| Standard model | Matching equipment | Feed size (mm) |

Capacity (t/h) |

Complete station capacity (t/h) |

Overall size (mm) |

|

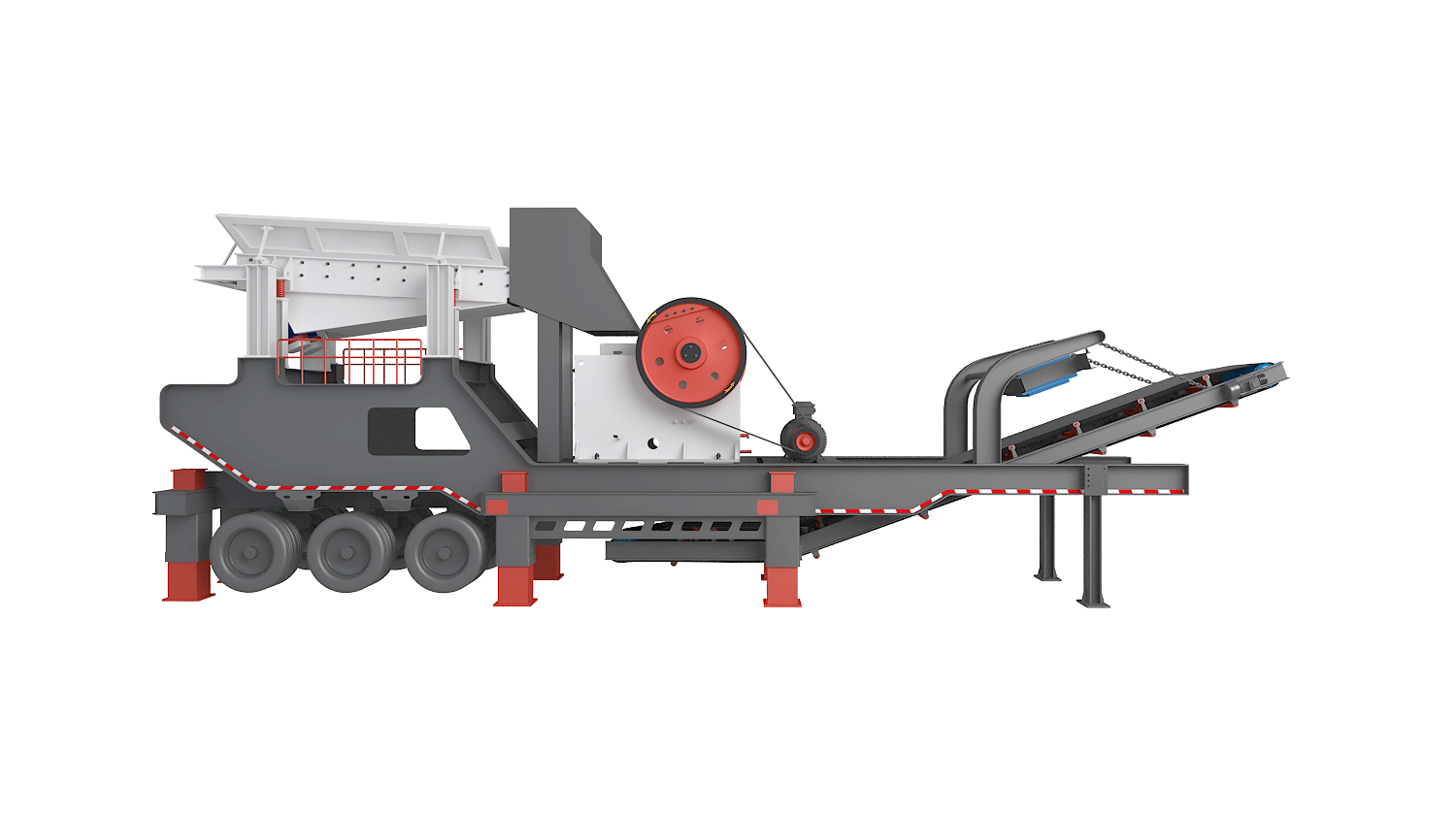

