| Model | Matching model | Matching equipment | Feed size (mm) |

Capacity (t/h) |

Overall size (mm) |

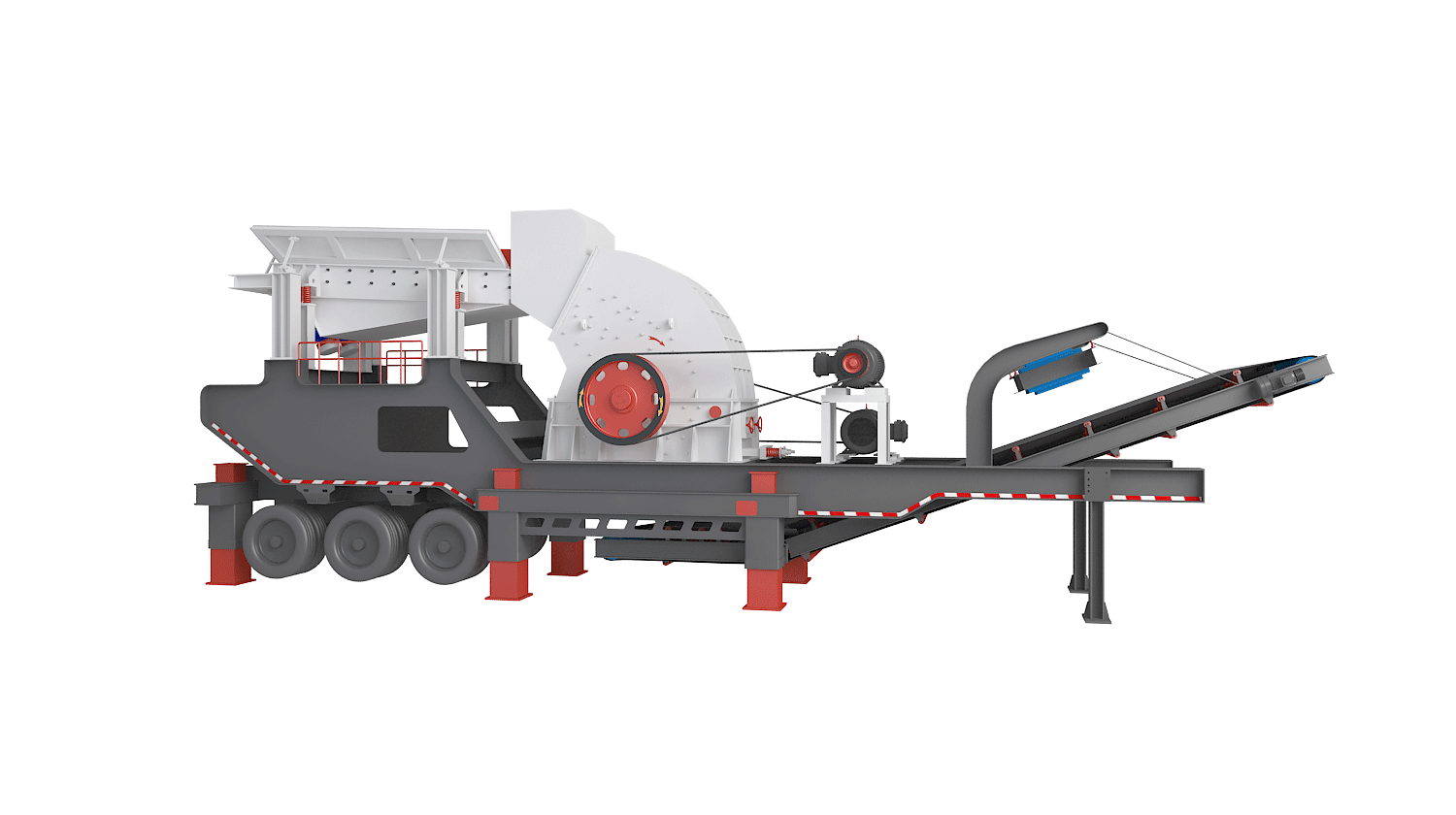

| KLZ-T150 | ZGCX1038 | Z1310 | ≤650 | 150-180 | 13500×2800×4500 |

| KLZ-T300 | ZGCX1238 | Z1512 | ≤750 | 250-320 | 13900×2800×5200 |

| KLZ-2470 | 4YK2470 | - | - | 150-280 | 14700×4200×7500 |

