| Specification (diameter*length) | Cylinder volume (m³) |

Production capacity (t/h) |

Installation slope (%) |

Maximum intake temperature (℃) |

Main motor (kw) |

Total weight (t) |

| Φ1.2*8 | 9 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 |

| Φ1.2*10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 |

| Φ1.5*12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 |

| Φ1.5*14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 |

| Φ1.5*15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 |

| Φ1.8*12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 |

| Φ1.8*14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 |

| Φ2.2*12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 |

| Φ2.2*14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 |

| Φ2.2*16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Φ2.4*14 | 63.1 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Φ2.4*18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Φ2.4*20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Φ2.4*22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Φ2.6*24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Φ3.0*20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Φ3.0*25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Φ3.2*25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Φ3.6*28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |

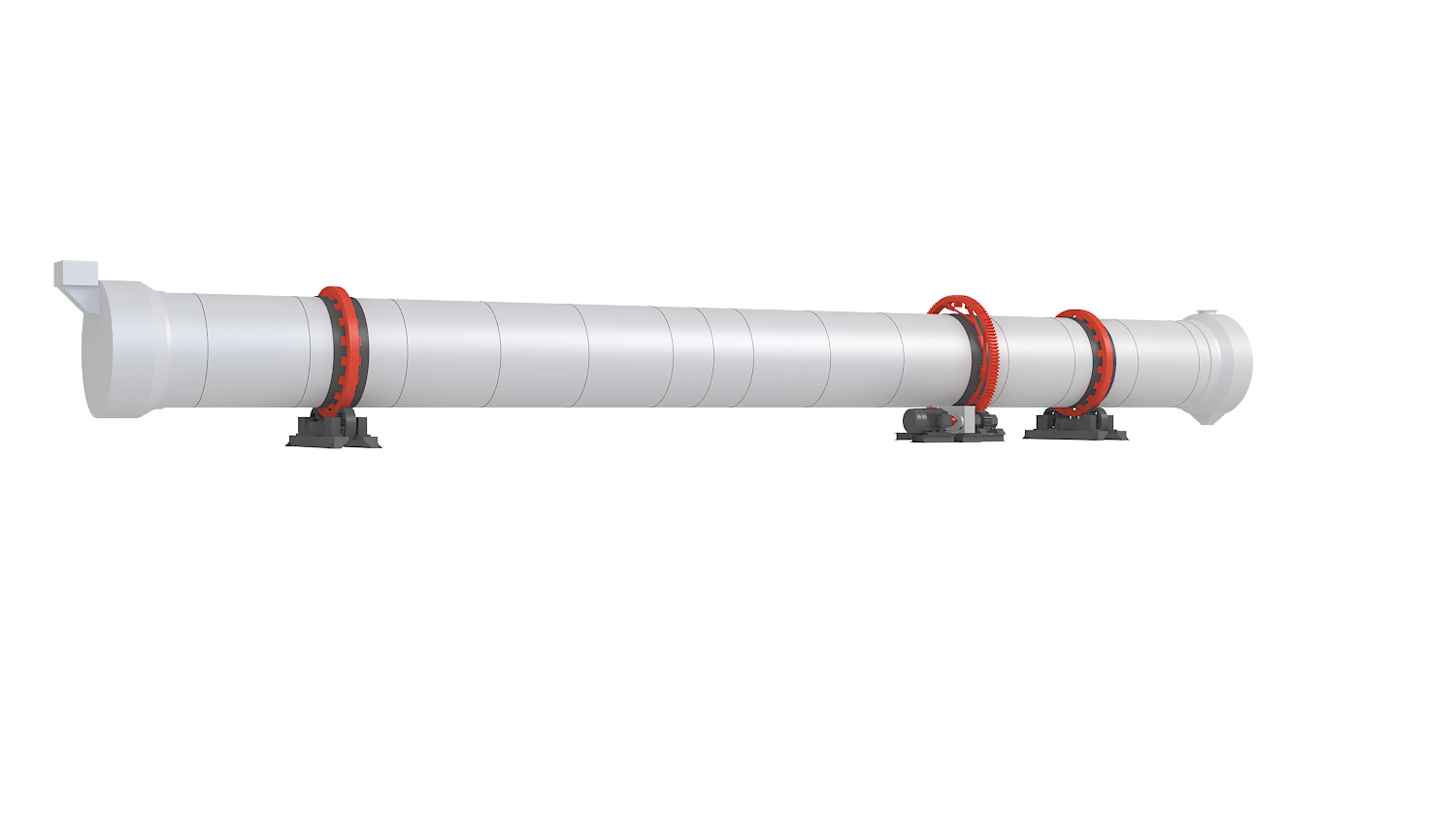

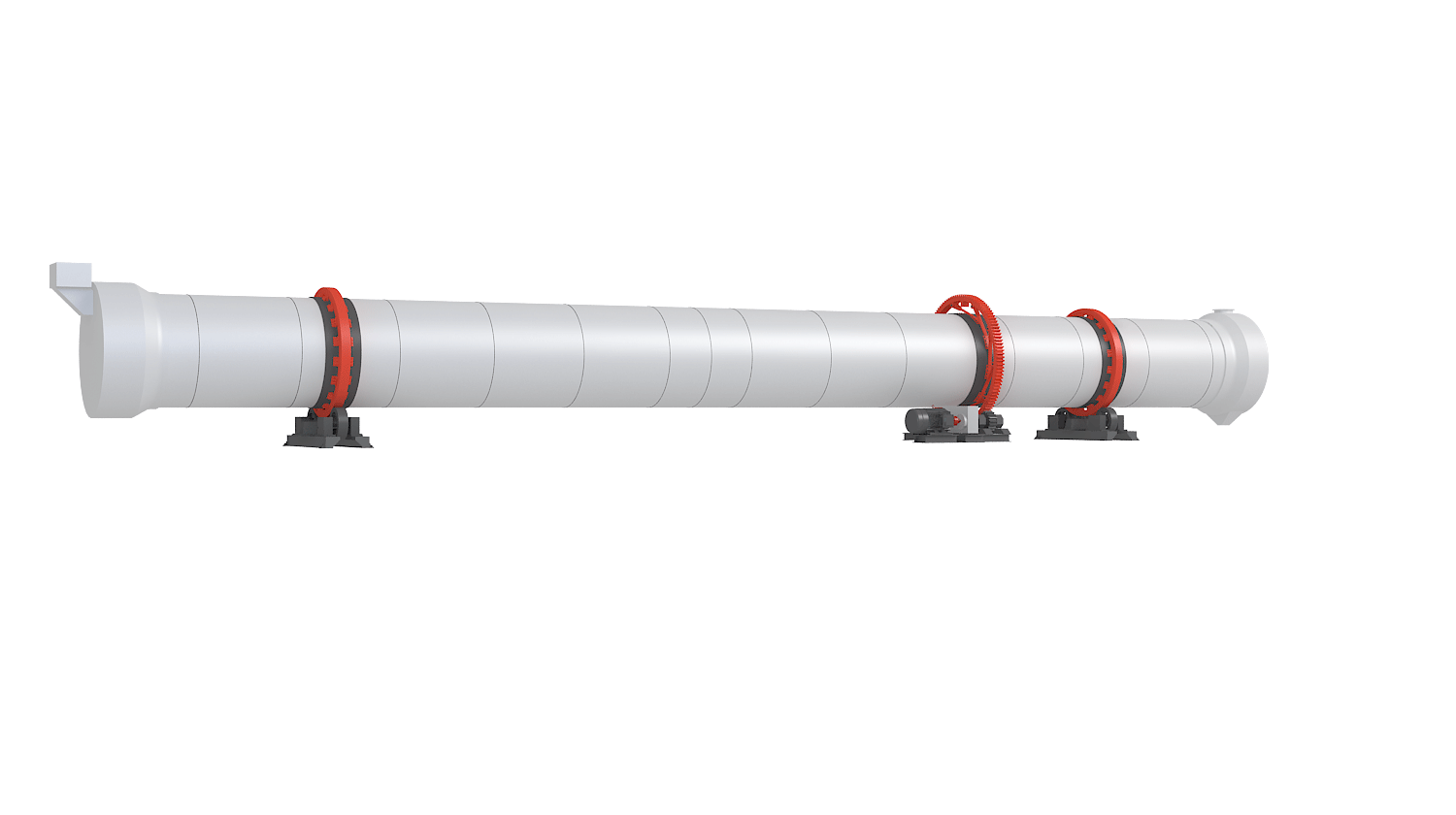

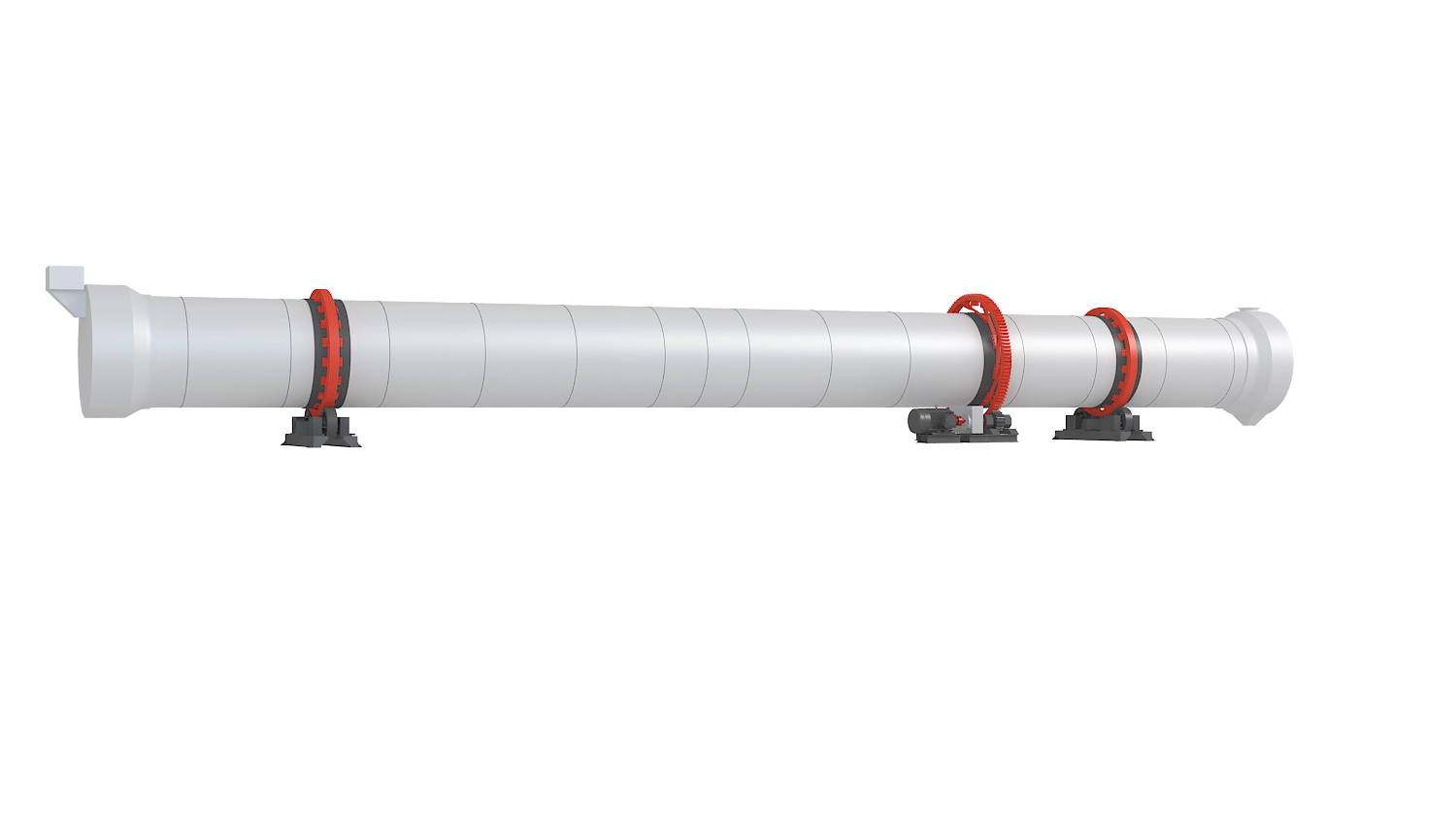

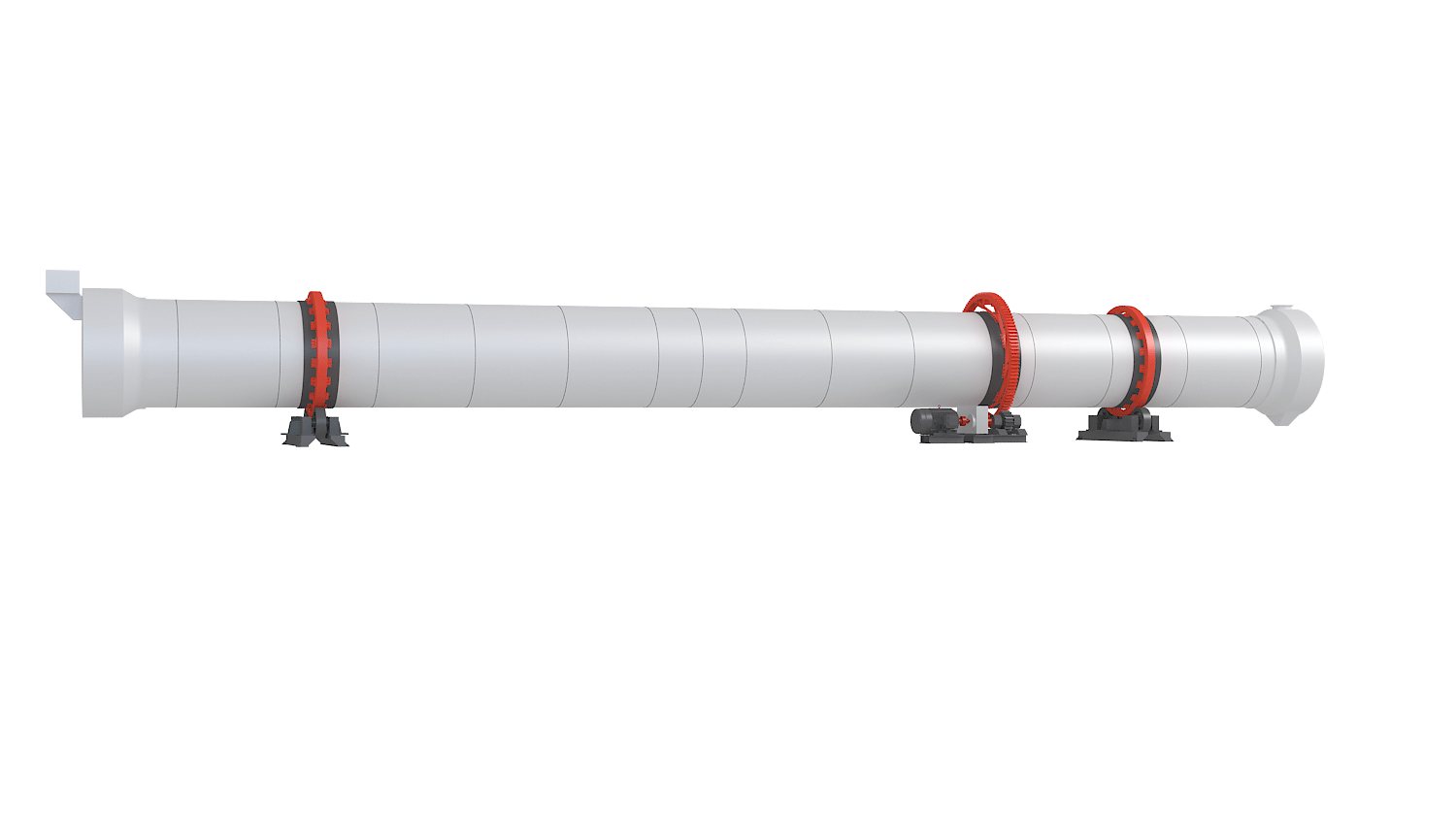

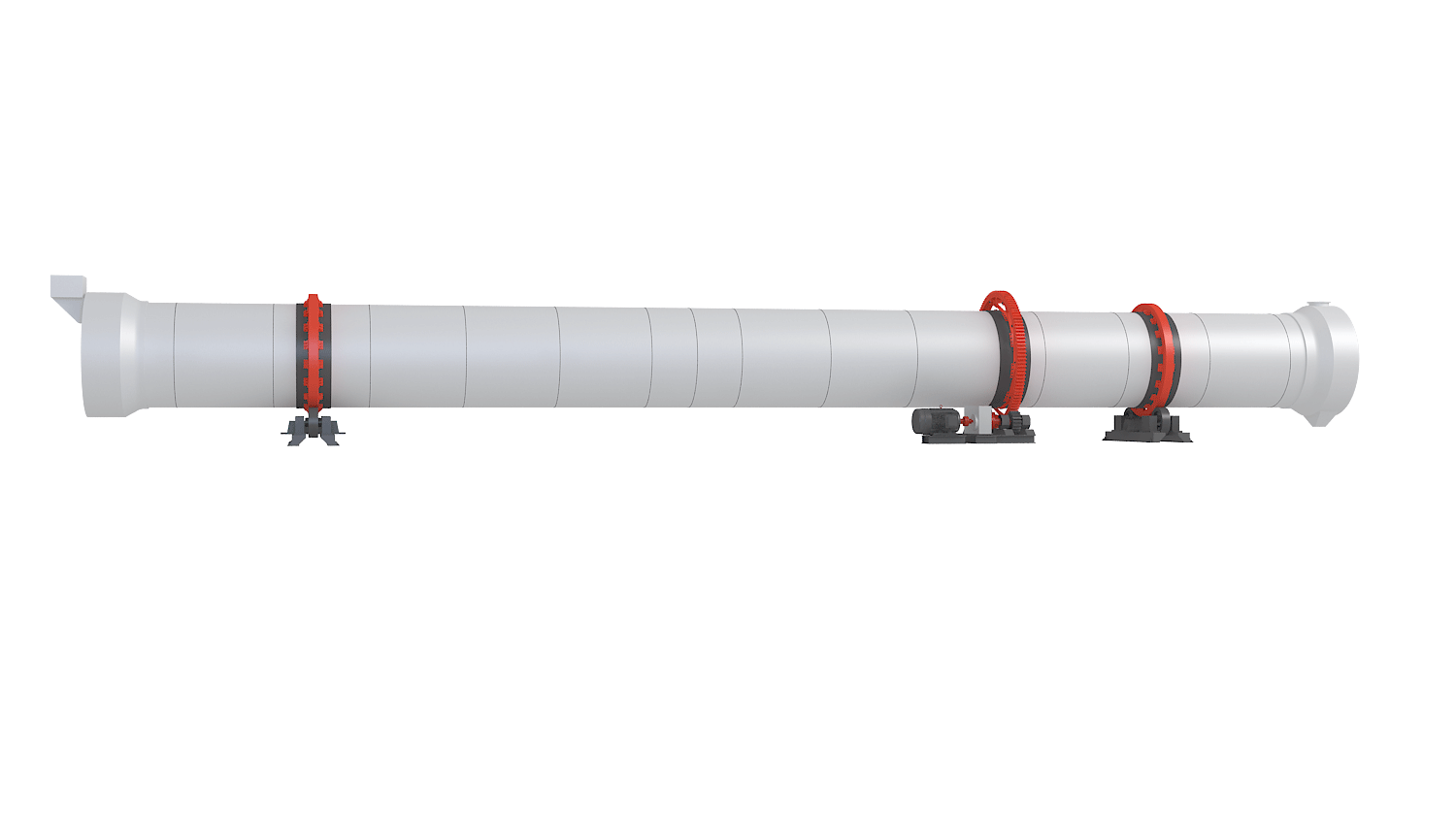

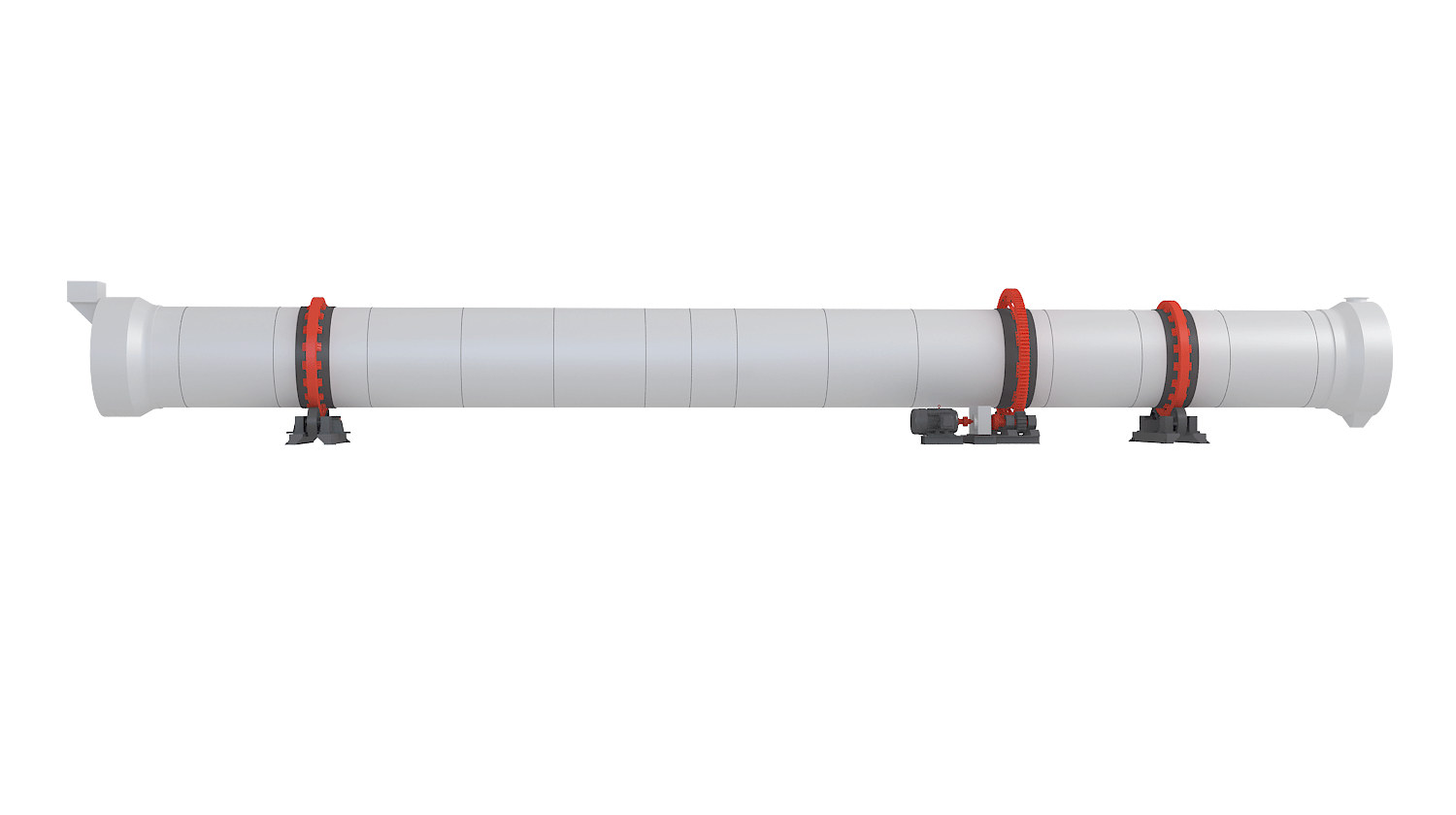

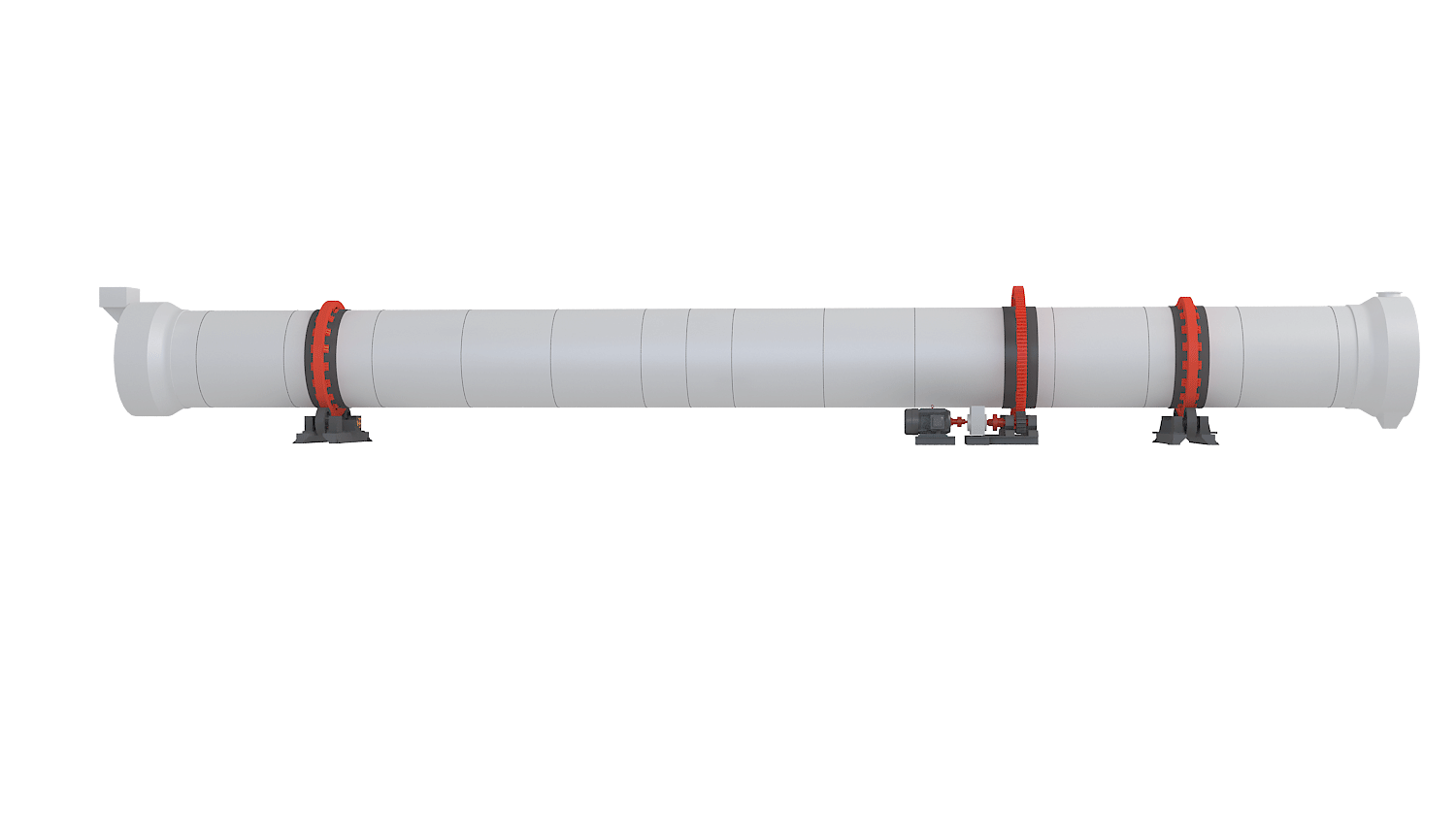