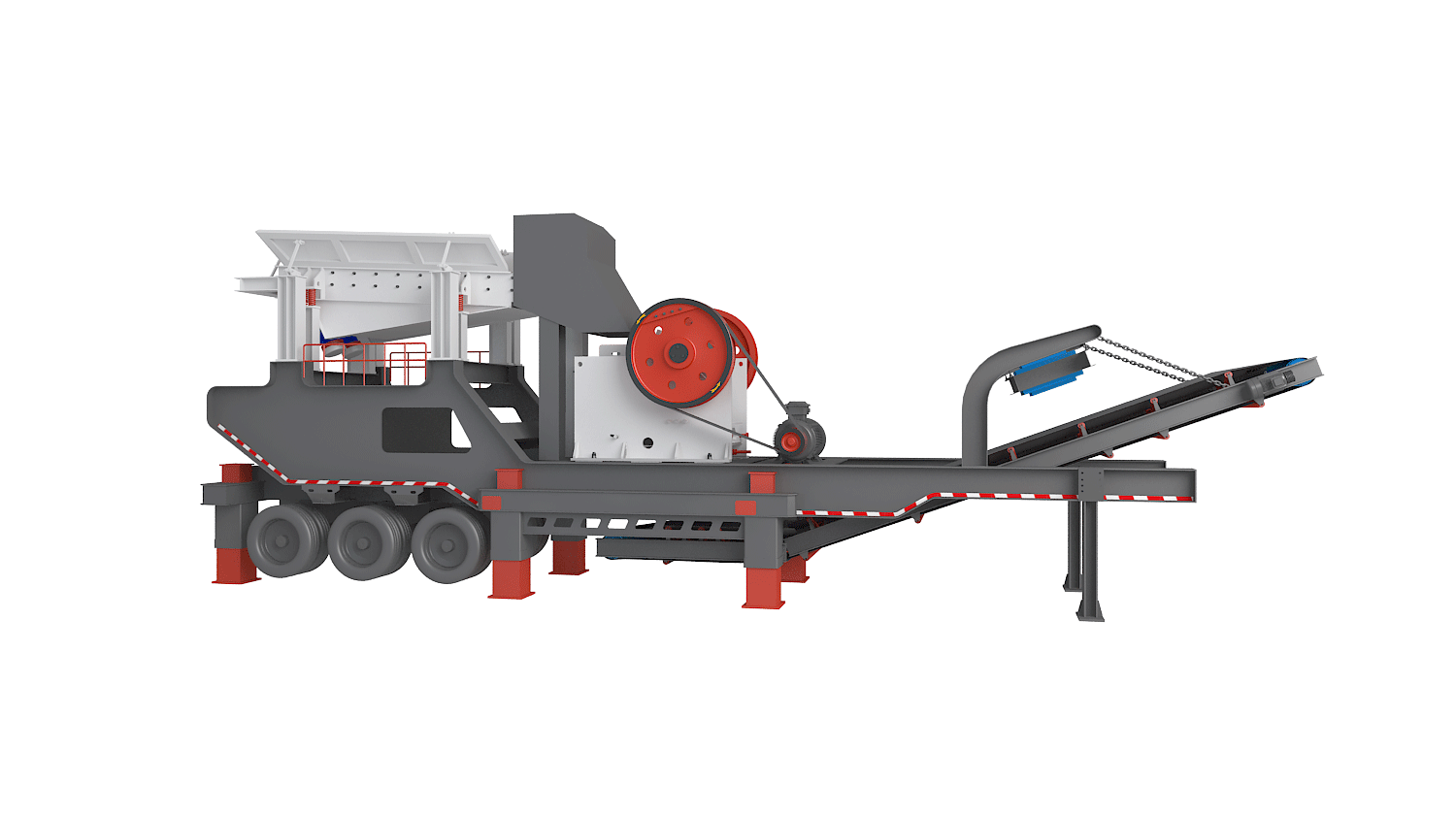

