6/4 | 11,15 | Y100L2-4 | 3 | 20814 | |

| FLG-2400 | 3.6 | 6800 | 580 | Φ2400 | 9130 | Y200L2-6 | 22 | Y112M-4 | 4 | 24194 | |

| FLG-3000 | 3.2 | 11625 | 890 | Φ3000 | 12500 | Y200L-4 | 30 | Y112M-4 | 4 | 42188 |

| Model | Spiral speed (r/min) |

Return sand volume (t/d) |

Overflow handling capacity (t/d) |

Spiral diameter (mm) |

Spiral length (mm) |

Slope of sink | Drive motor model | Power (kw) |

Lifting motor model | Power (kw) |

Weight (kg) |

| 2FLG-1200 | 5,6,7 | 2290-3200 | 310 | Φ1200 | 6500 | 14-18 | Y132M2-6 | 5.5*2 | Y90L1-4 | 1.5*2 | 15840 |

| 2FLG-1500 | 2.5,4,6 | 2240-5360 | 460 | Φ2500 | 8230 | Y160M-6 | 7.5*2 | Y100L1-4 | 2.2*2 | 22903 | |

| 2FLG-2000 | 3.6,5.5 | 6400-10800 | 750 | Φ2000 | 8400 | Y160L-4 | 15*2 | Y100L2-4 | 3*2 | 34621 | |

| 2FLG-2400 | 3.63 | 13600 | 1160 | Φ2400 | 9130 | Y200L2-6 | 22*2 | Y112M-4 | 4*2 | 42460 | |

| 2FLG-3000 | 3.2 | 23300 | 1785 | Φ3000 | 12500 | Y200L-4 | 30*2 | Y112M-4 | 4*2 | 73030 |

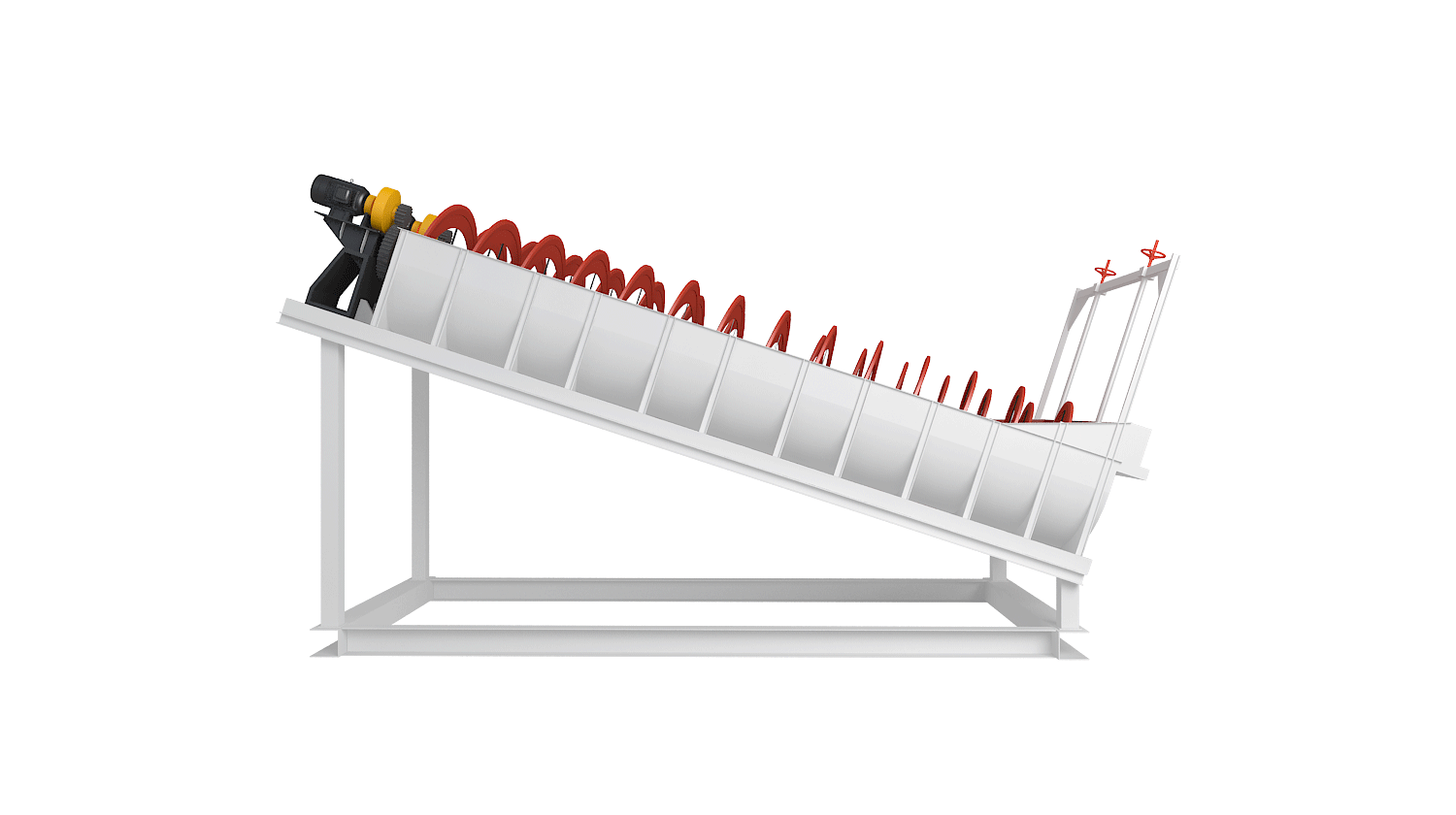

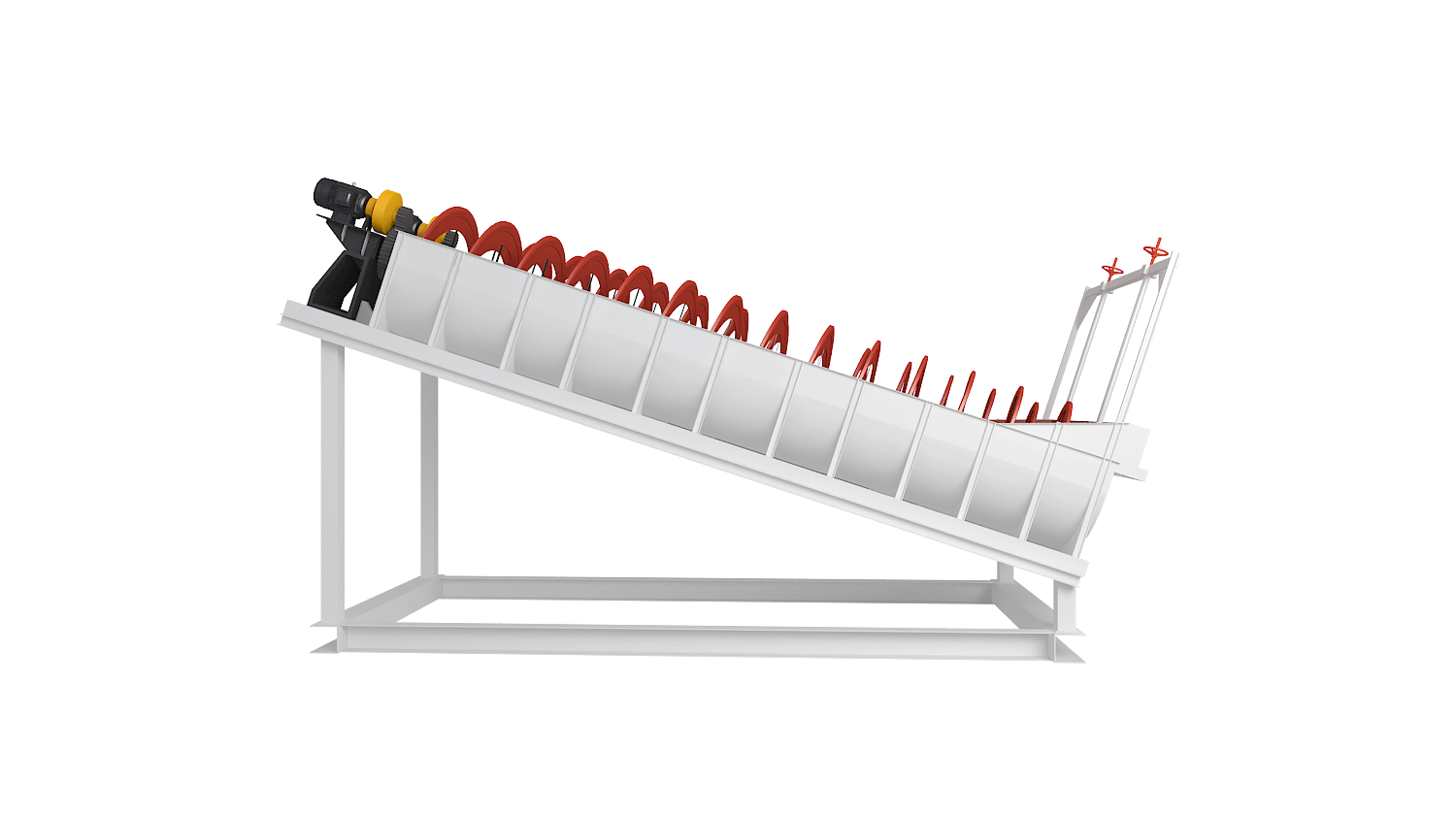

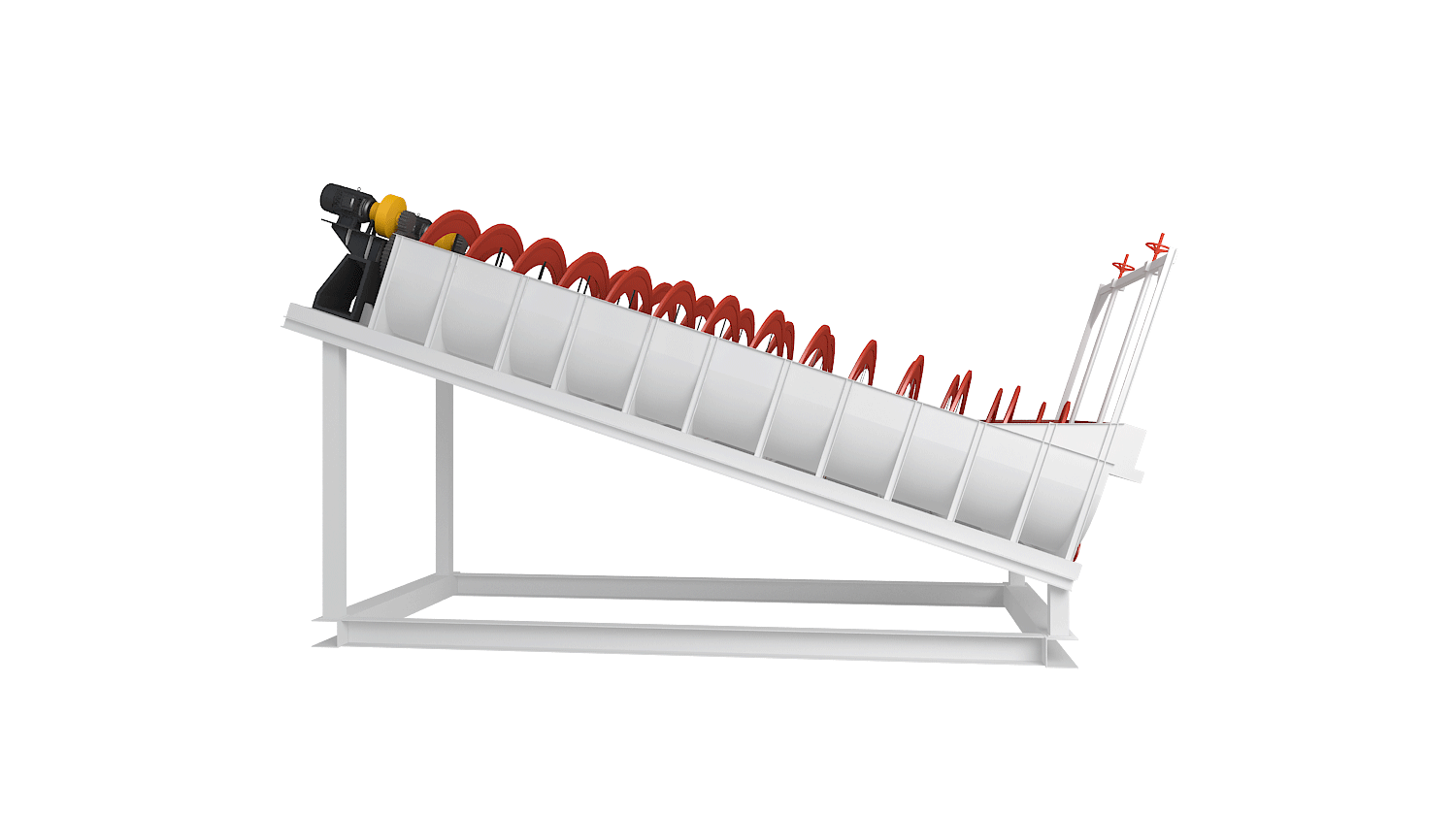