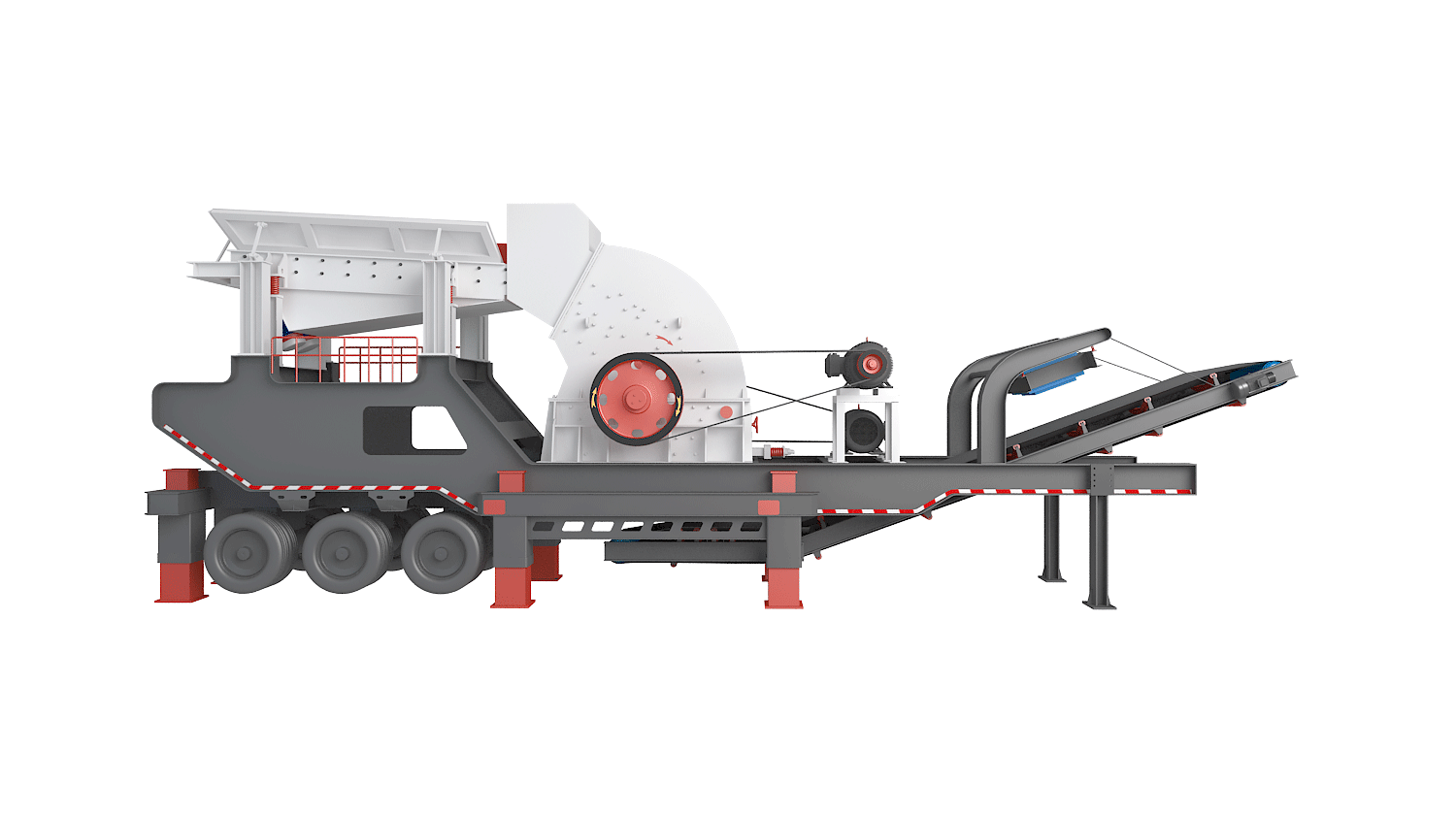

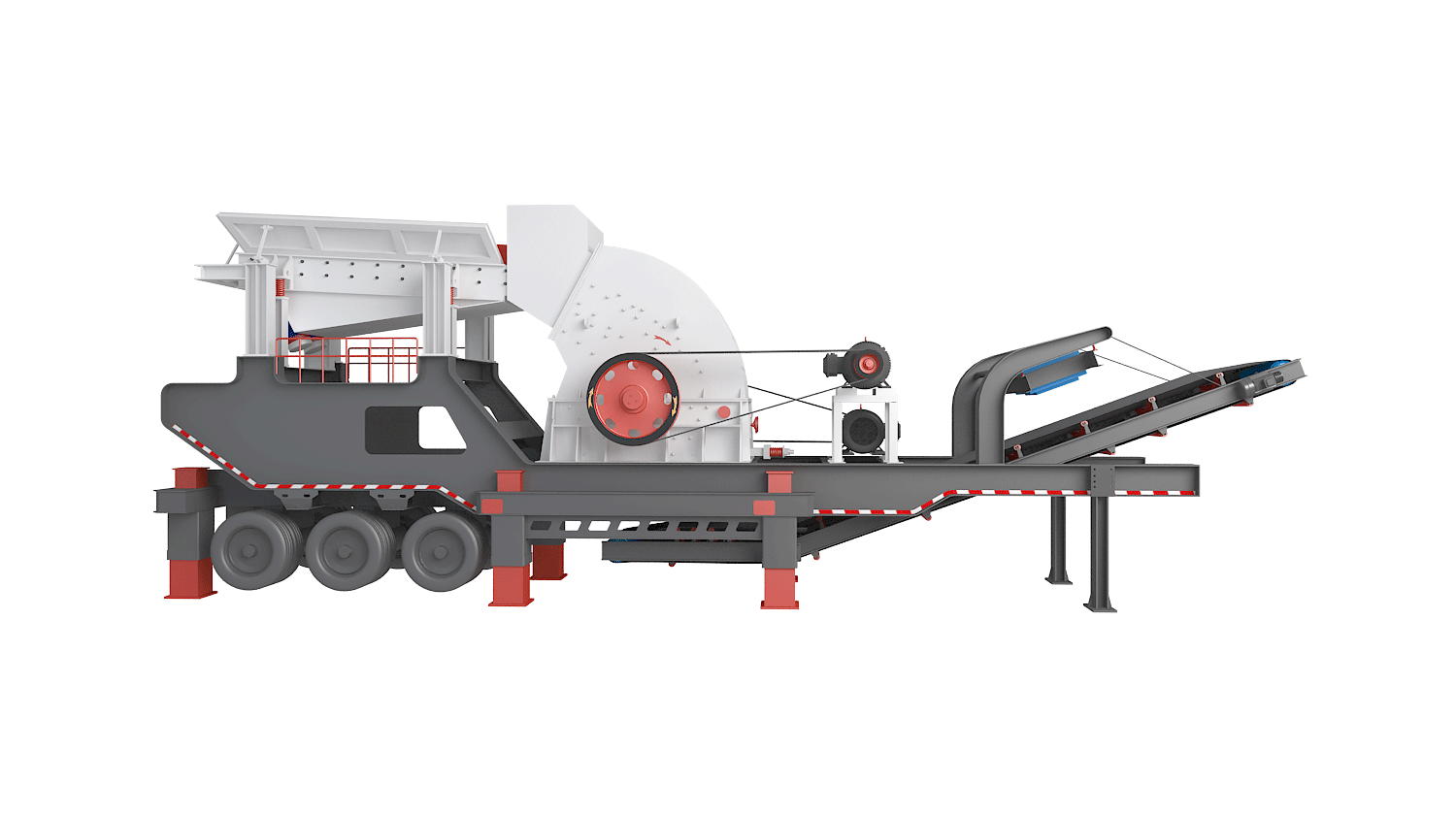

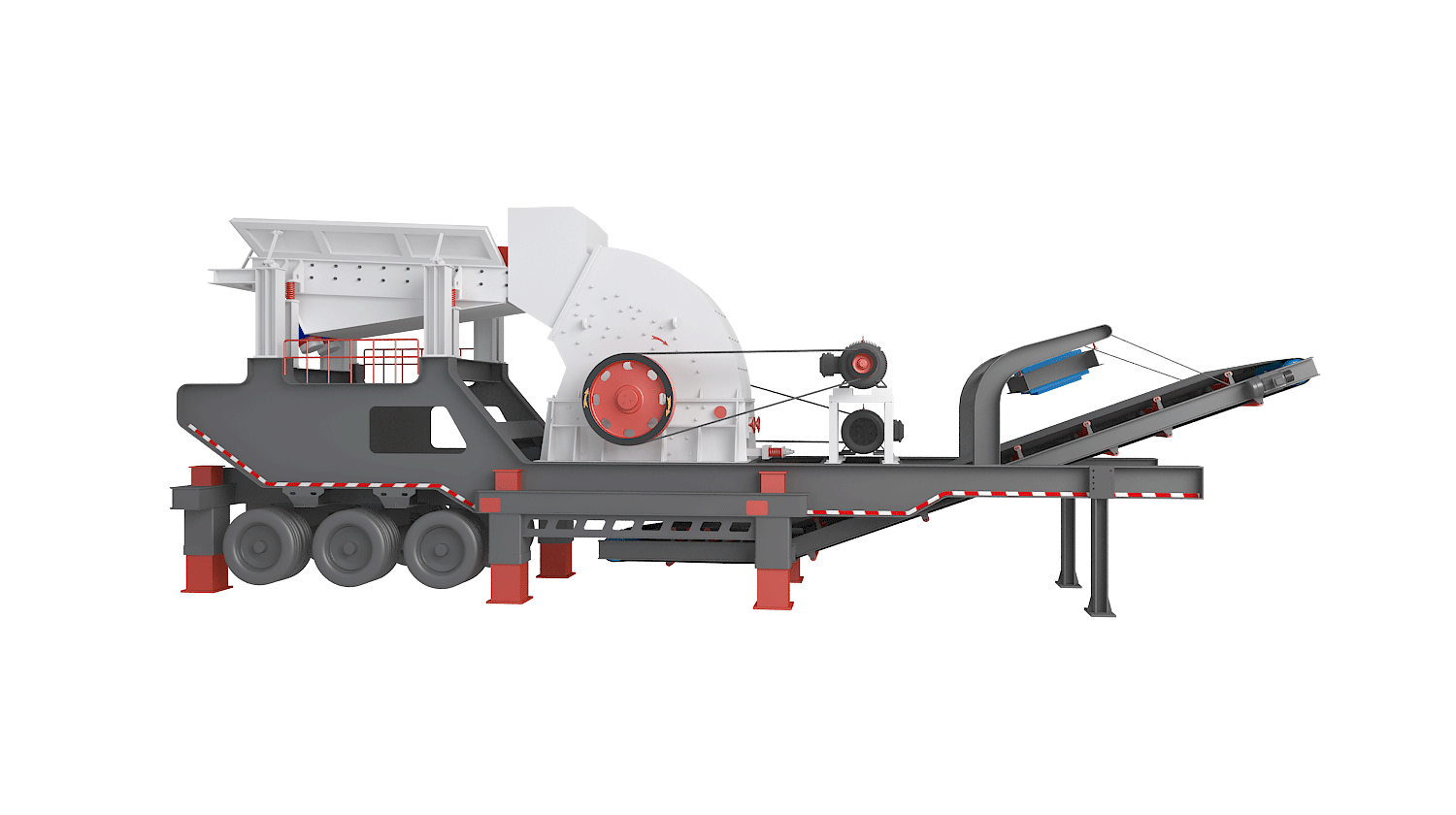

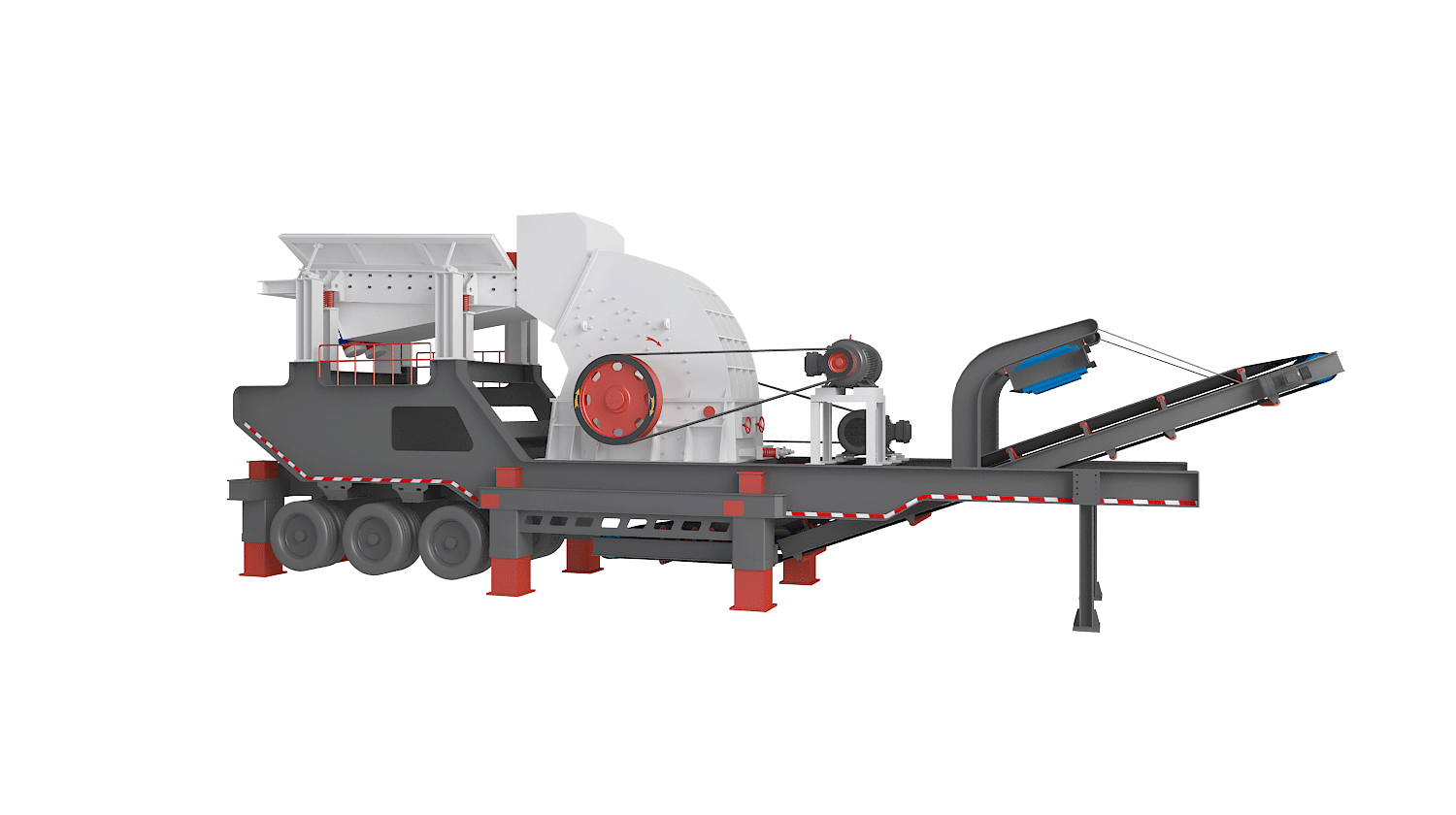

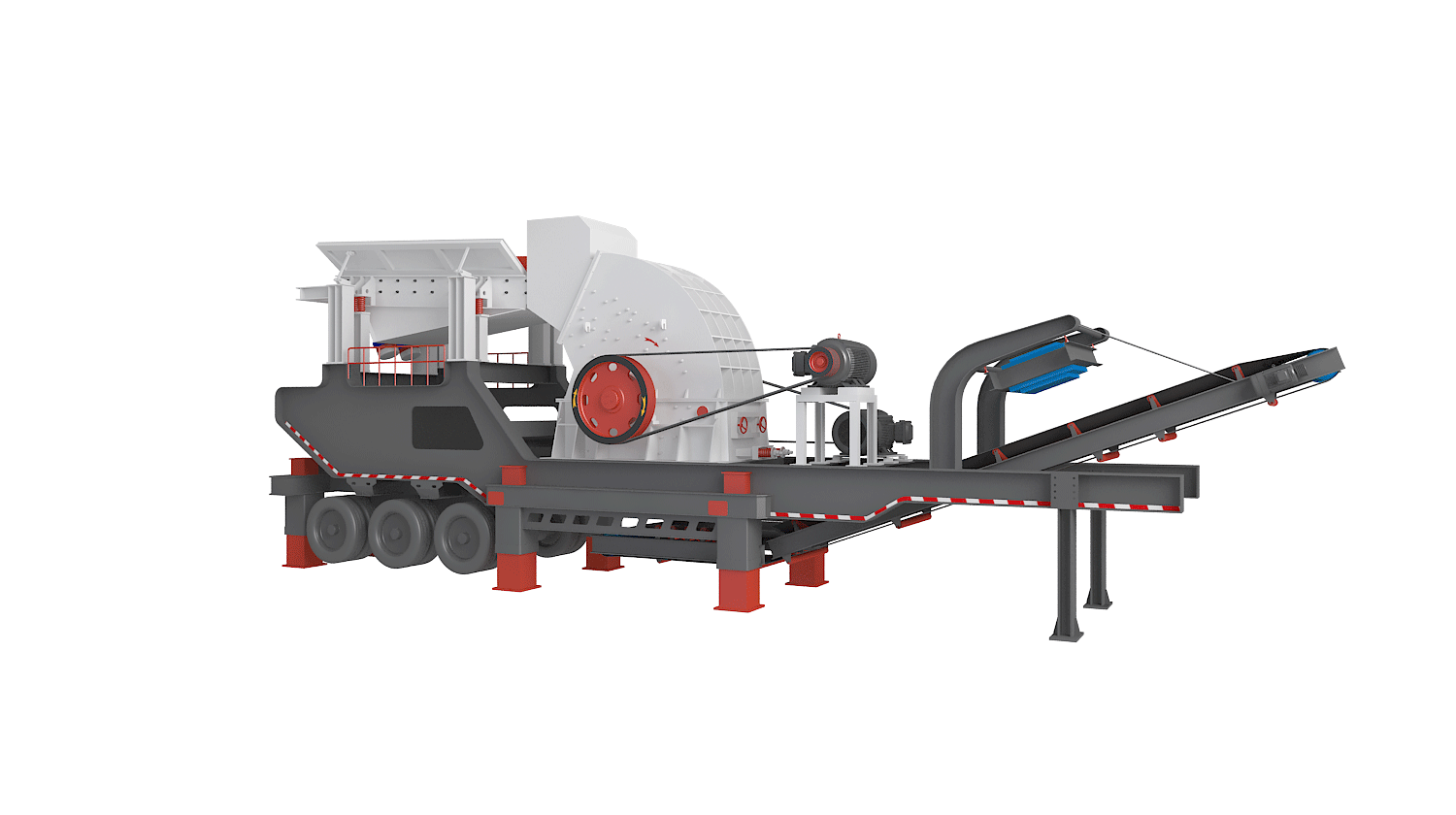

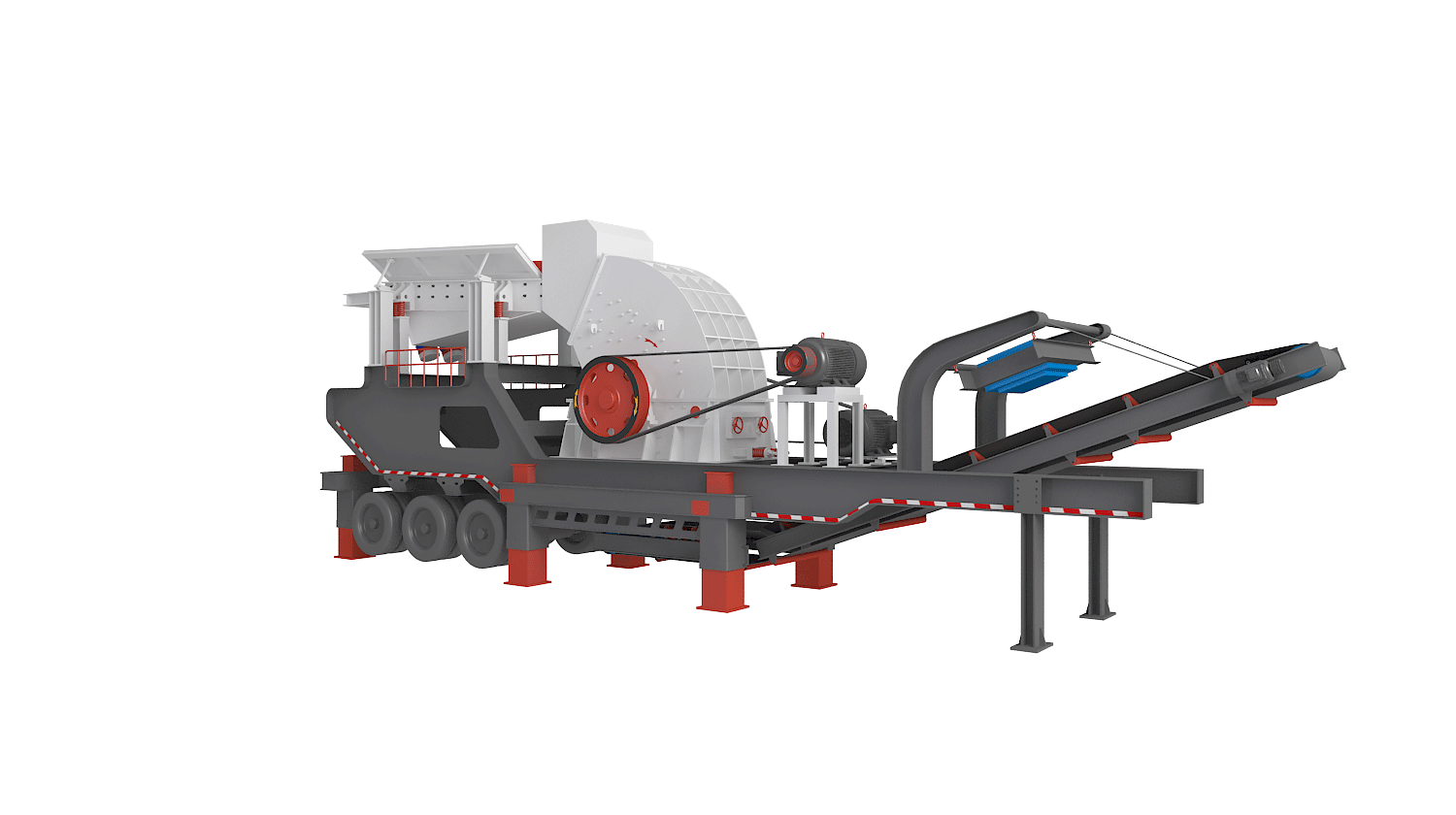

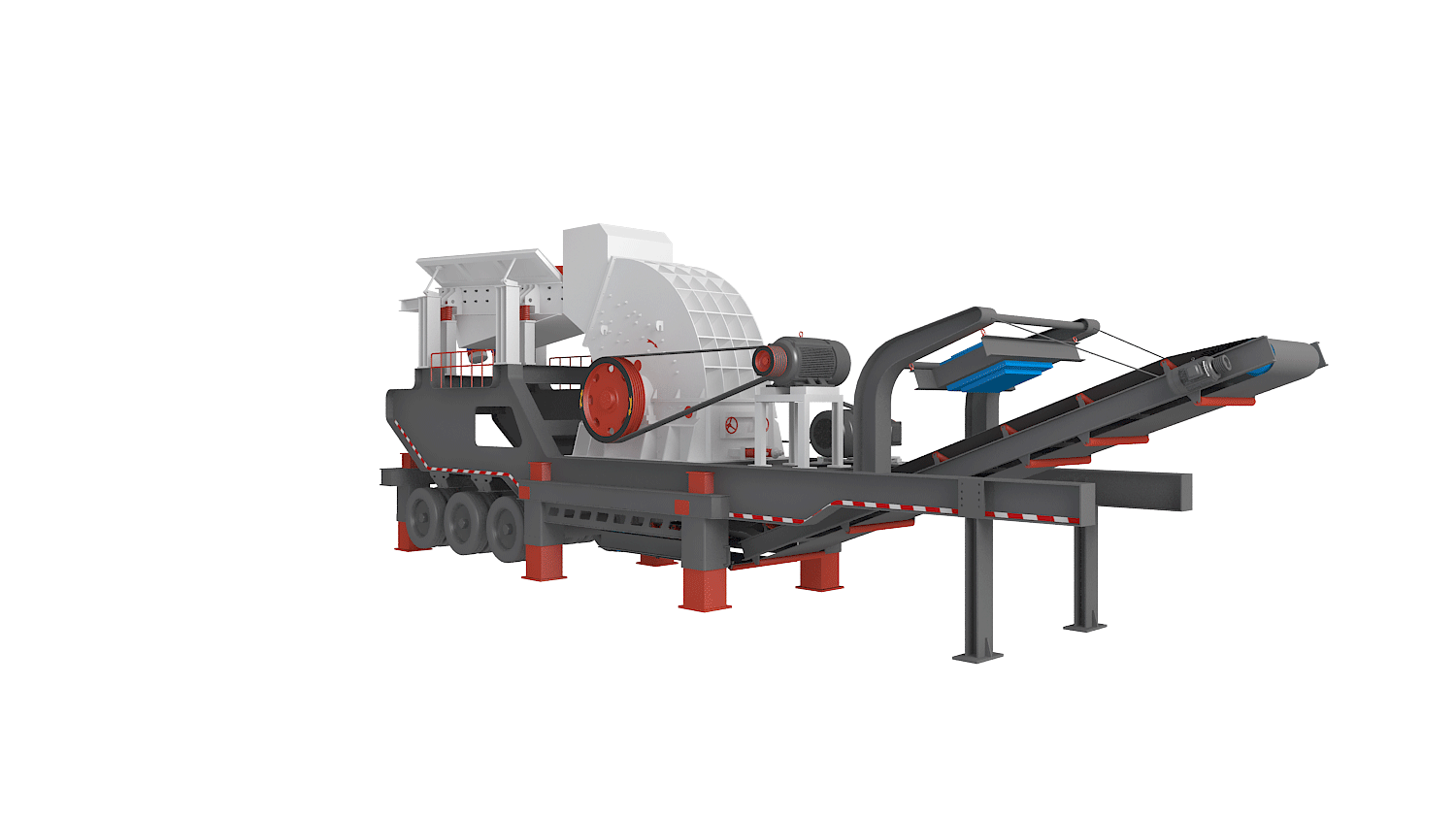