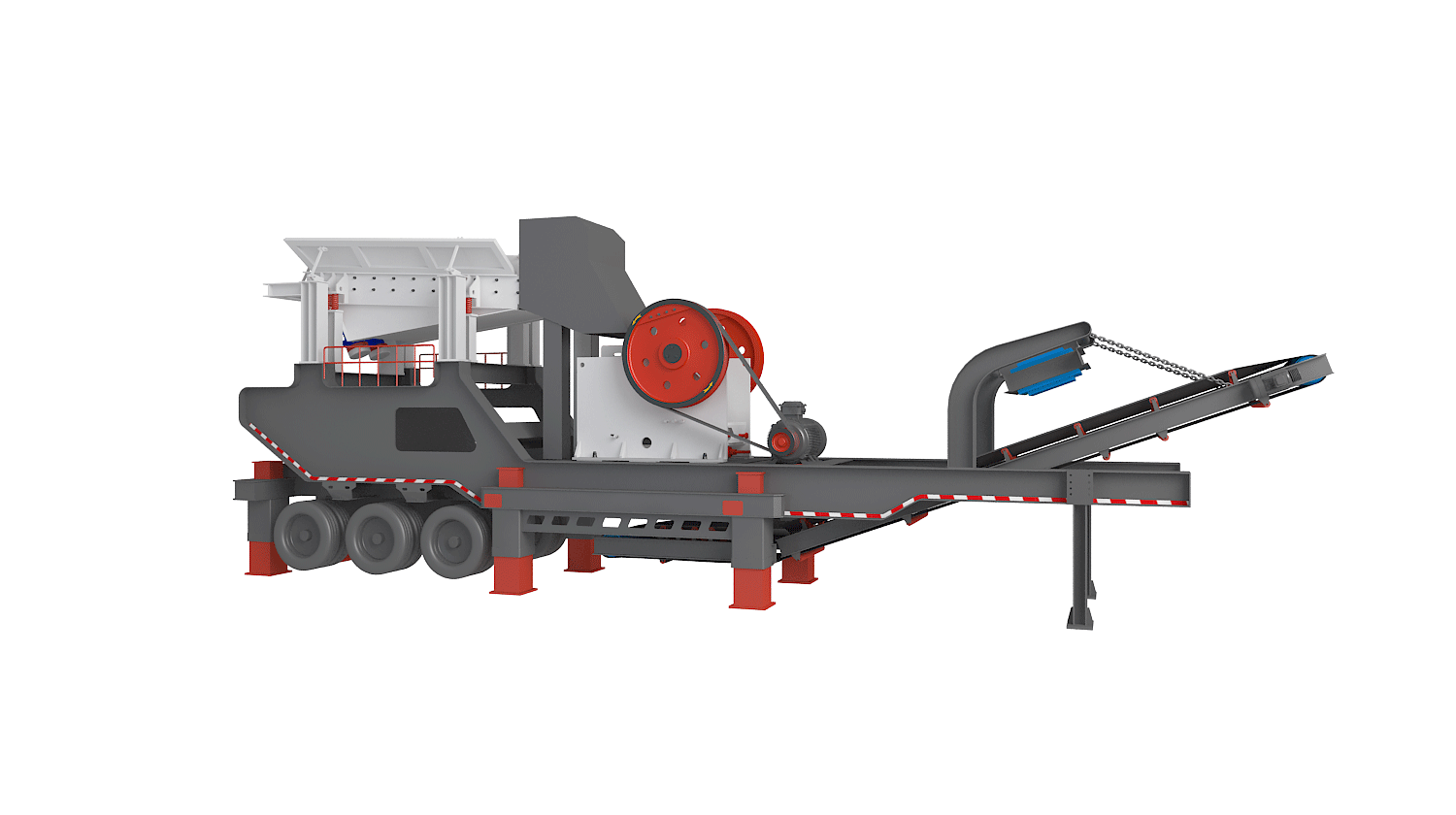

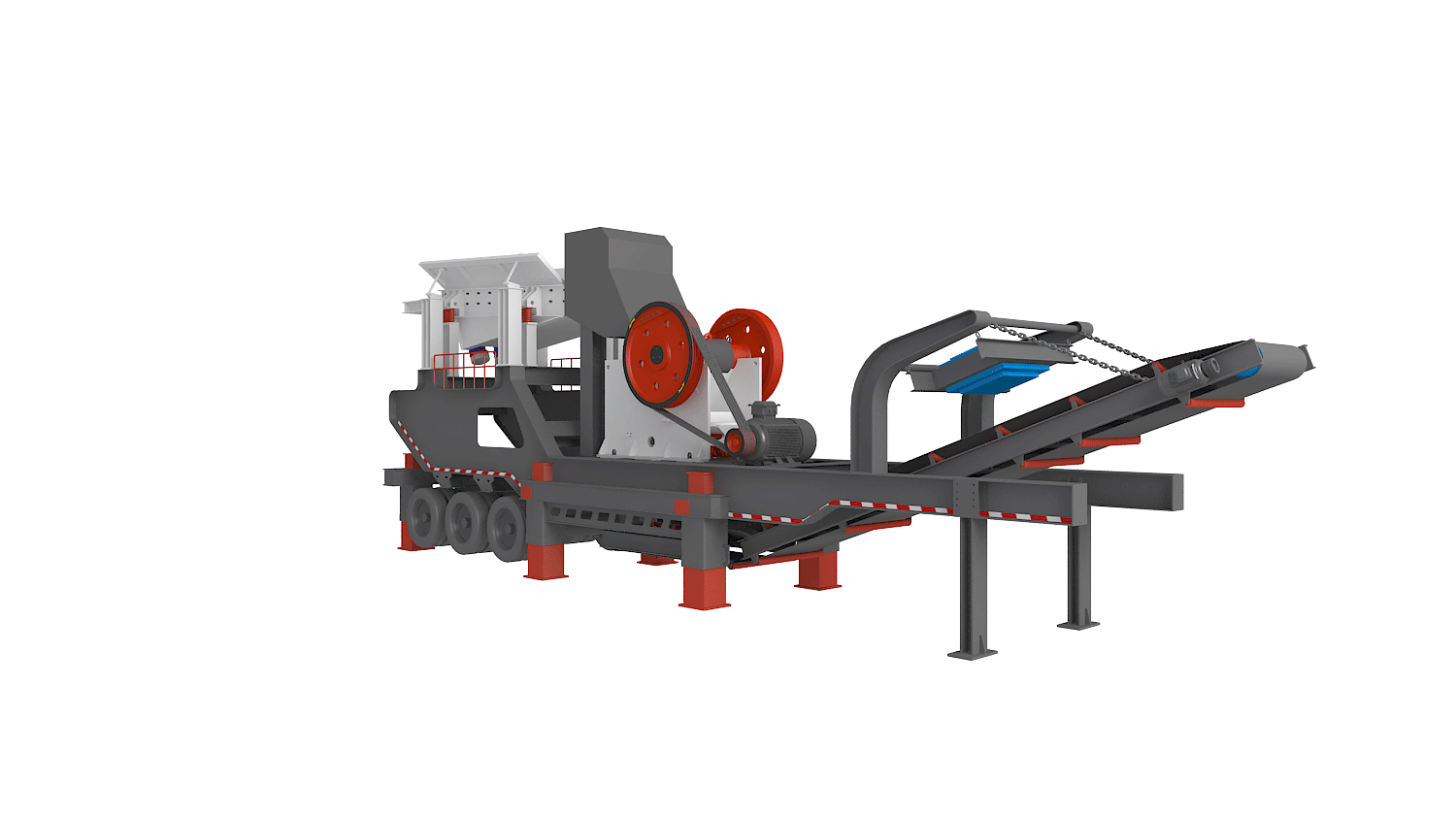