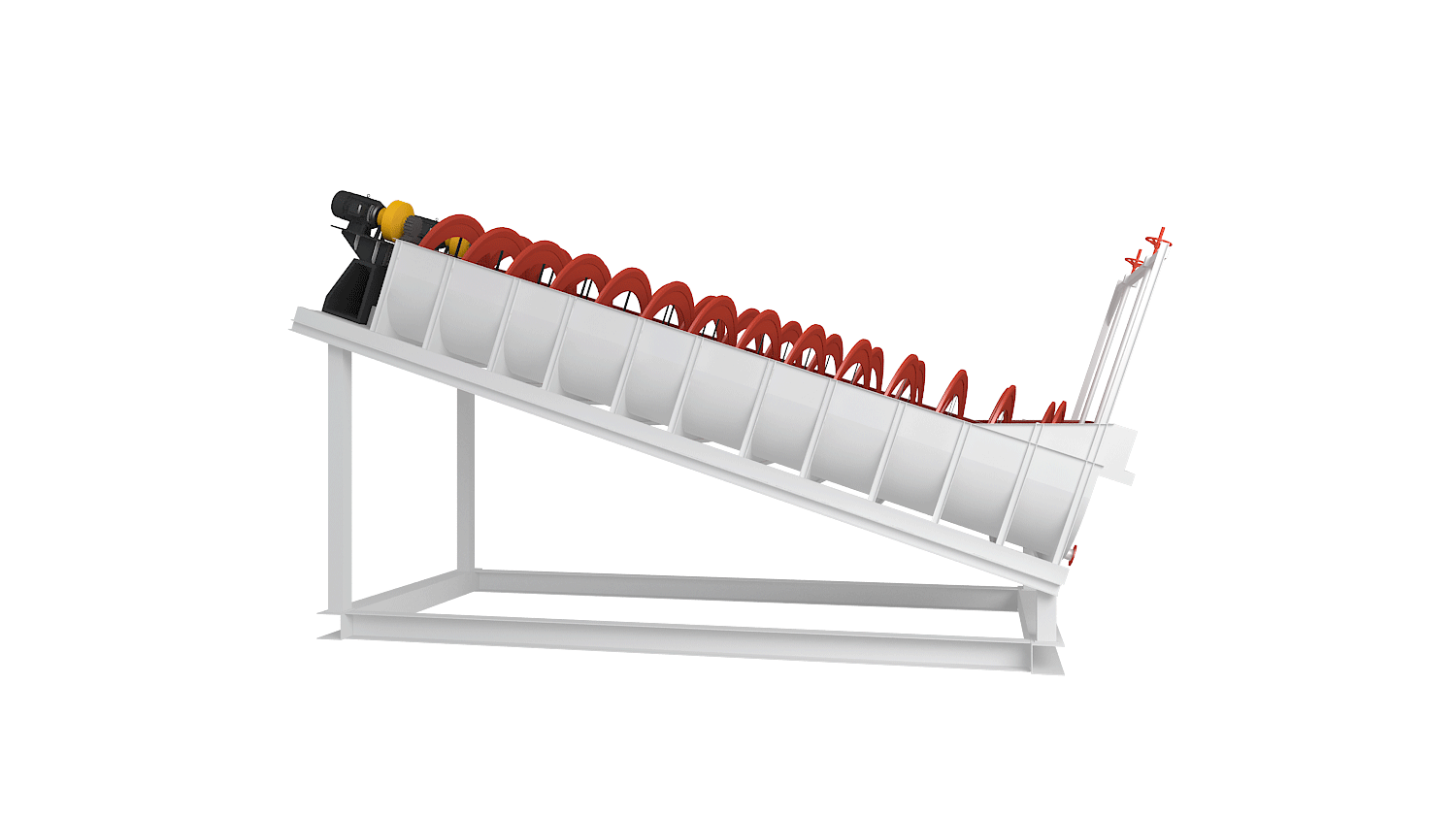

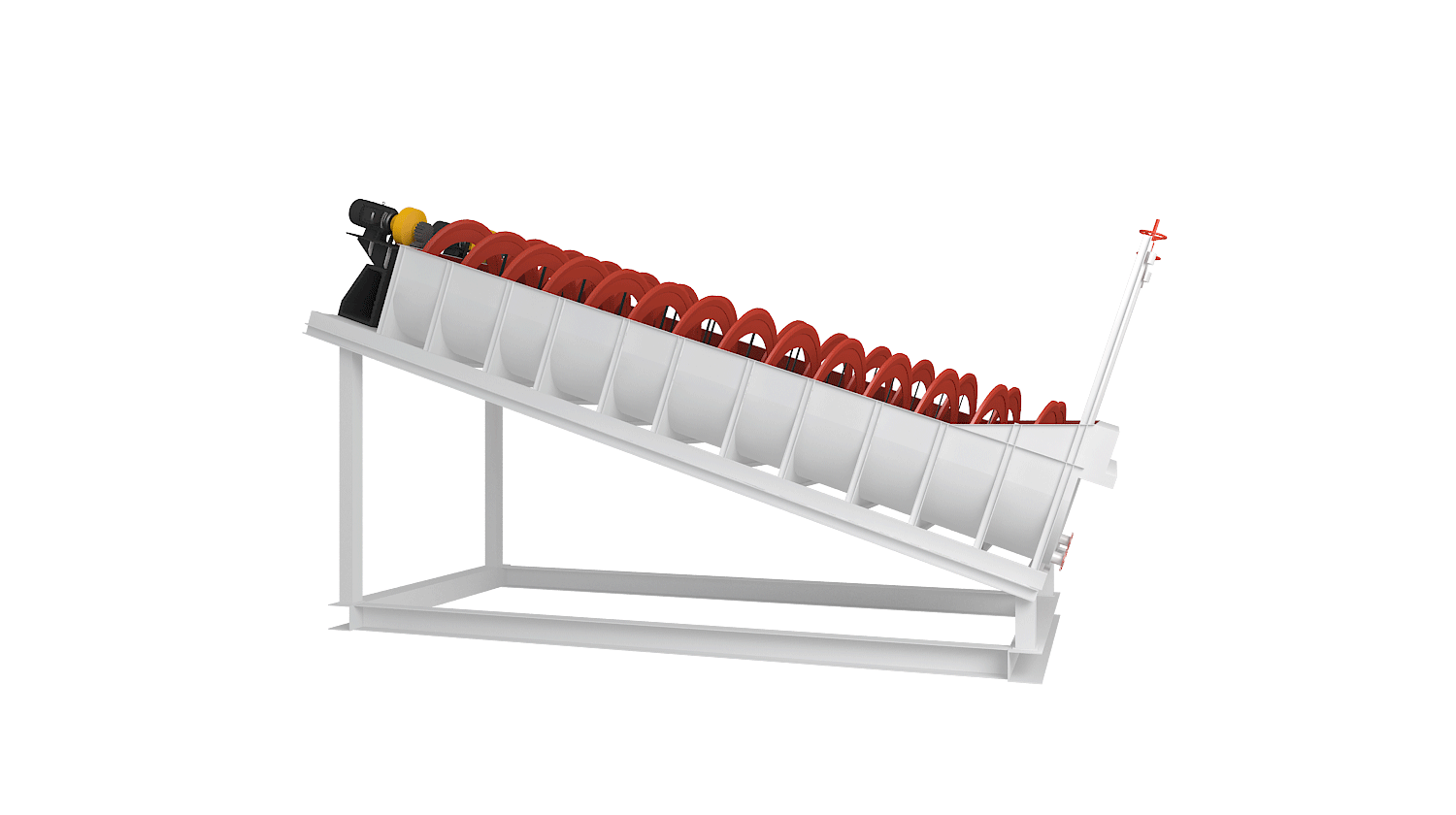

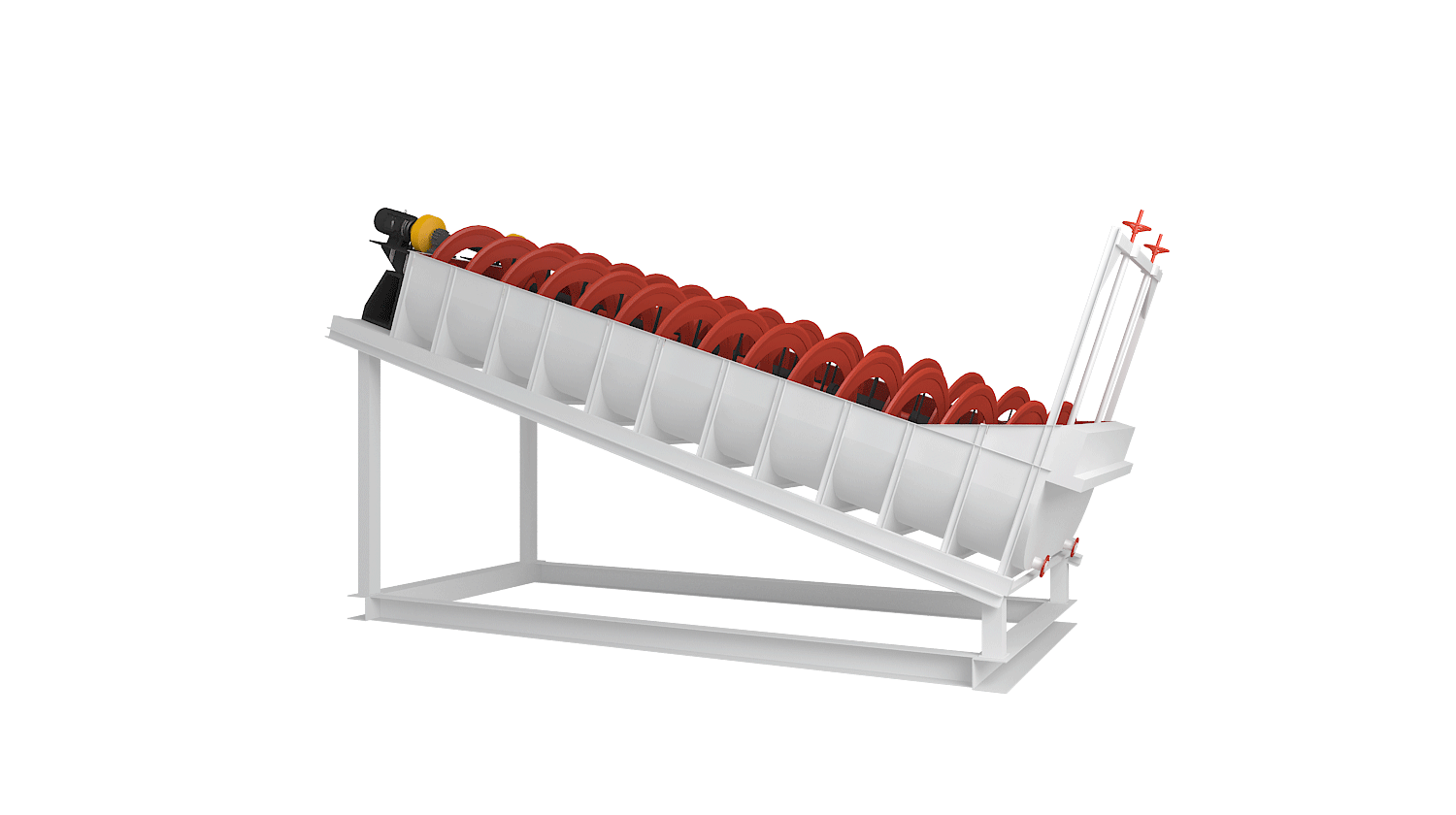

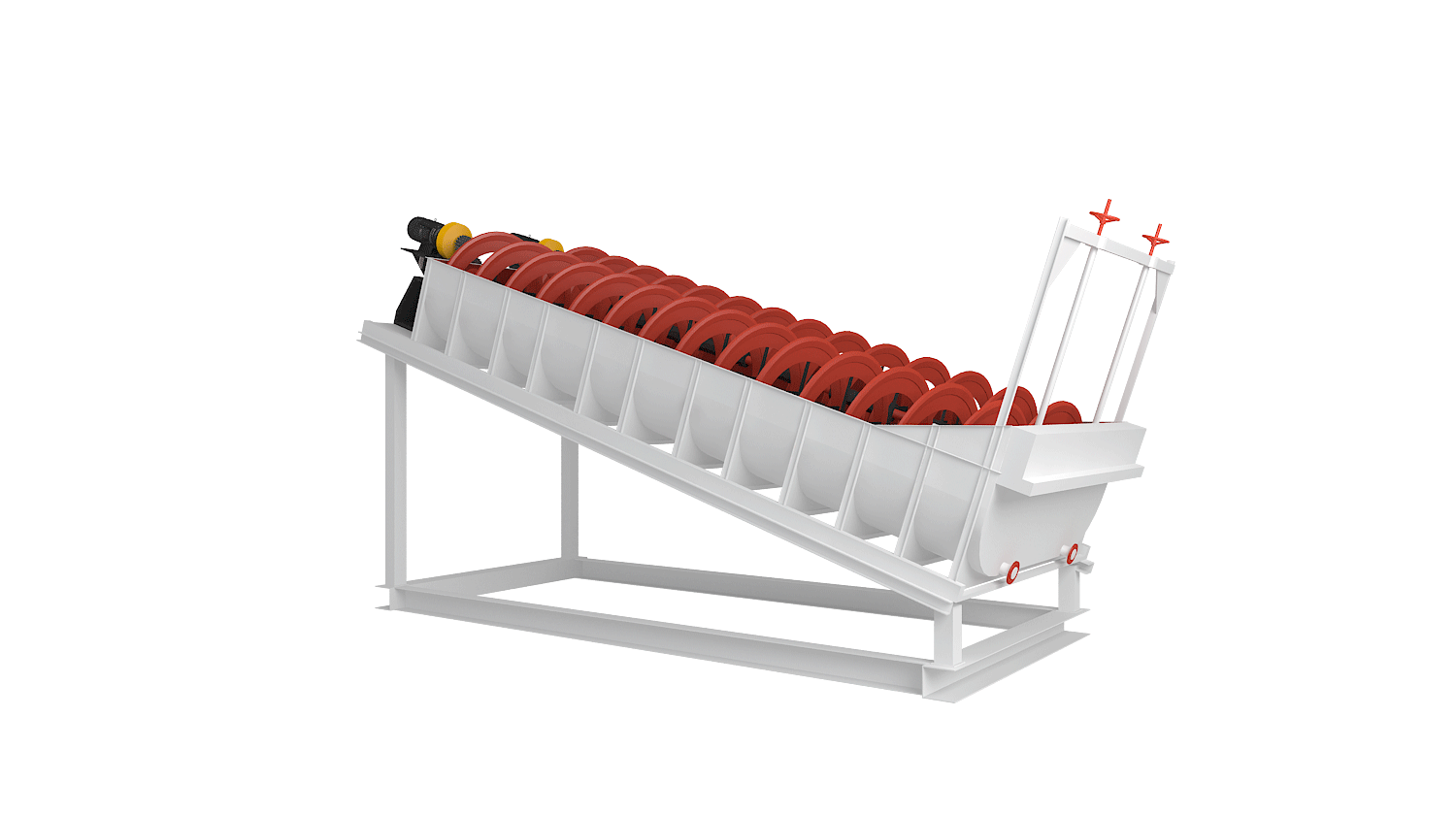

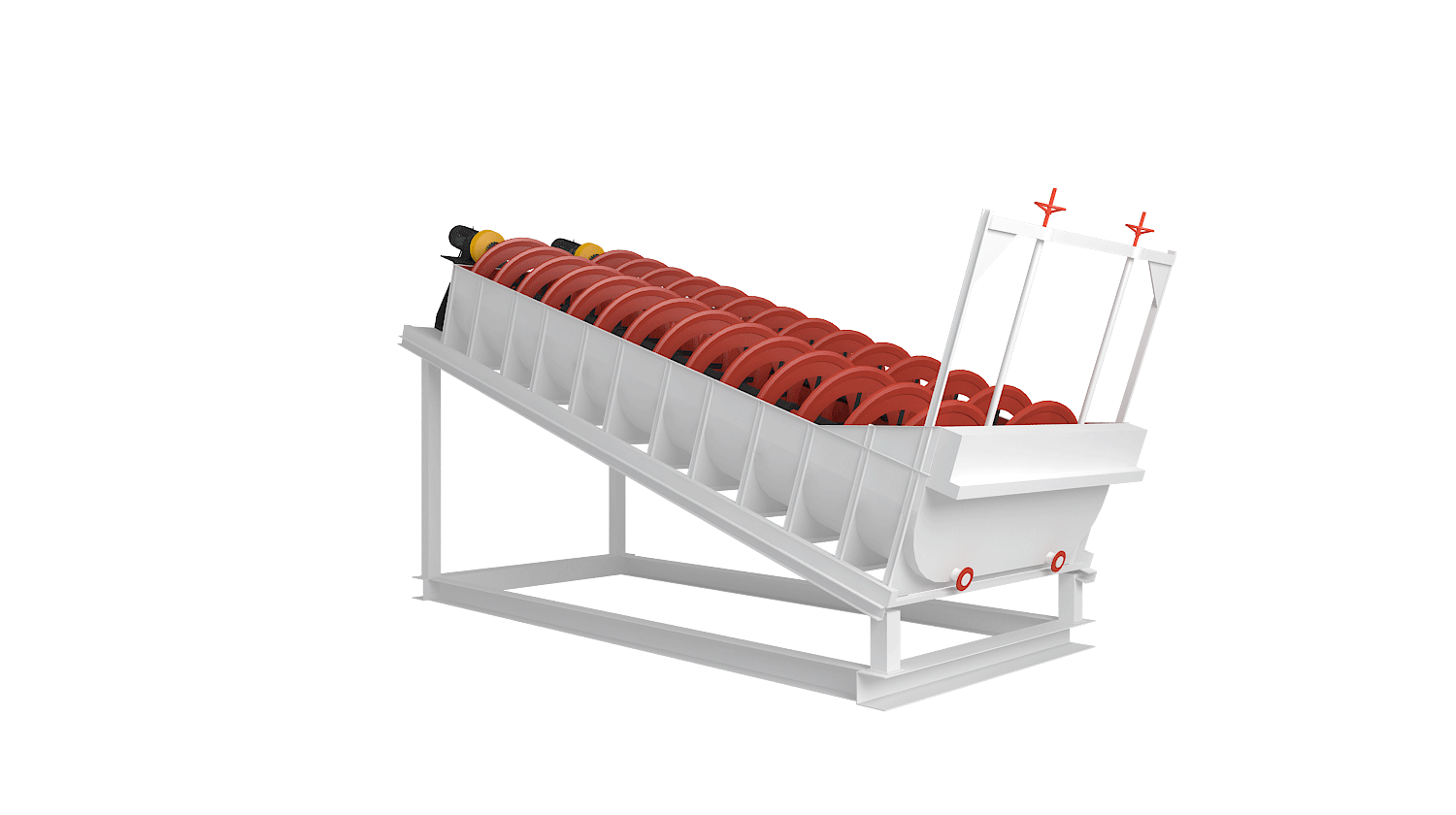

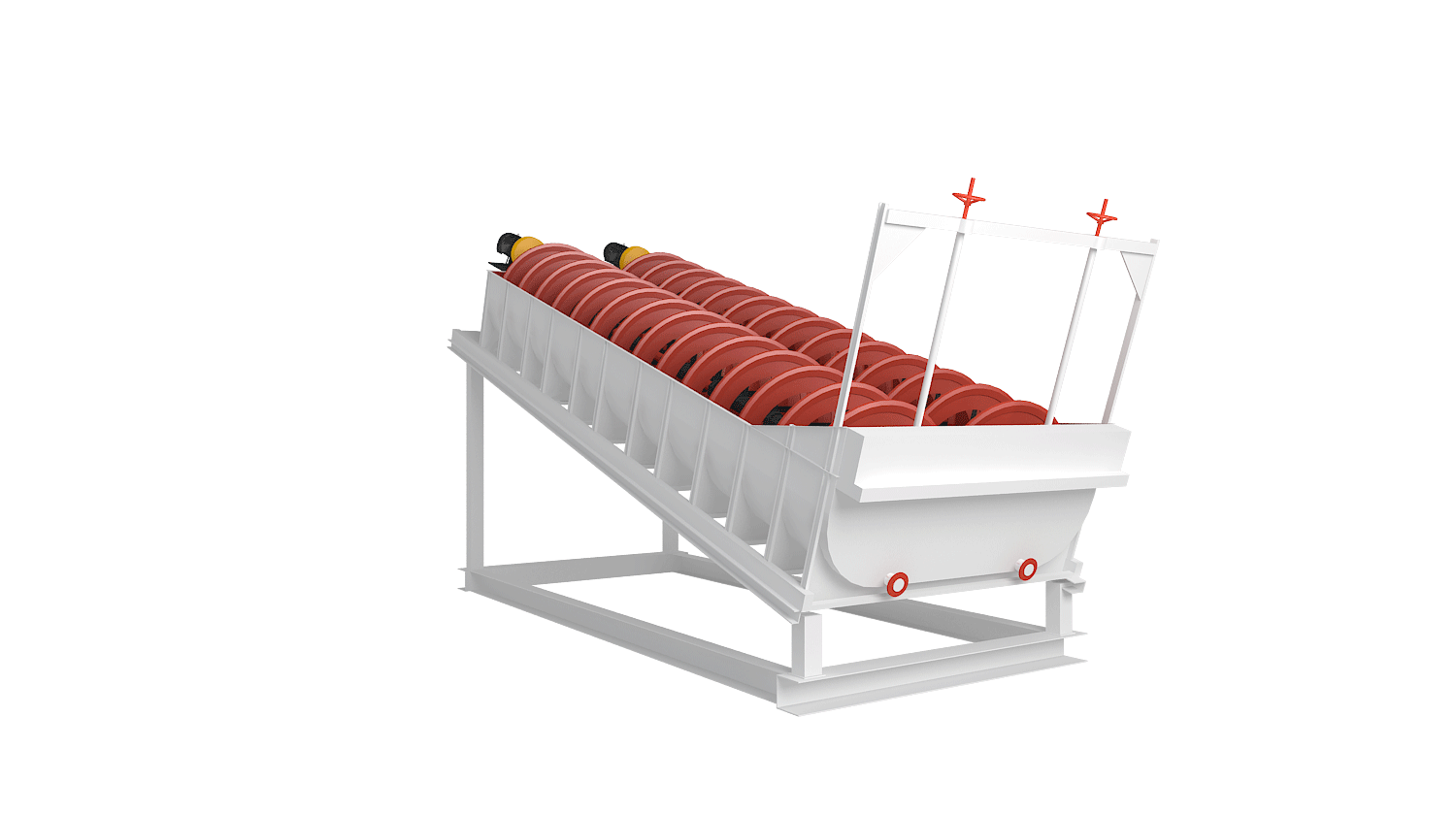

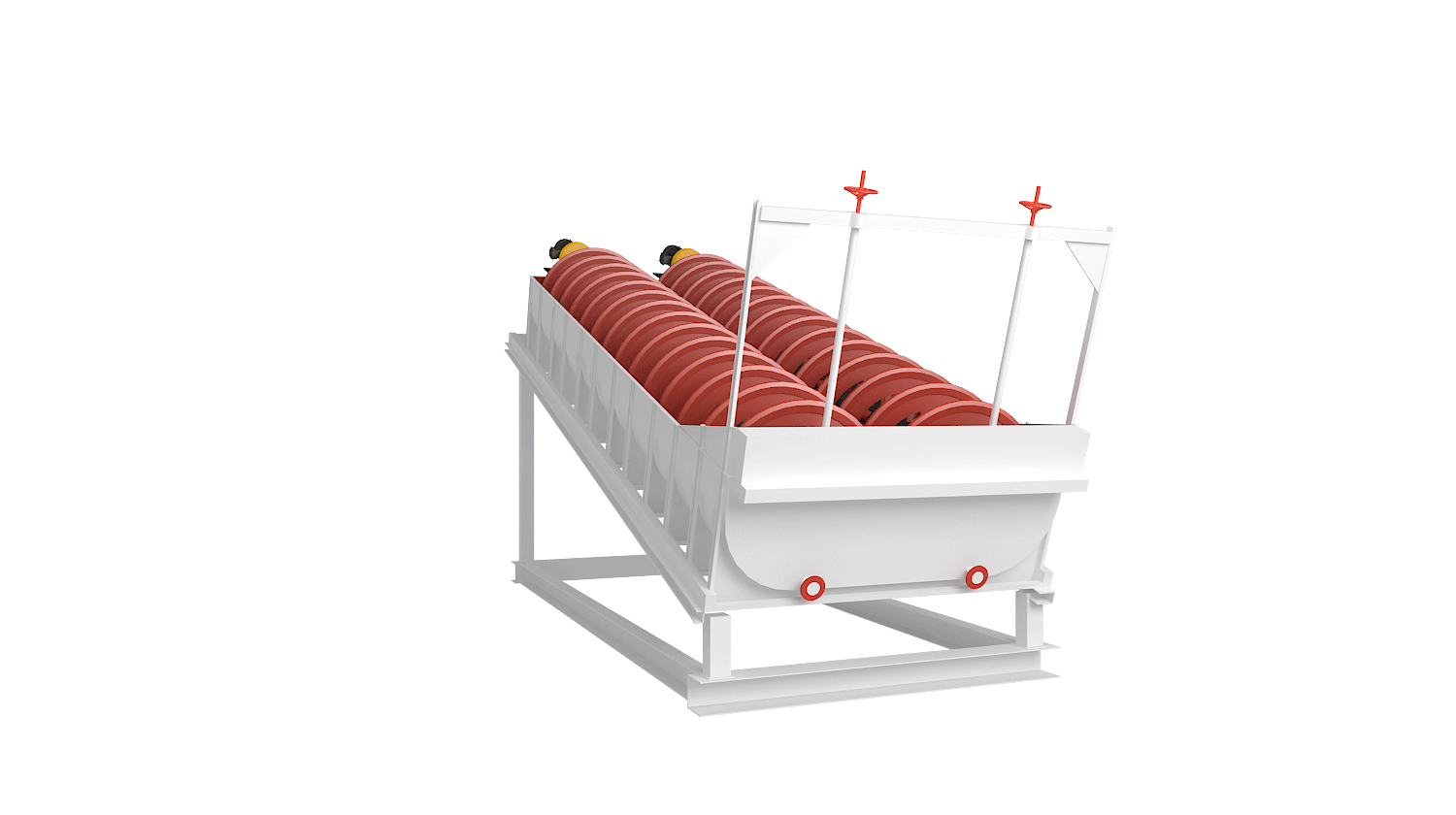

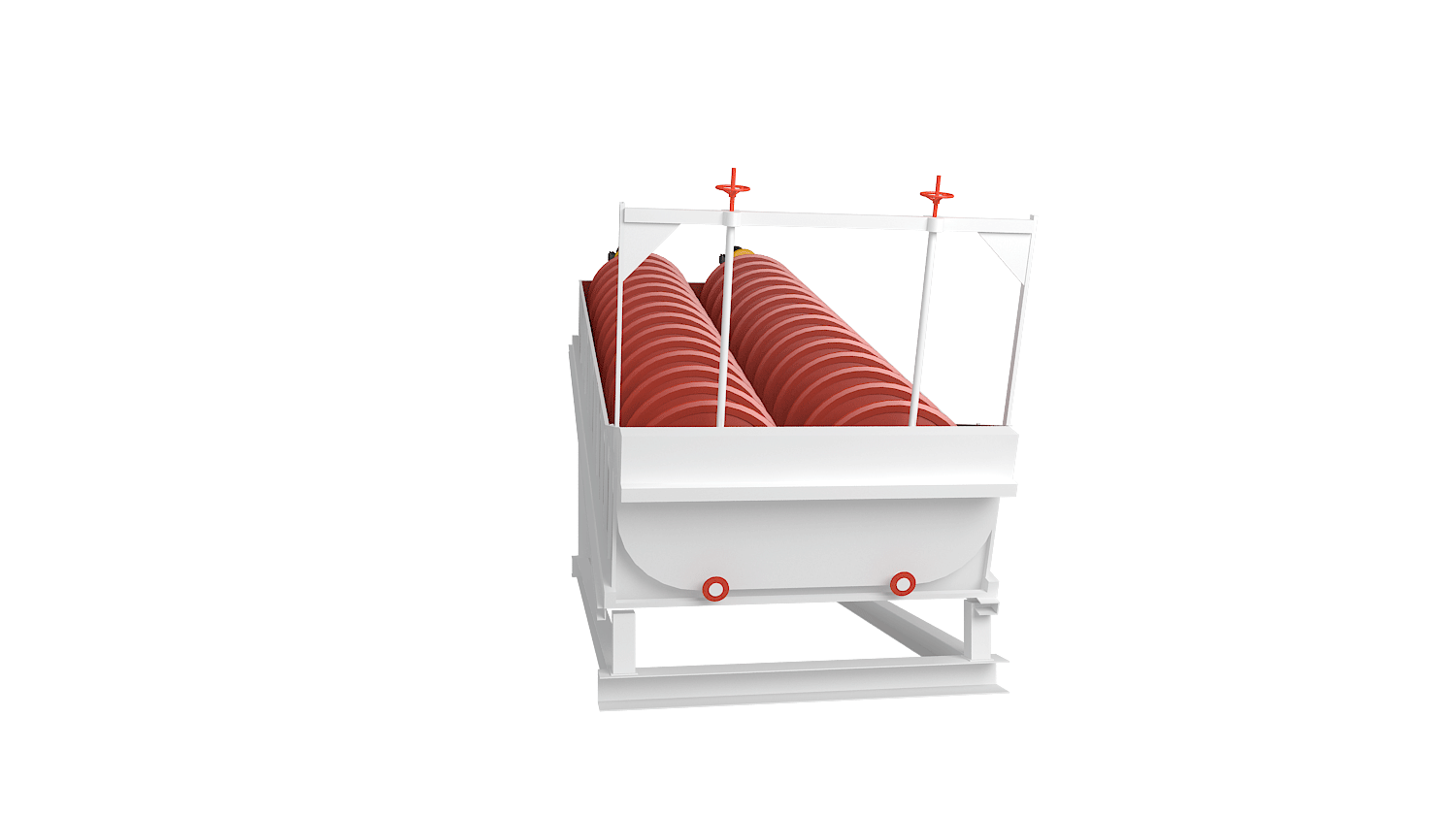