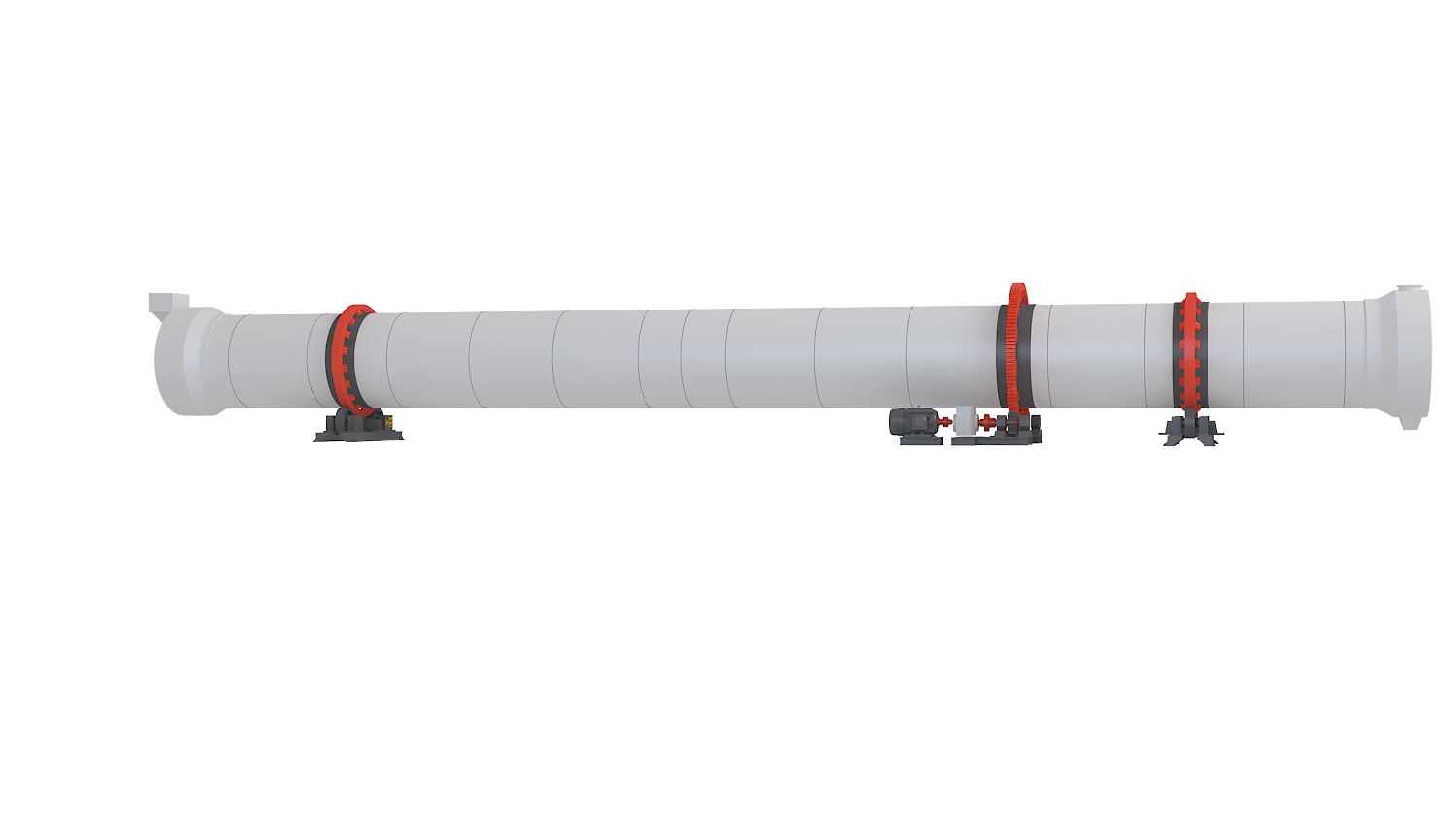

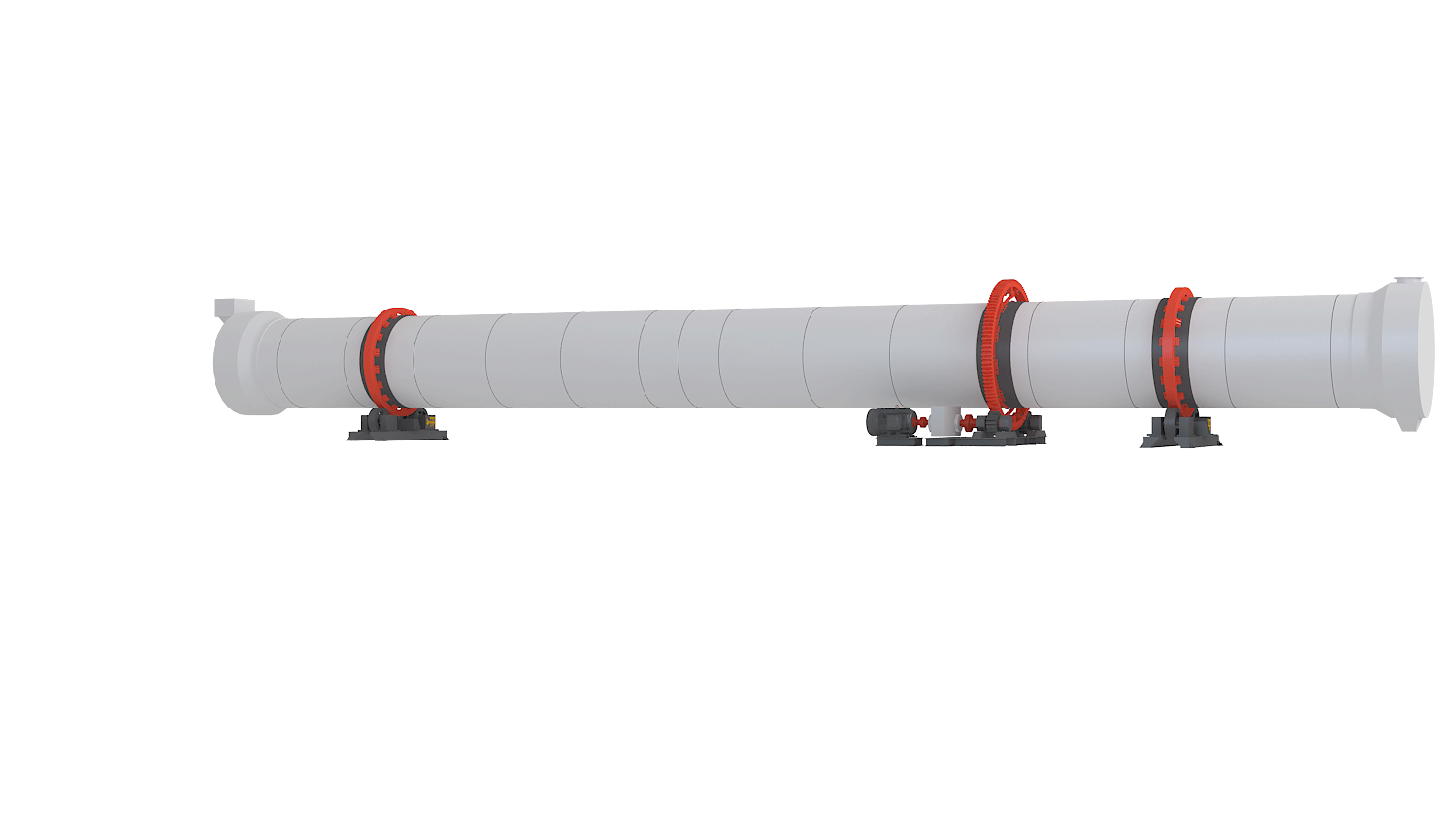

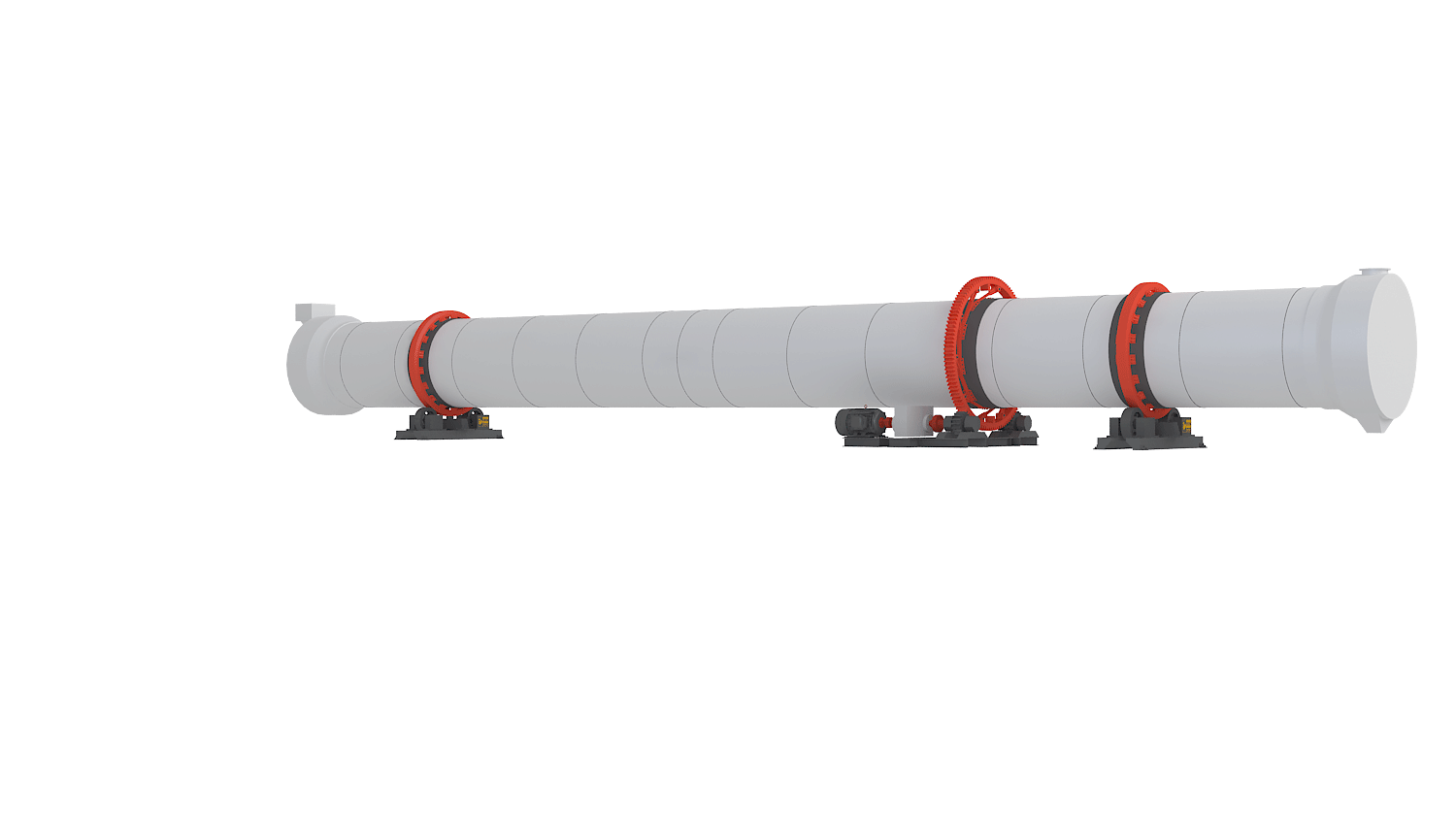

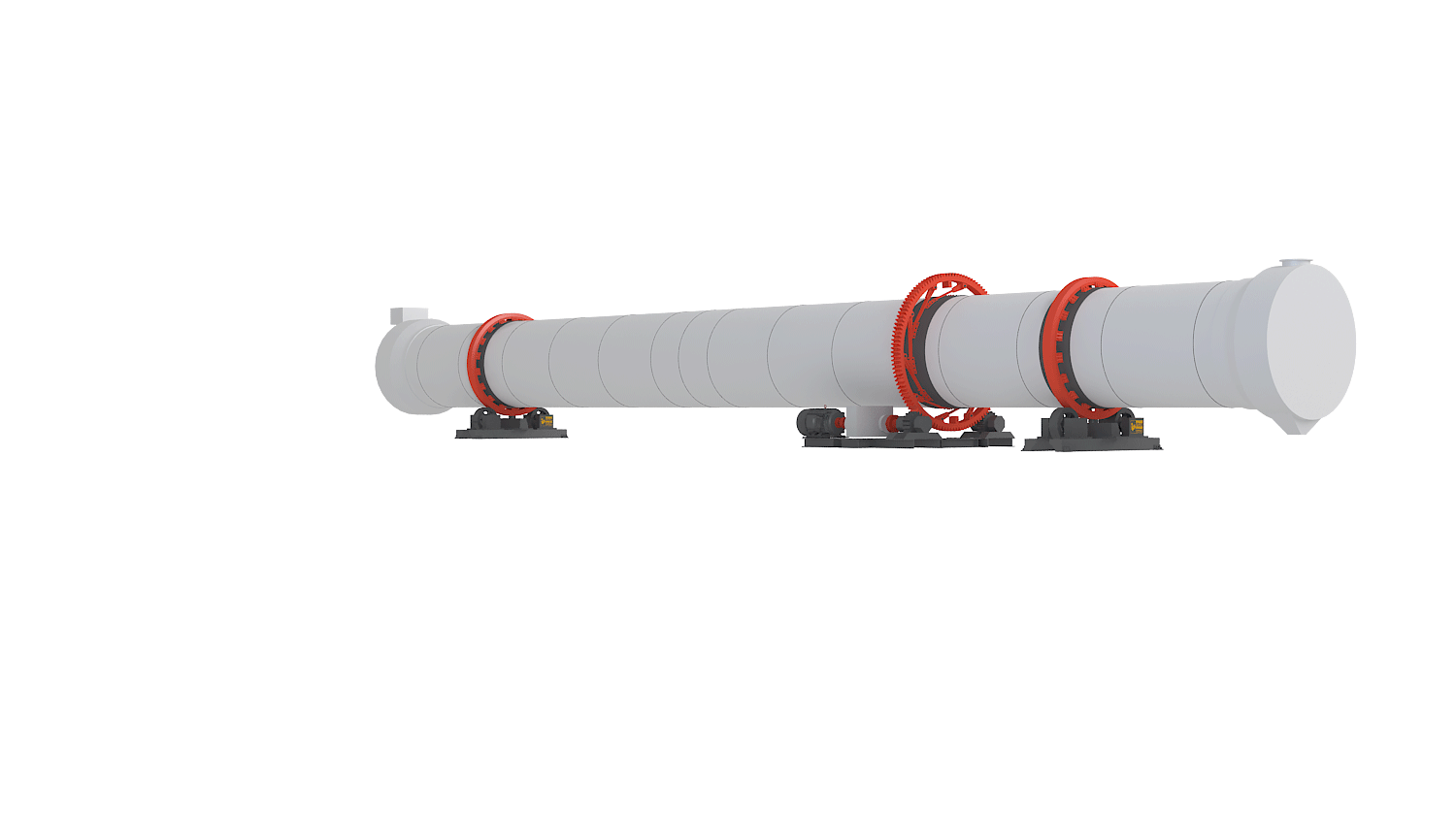

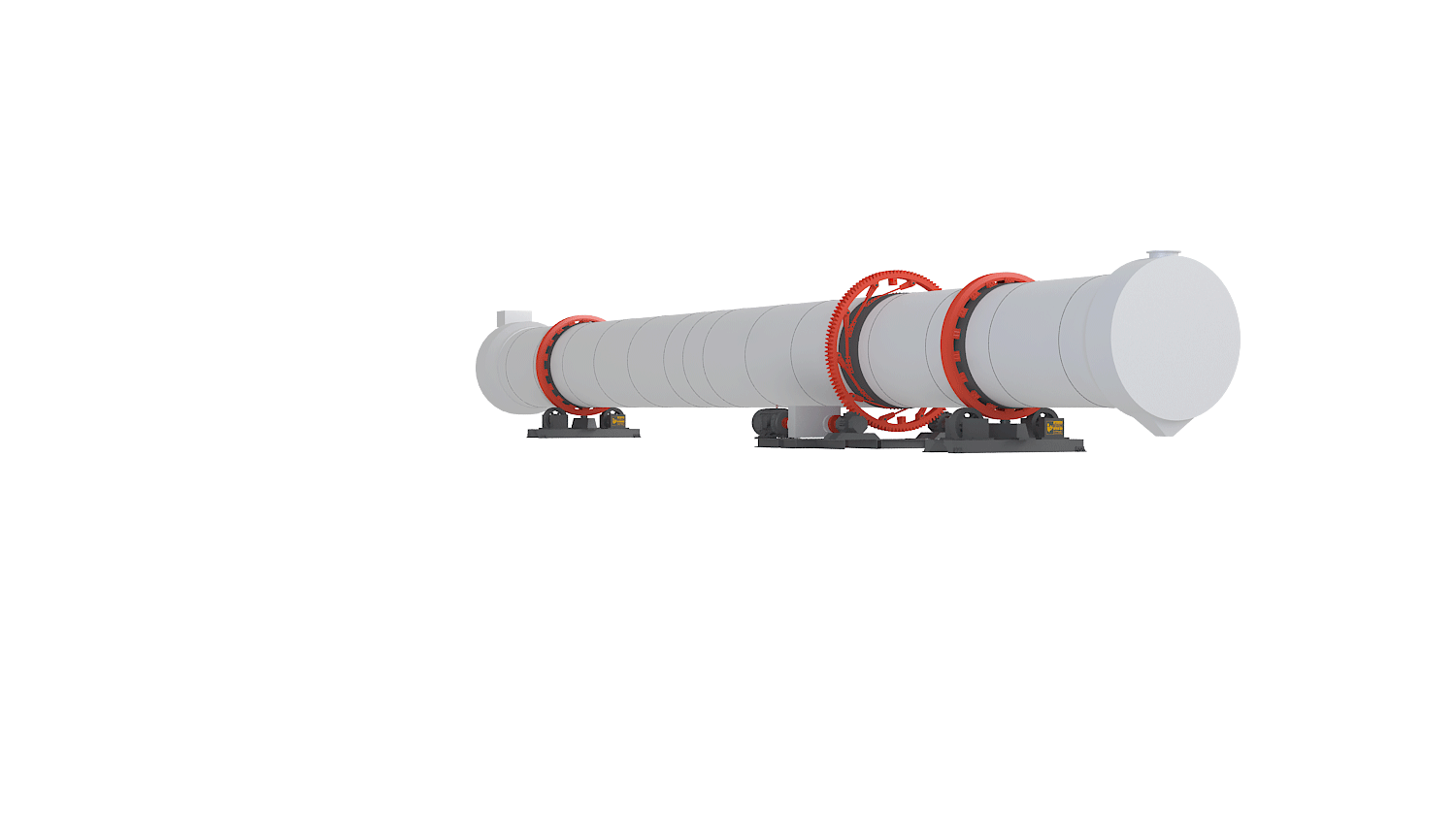

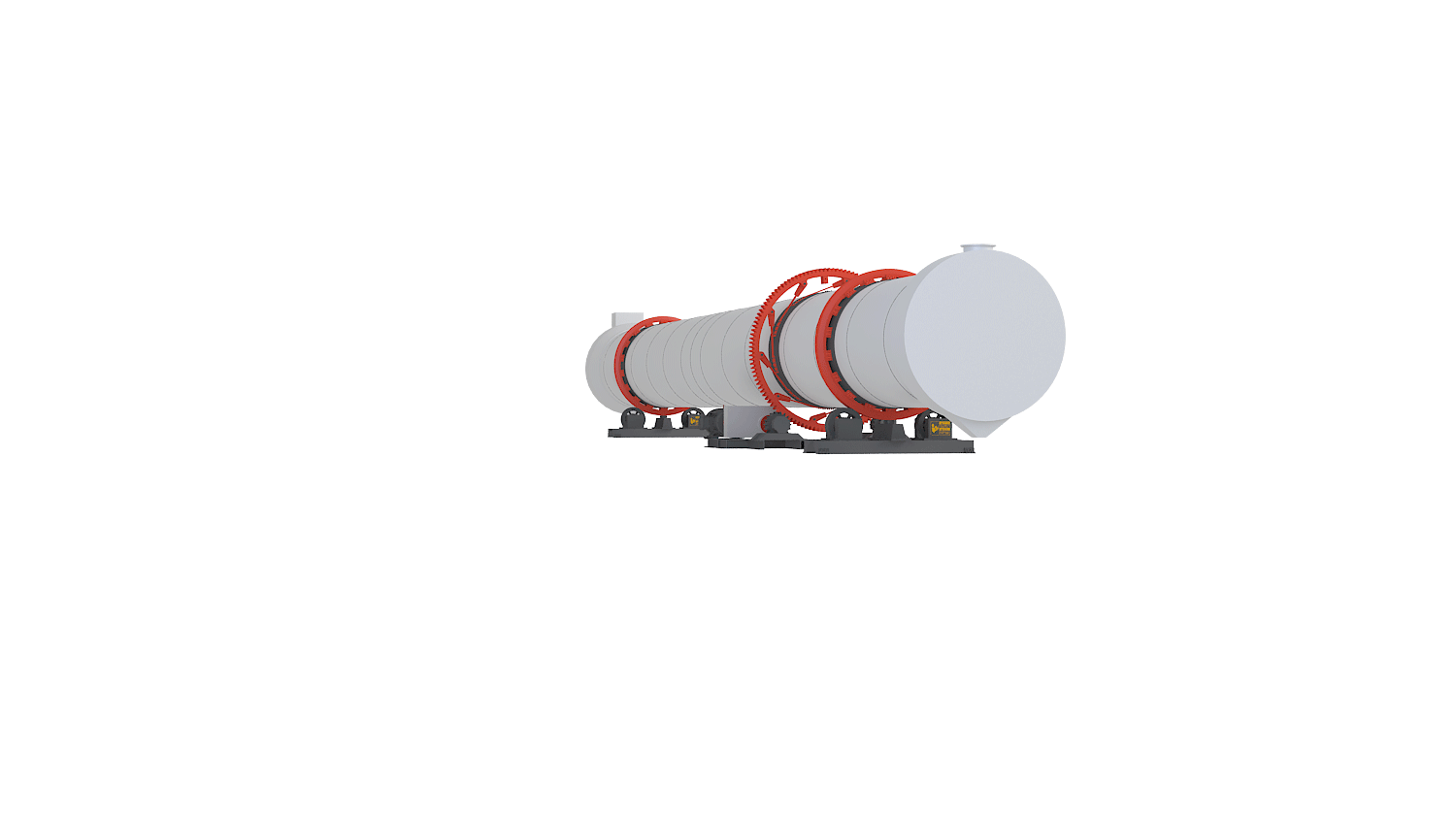

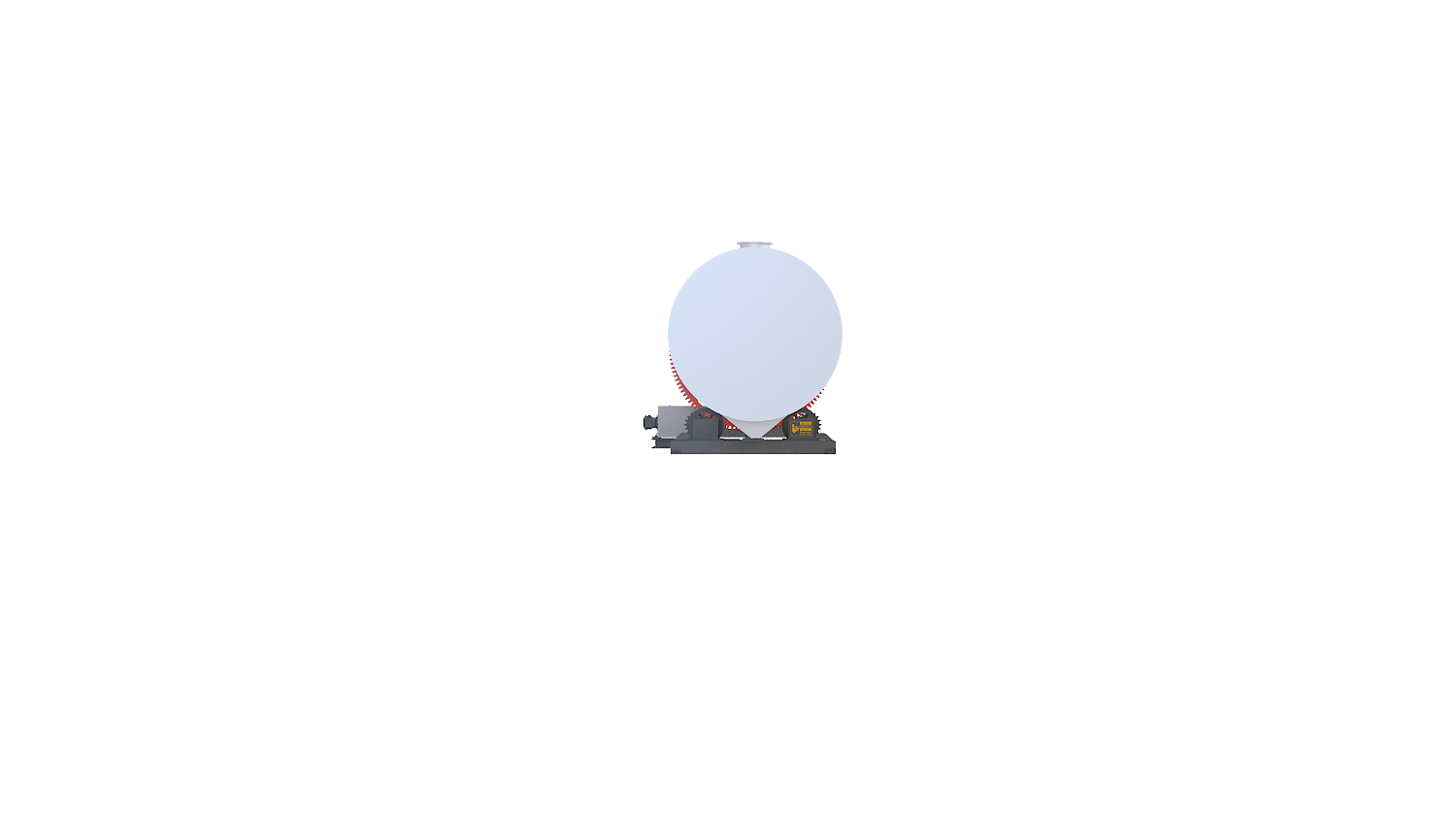

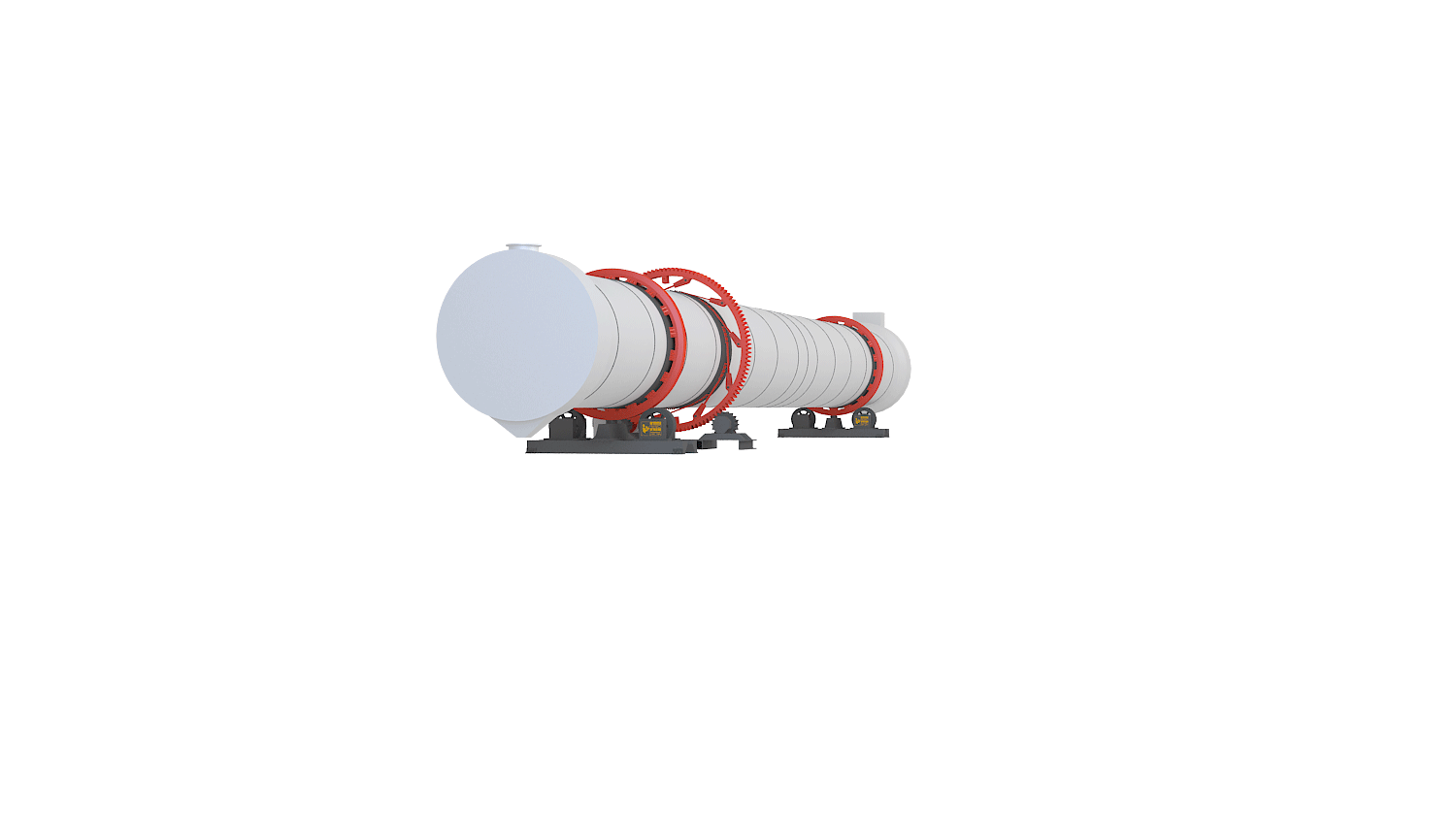

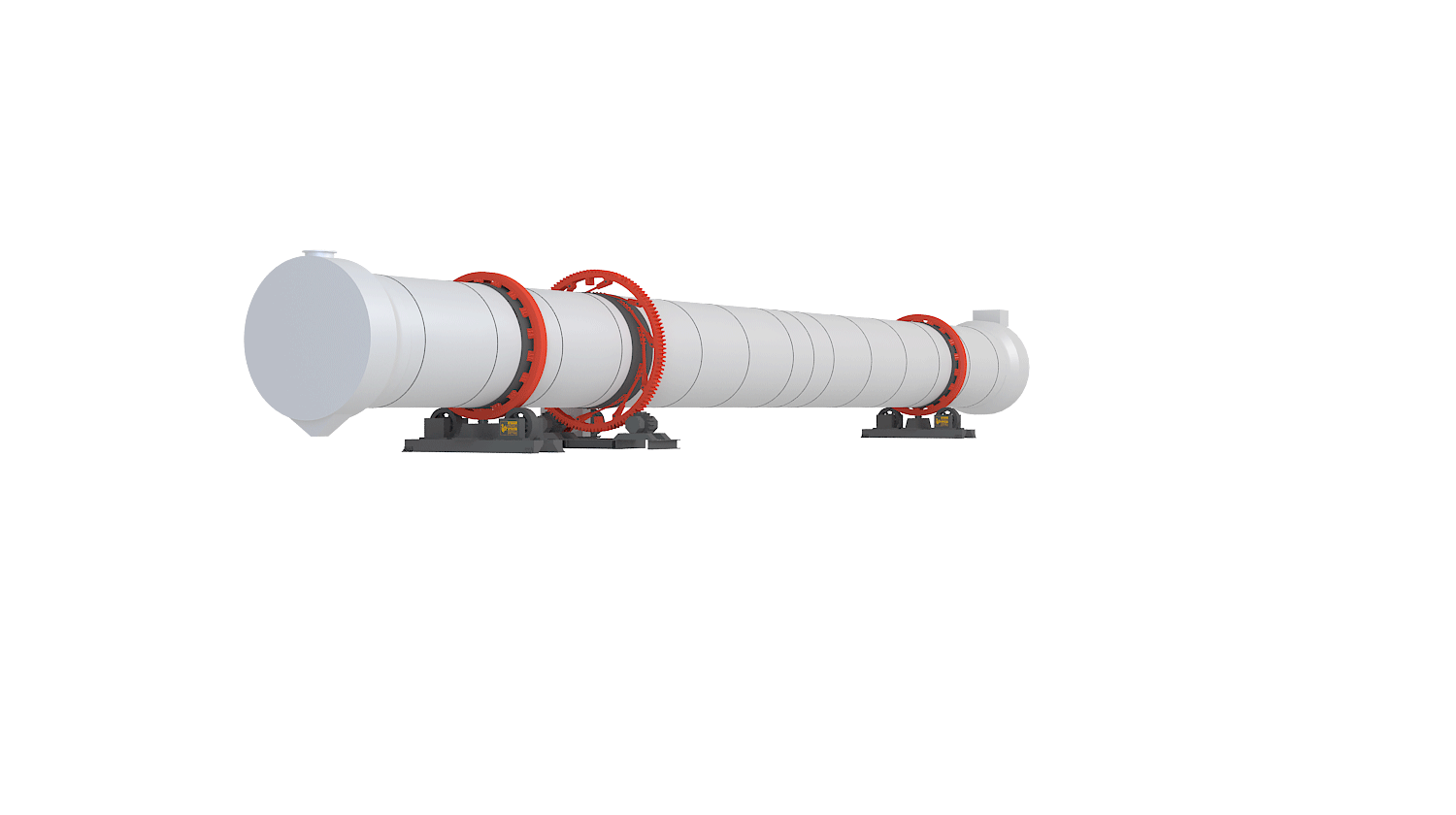

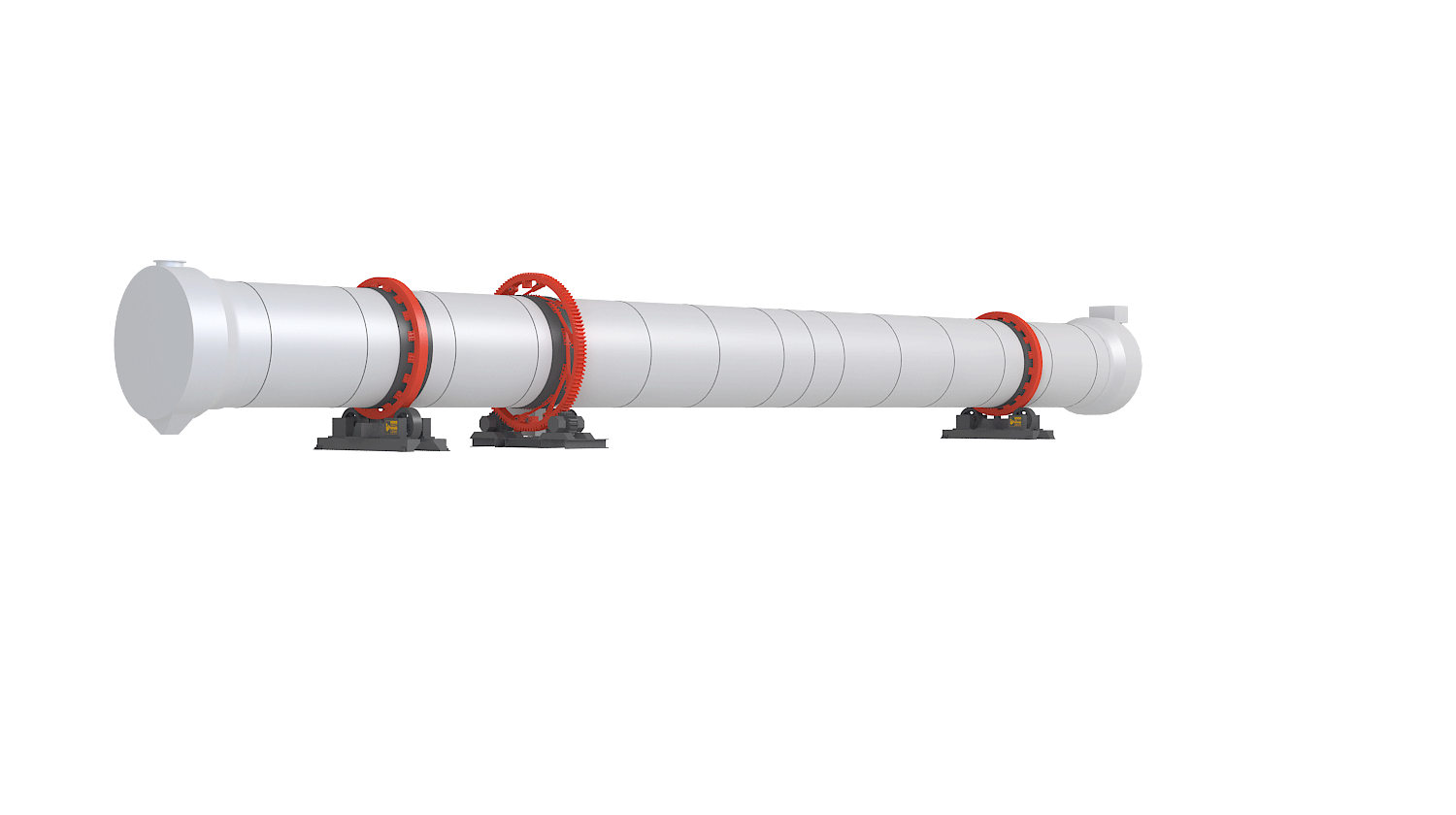

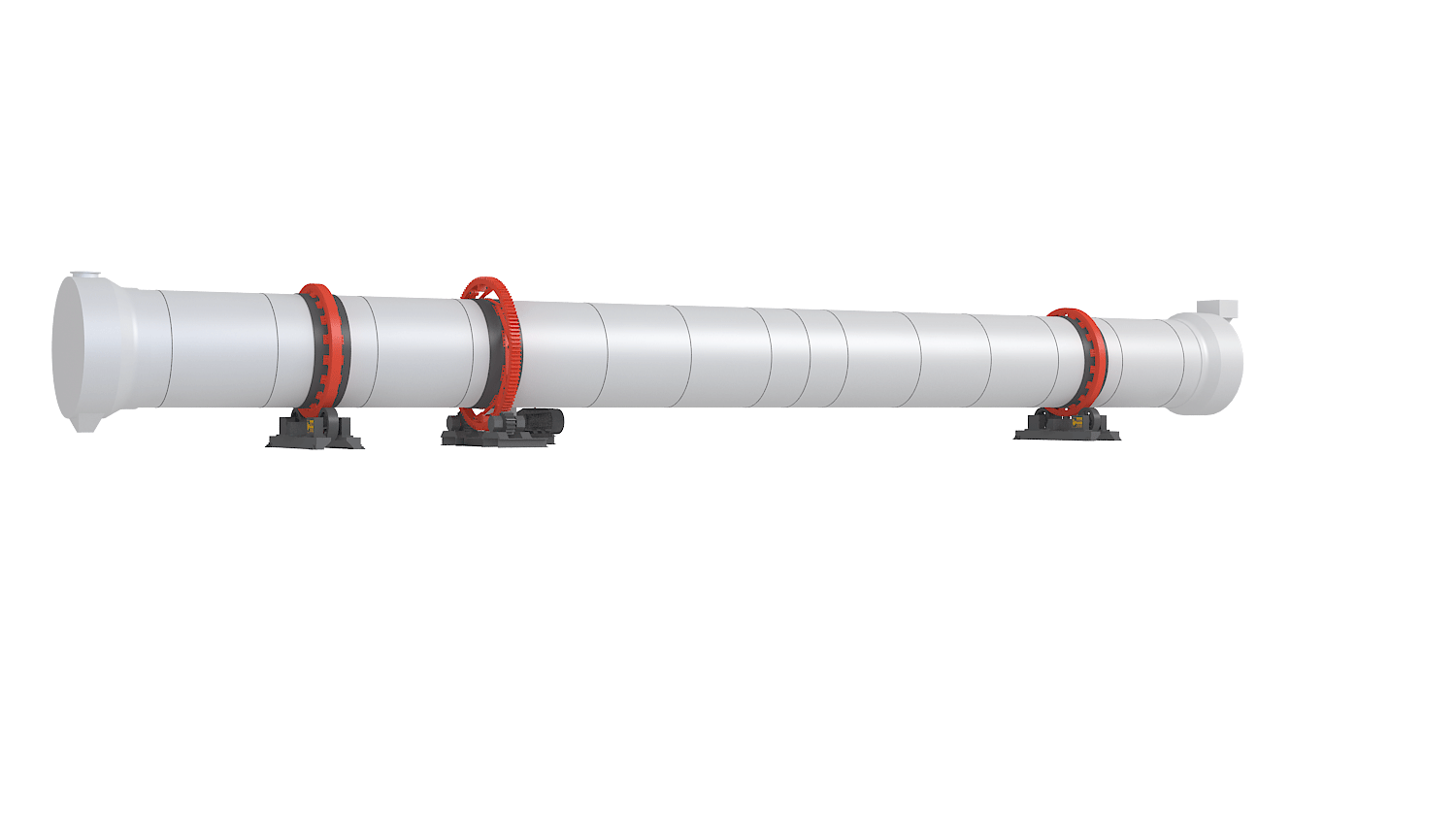