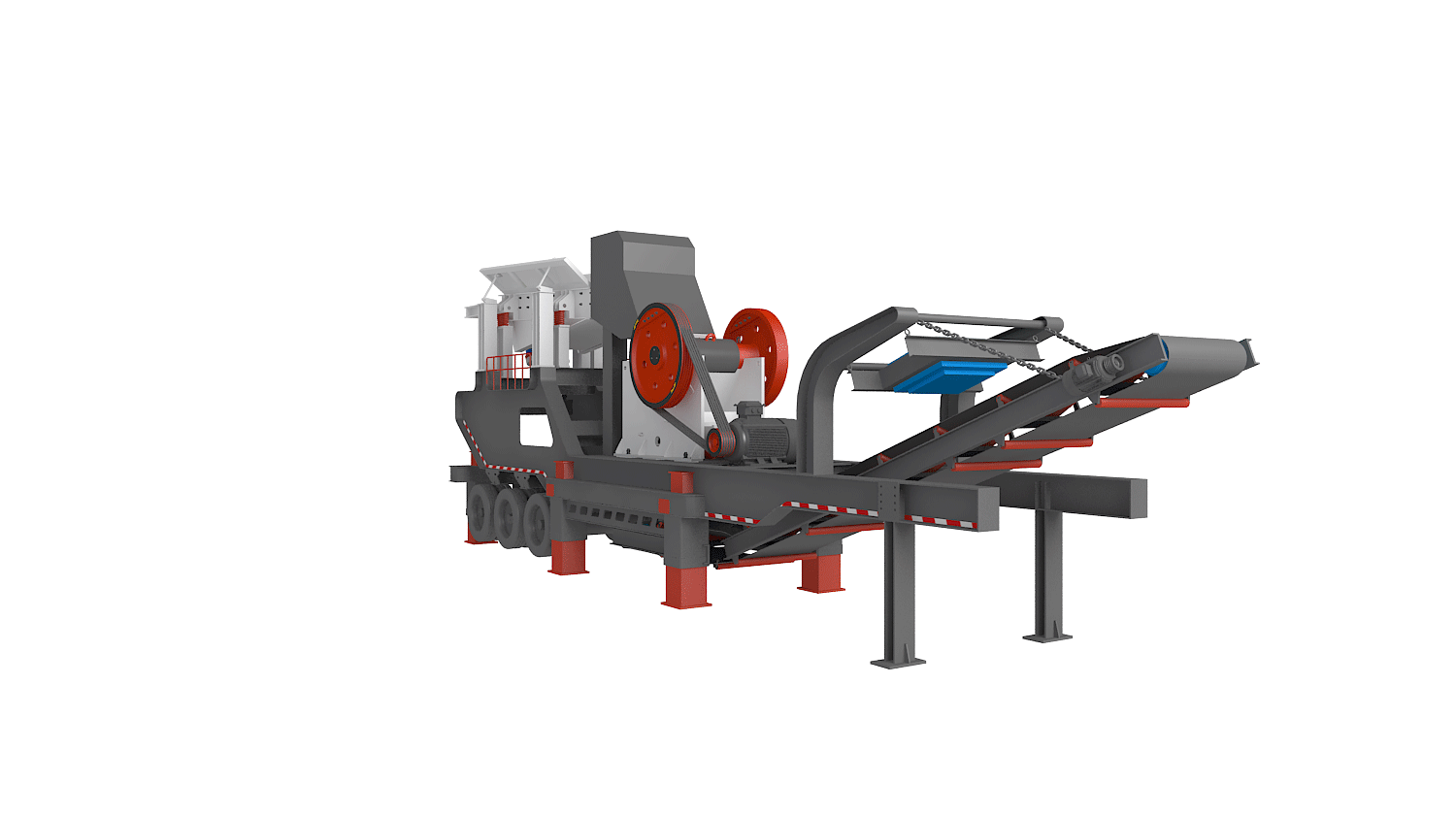