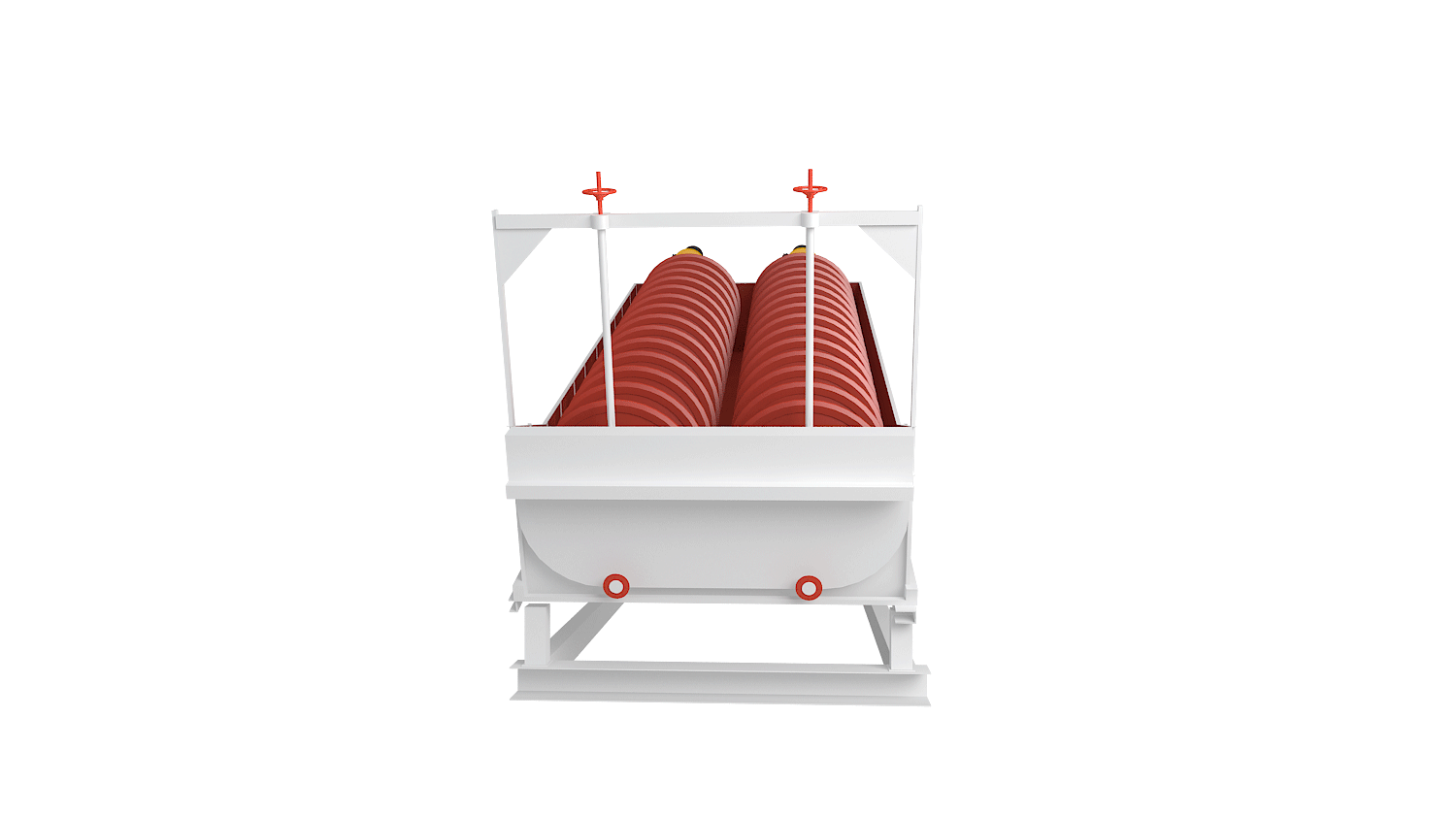

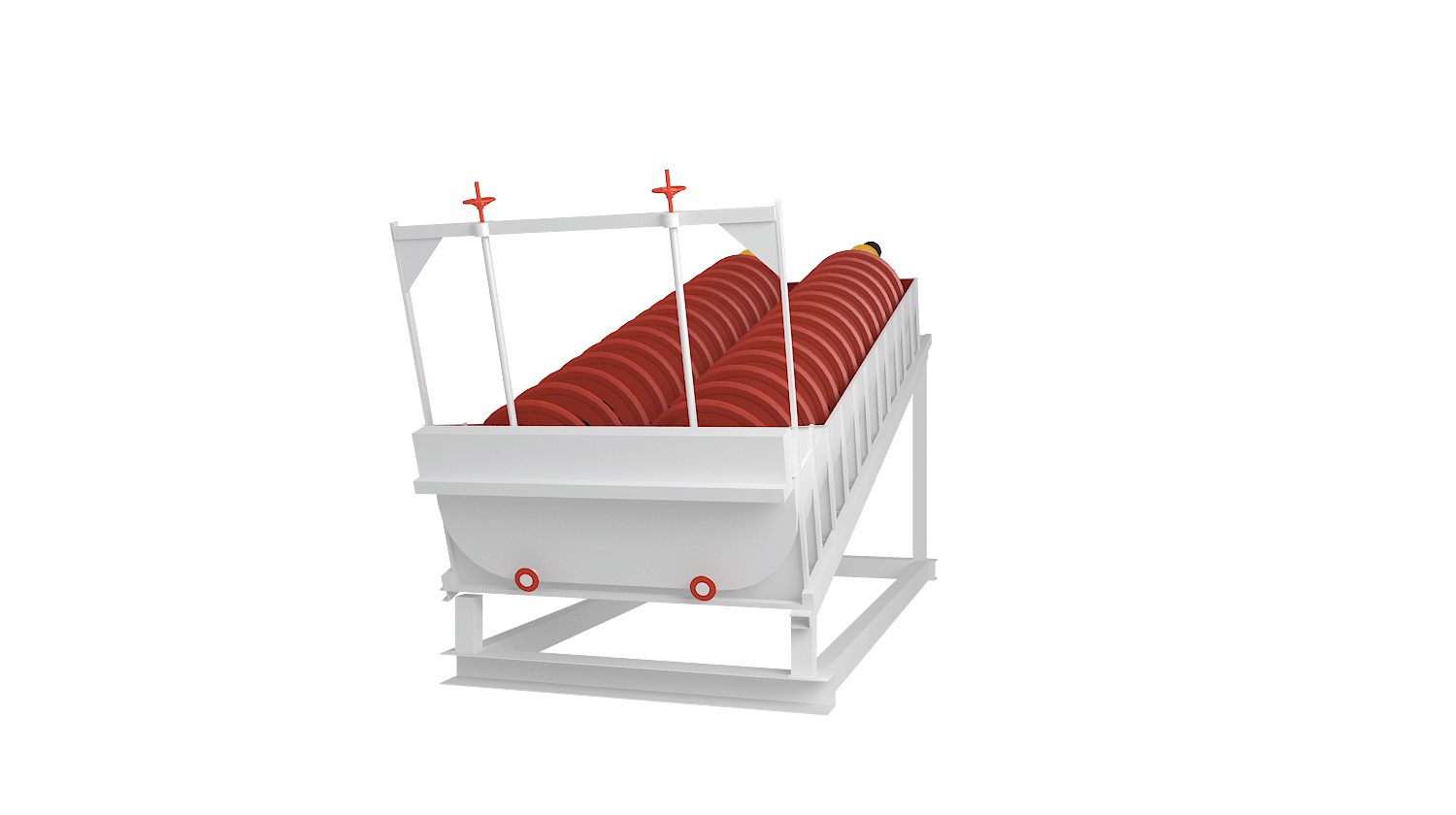

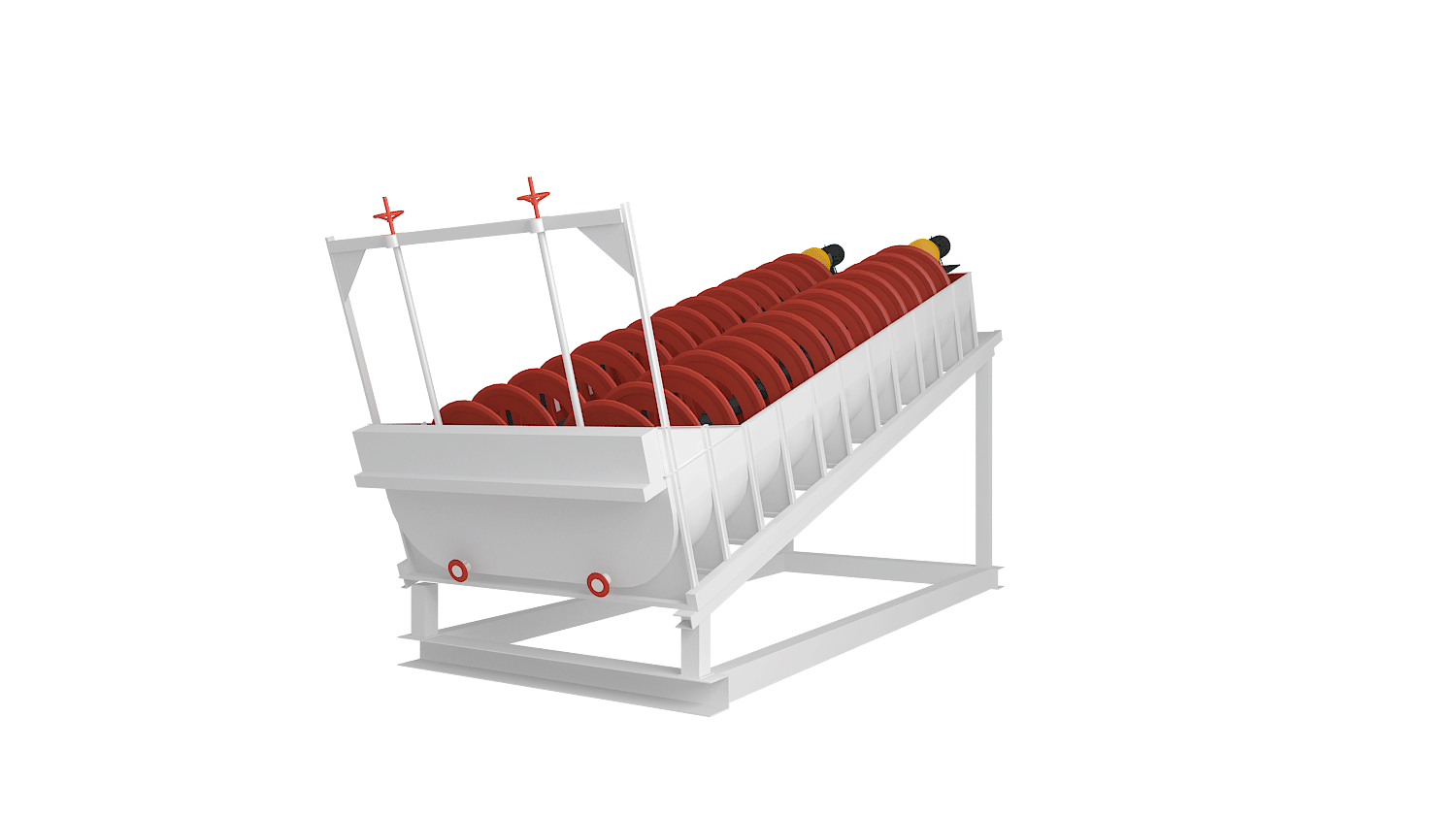

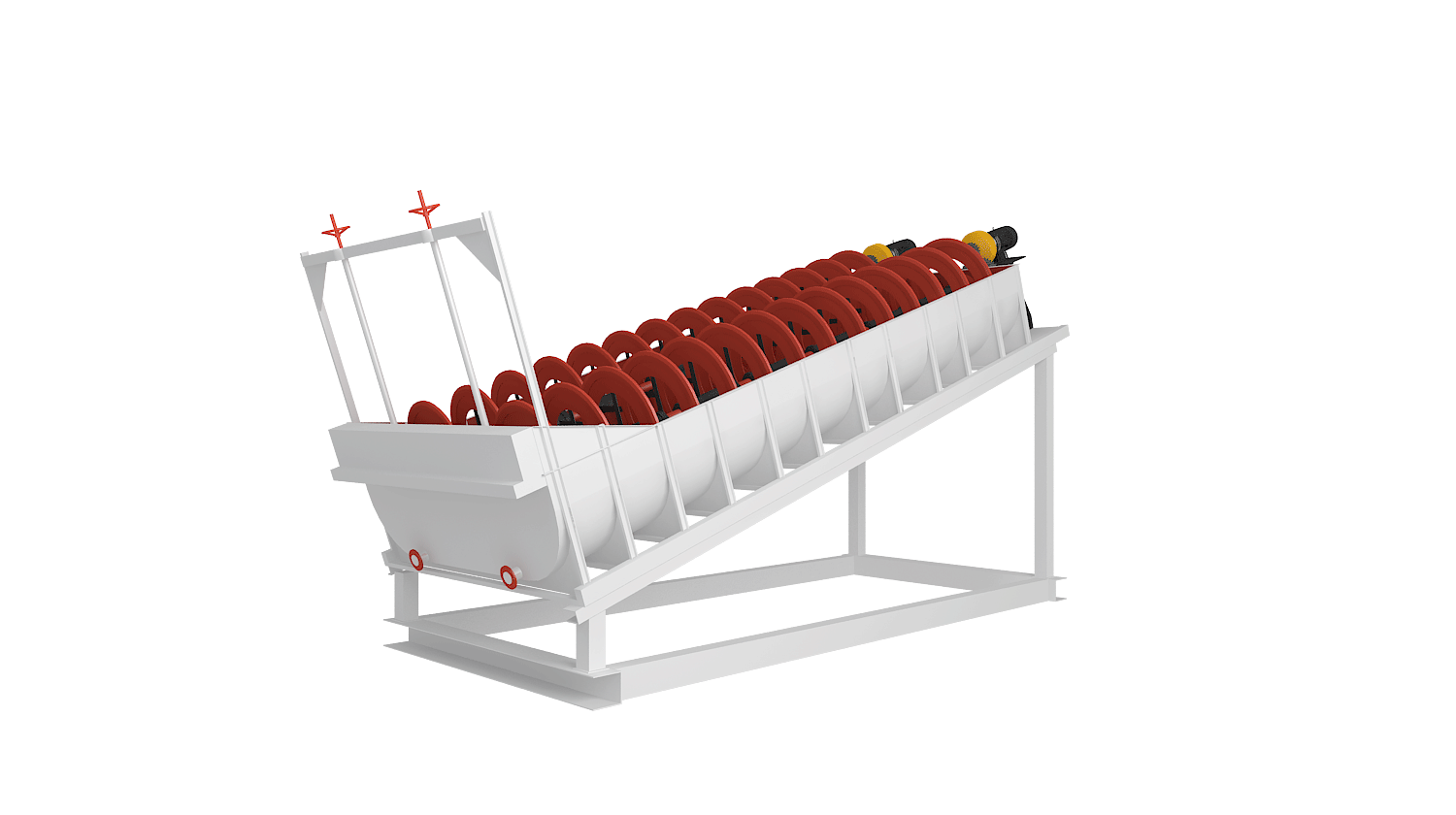

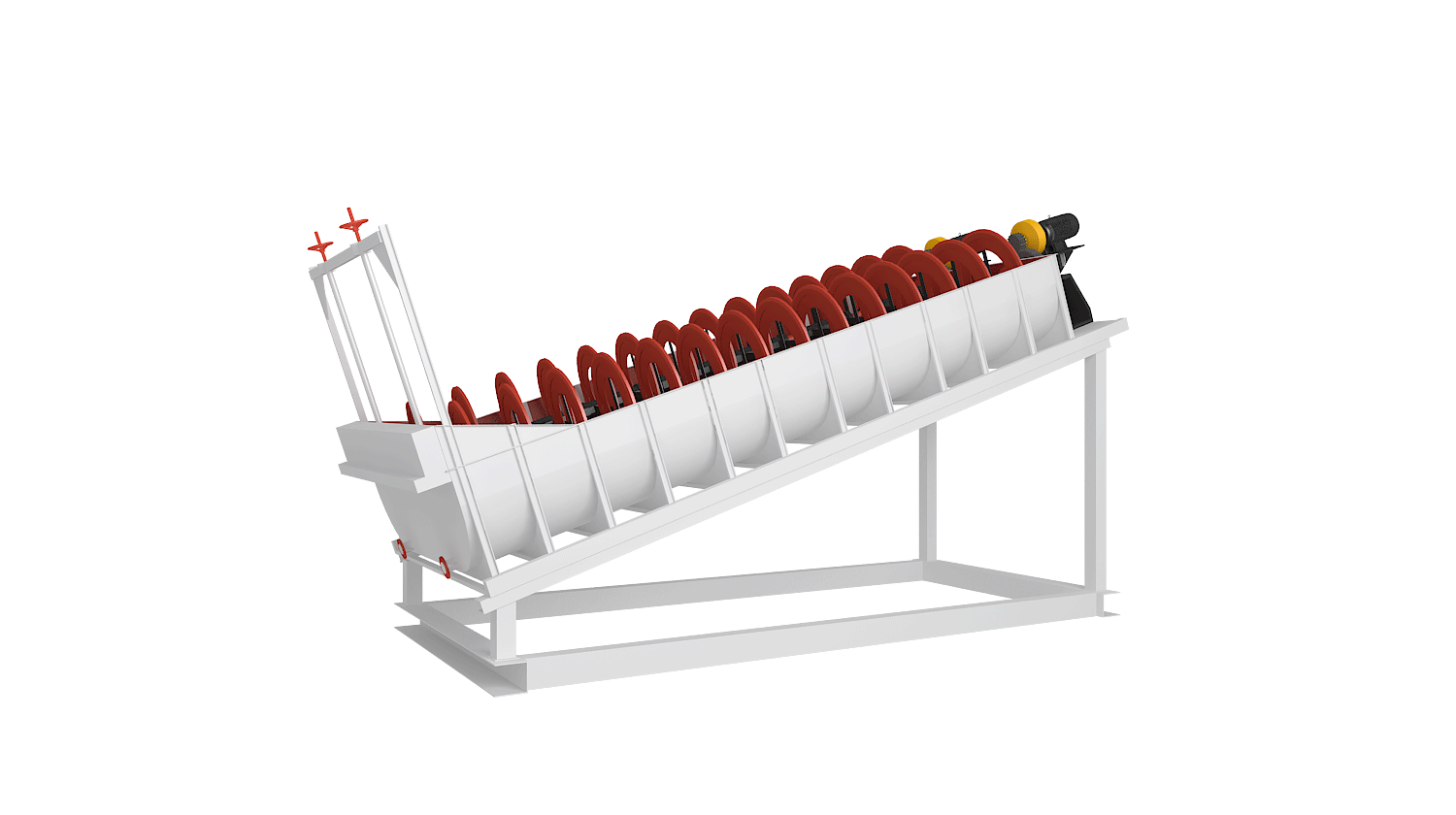

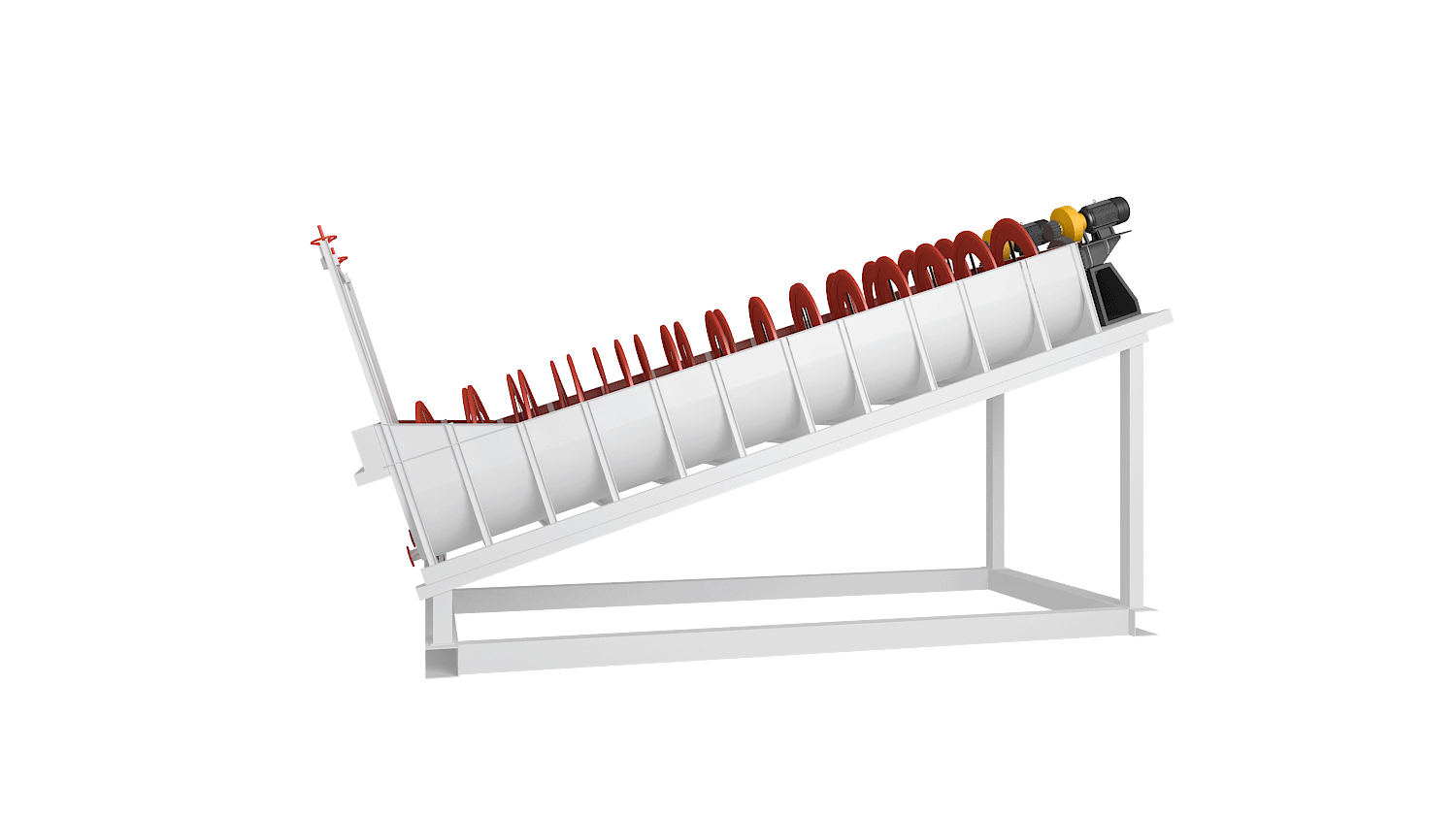

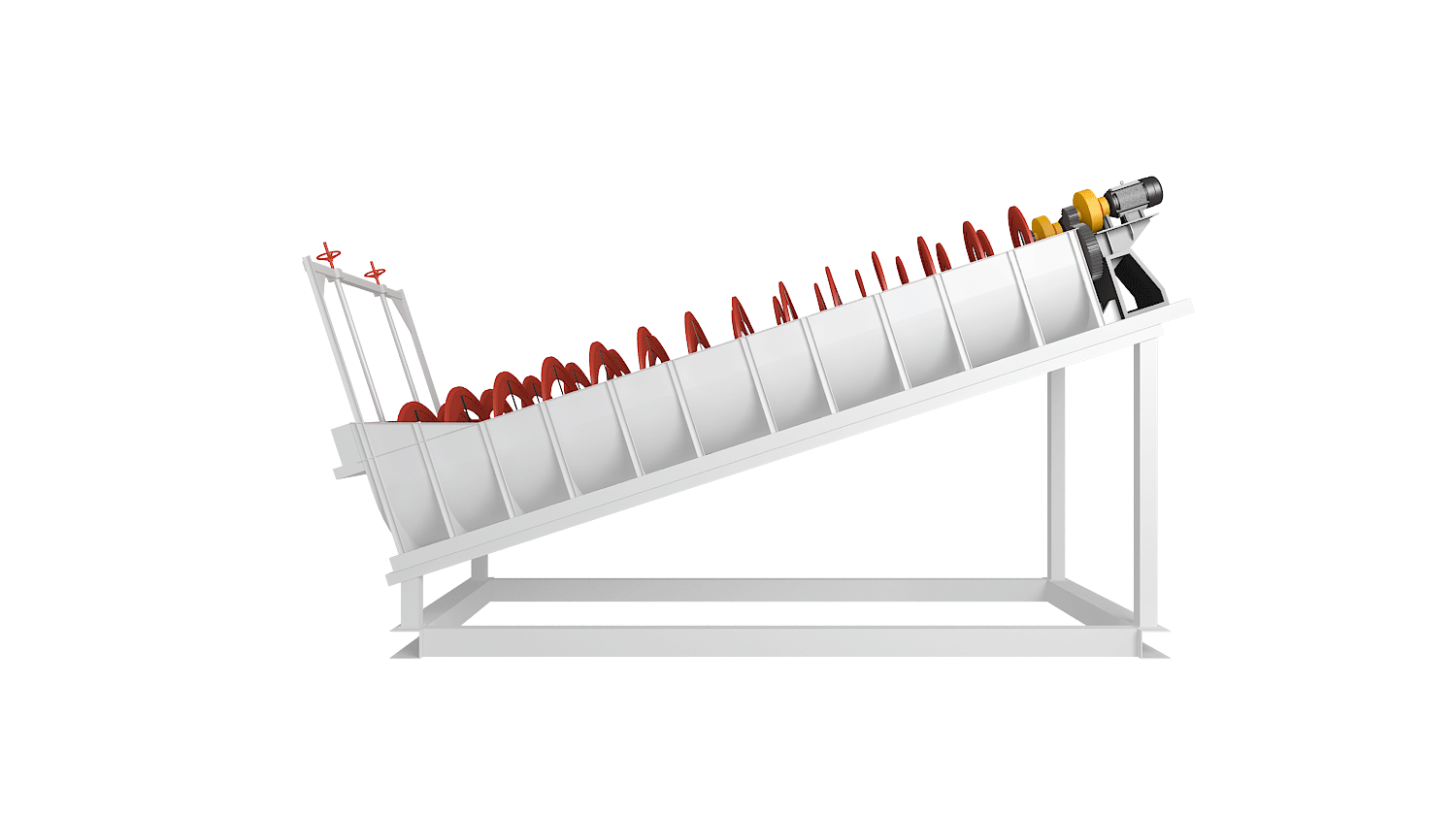

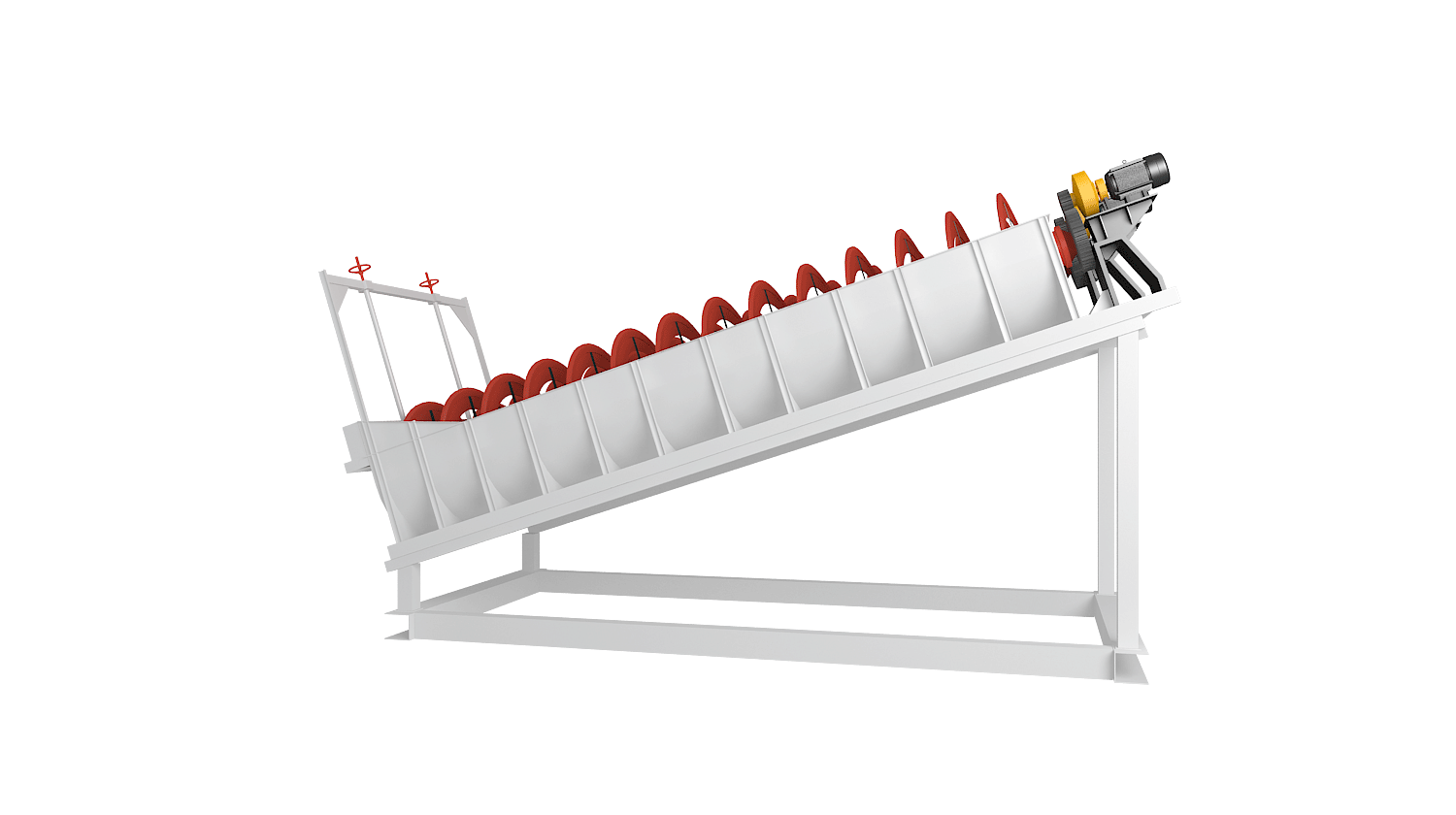

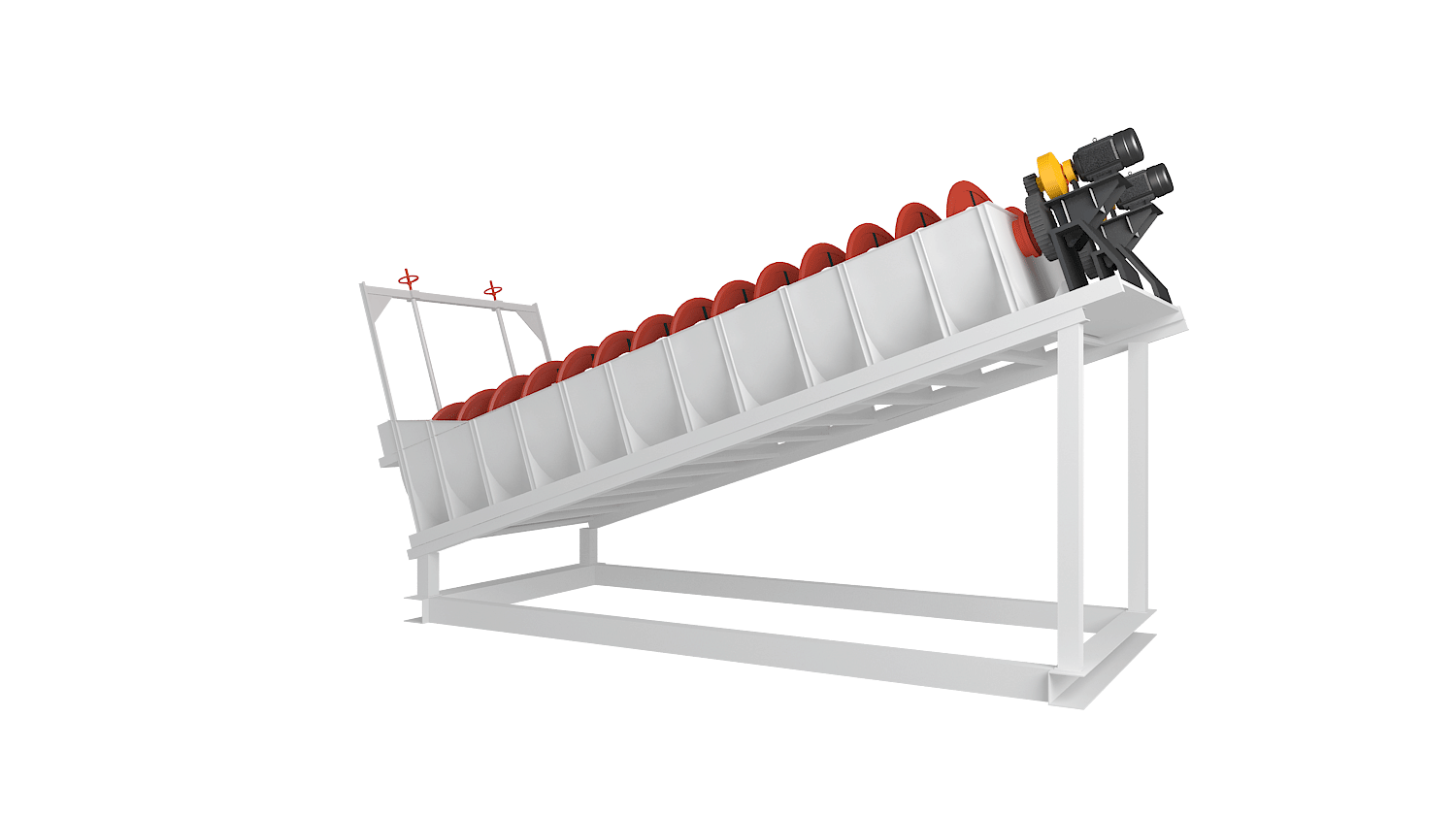