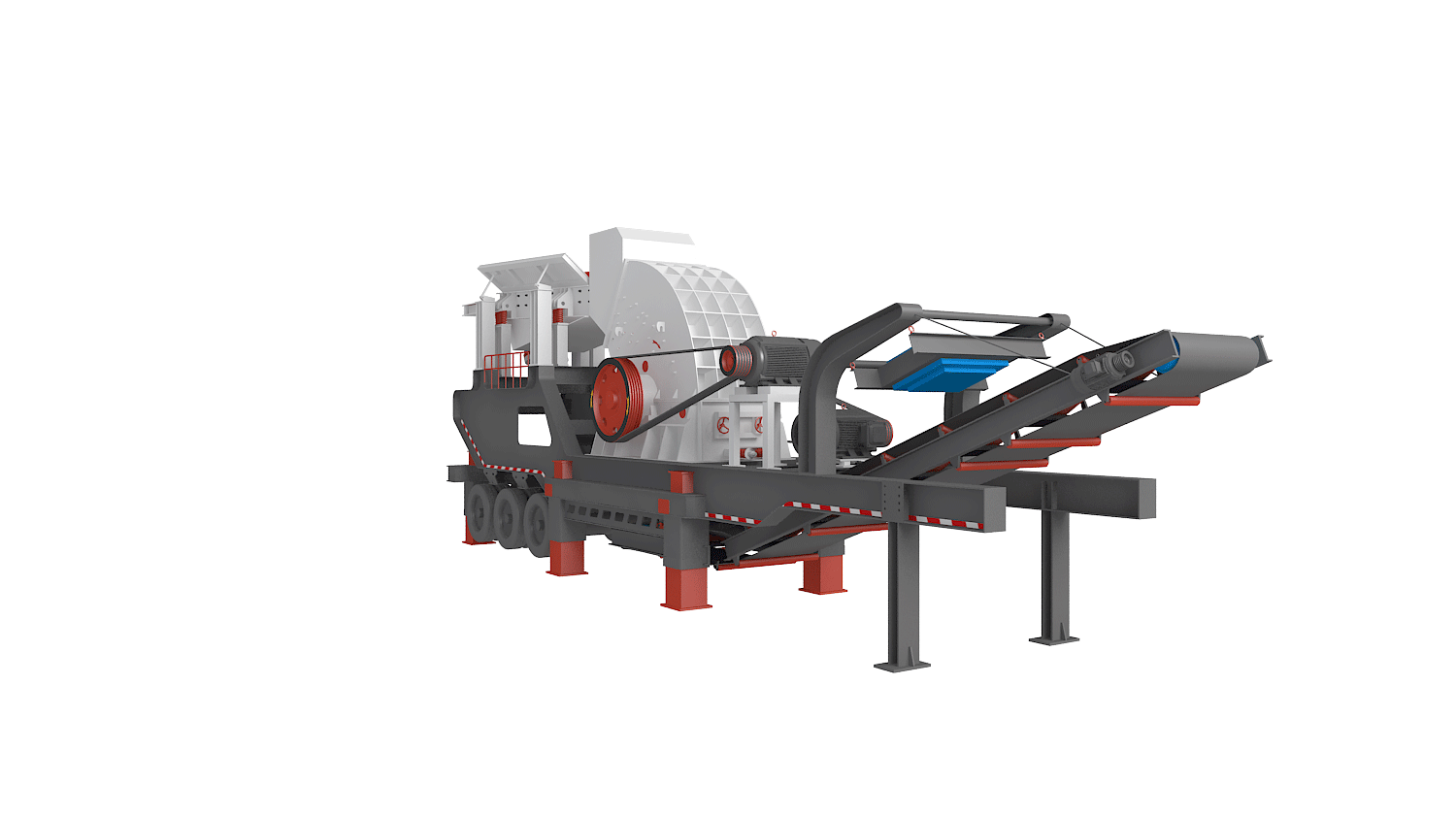

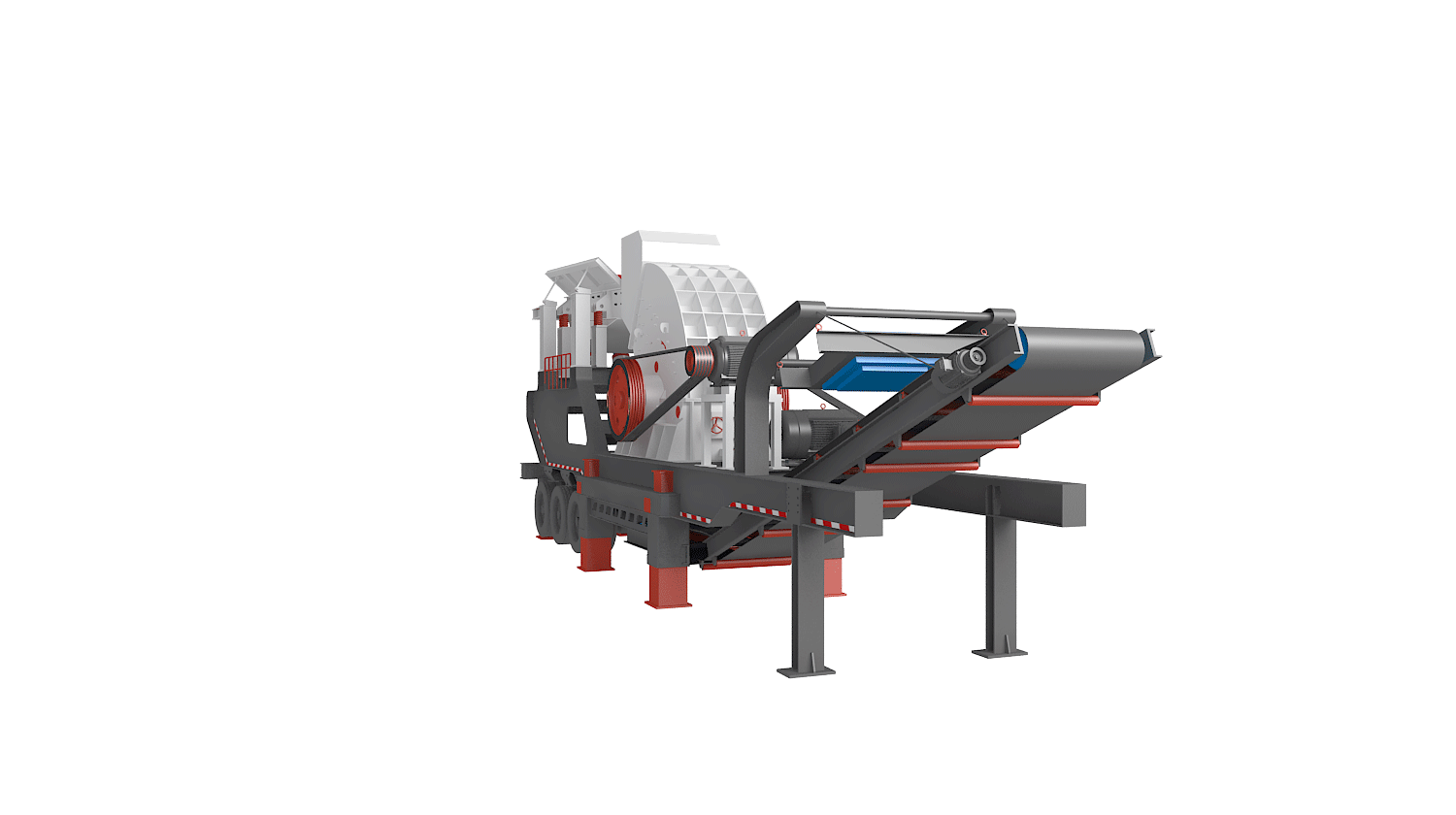

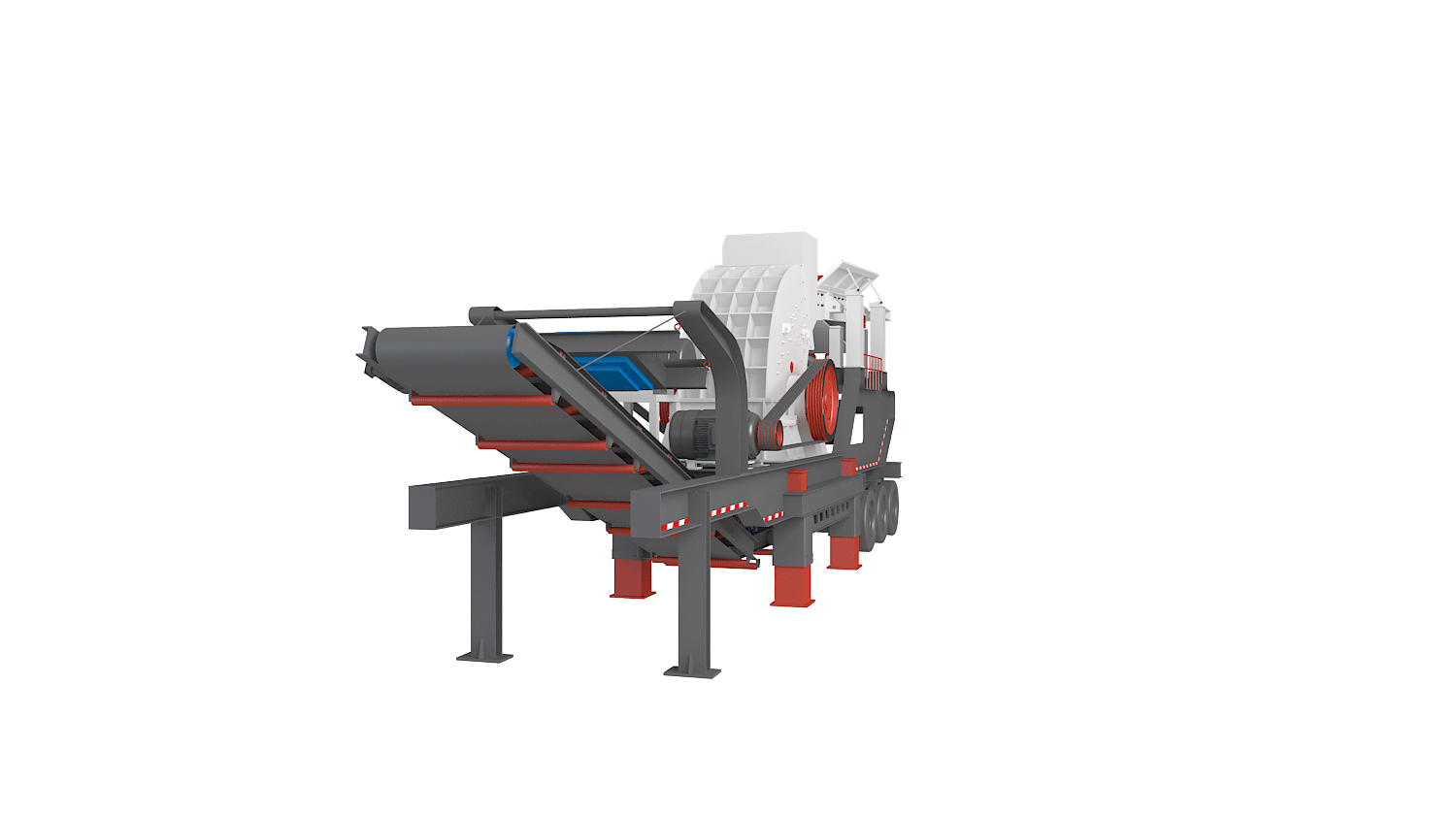

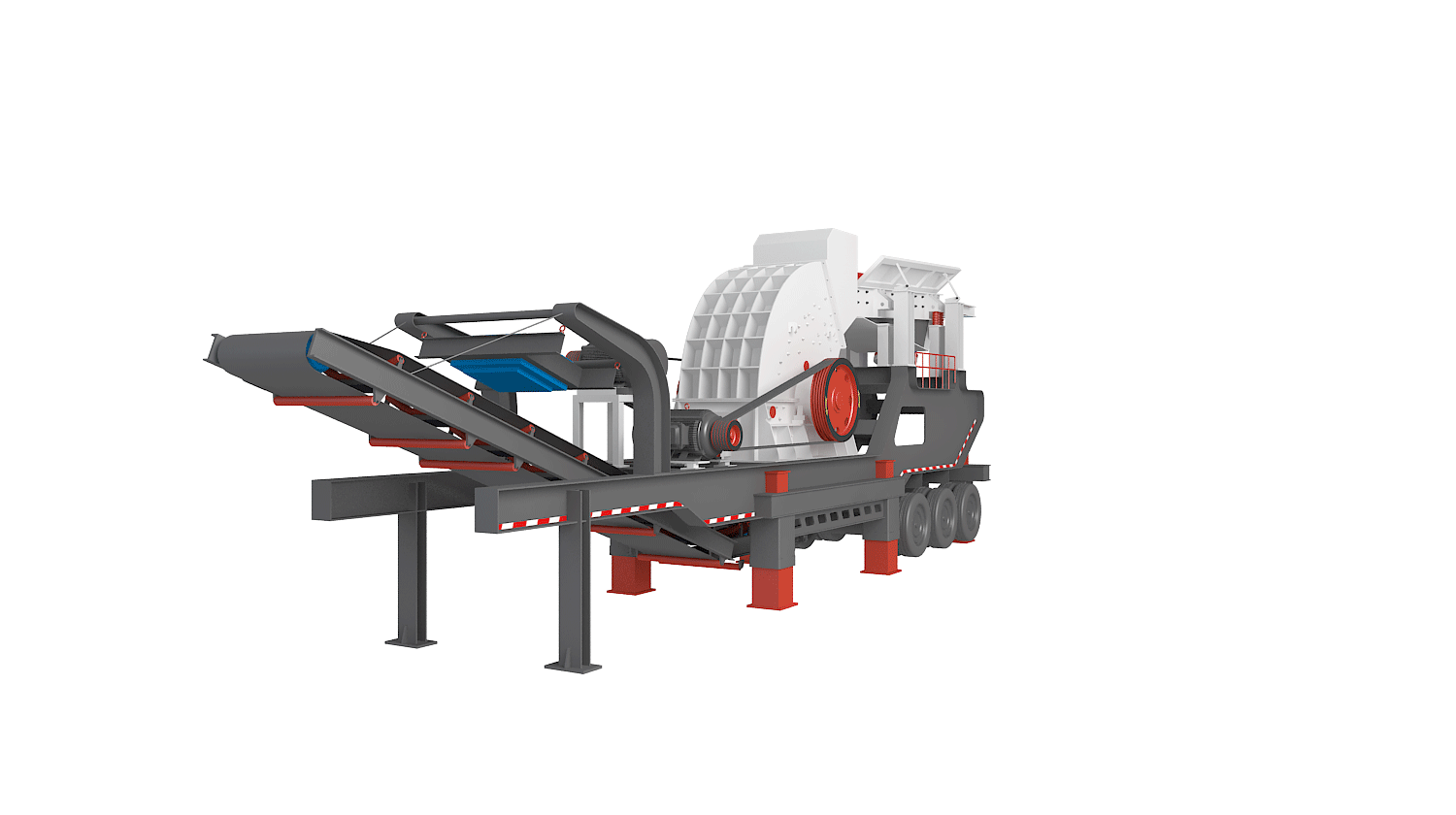

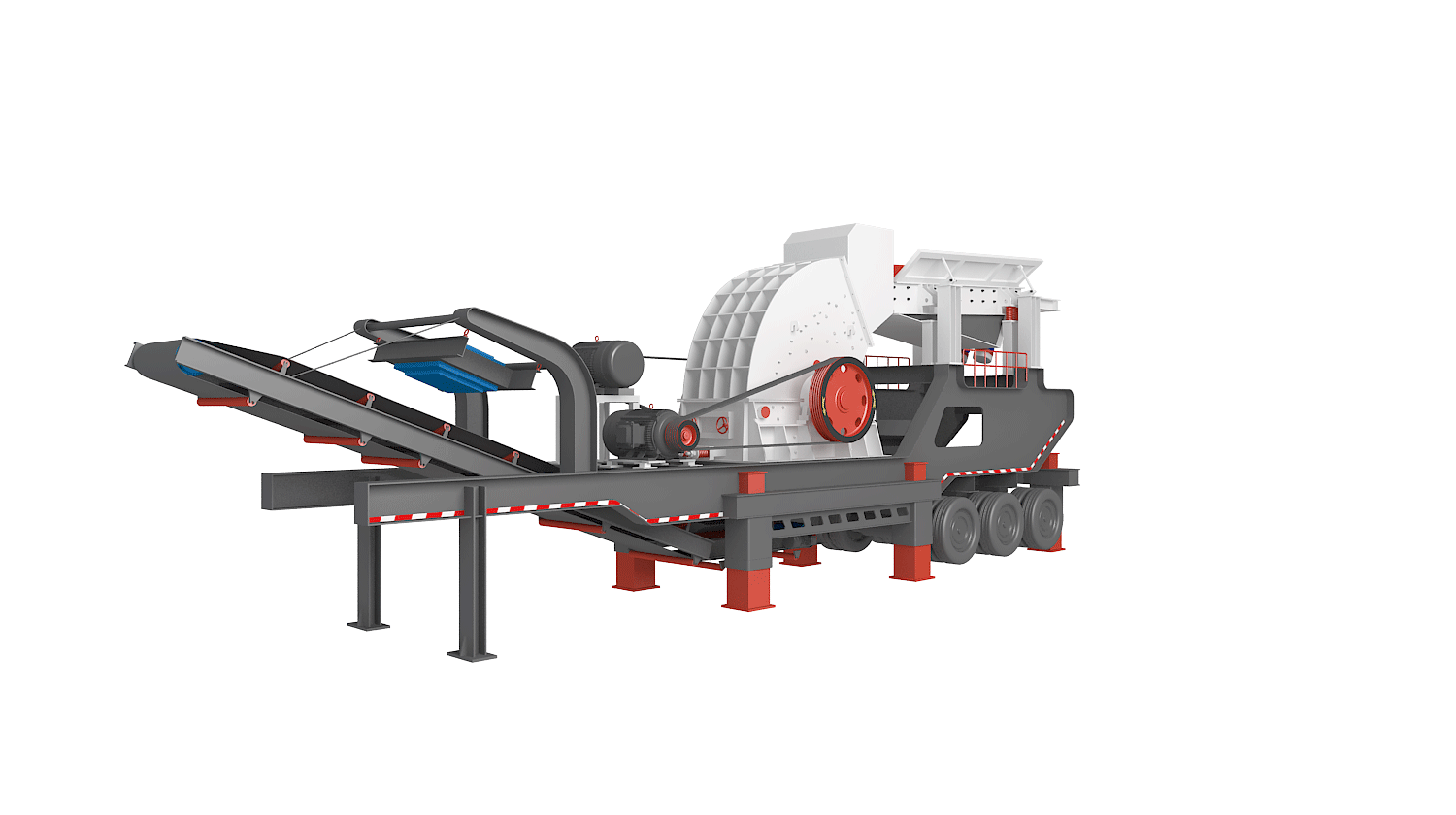

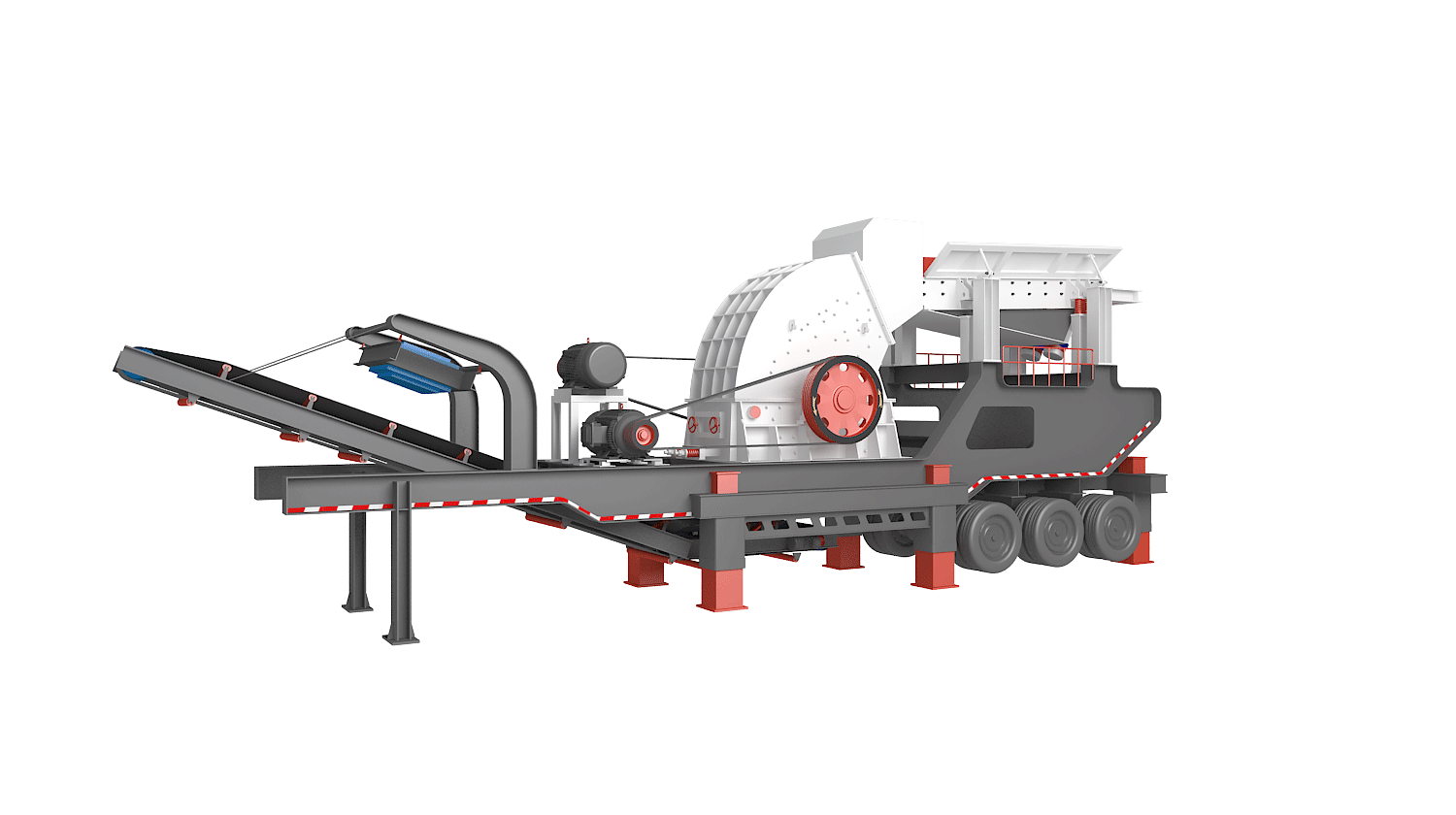

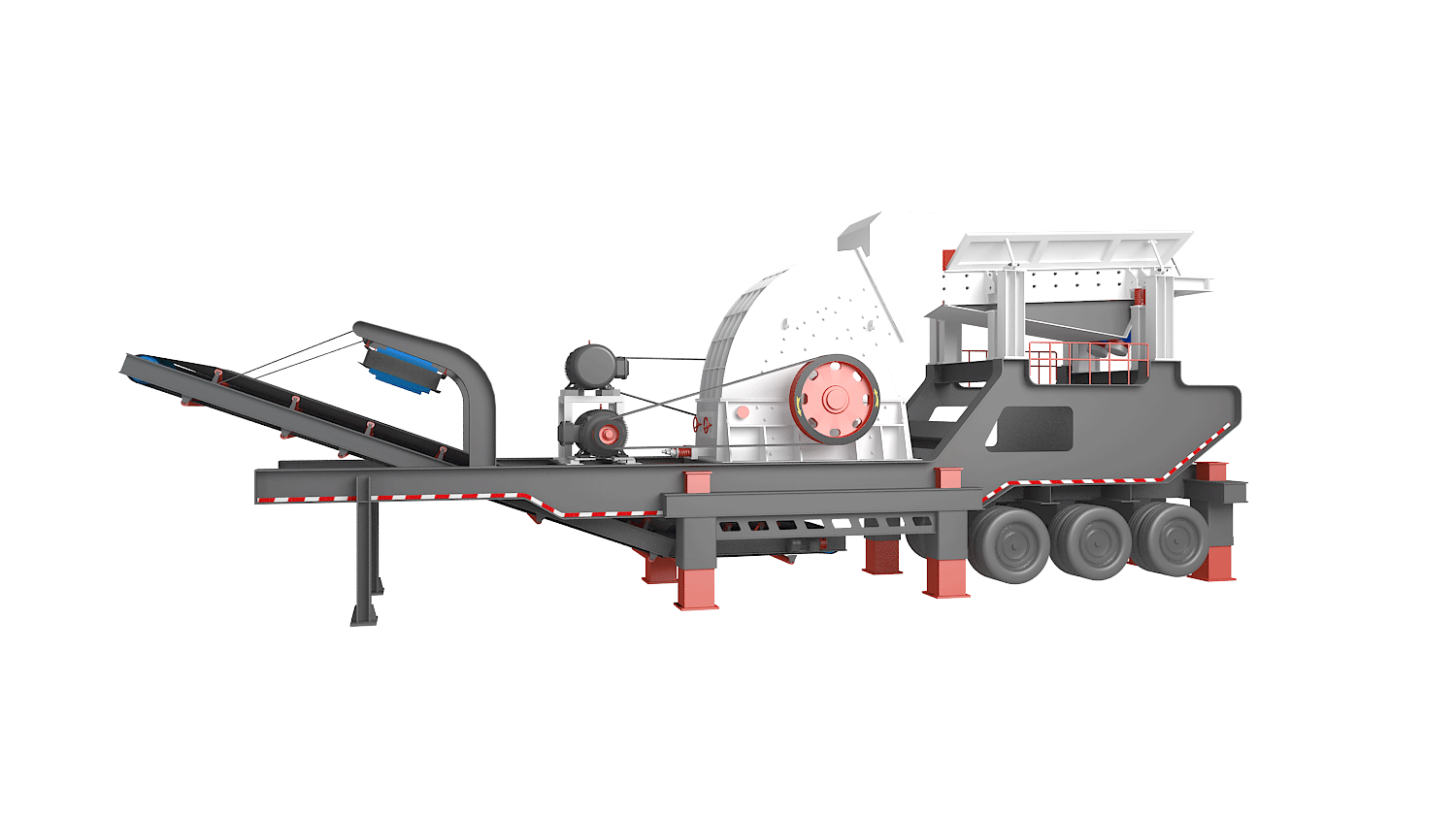

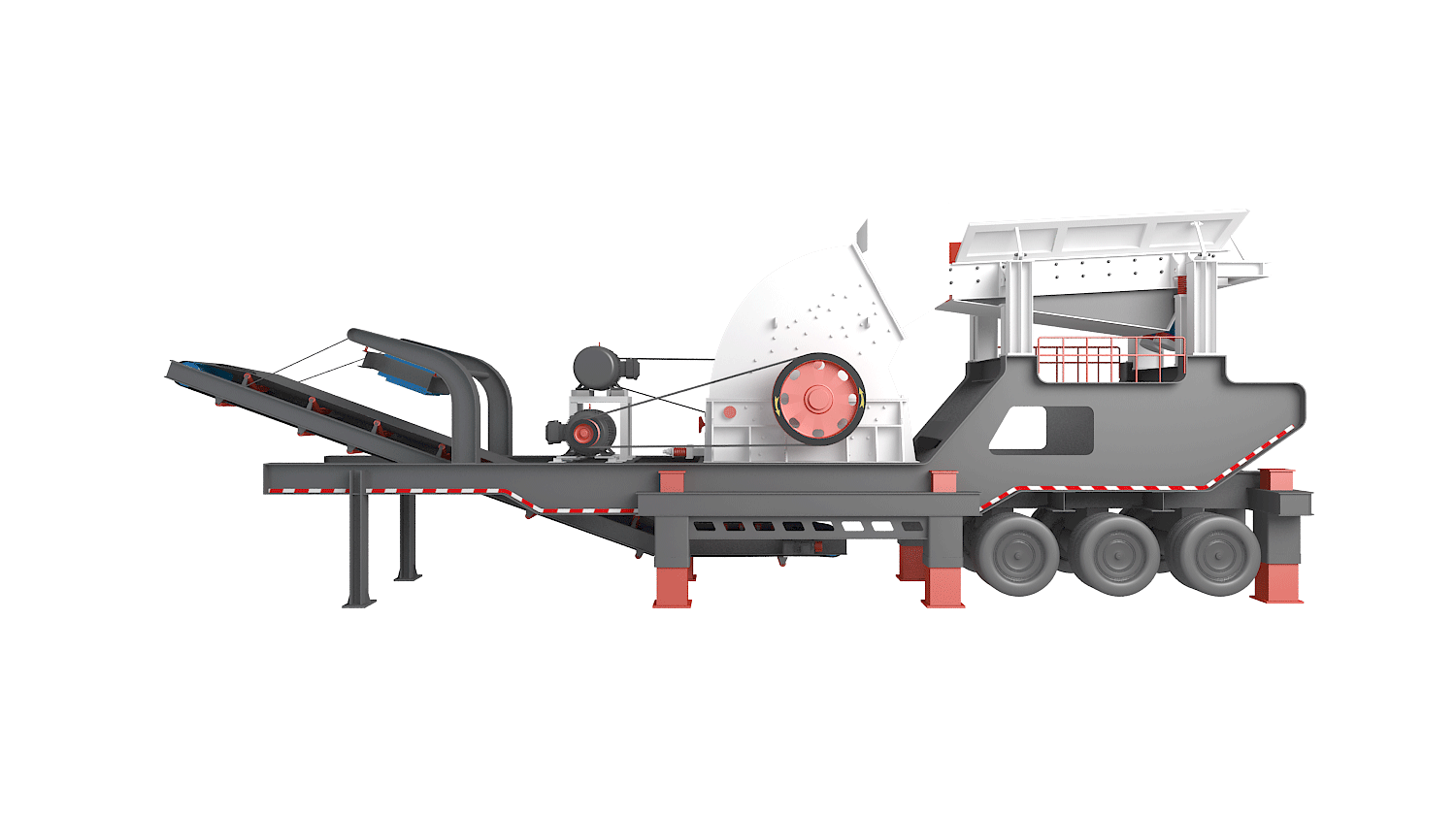