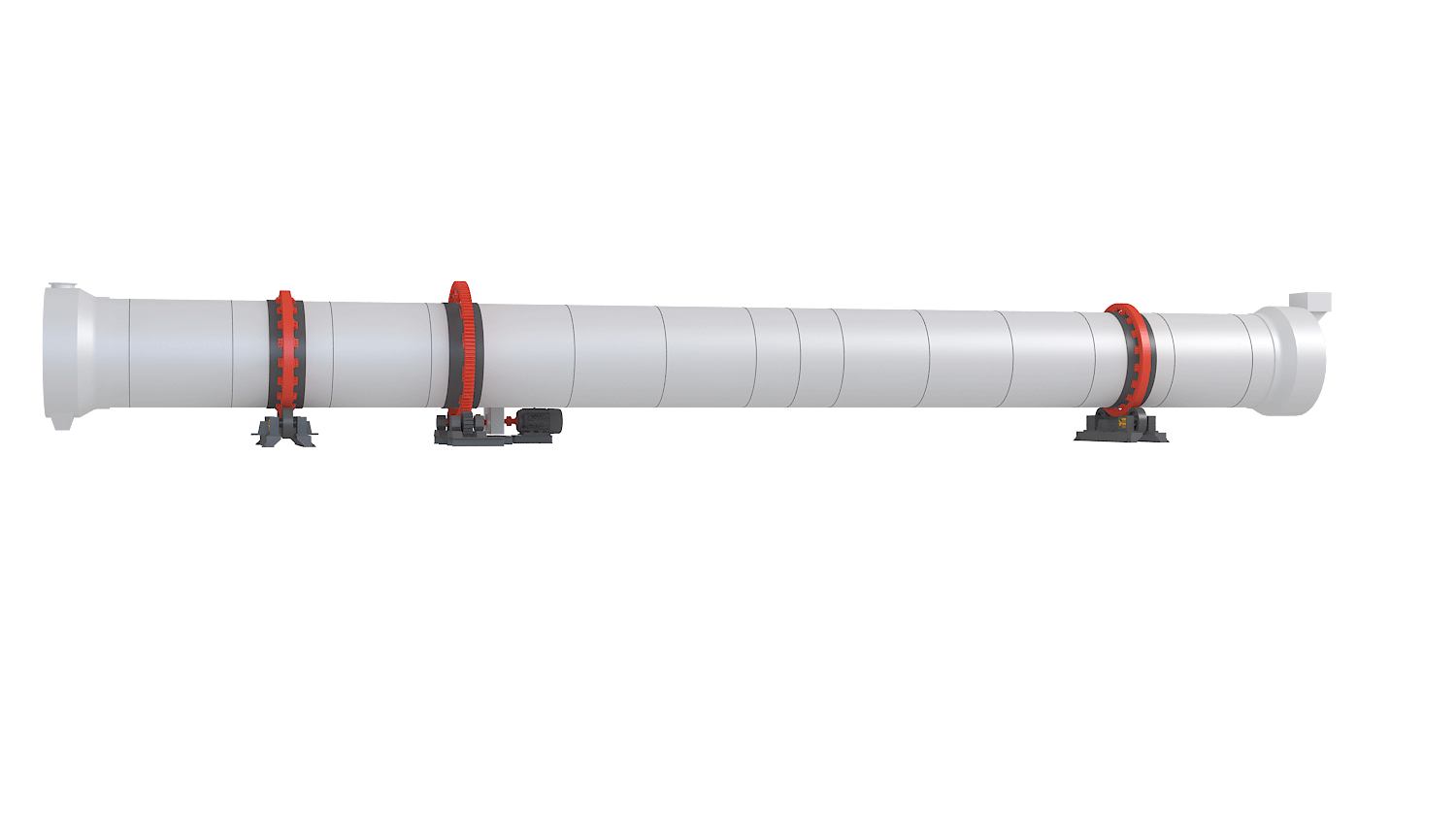

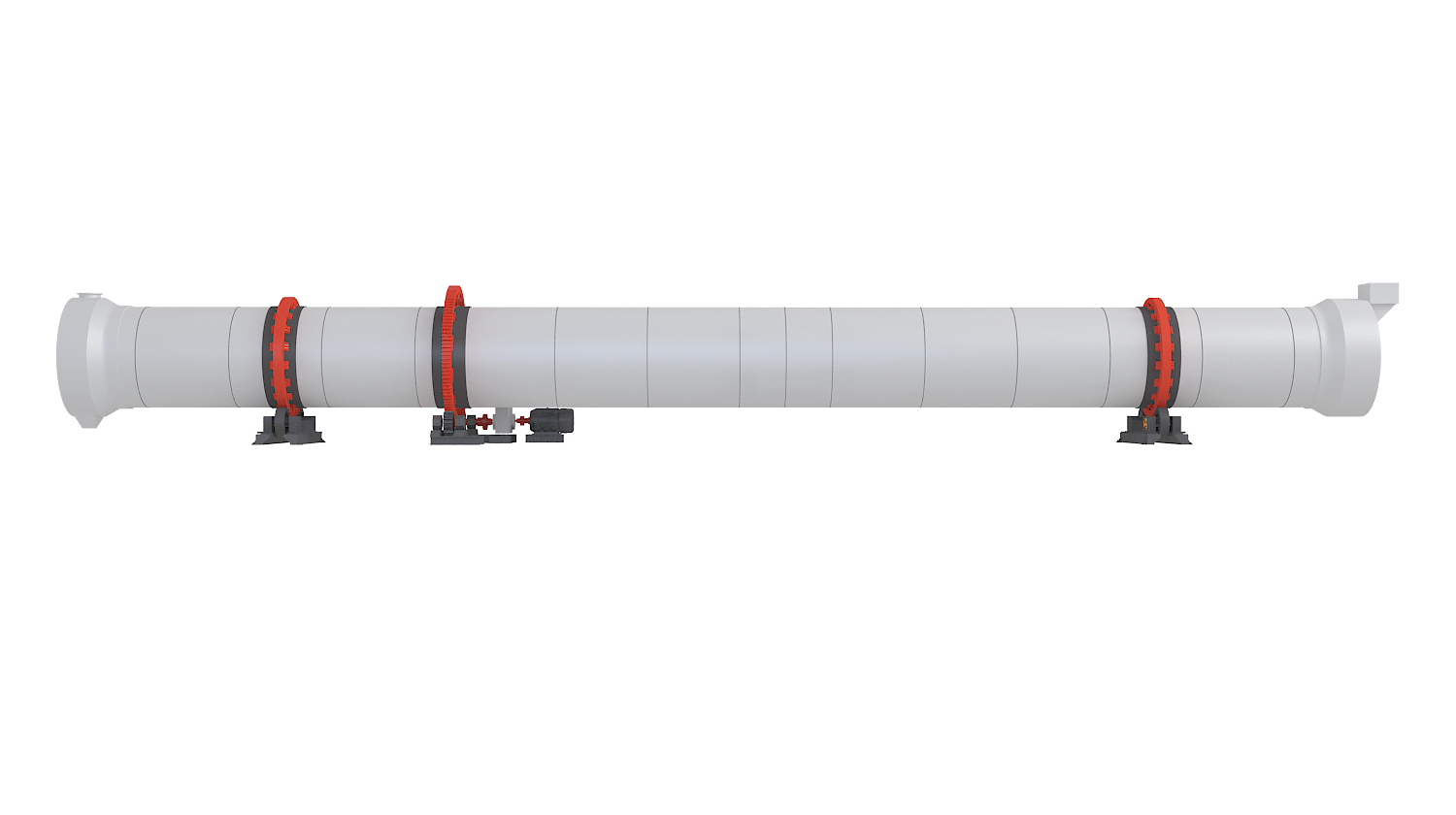

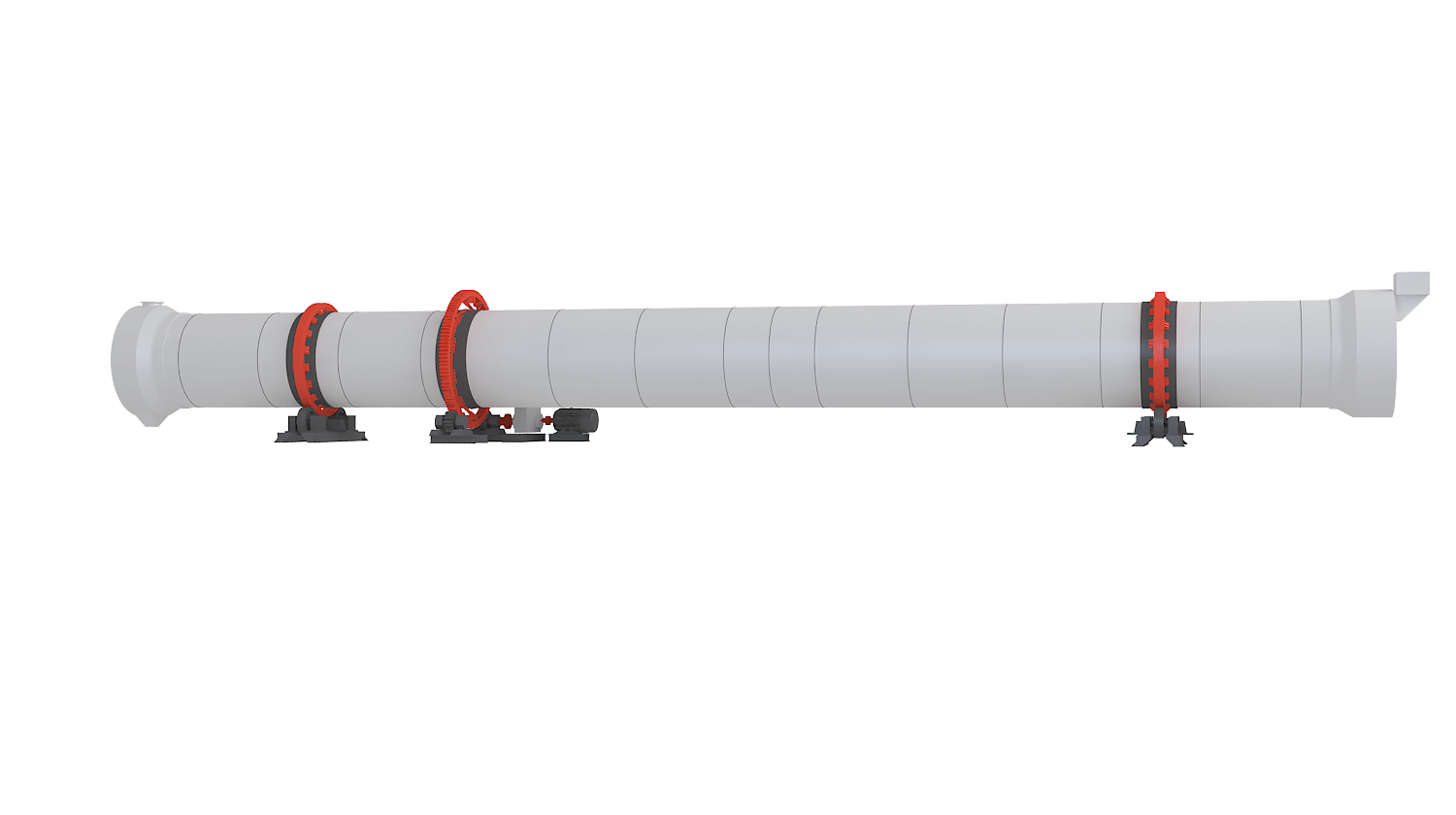

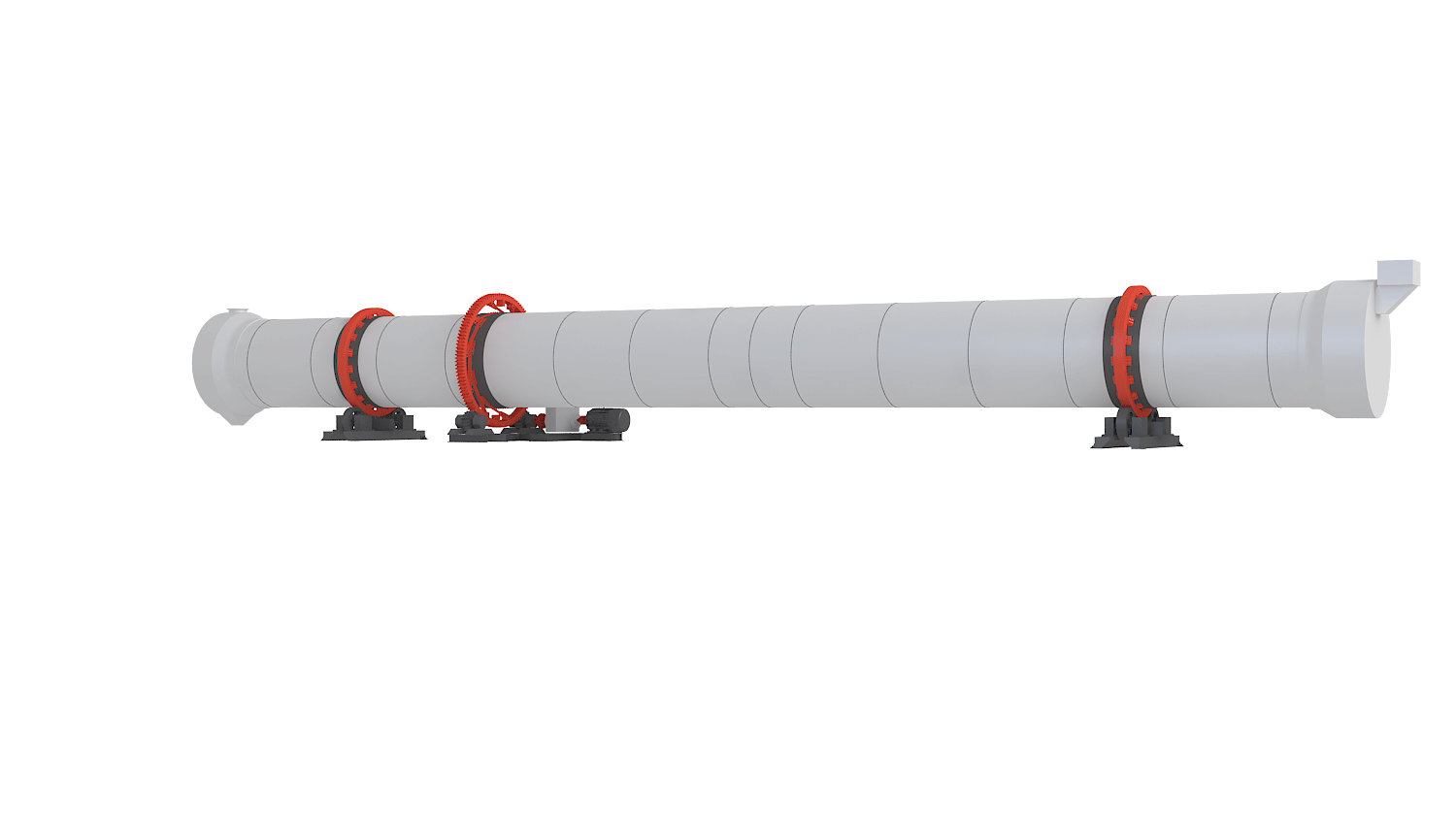

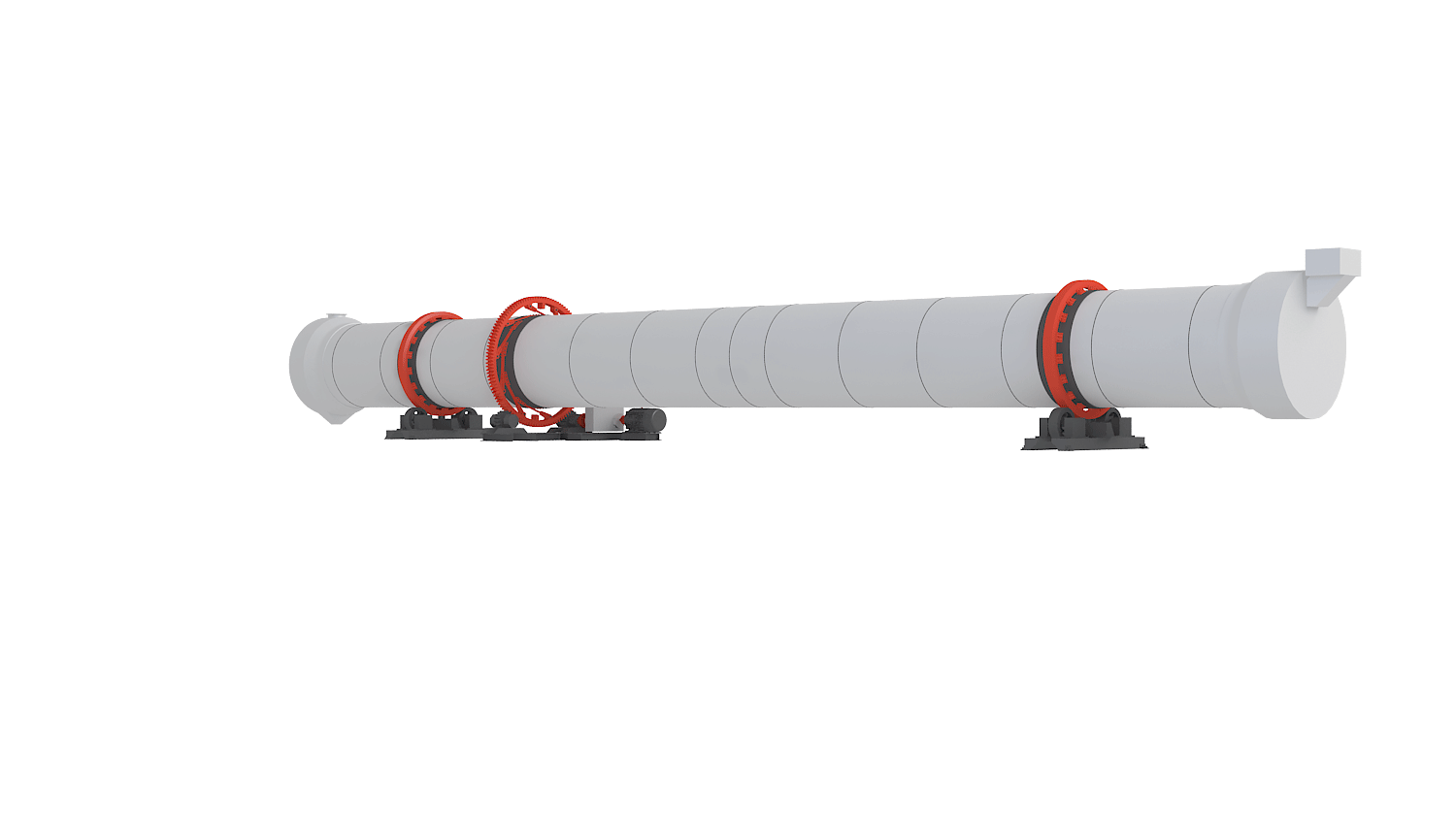

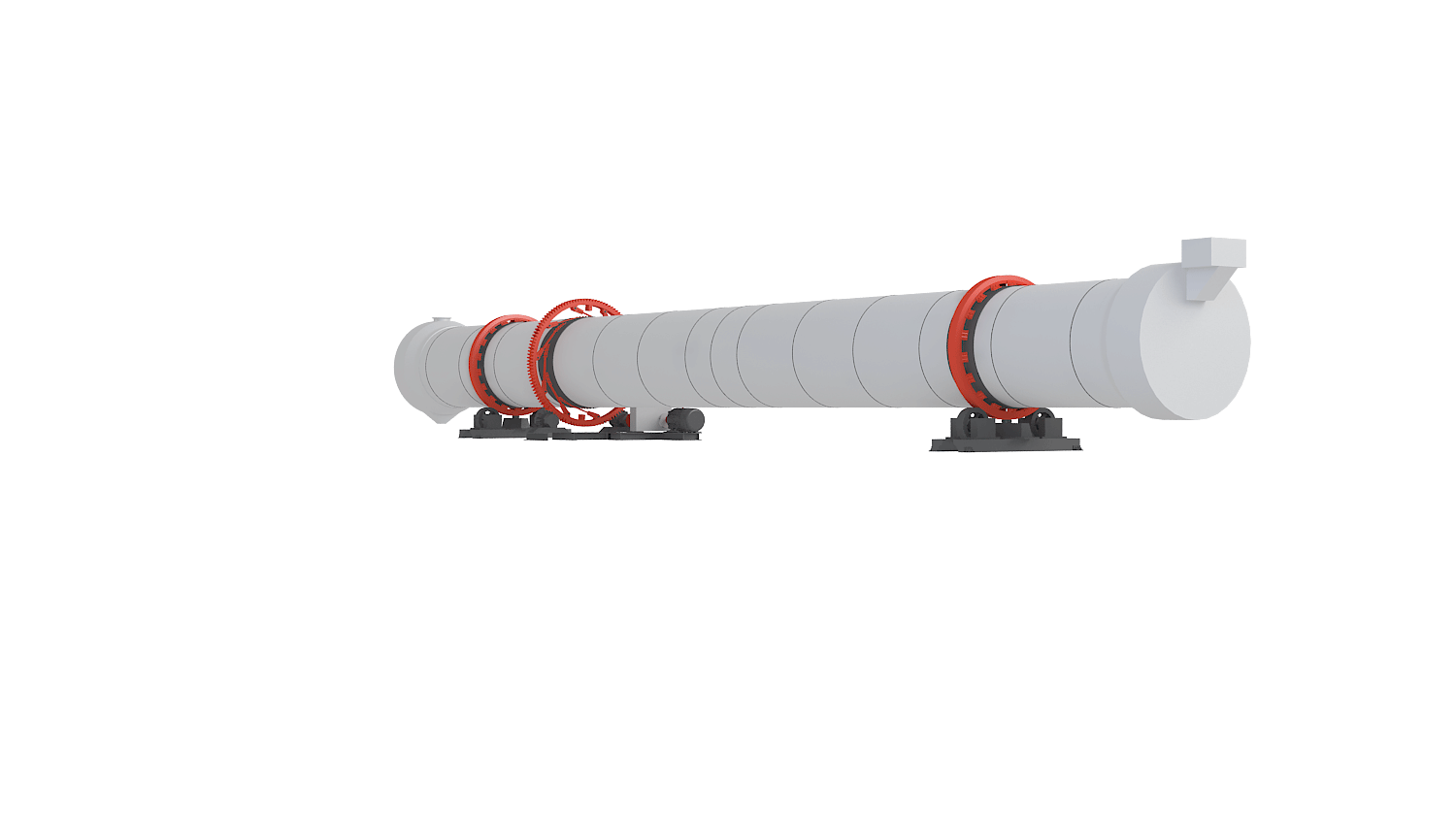

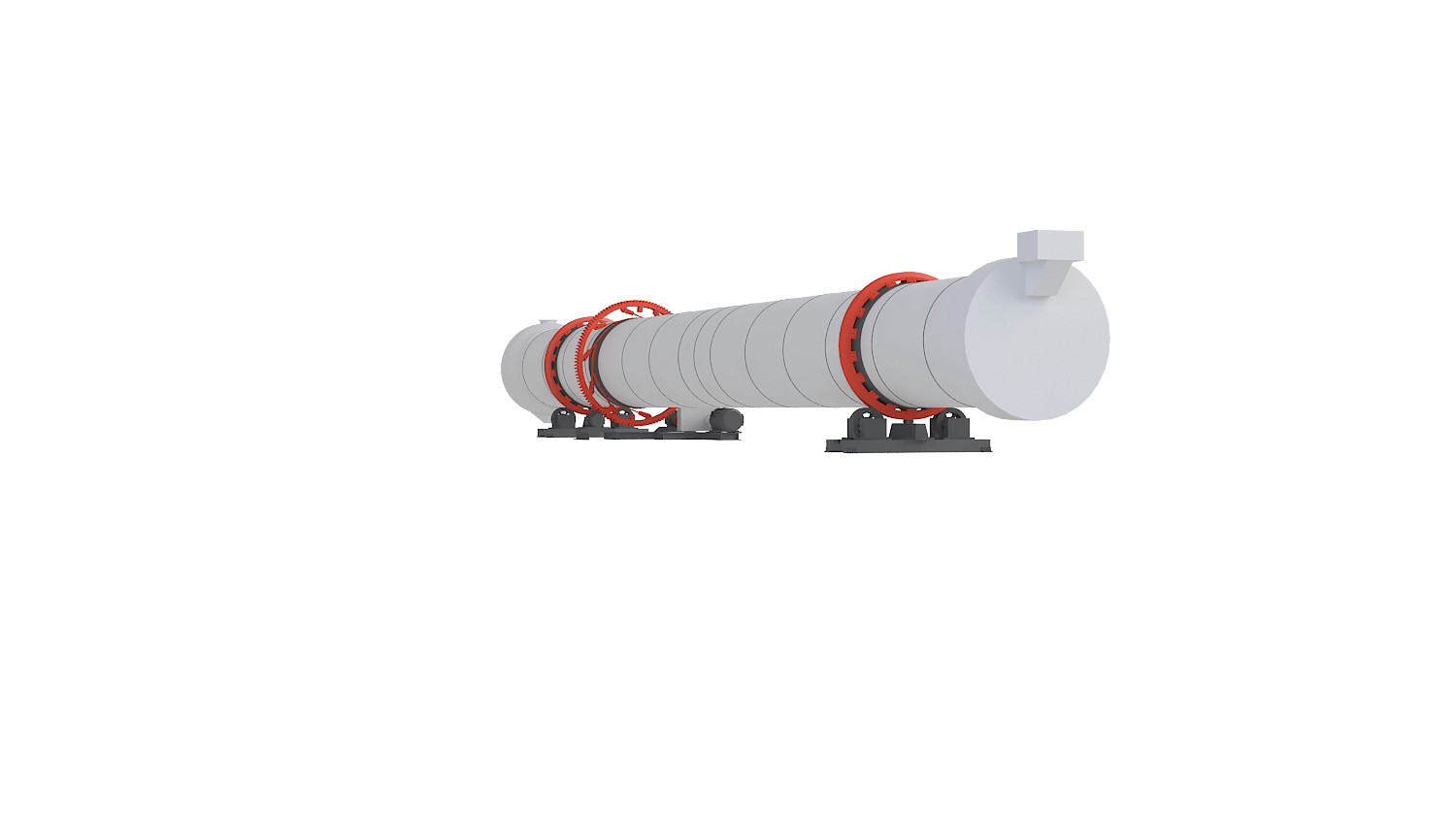

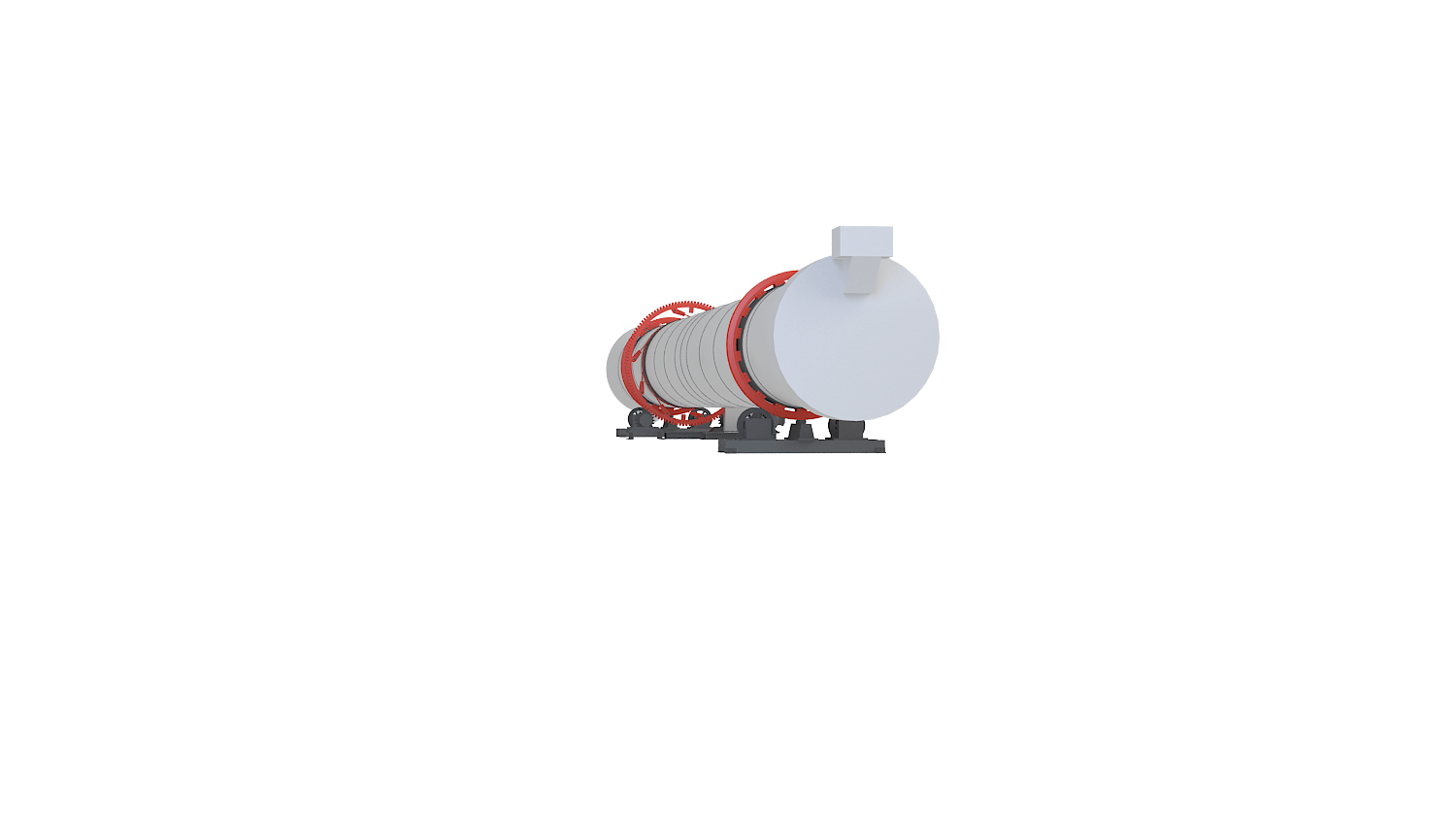

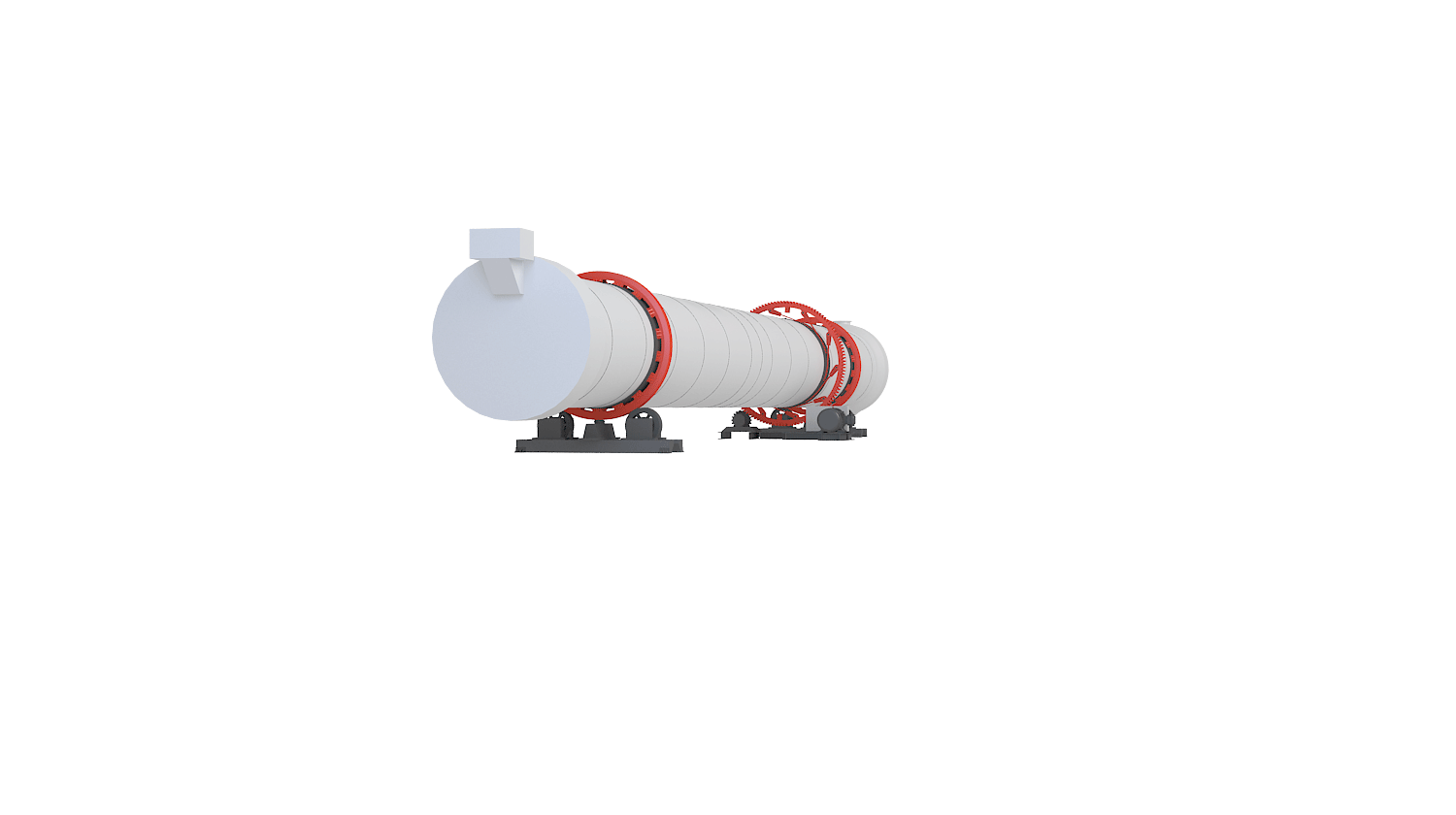

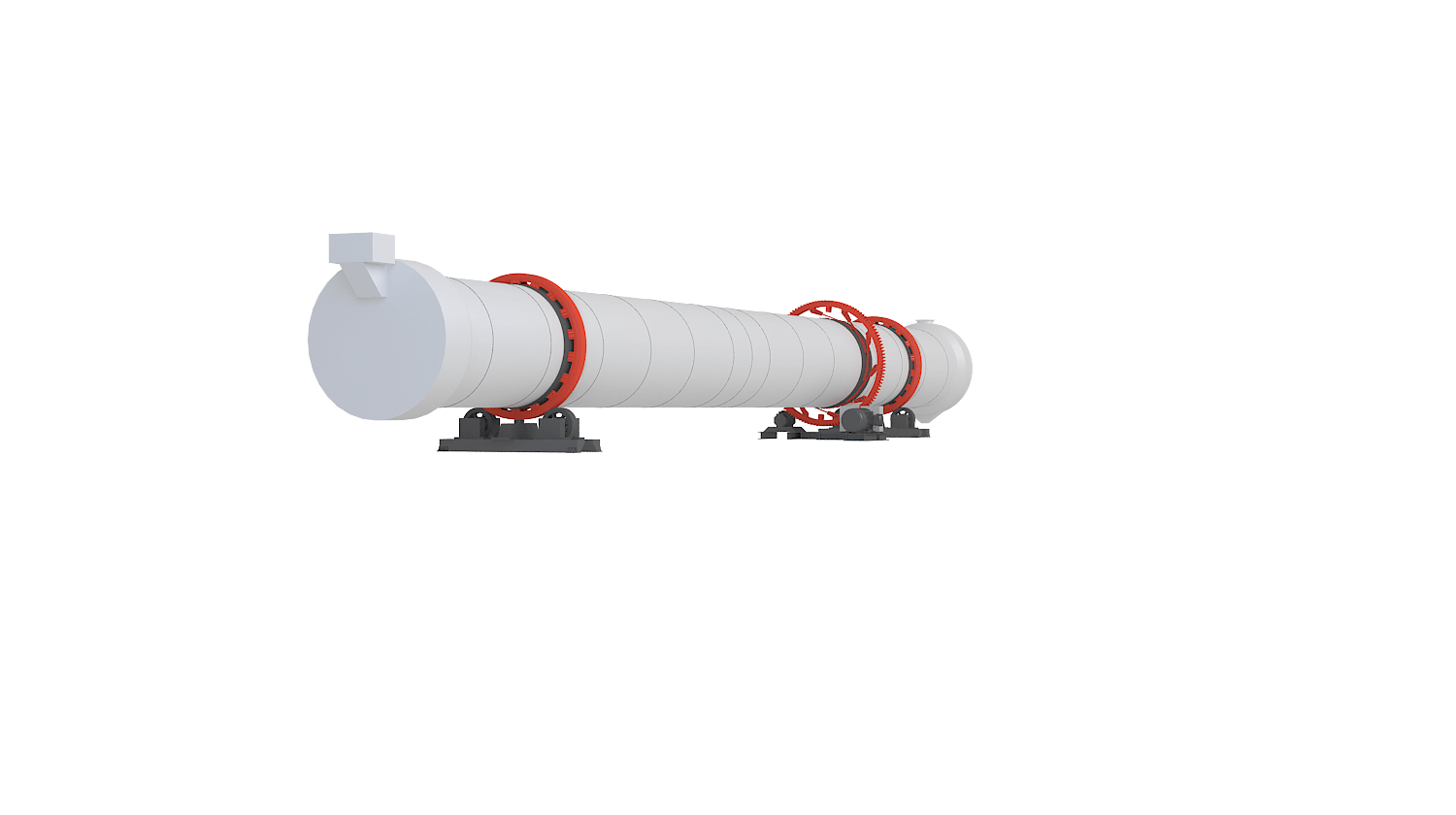