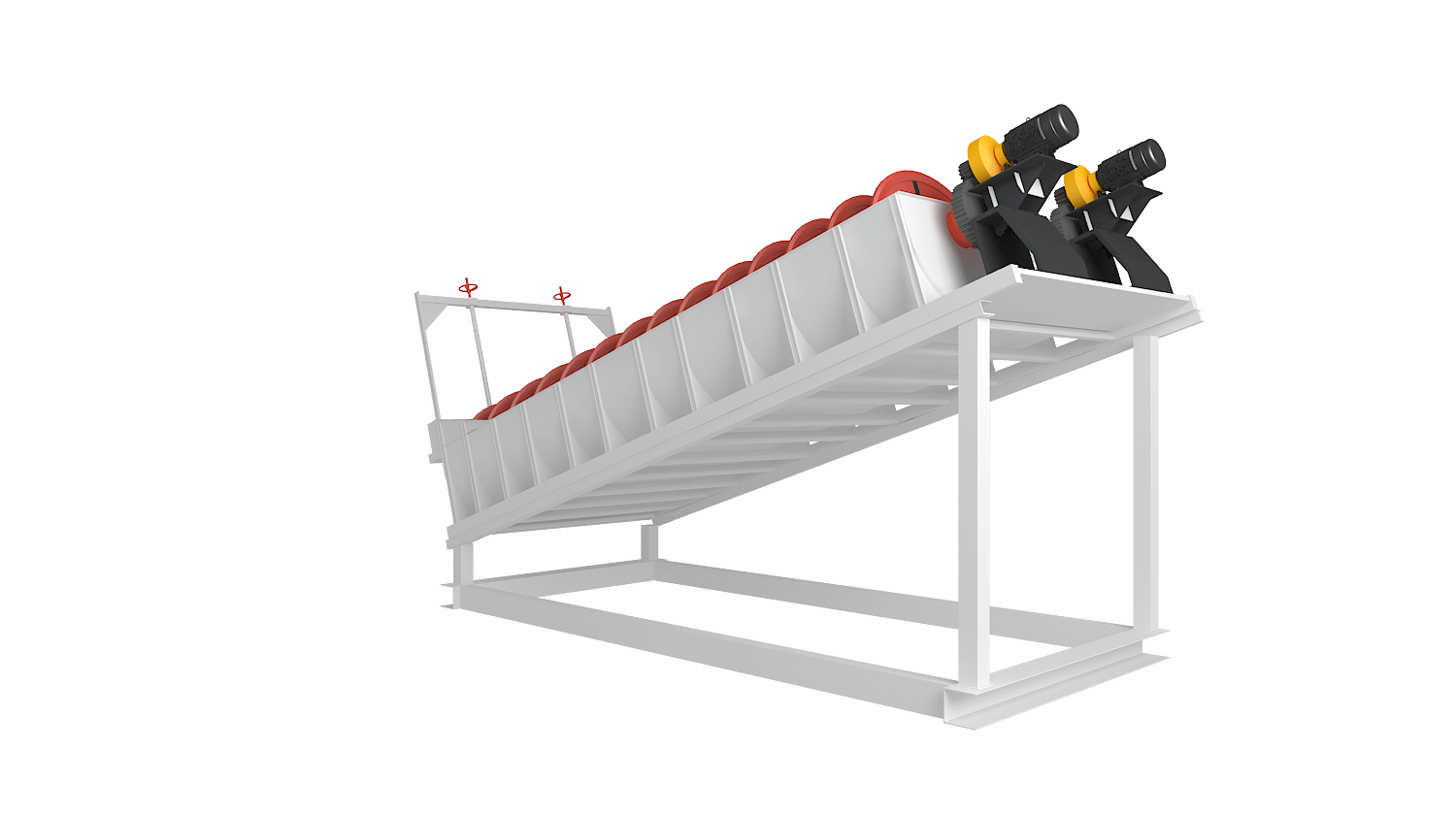

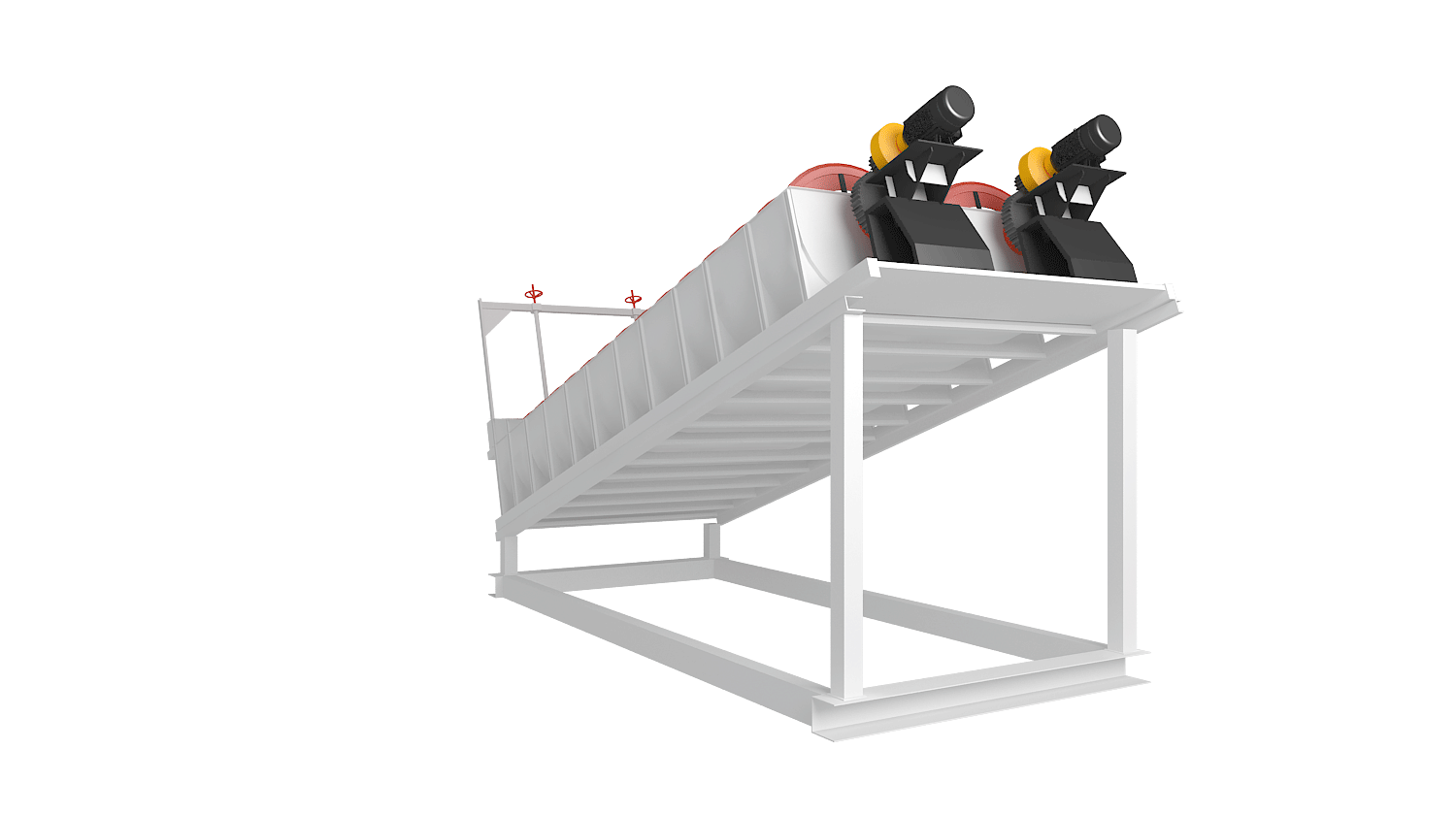

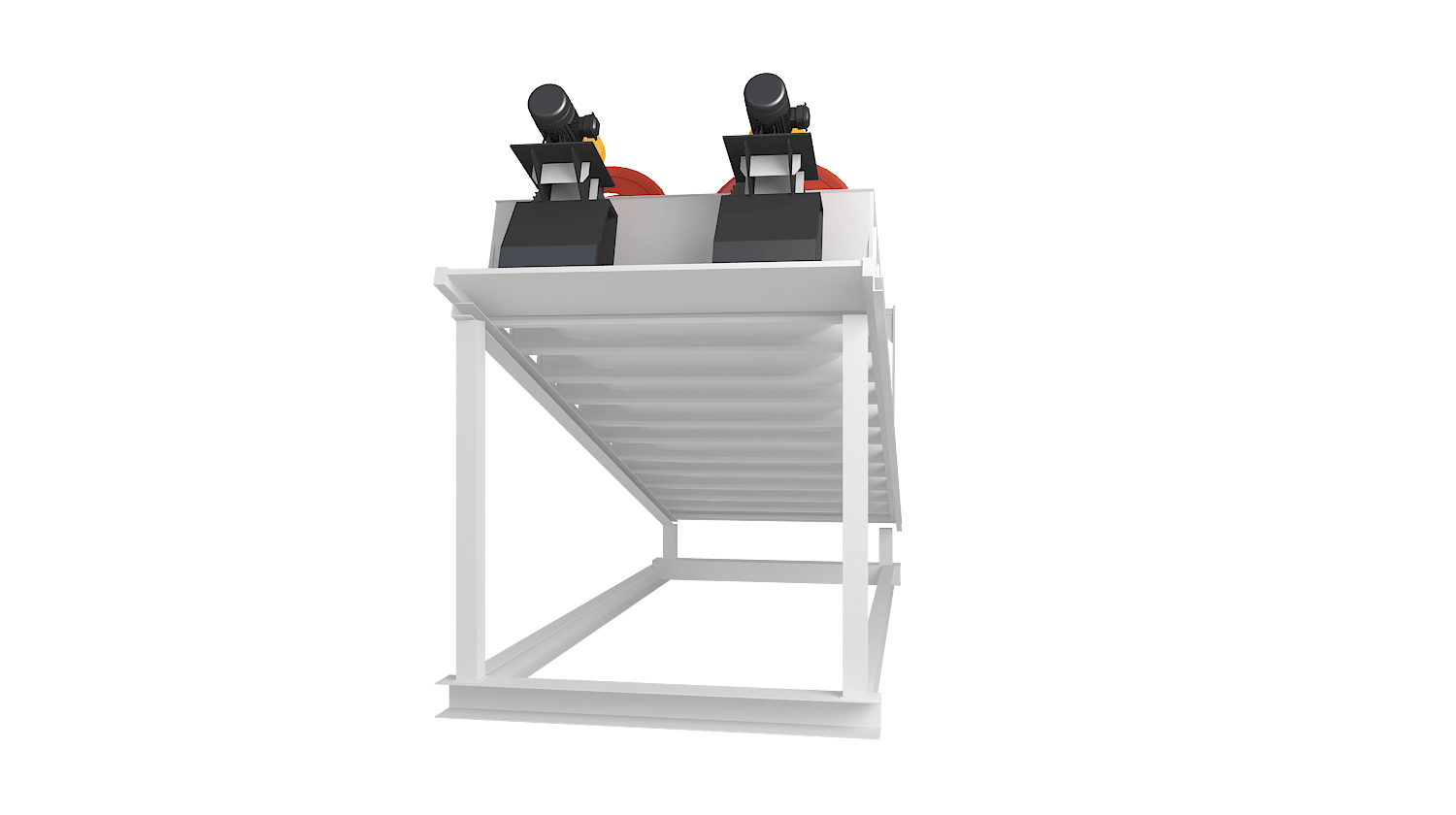

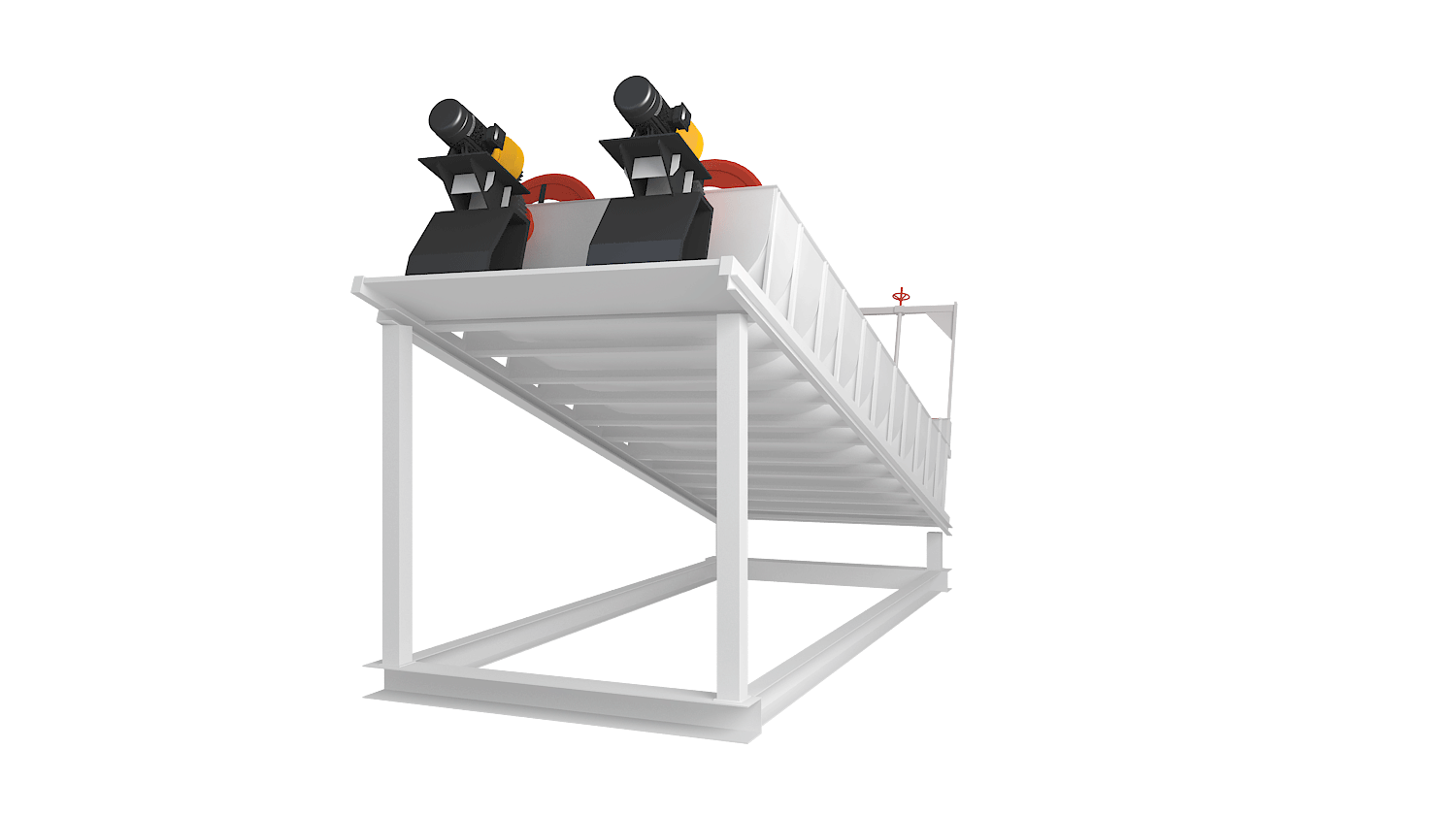

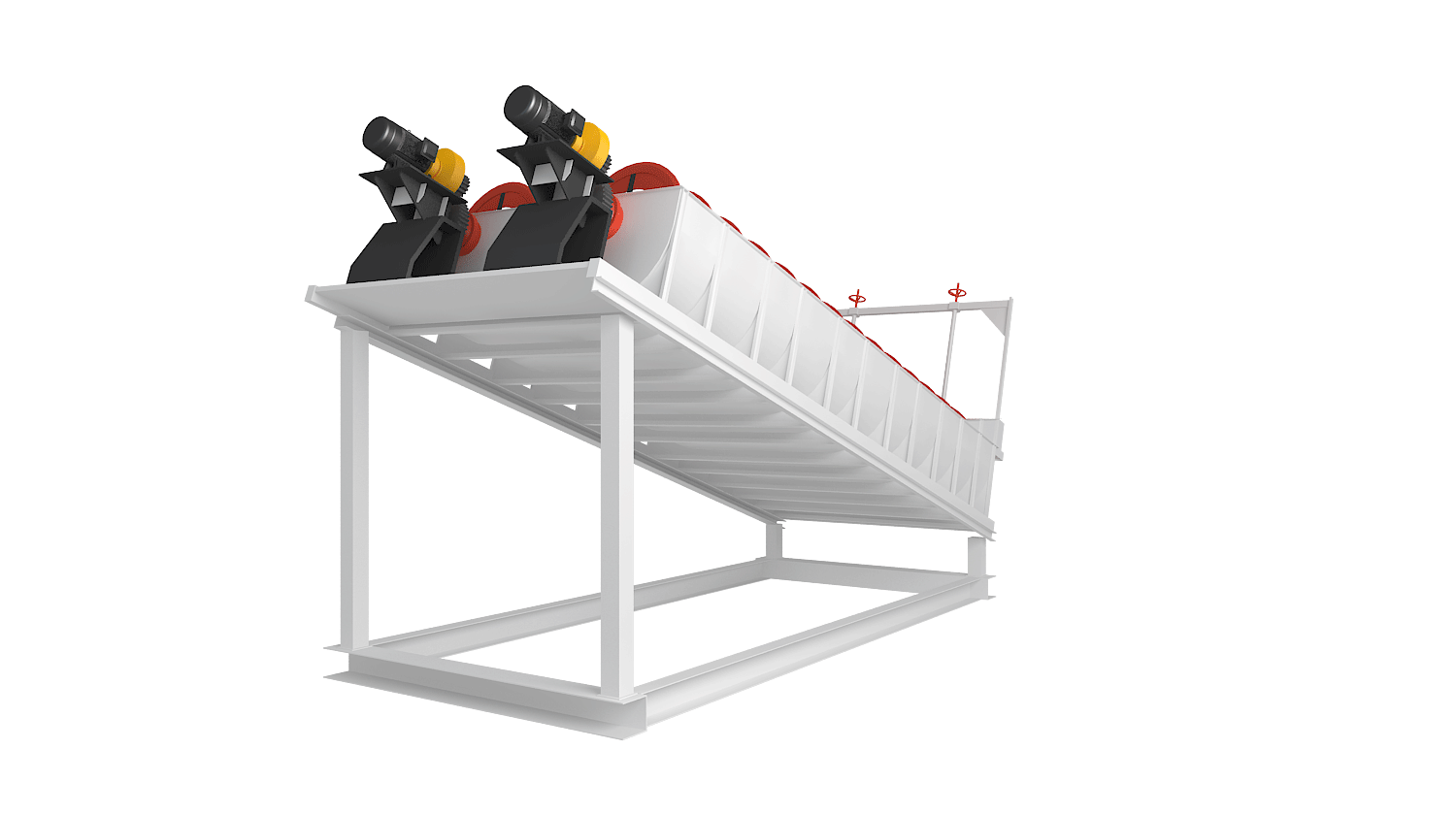

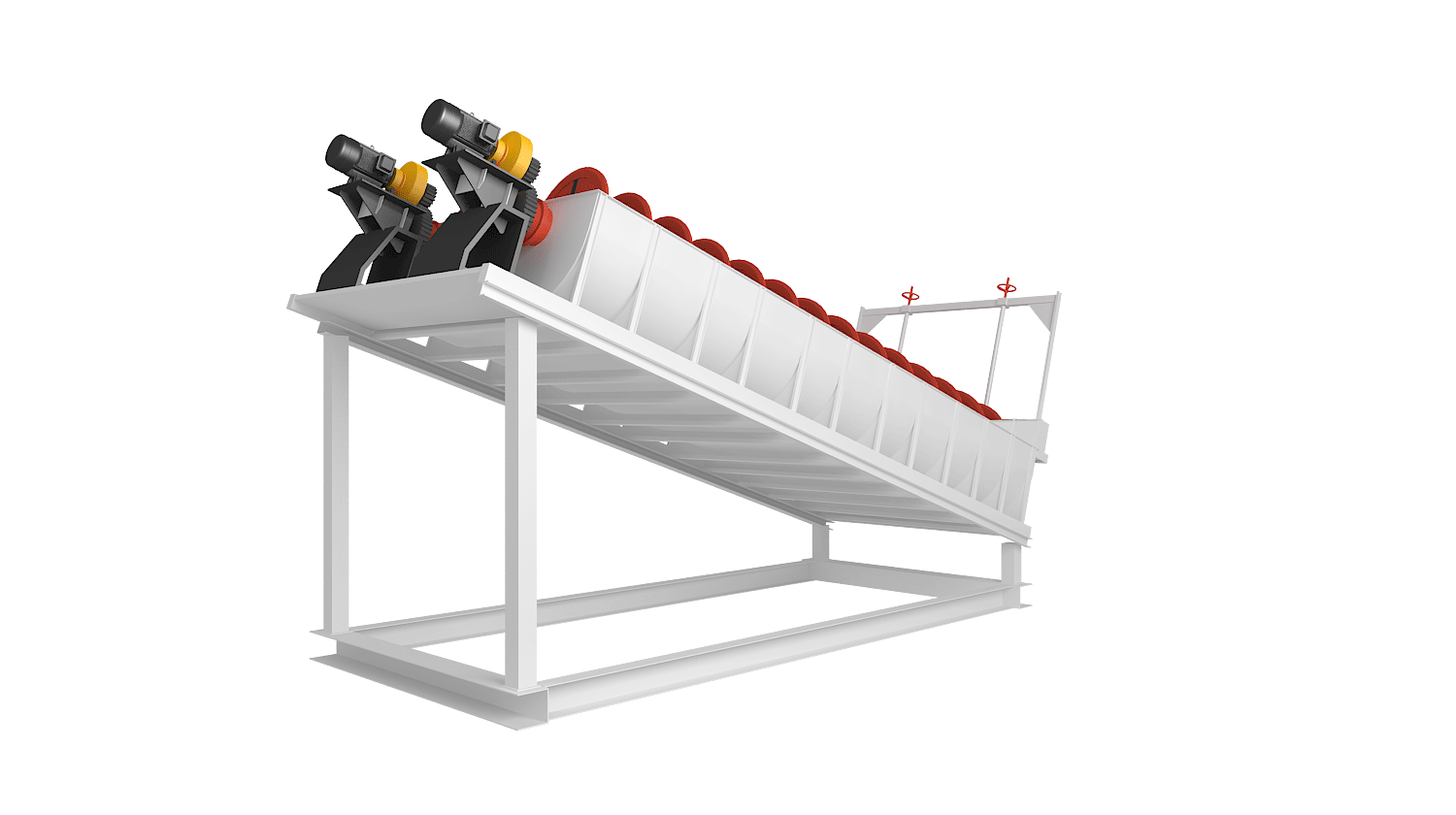

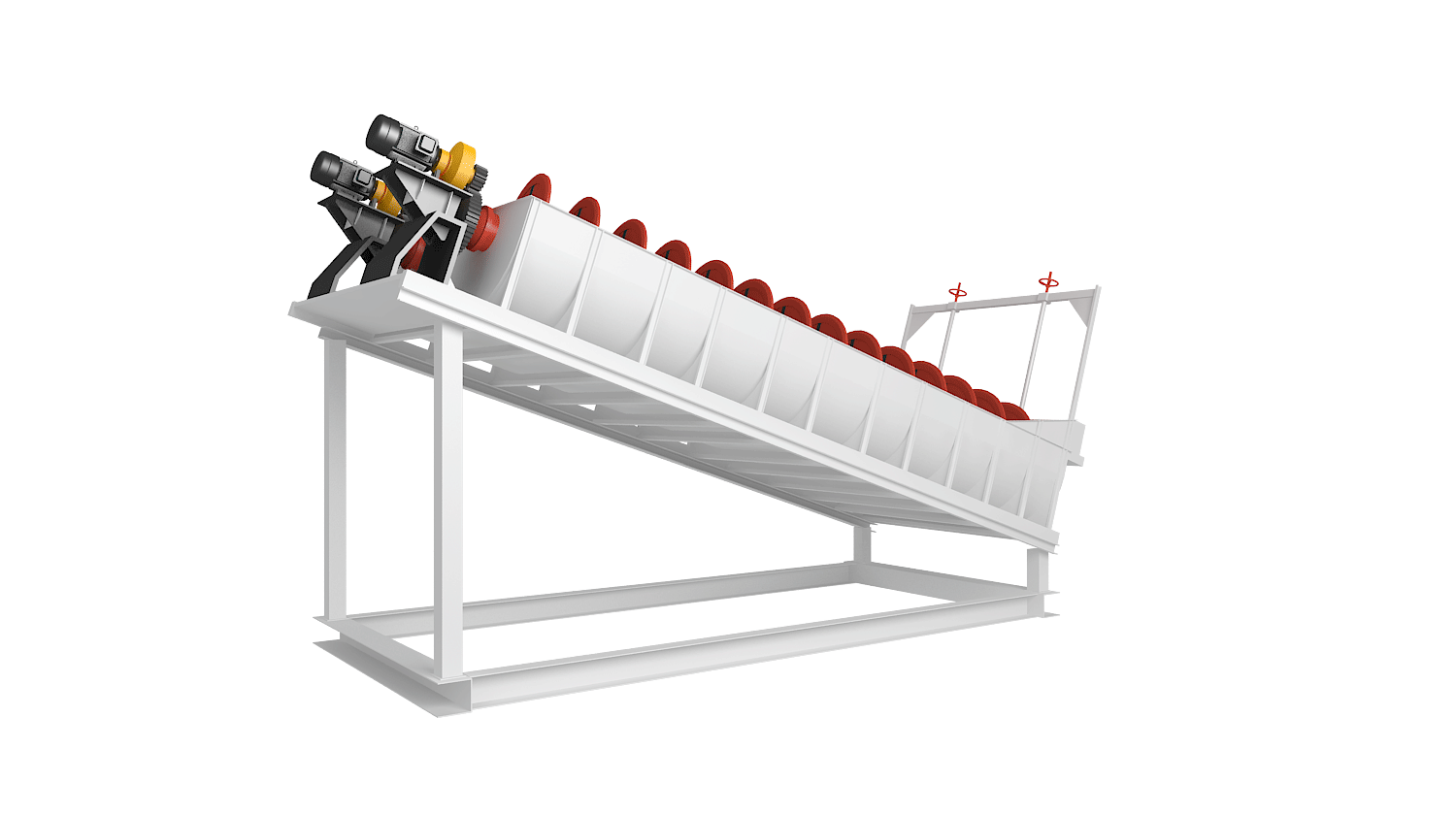

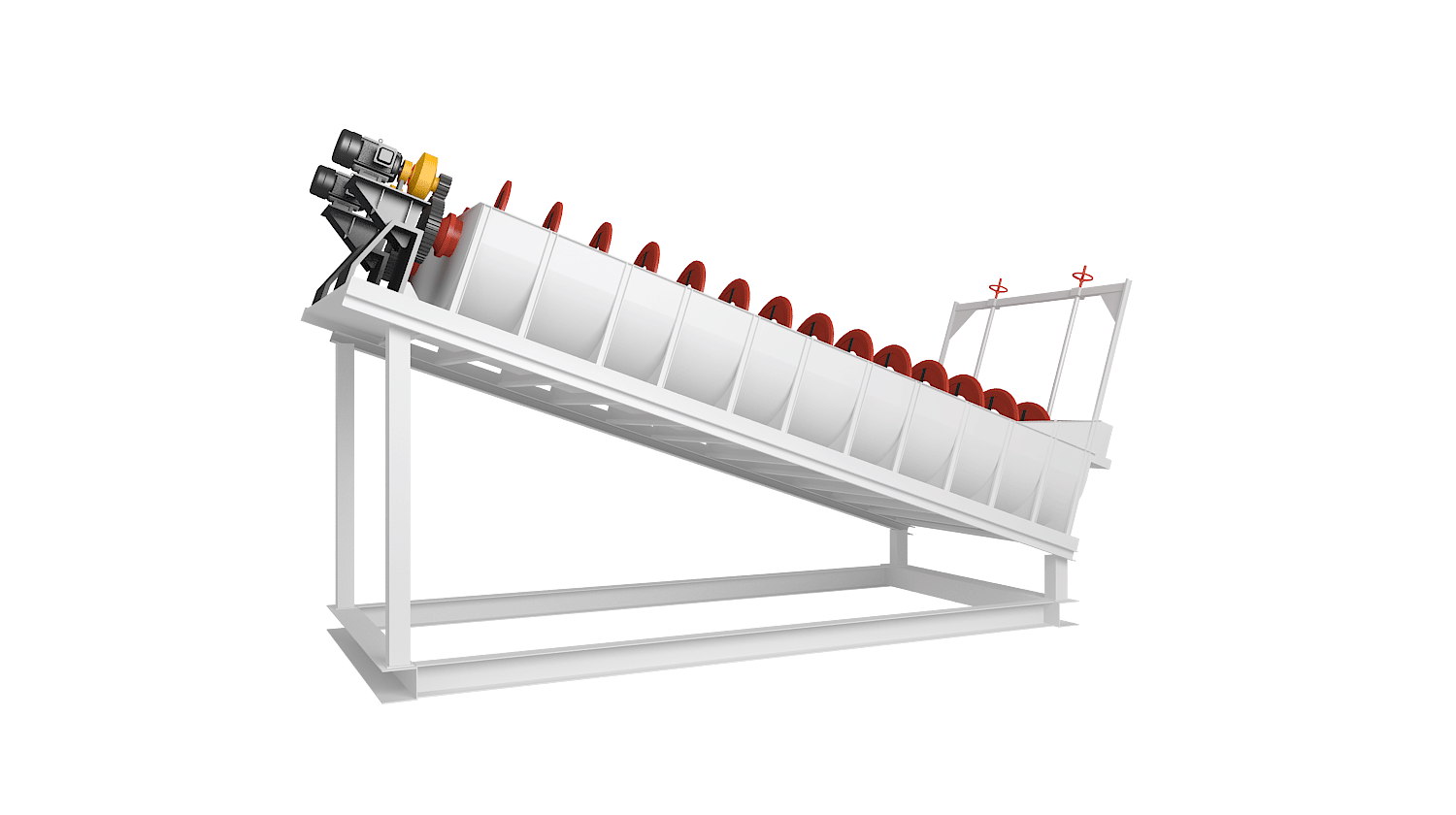

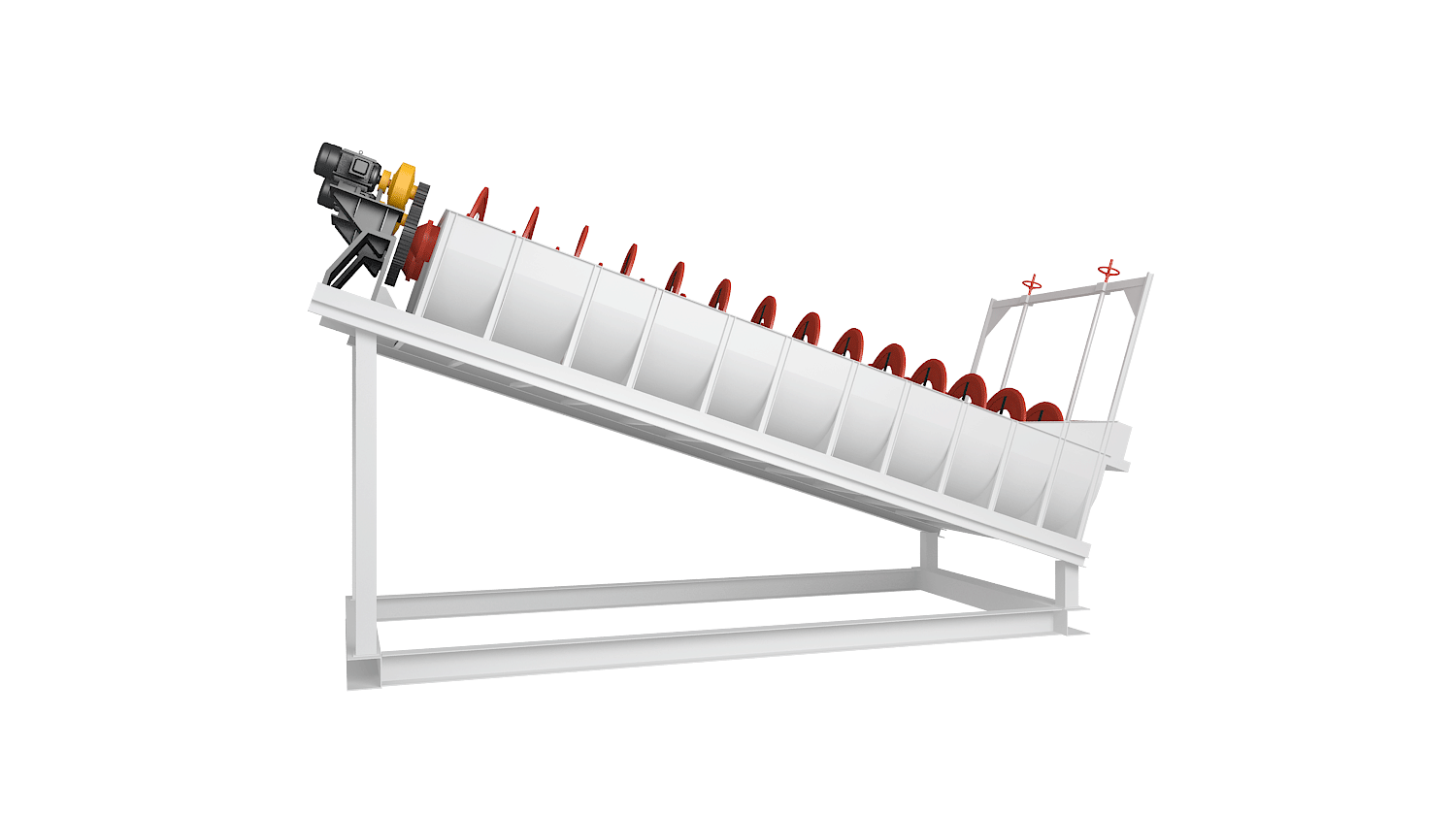