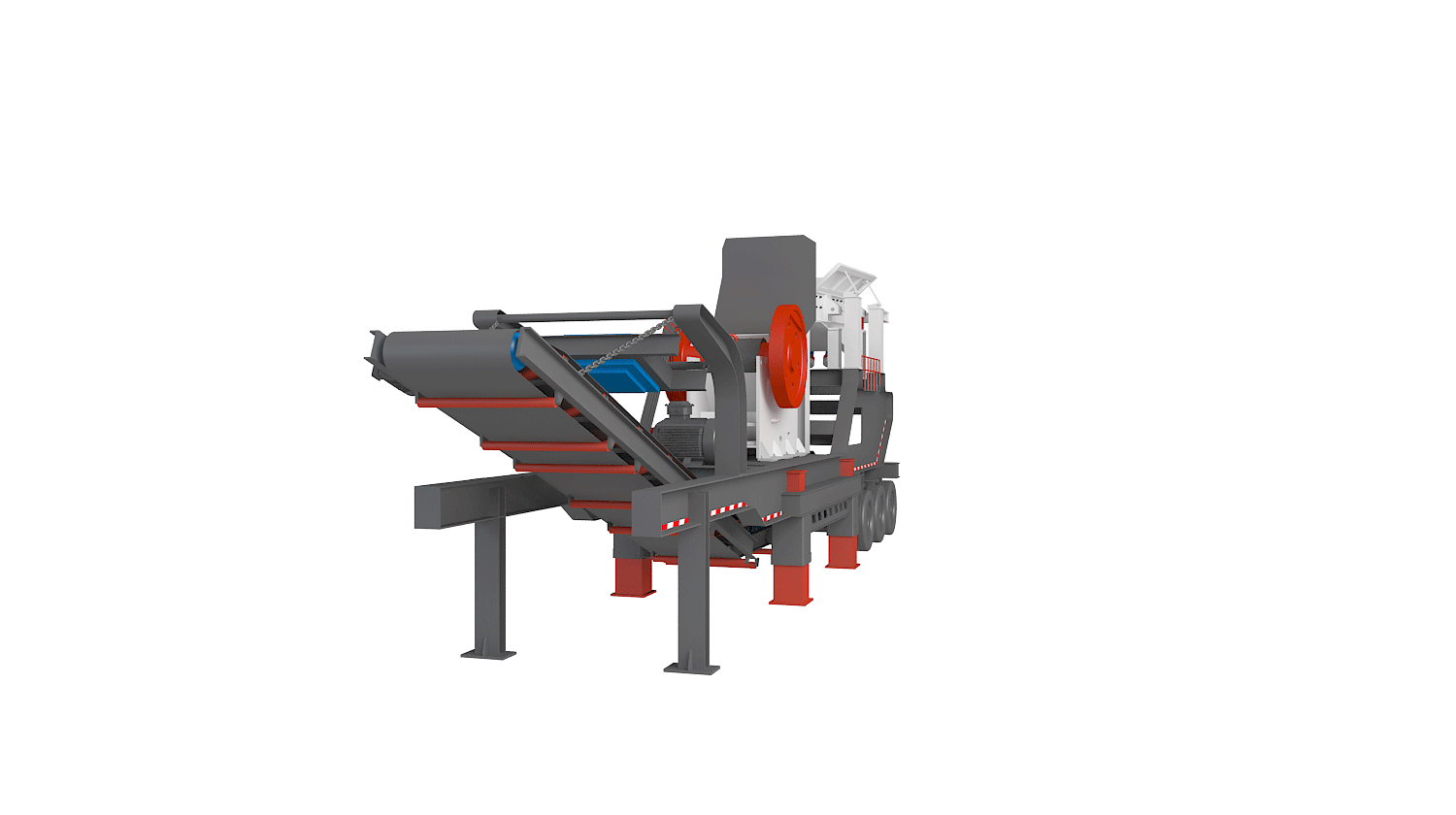

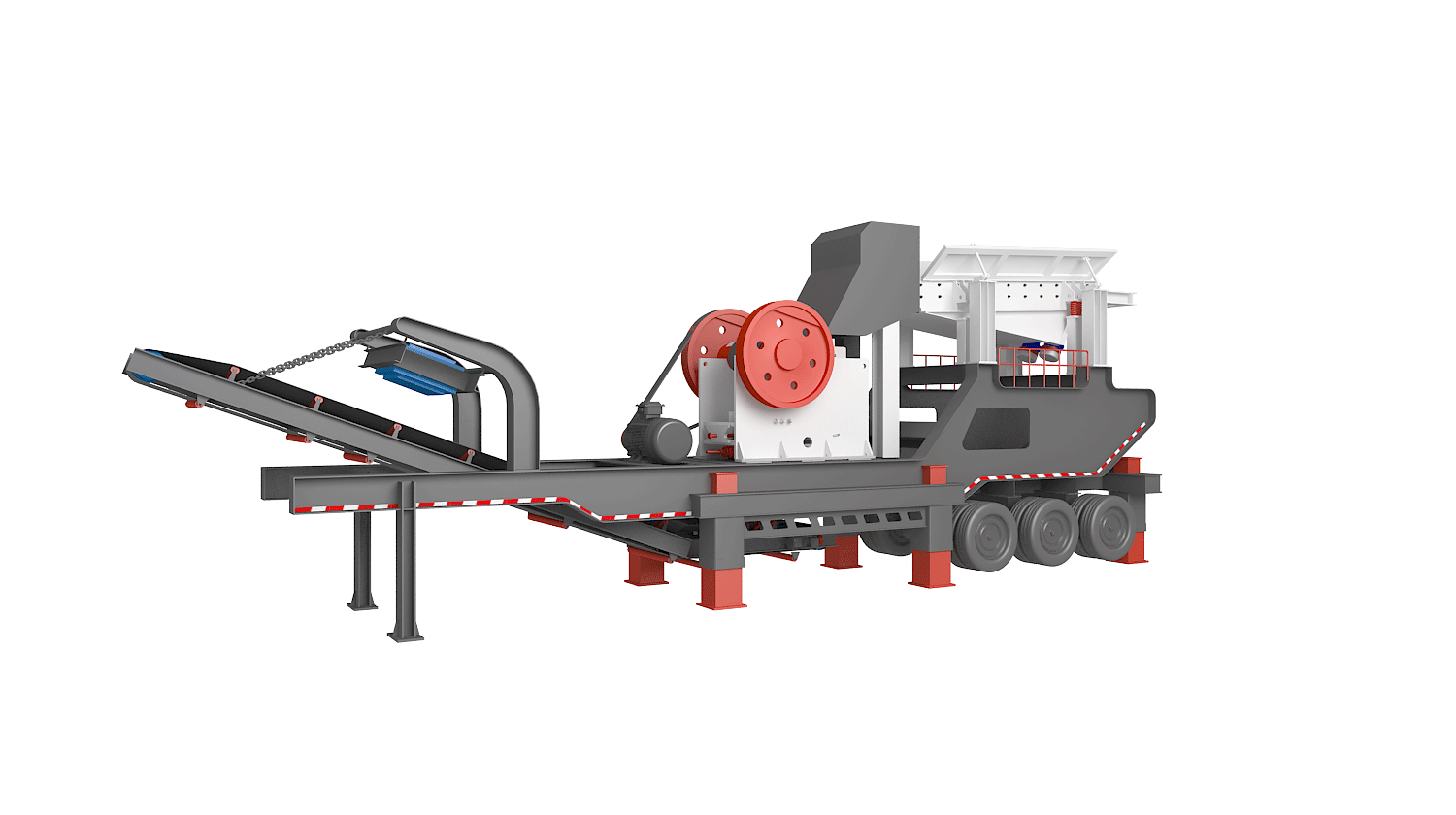