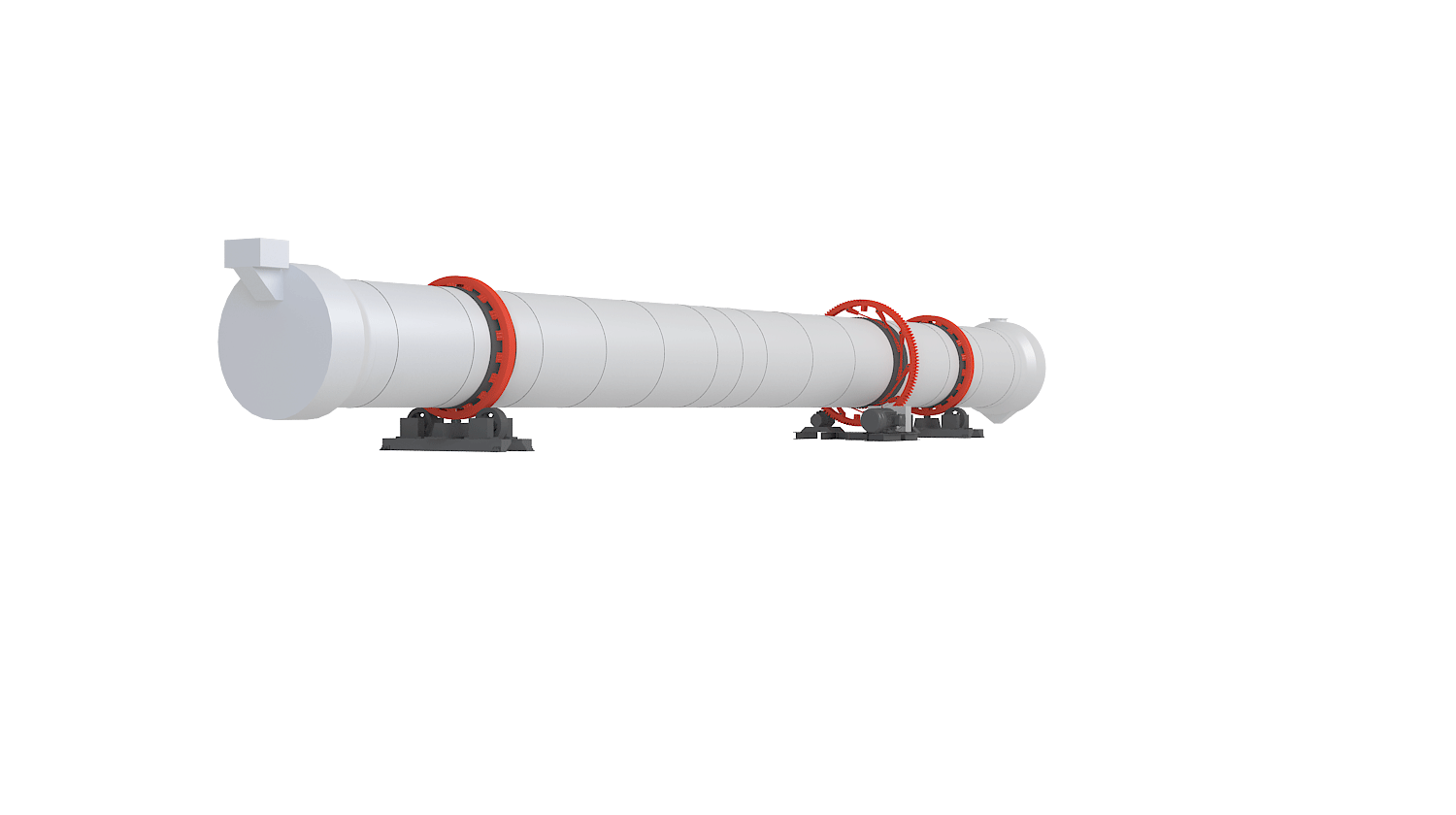

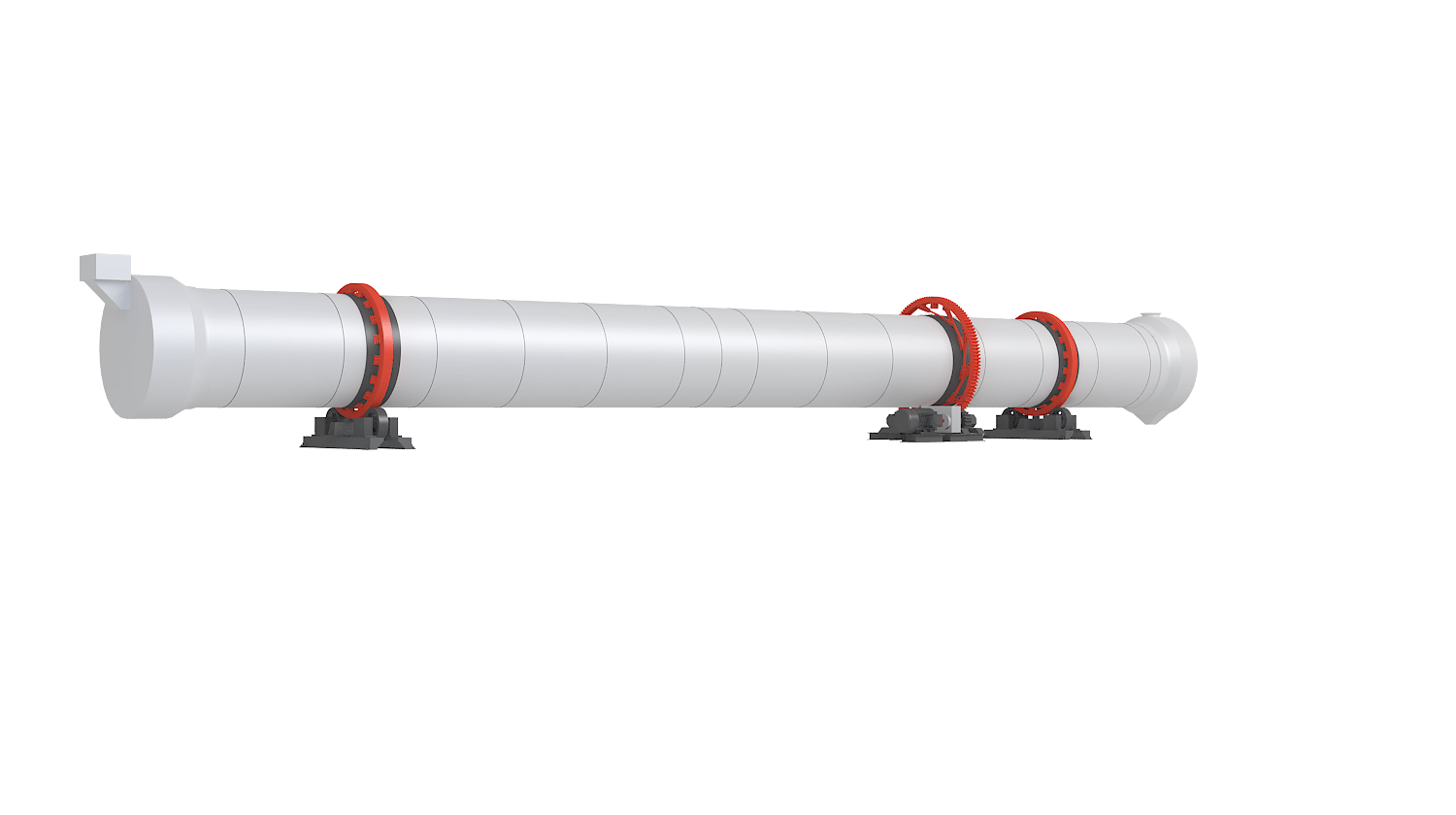

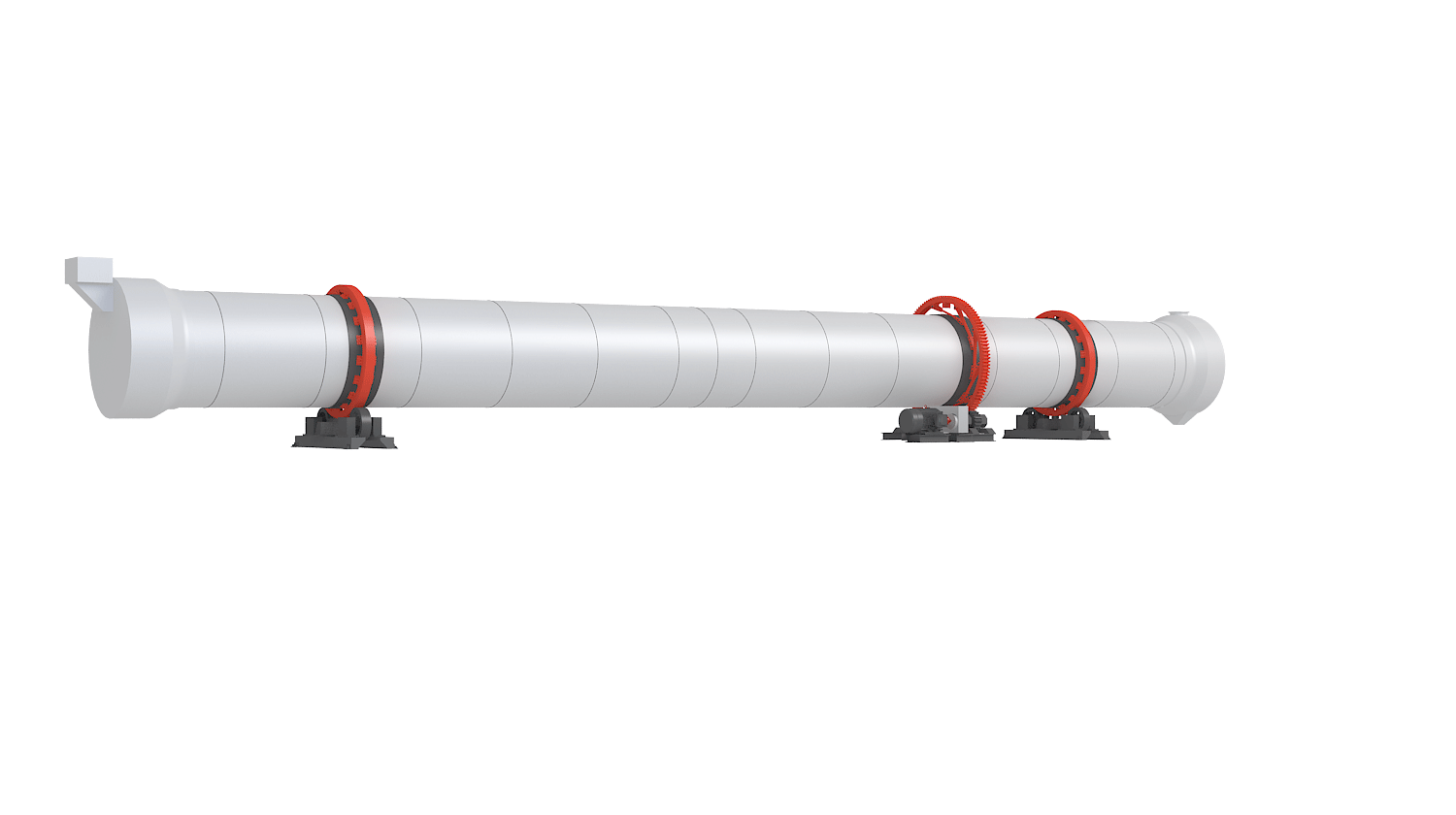

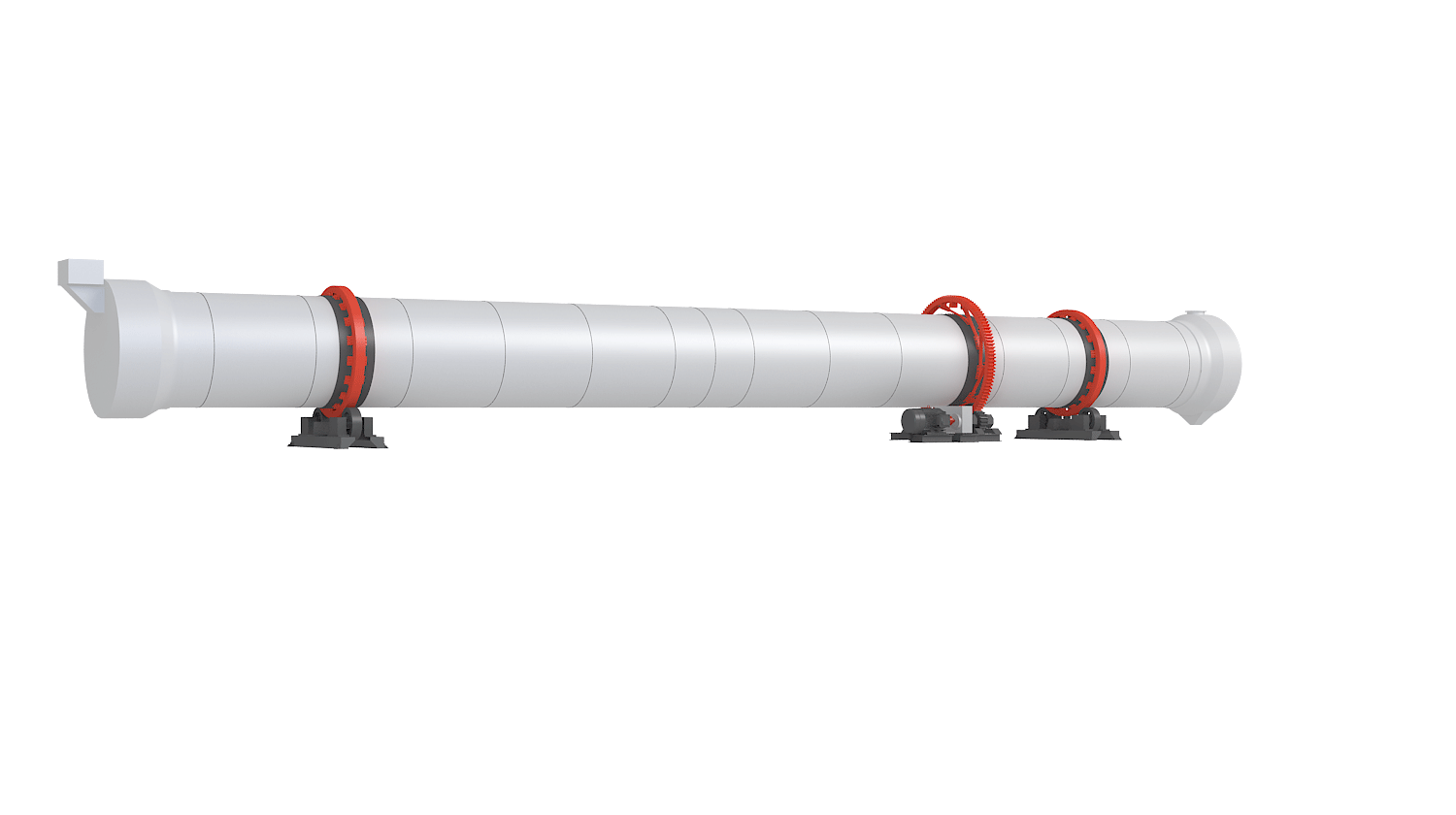

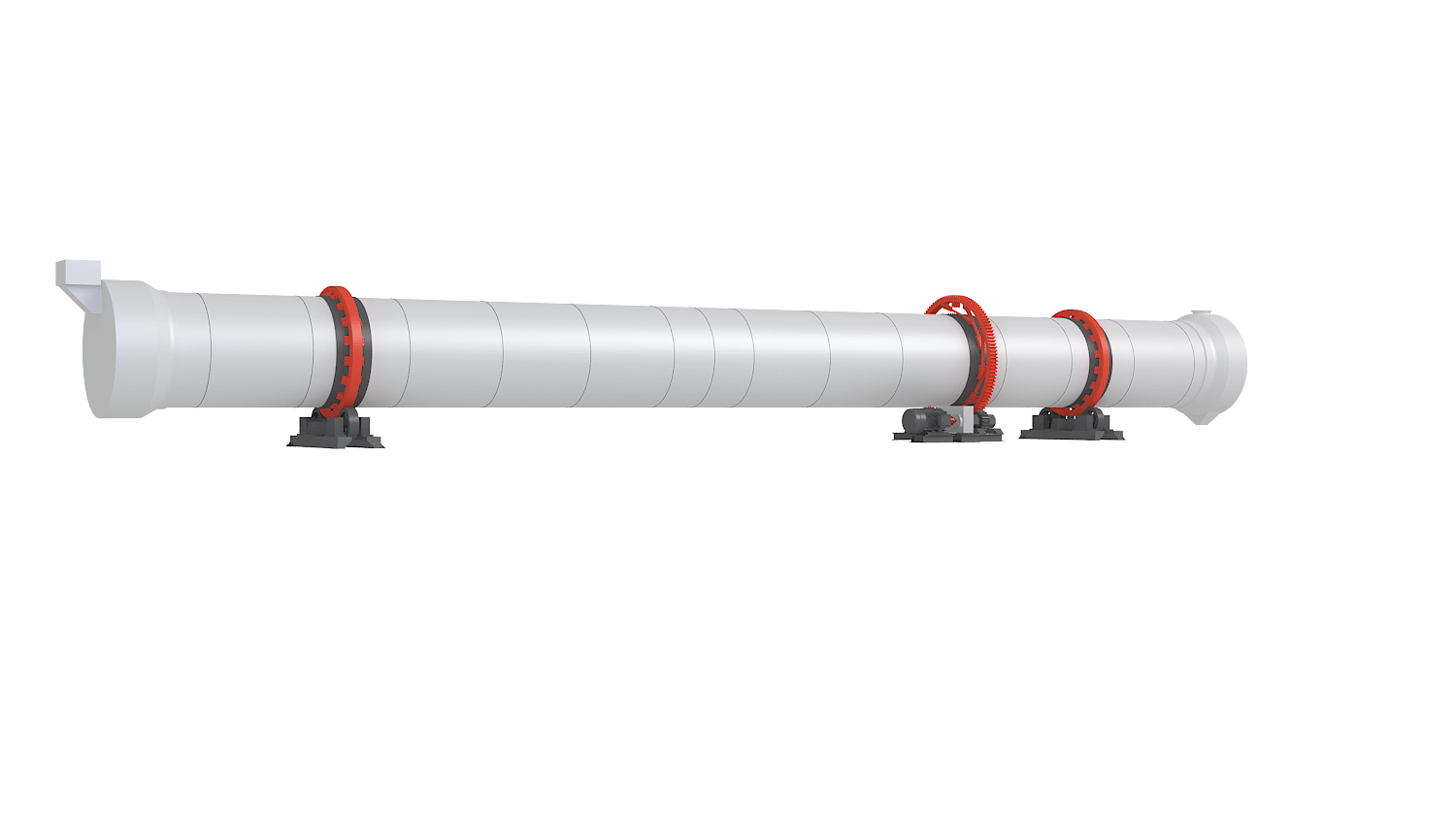

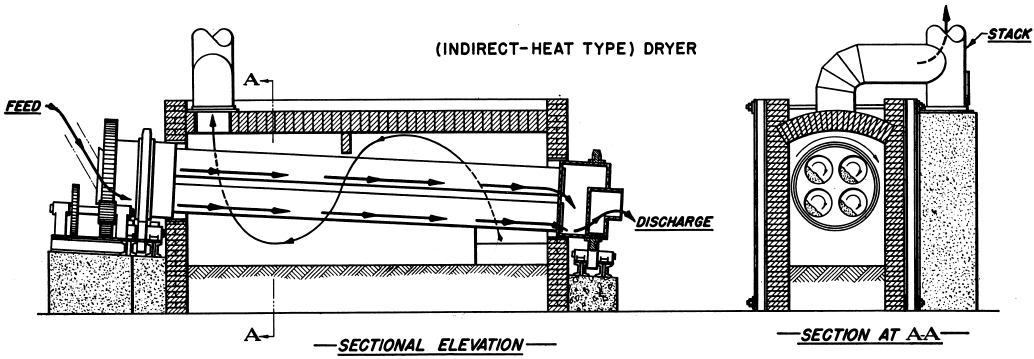

Rotary Dryer works by using a rotating drum to lift and tumble material through a stream of hot air. Wet material is fed into the dryer from one end. As the drum rotates, internal lifting plates continuously raise and scatter the material, increasing the contact surface with the hot gas flow. The heat causes moisture to evaporate, and dried material is gradually pushed toward the discharge end by the rotation and gravity. Moisture-laden exhaust gas exits from the opposite end, often treated by a dust removal system before release. This process ensures continuous, efficient, and uniform drying.