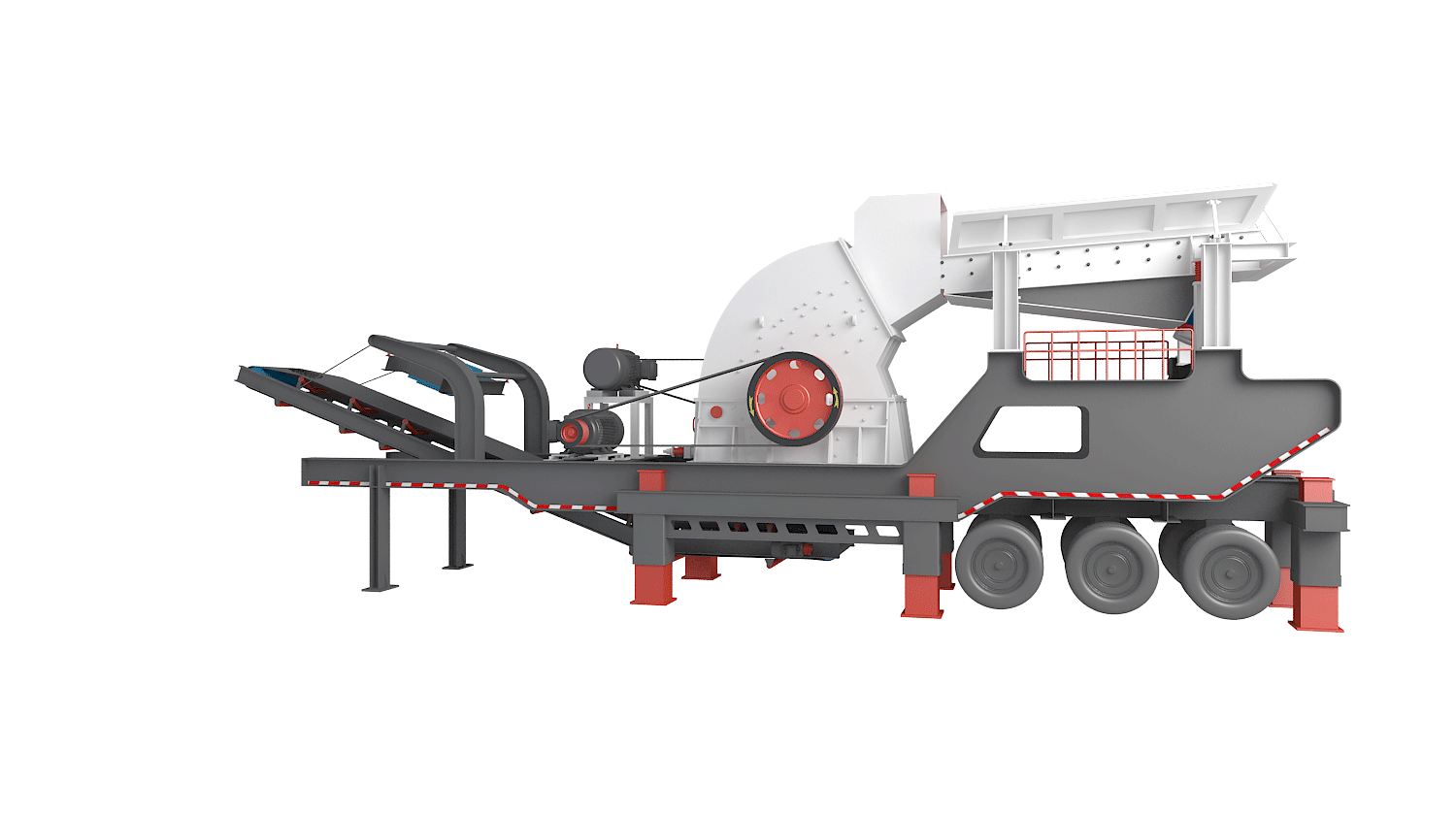

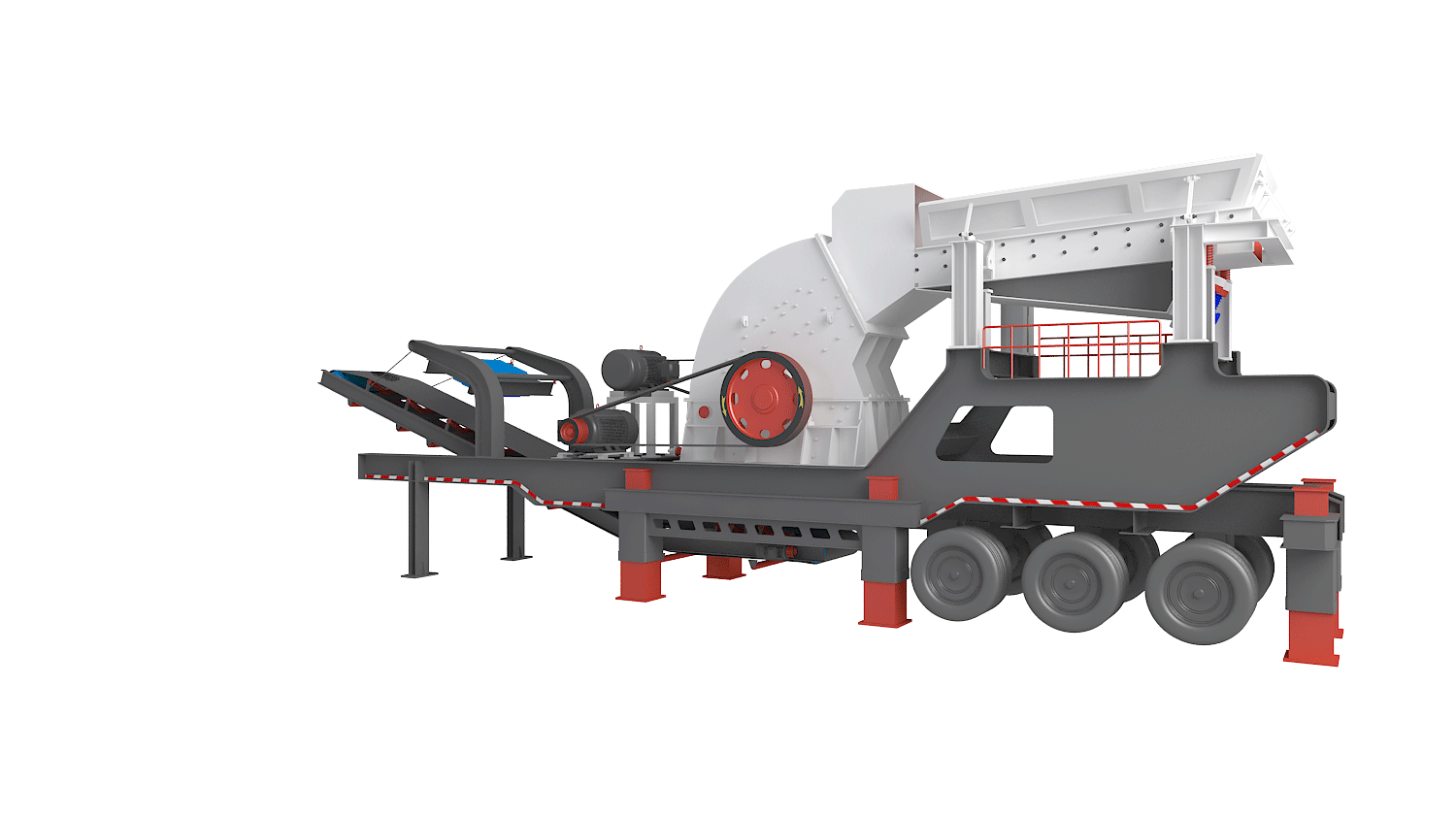

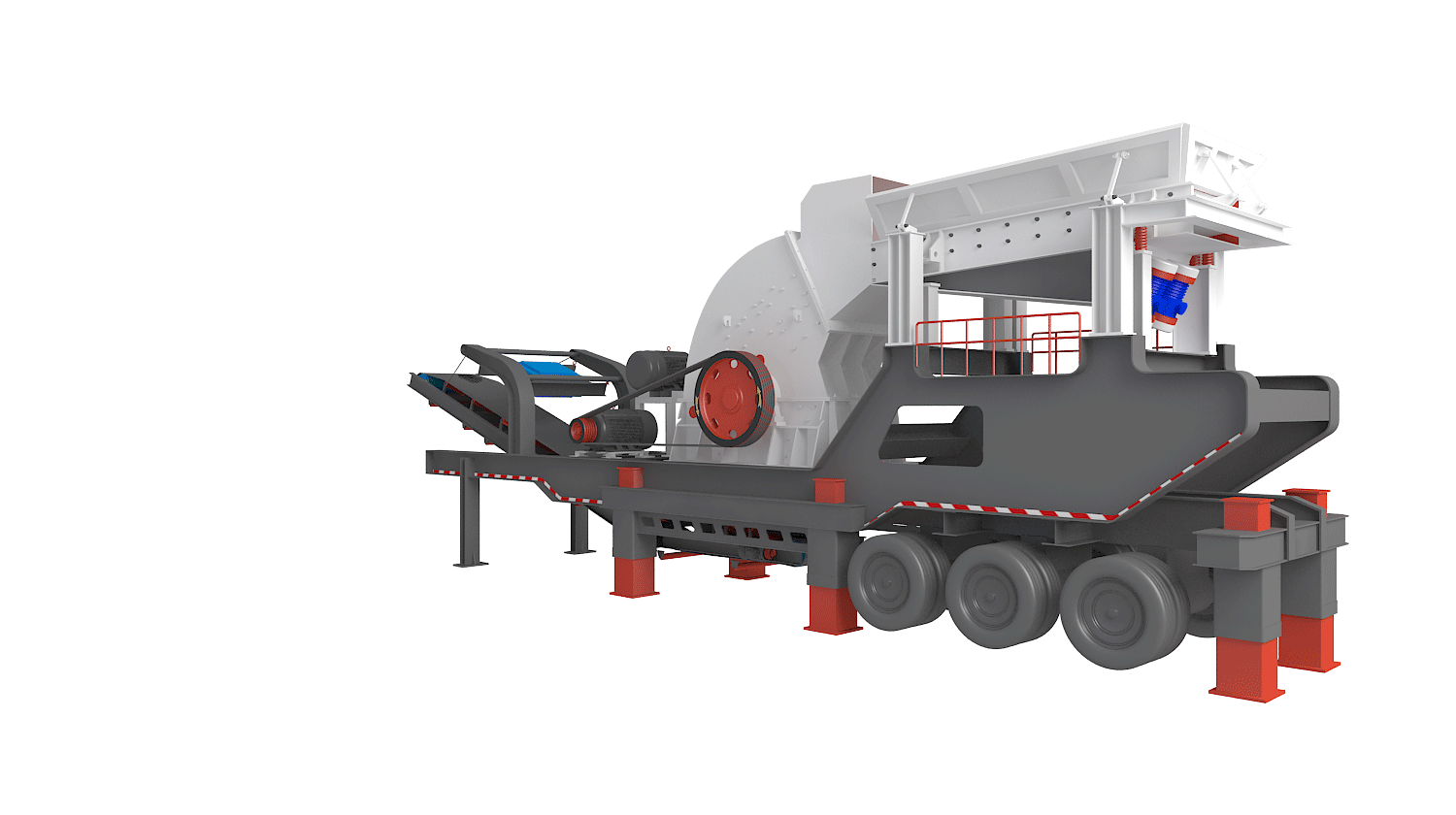

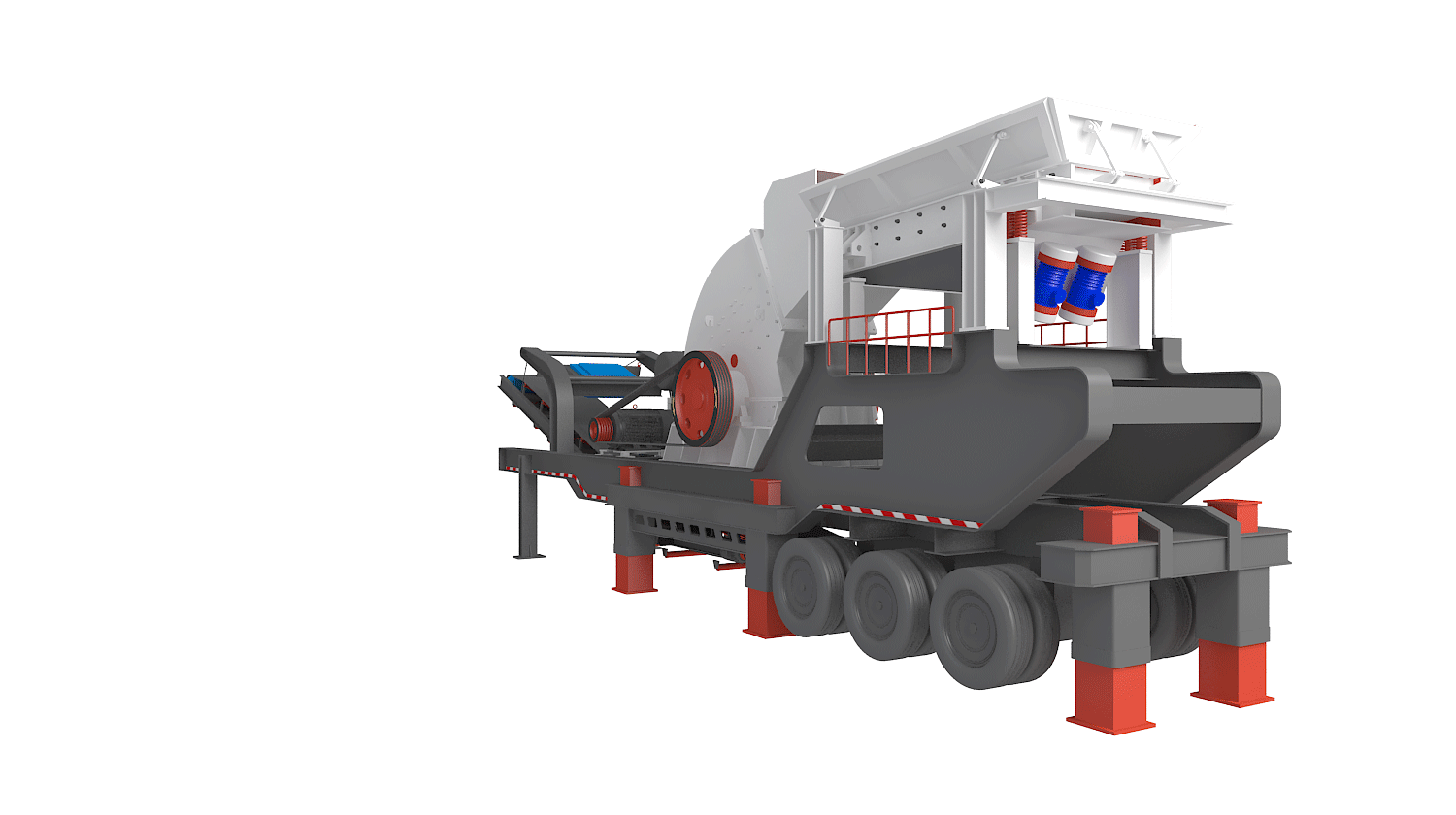

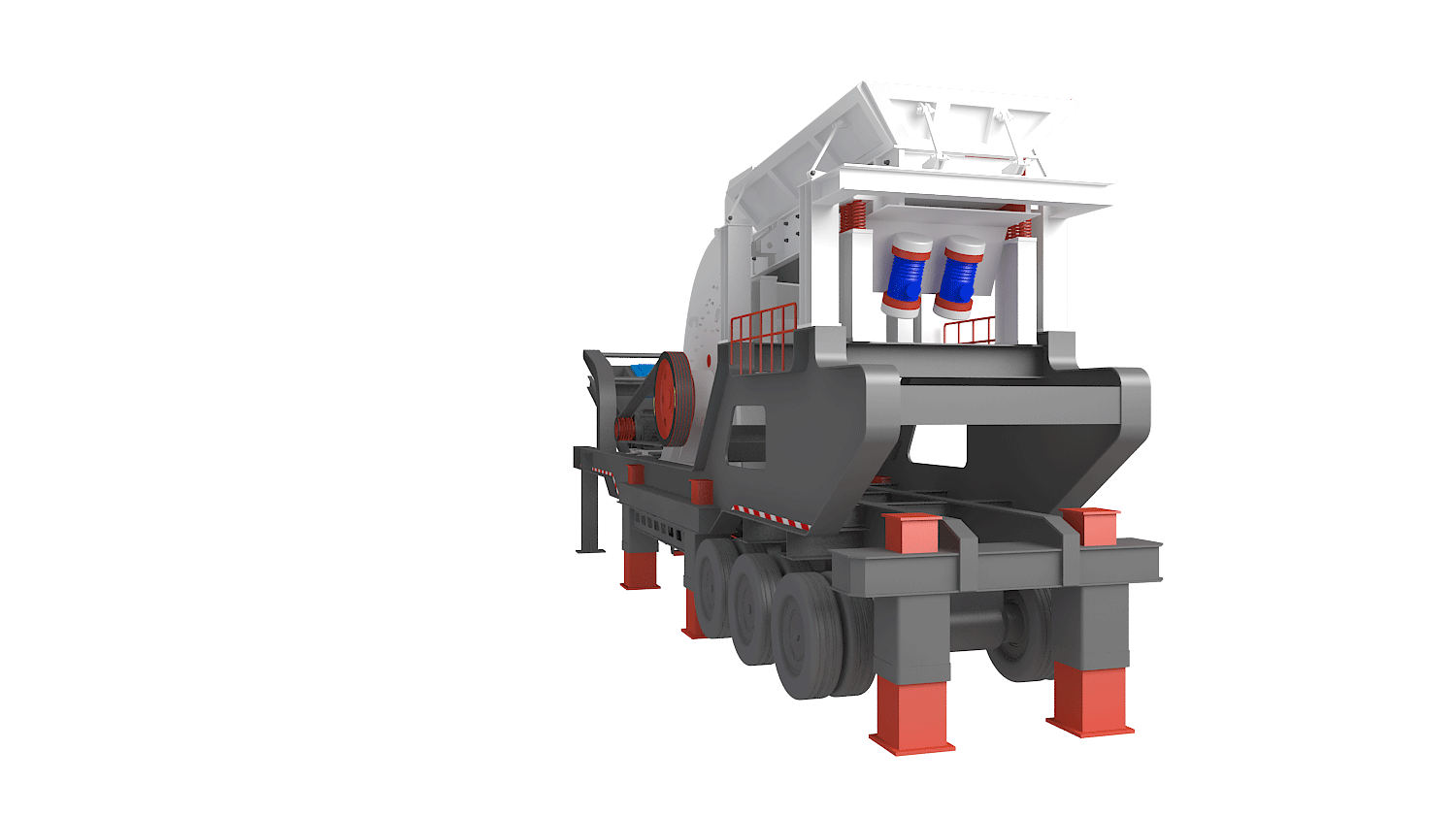

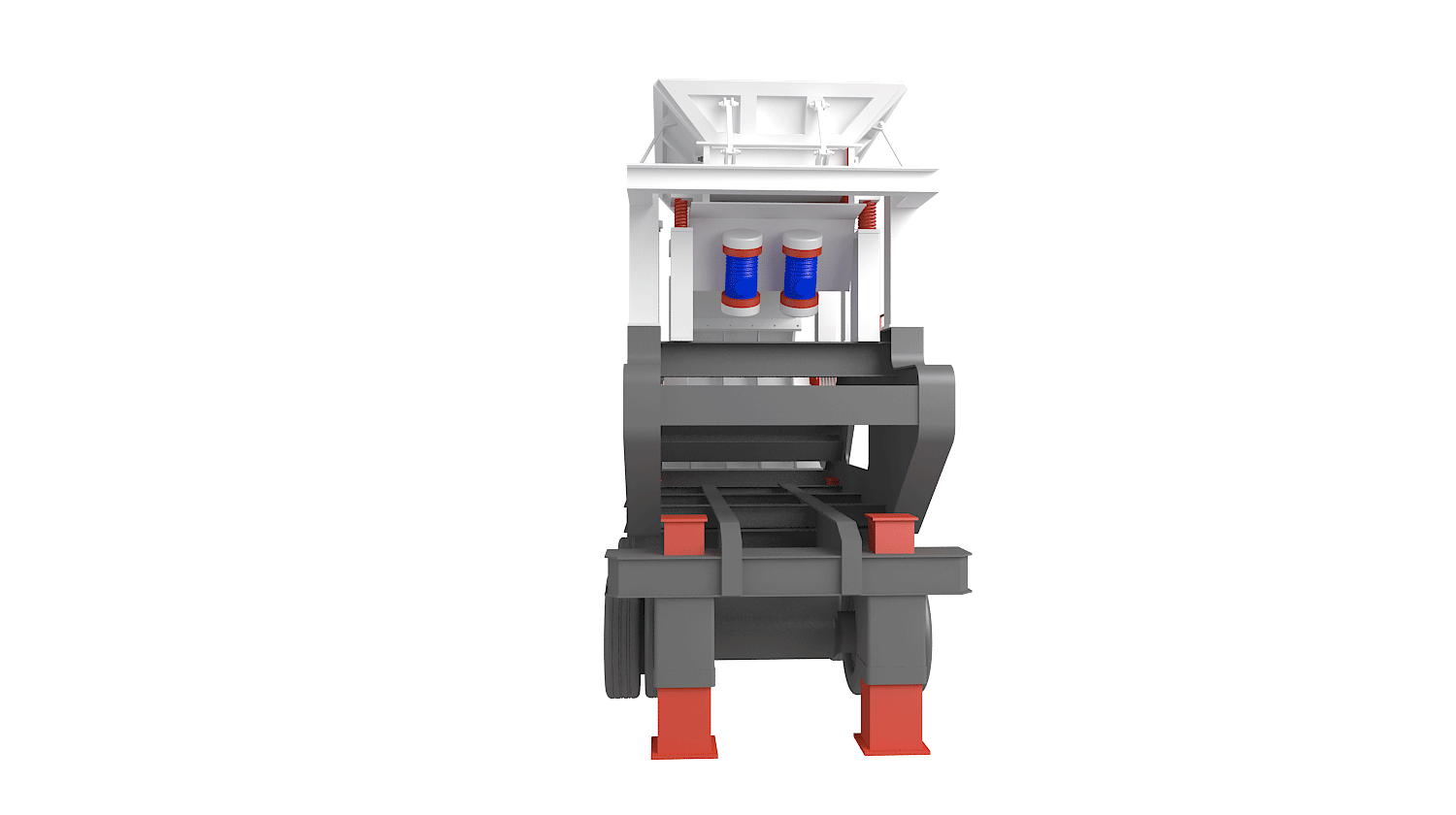

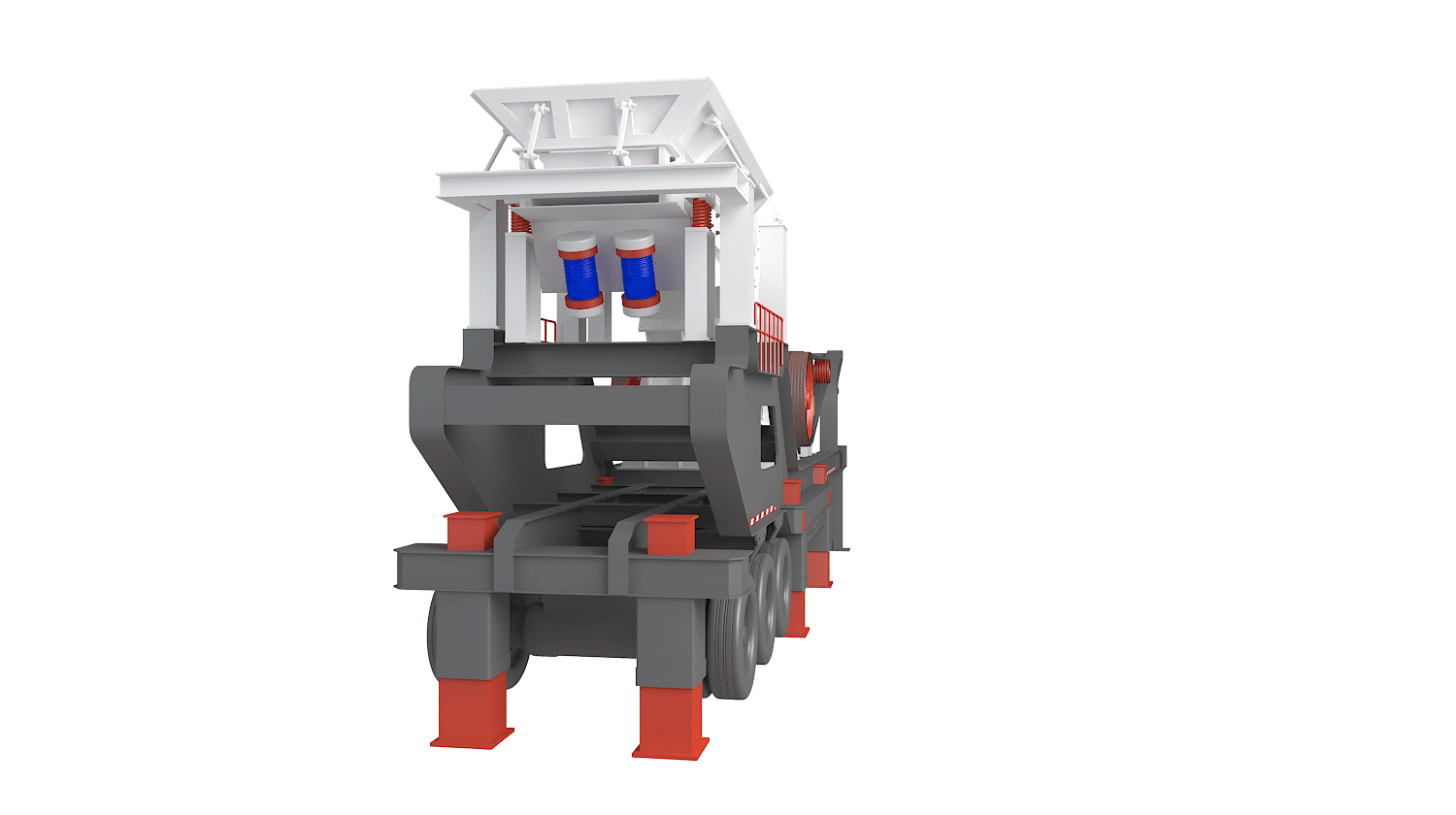