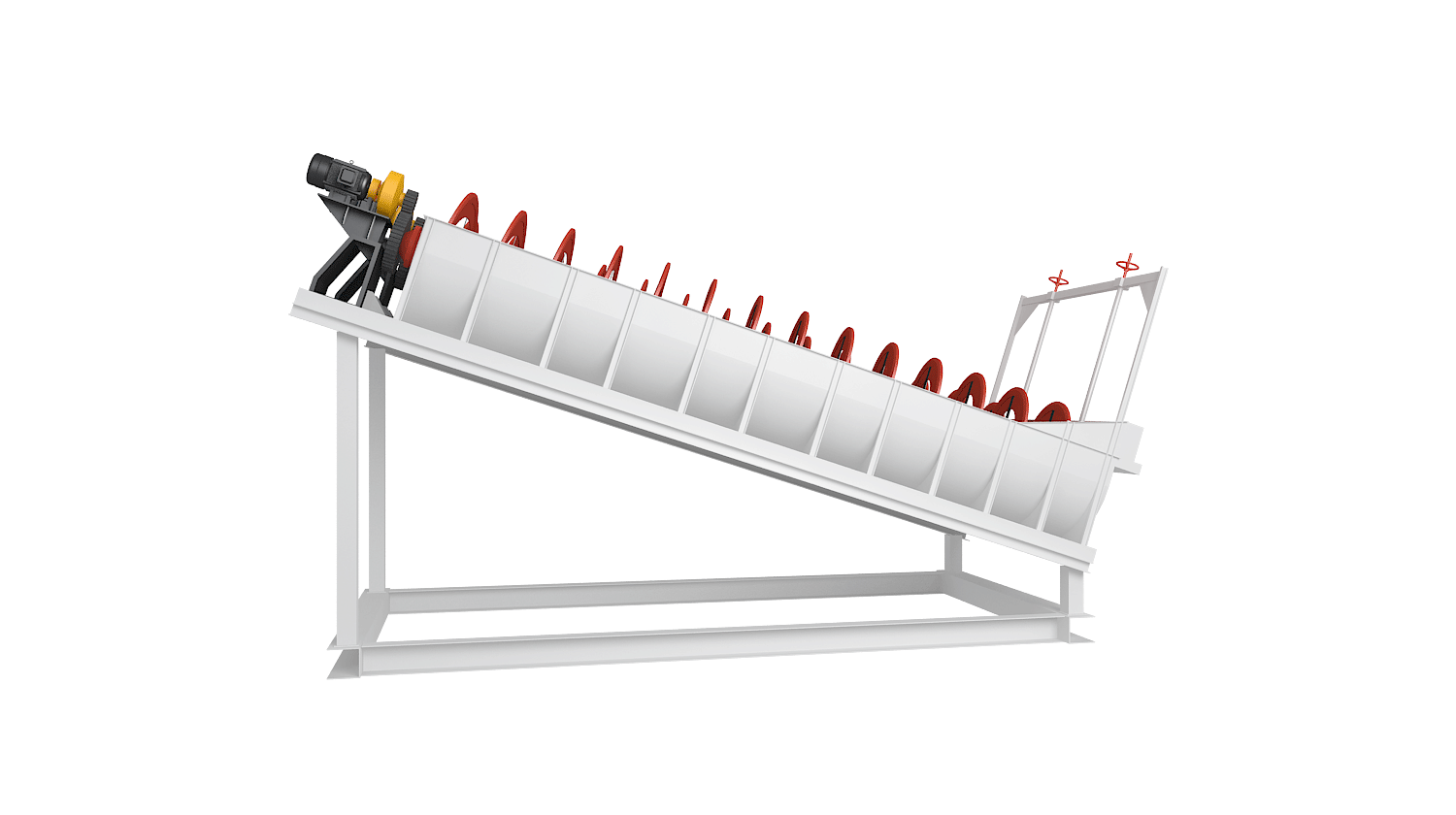

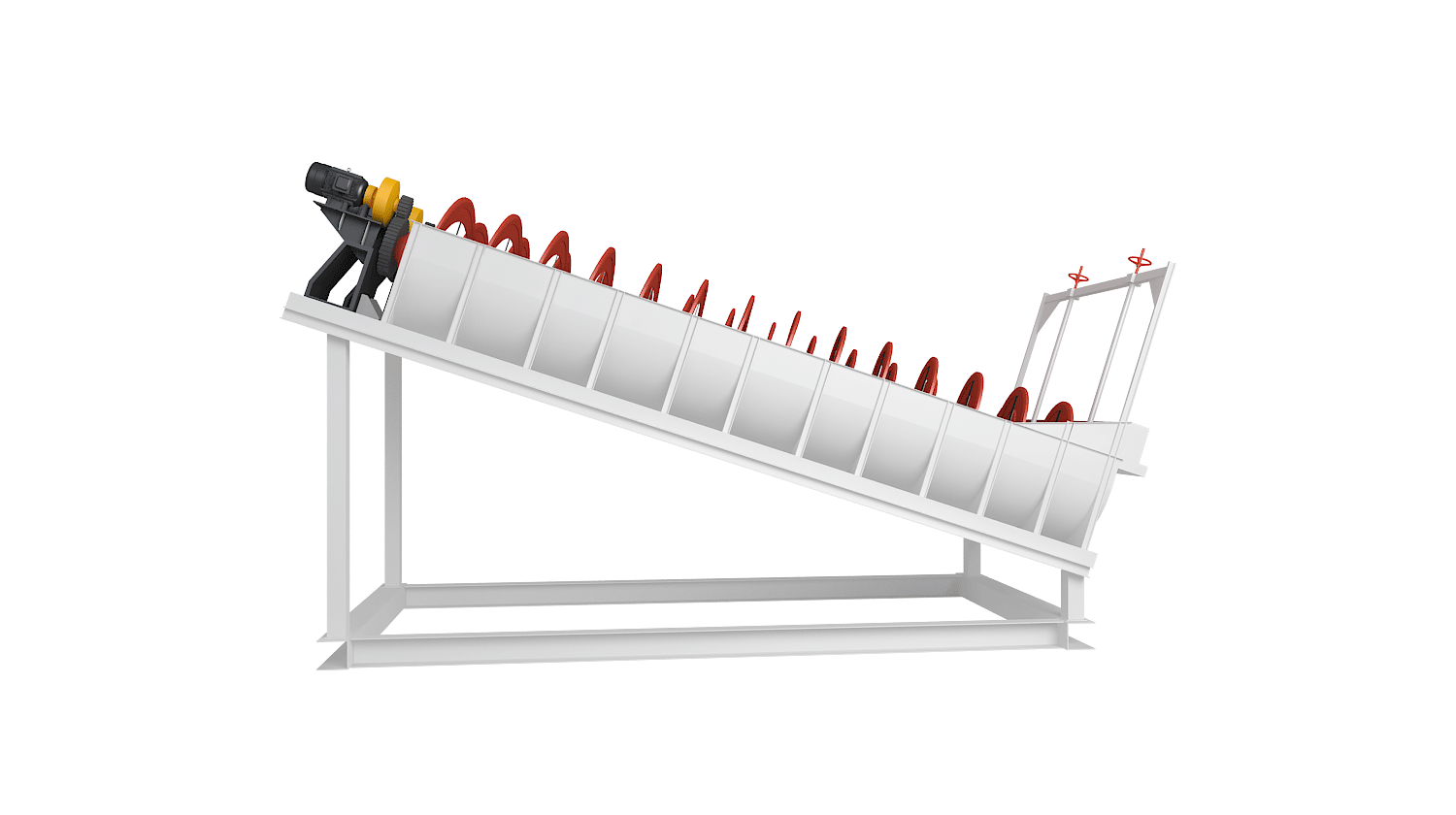

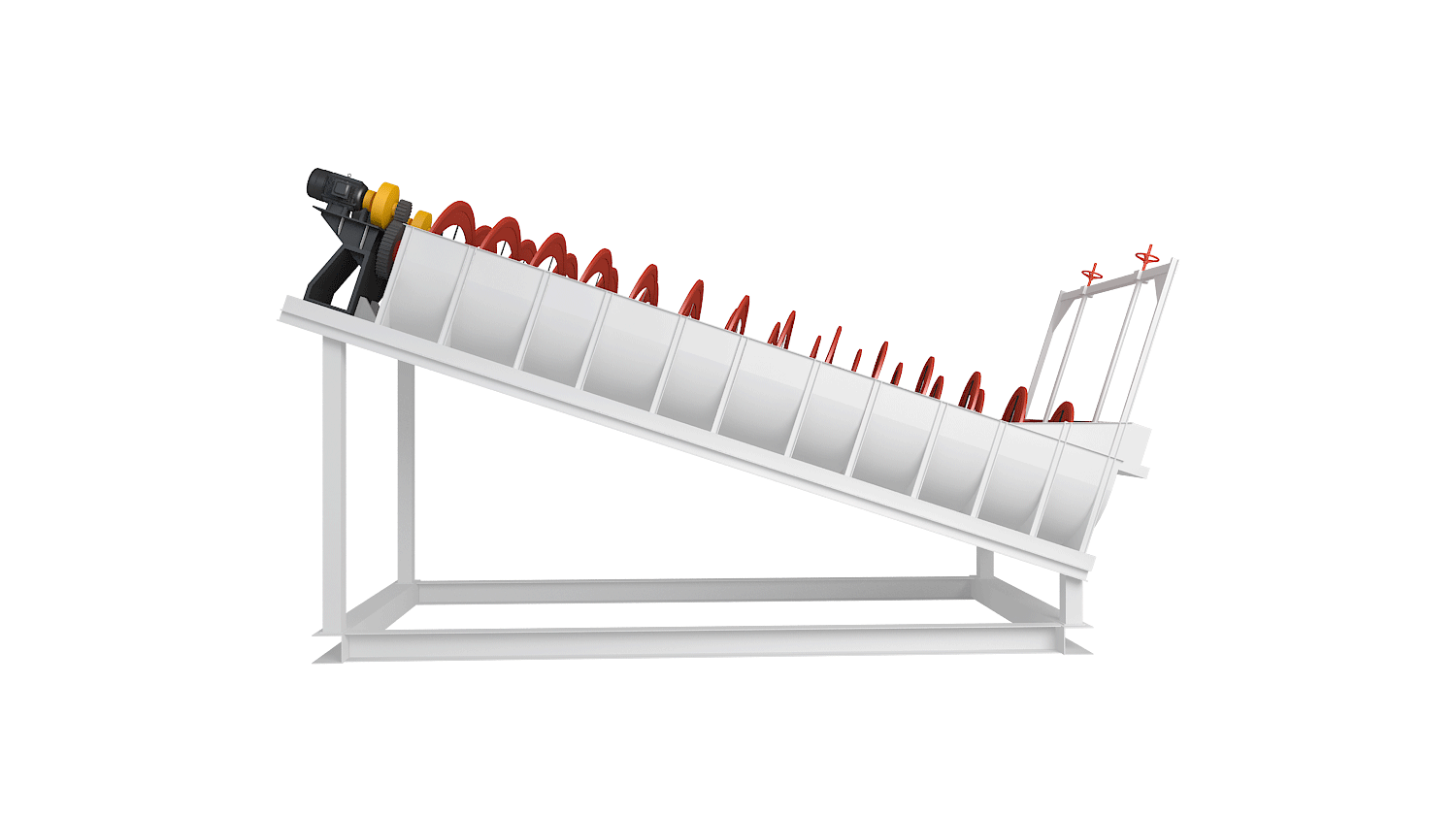

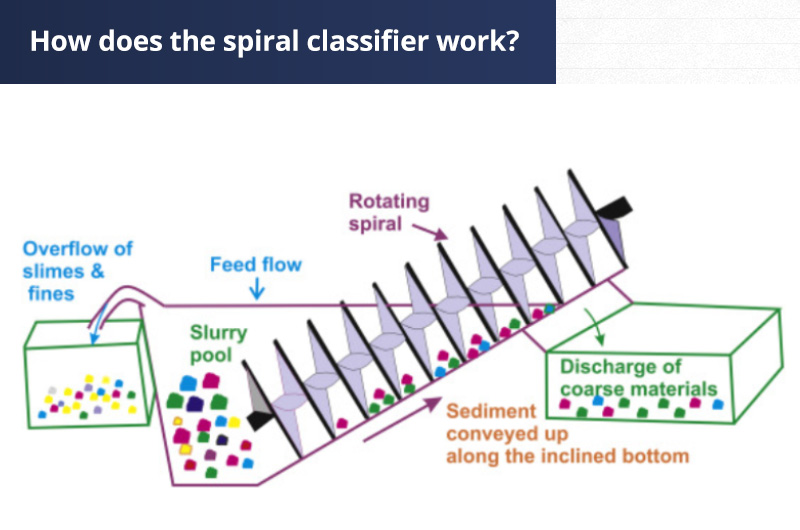

High Weir Spiral Classifier works on principle of sedimentation. When mixed with water, ore pulp enters inclined tank of classifier. Due to different settling speeds of solid particles, fine particles float to top and overflow with water, while coarse particles settle at bottom.

A spiral screw rotates continuously, lifting settled coarse particles to discharge port for recirculation or further processing. Height of weir ensures efficient separation, and adjustable speed of spiral allows flexible operation depending on material properties.