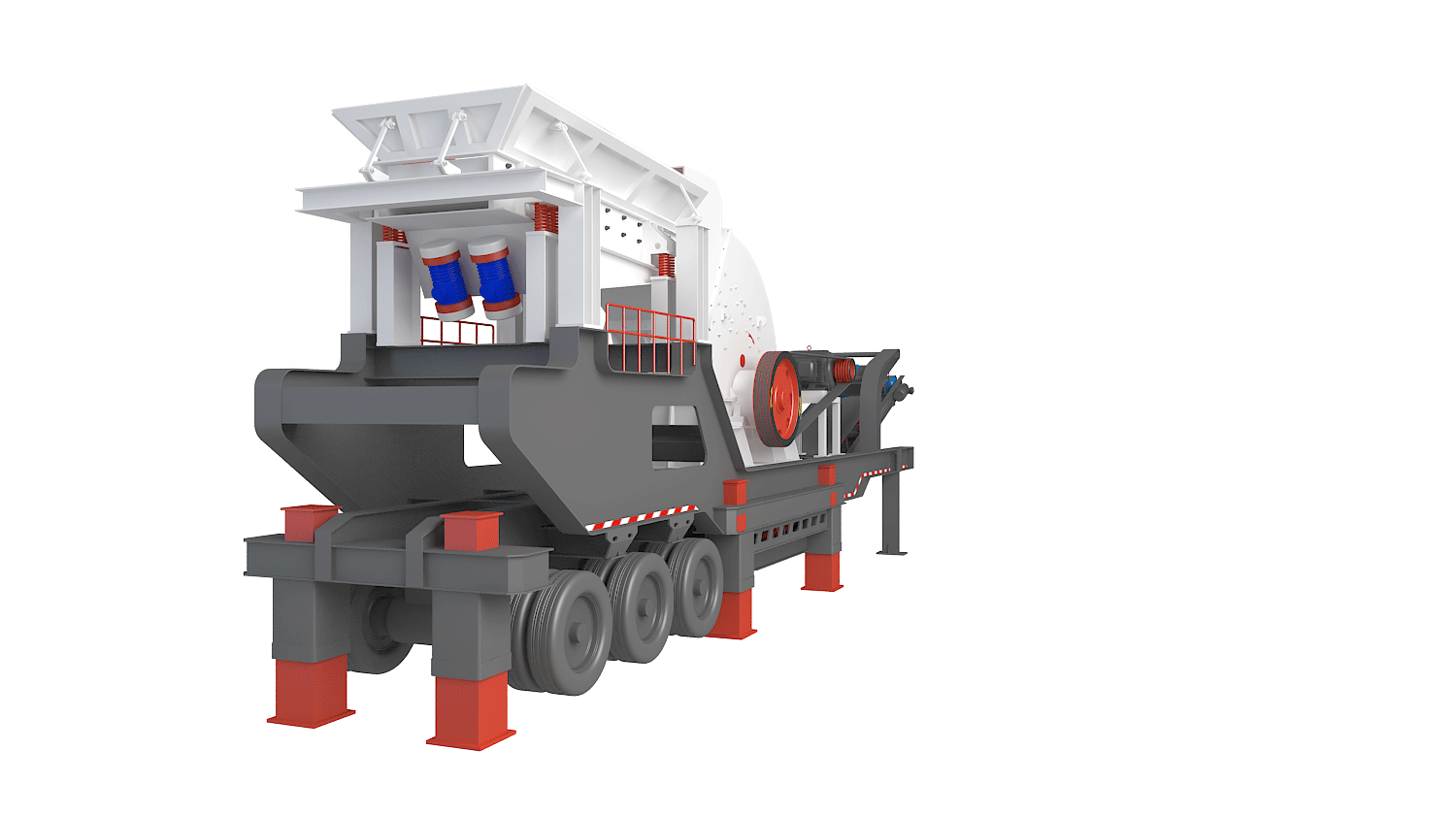

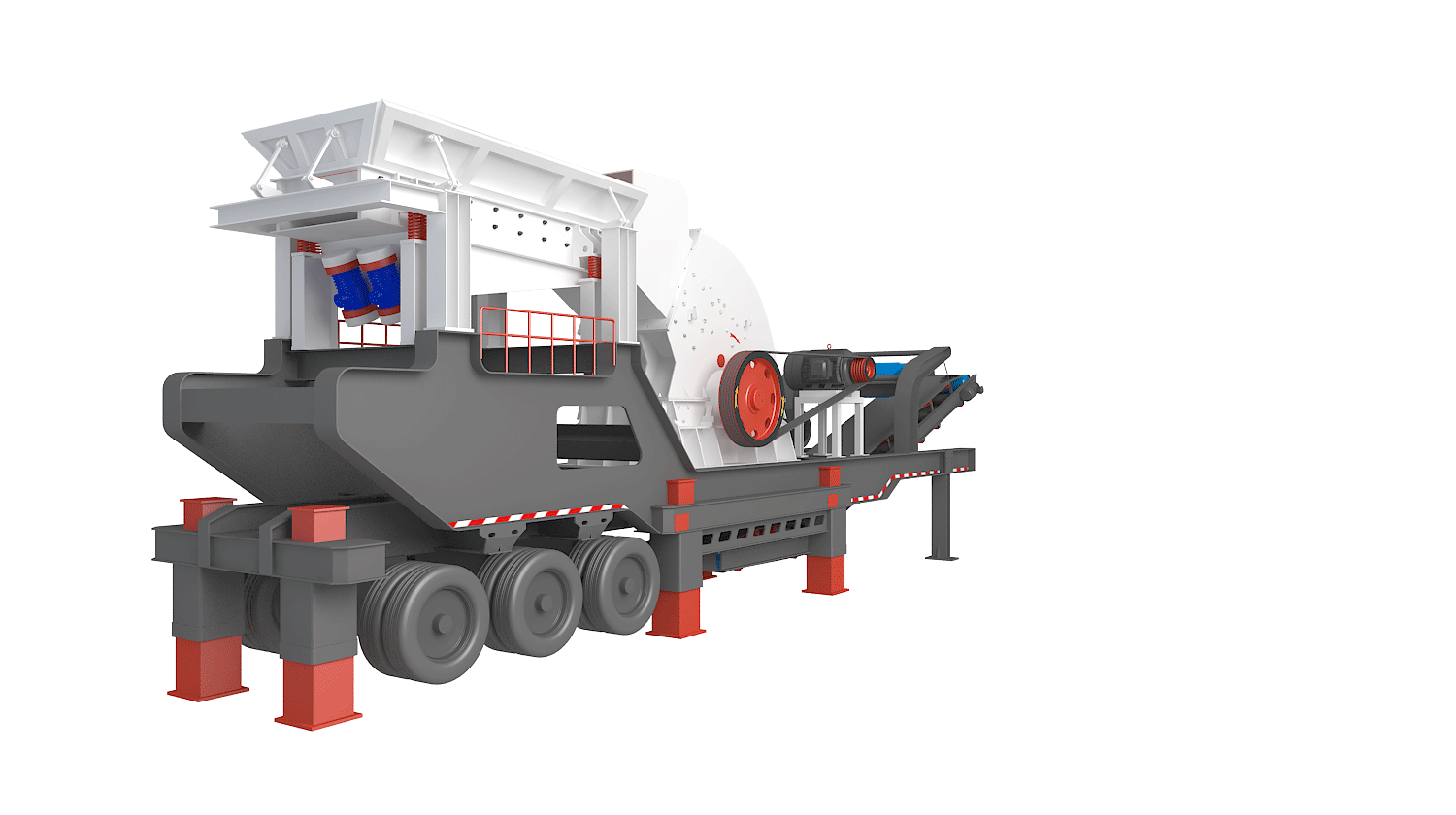

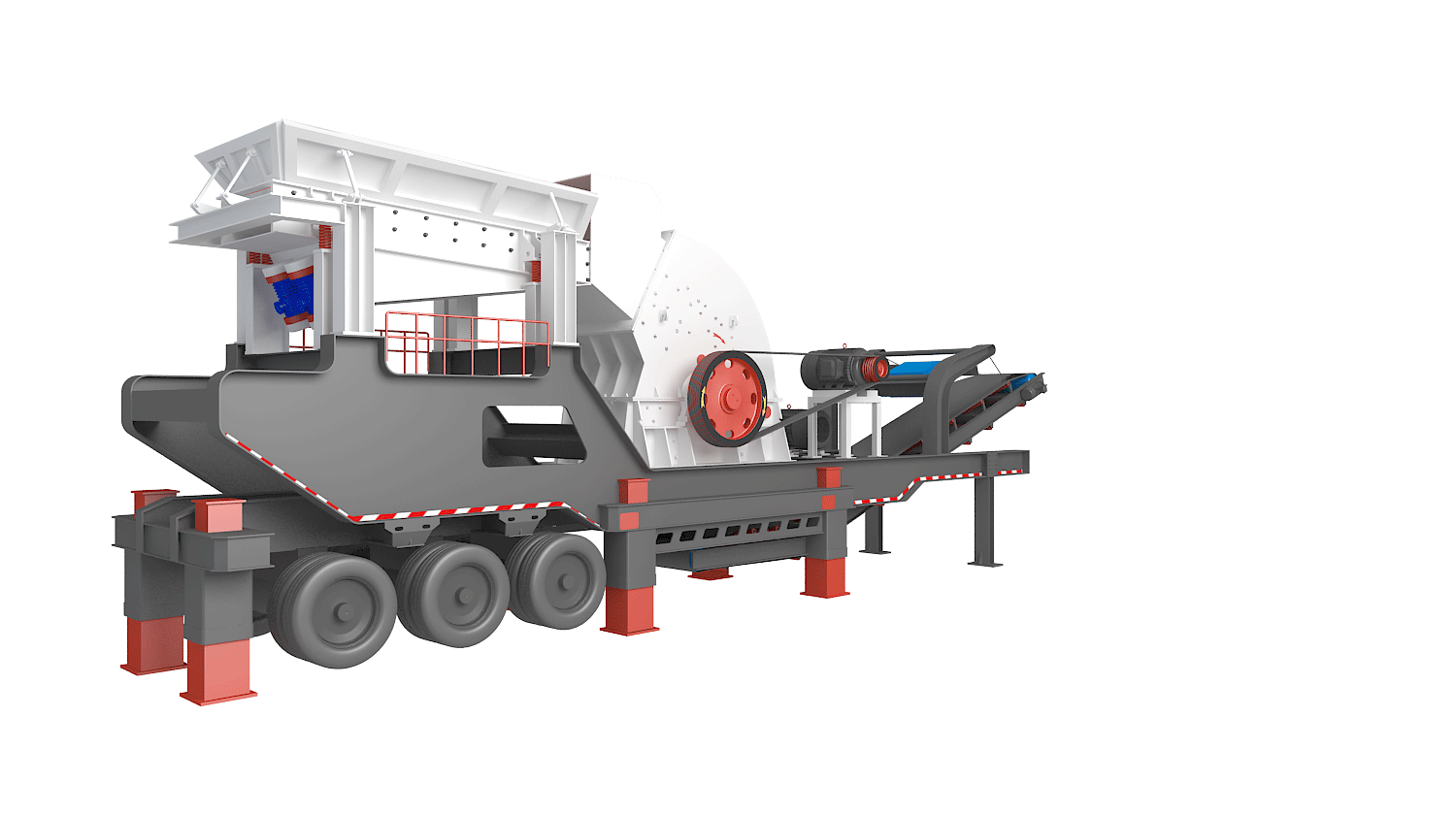

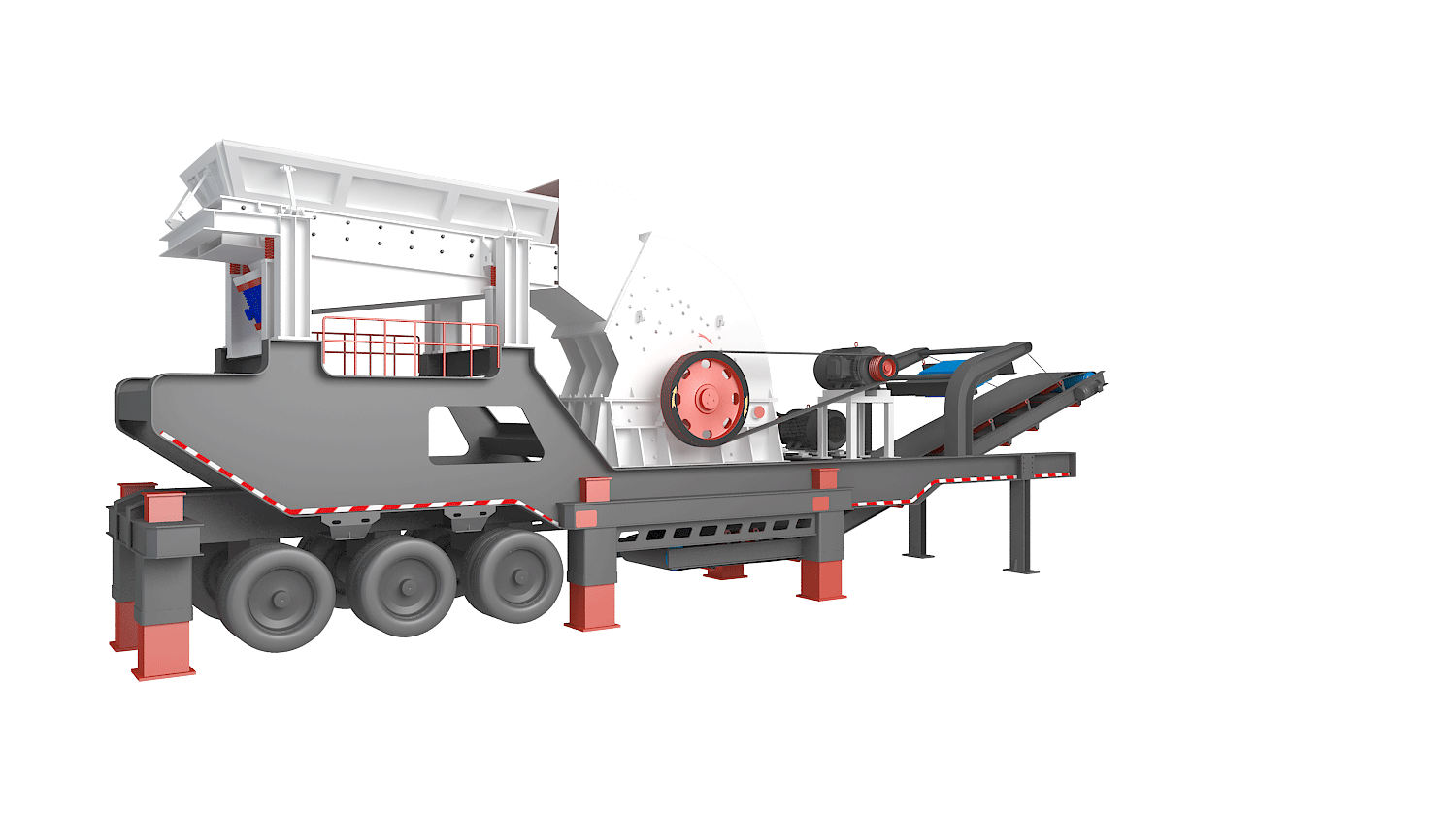

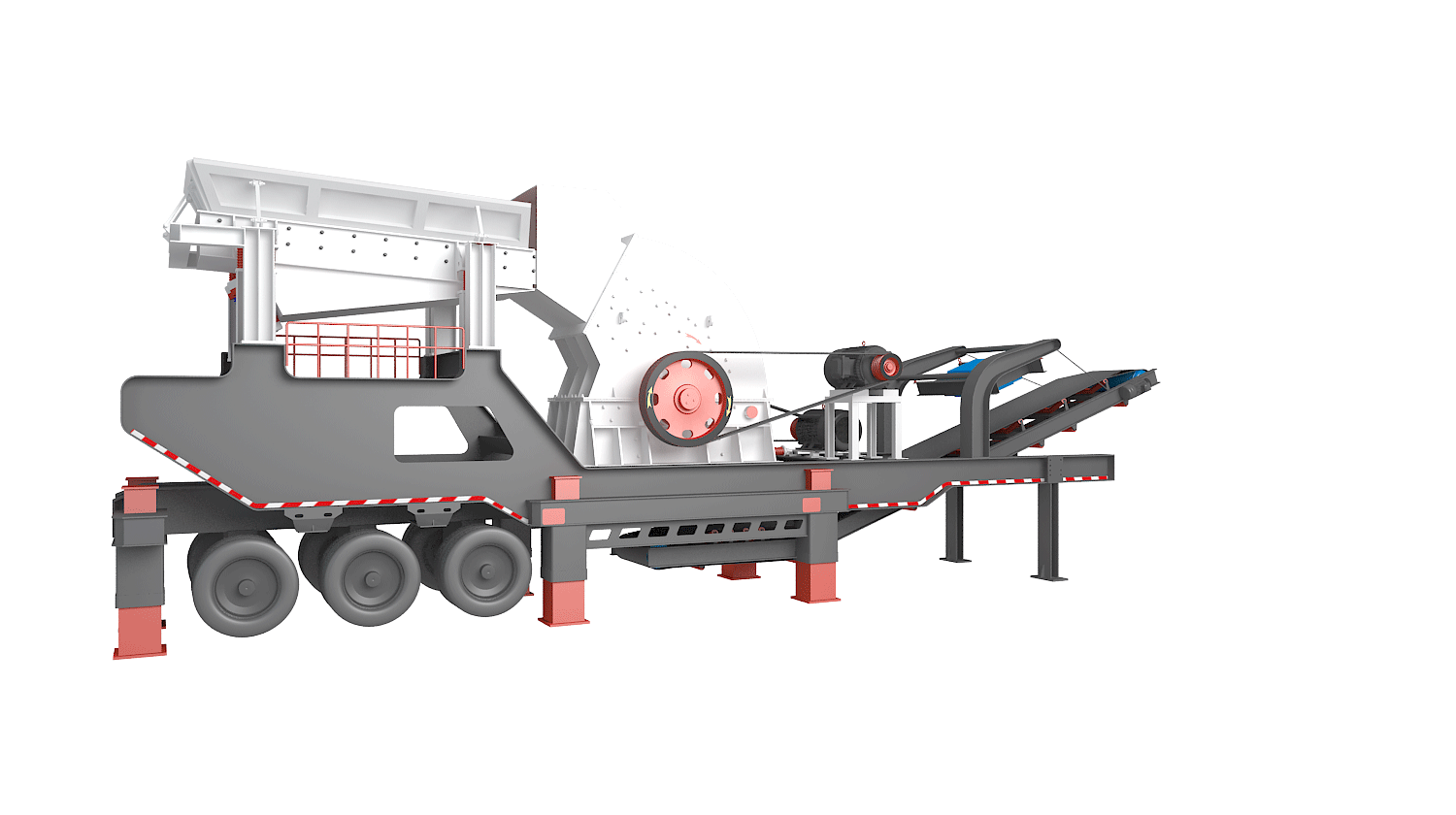

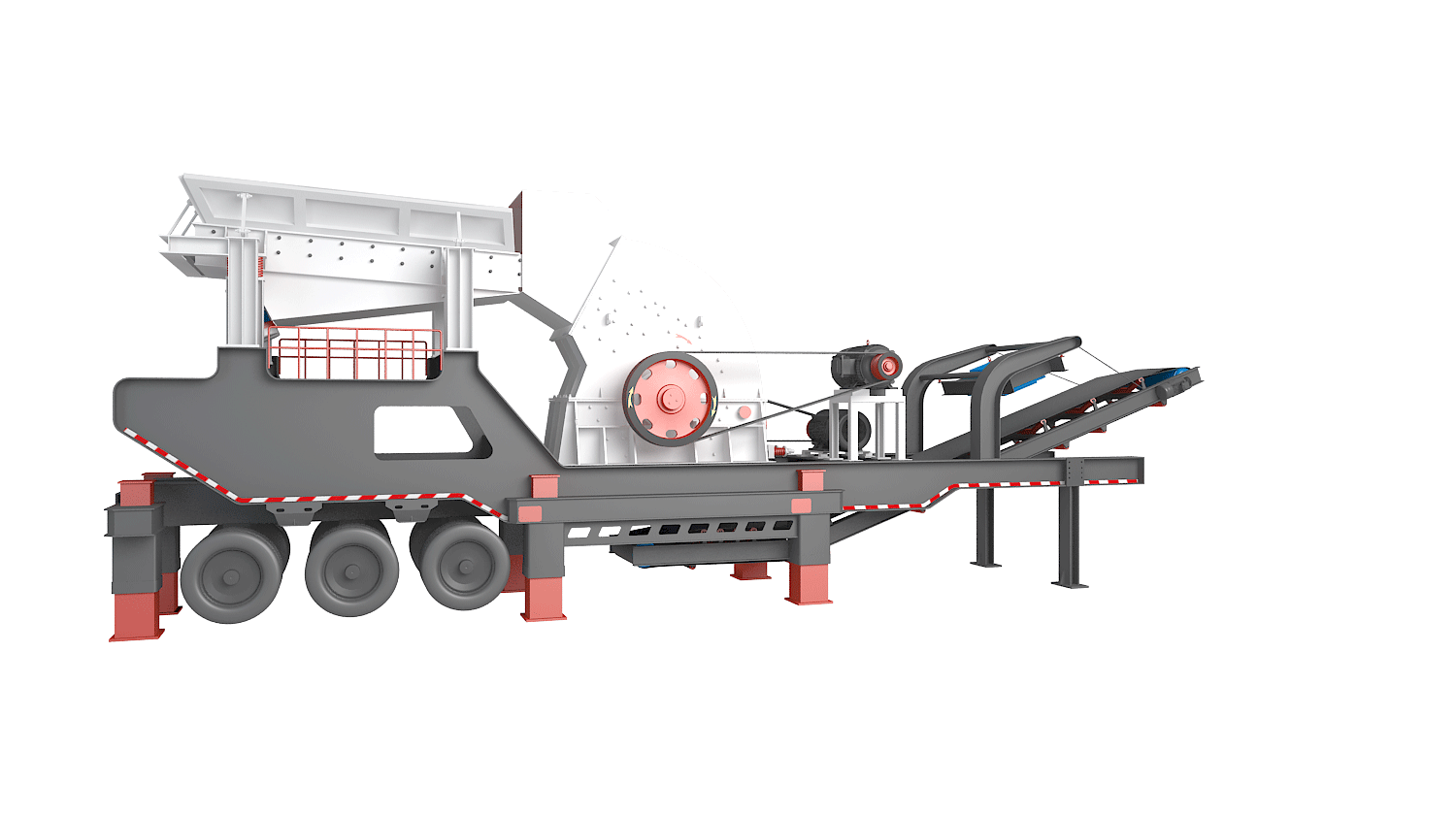

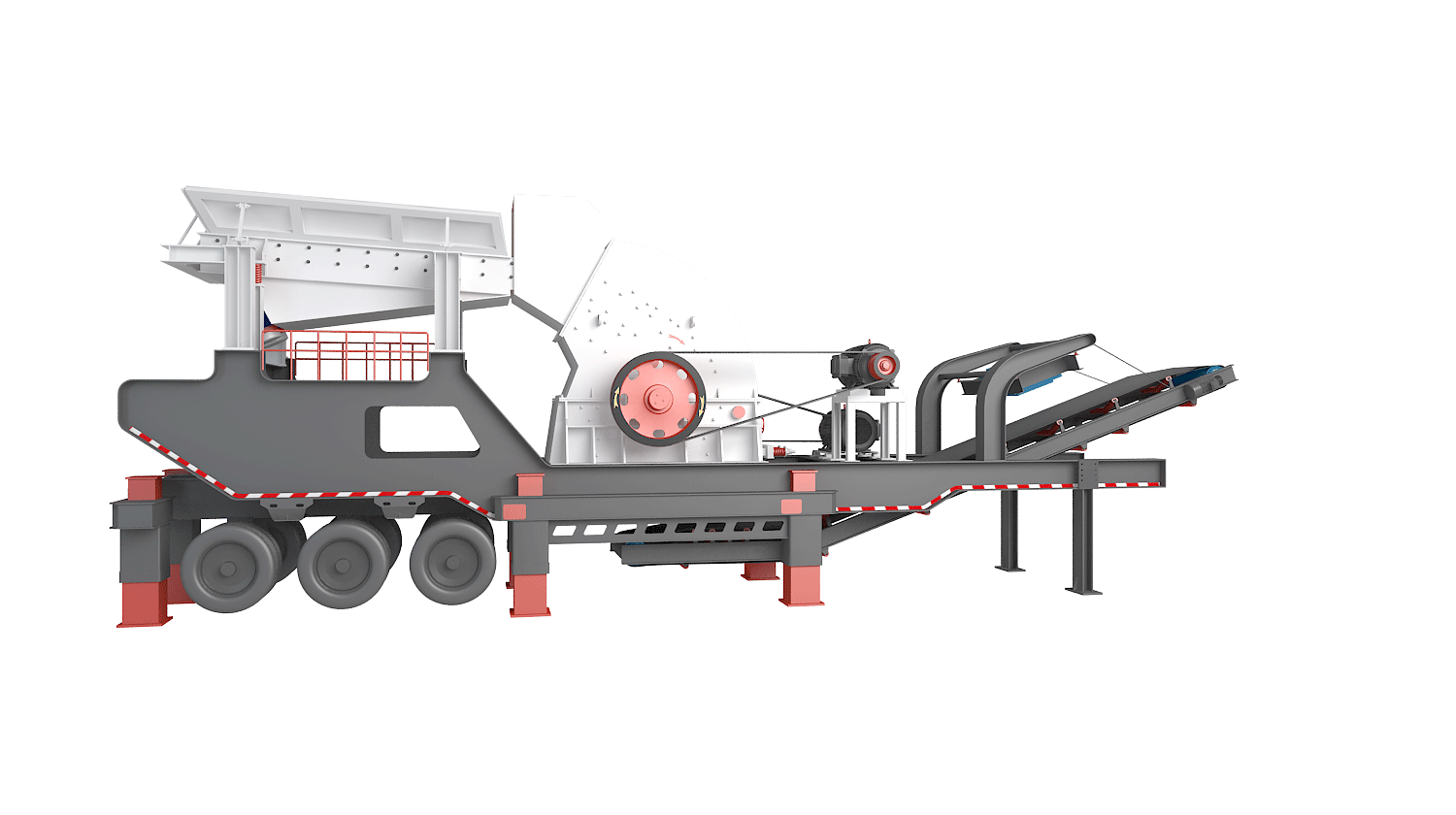

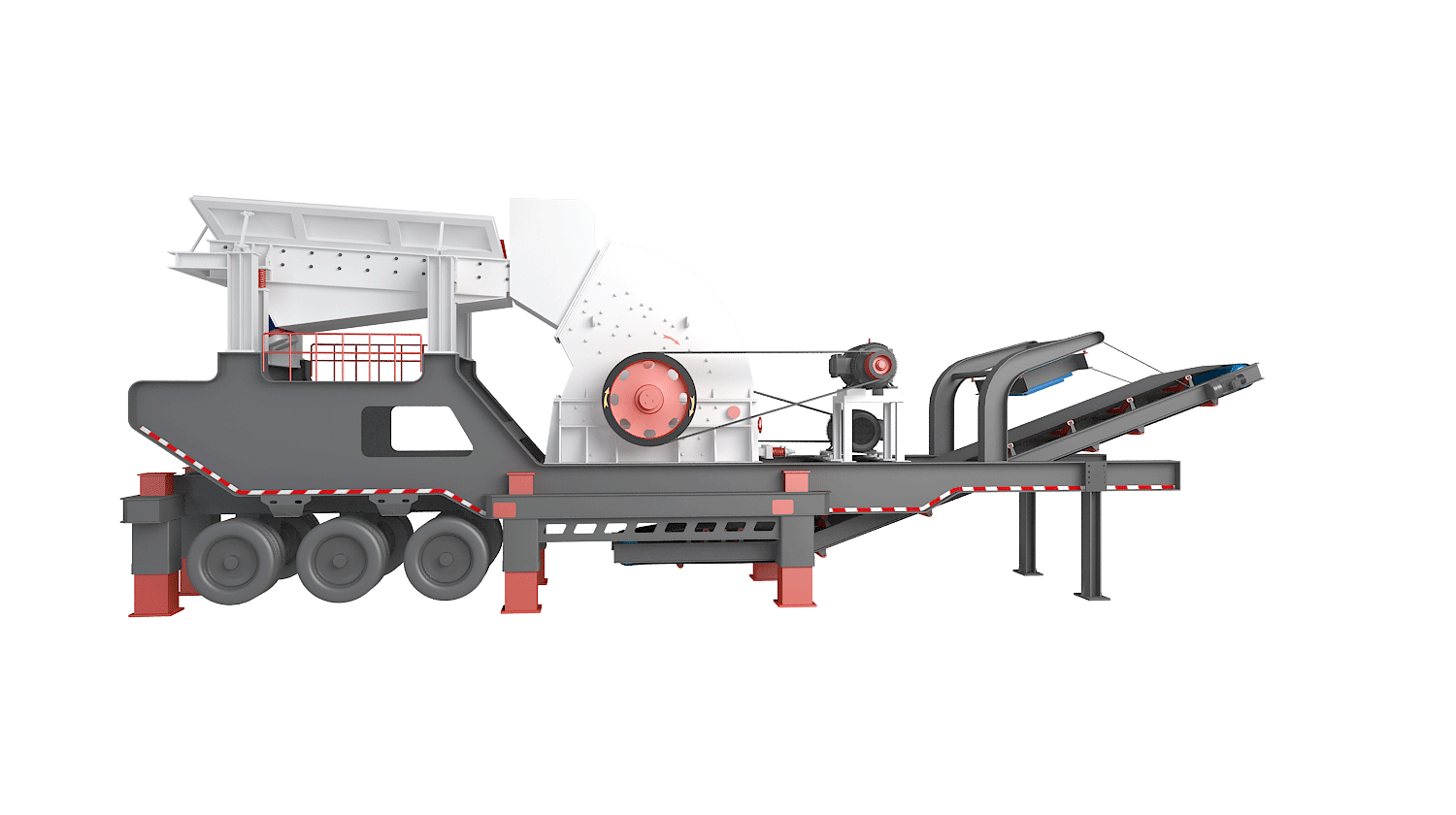

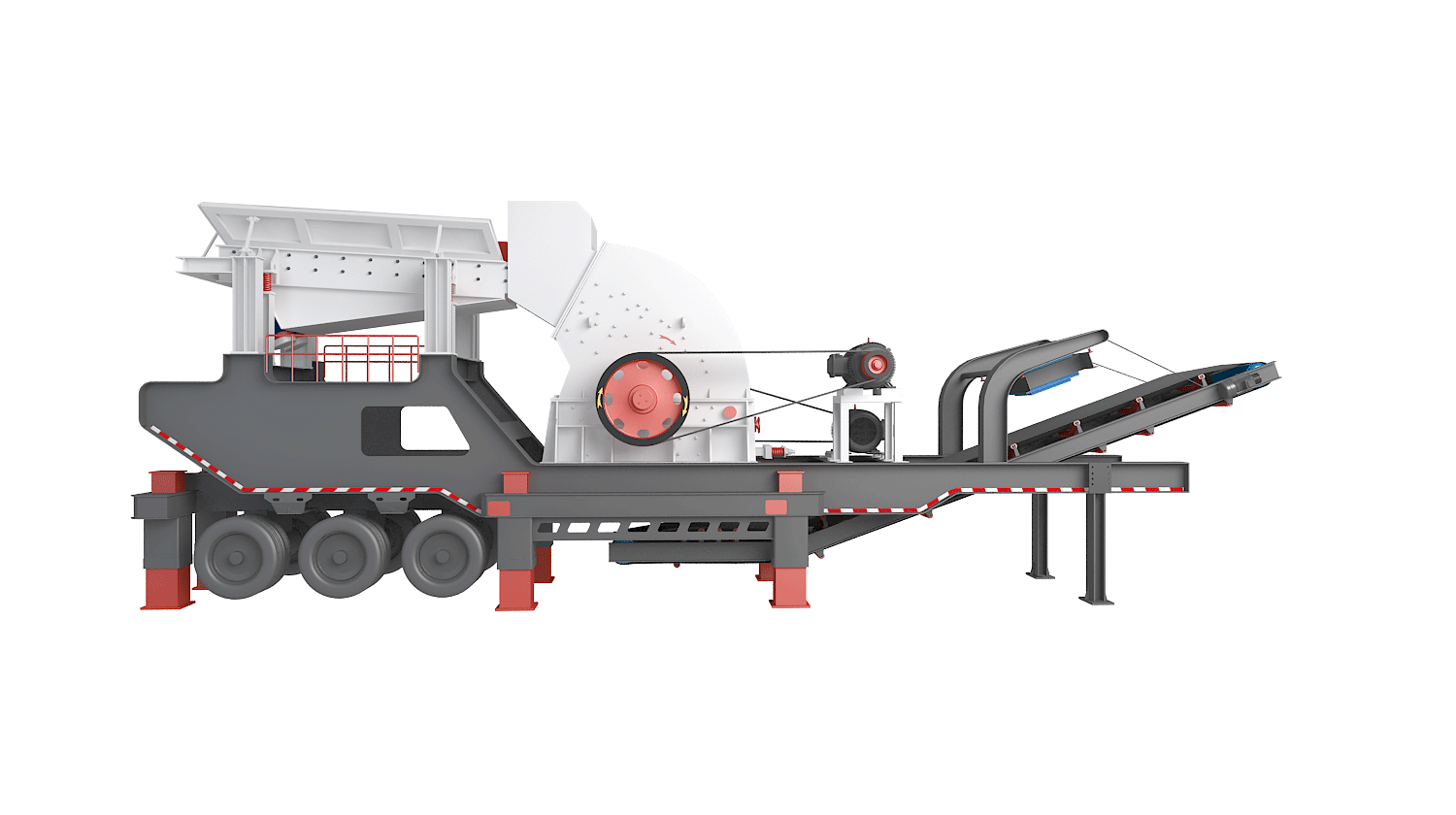

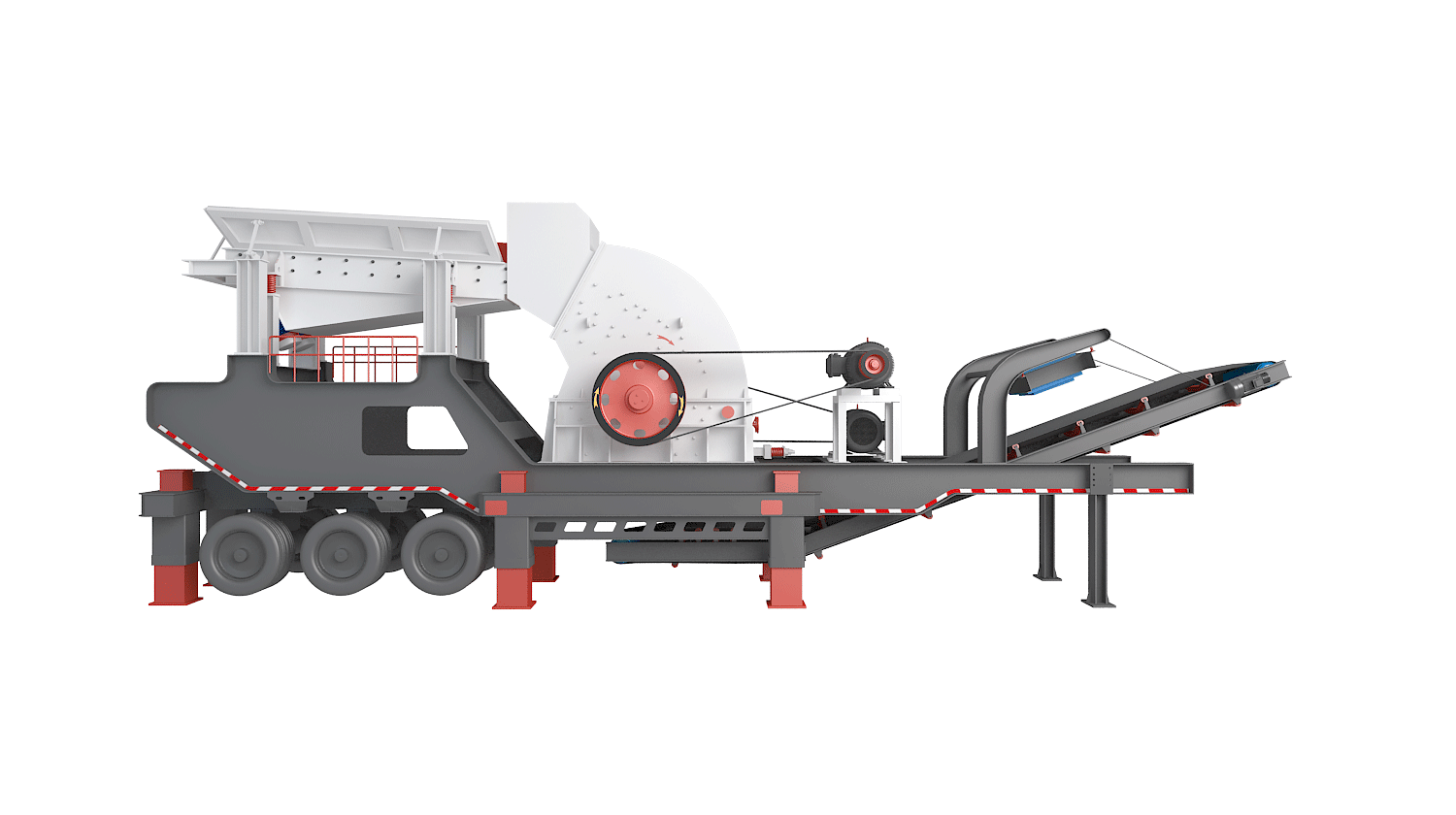

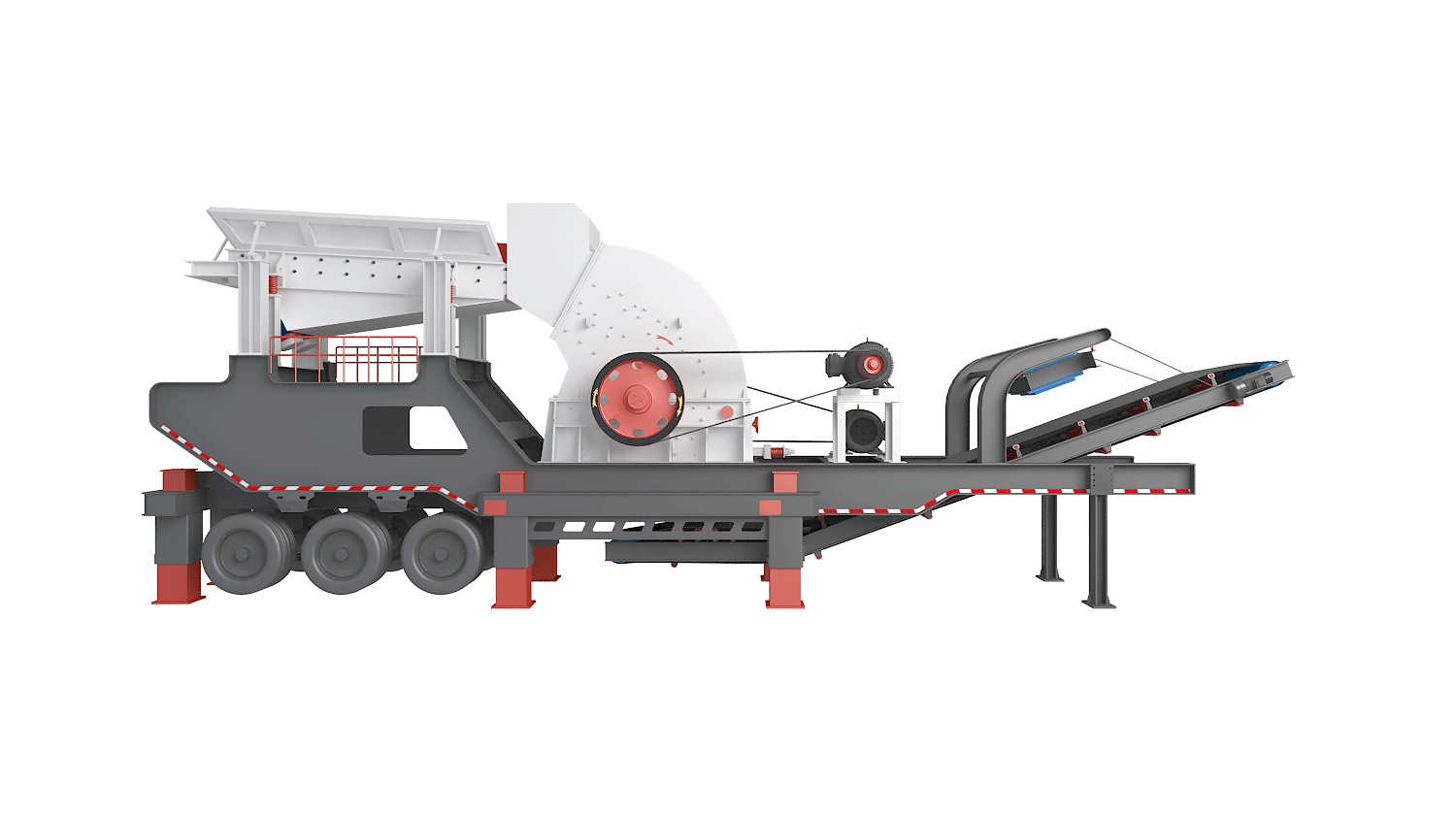

Raw materials such as limestone or coal are loaded into feeding hopper by excavator or loader. Material then enters primary crusher (usually jaw crusher or impact crusher) where it is broken down into smaller pieces.

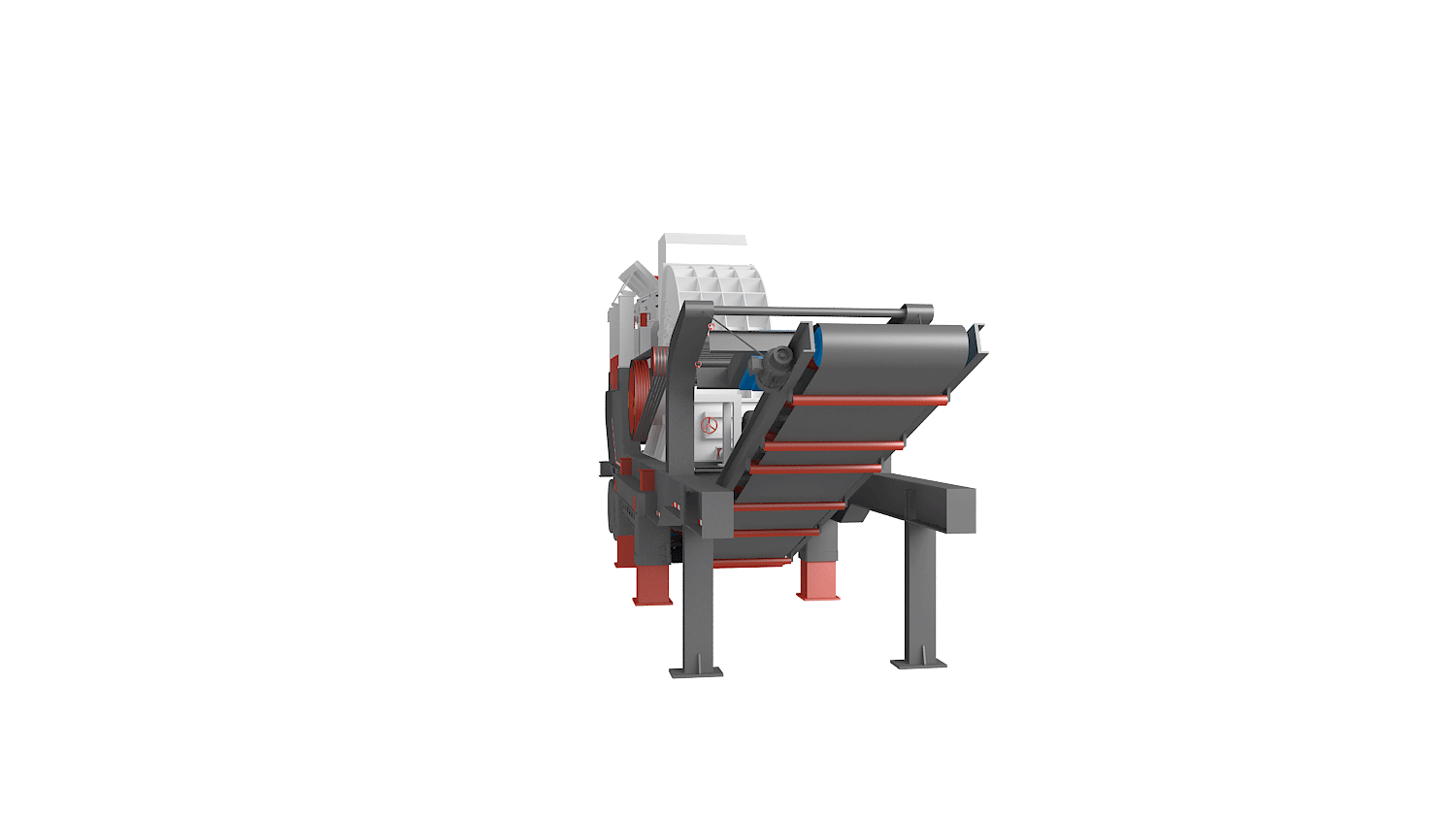

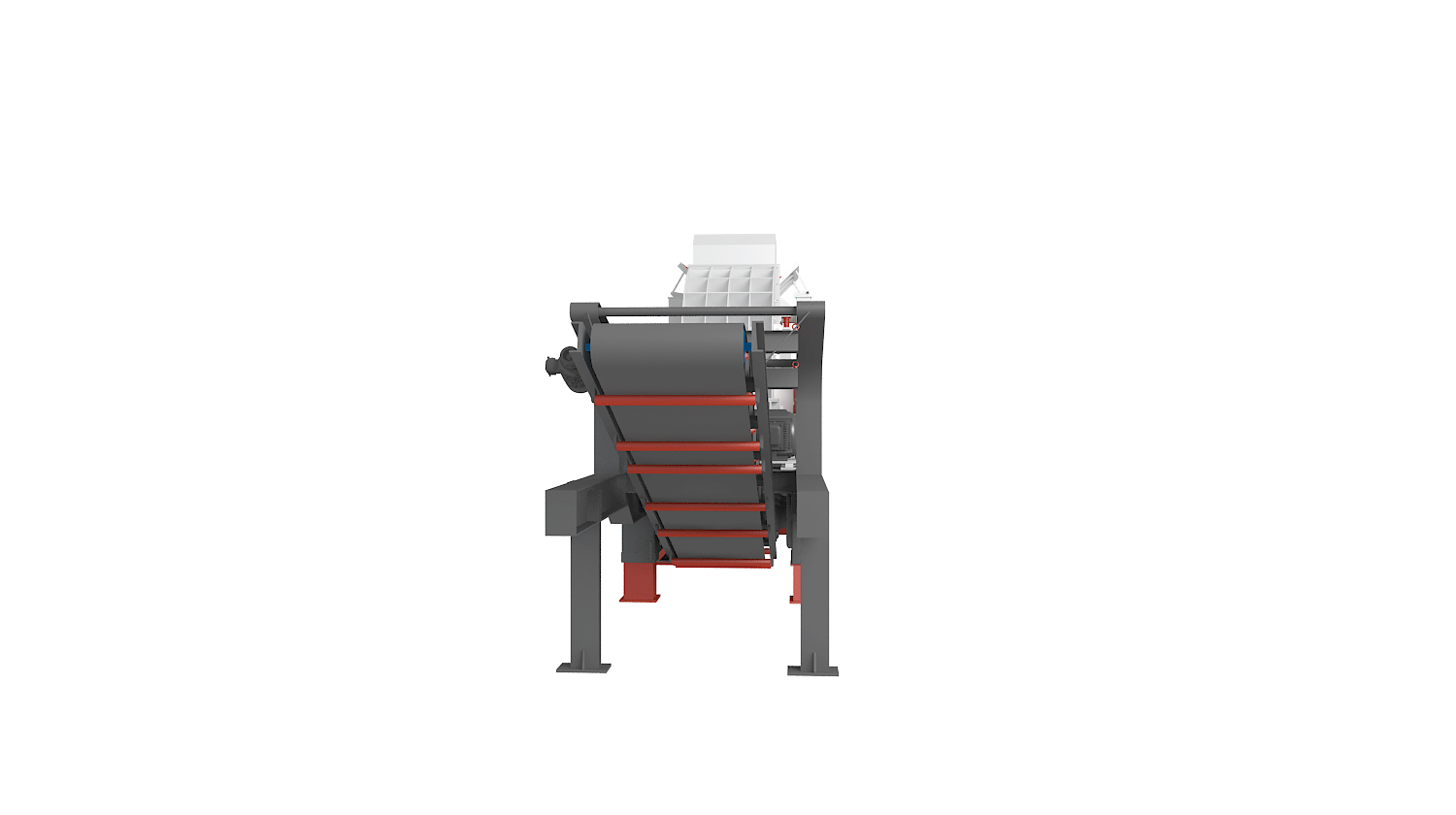

Crushed material is transferred via integrated belt conveyor to vibrating screen for classification. Oversized material is returned to crusher for further reduction, while qualified product is discharged for storage or further processing.

Mobile chassis enables entire system to move easily between work sites. Diesel engine or electric motor powers equipment, and centralized control system ensures safe and efficient operation. Optional dust suppression systems and noise reduction designs help minimize environmental impact during operation.