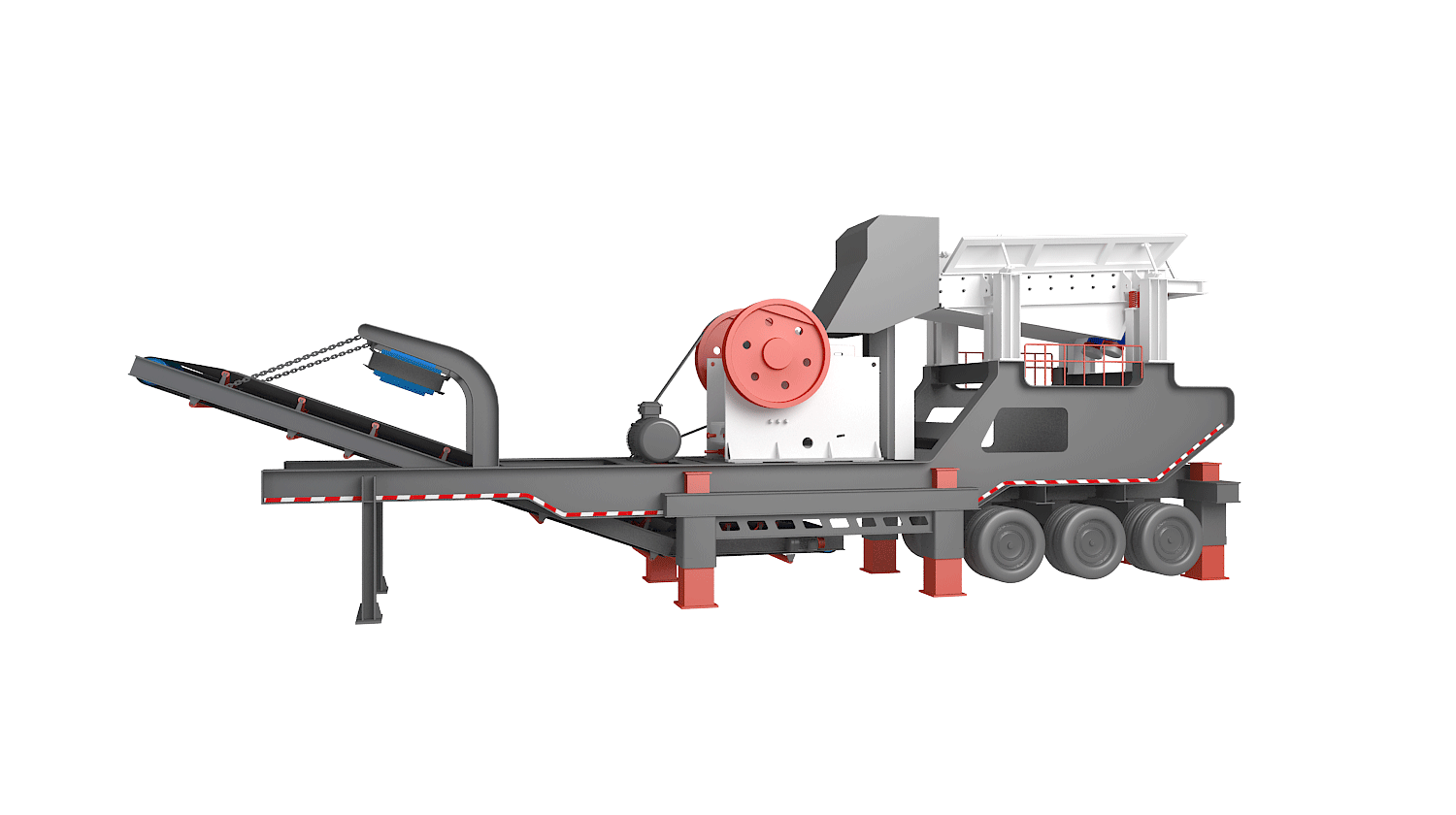

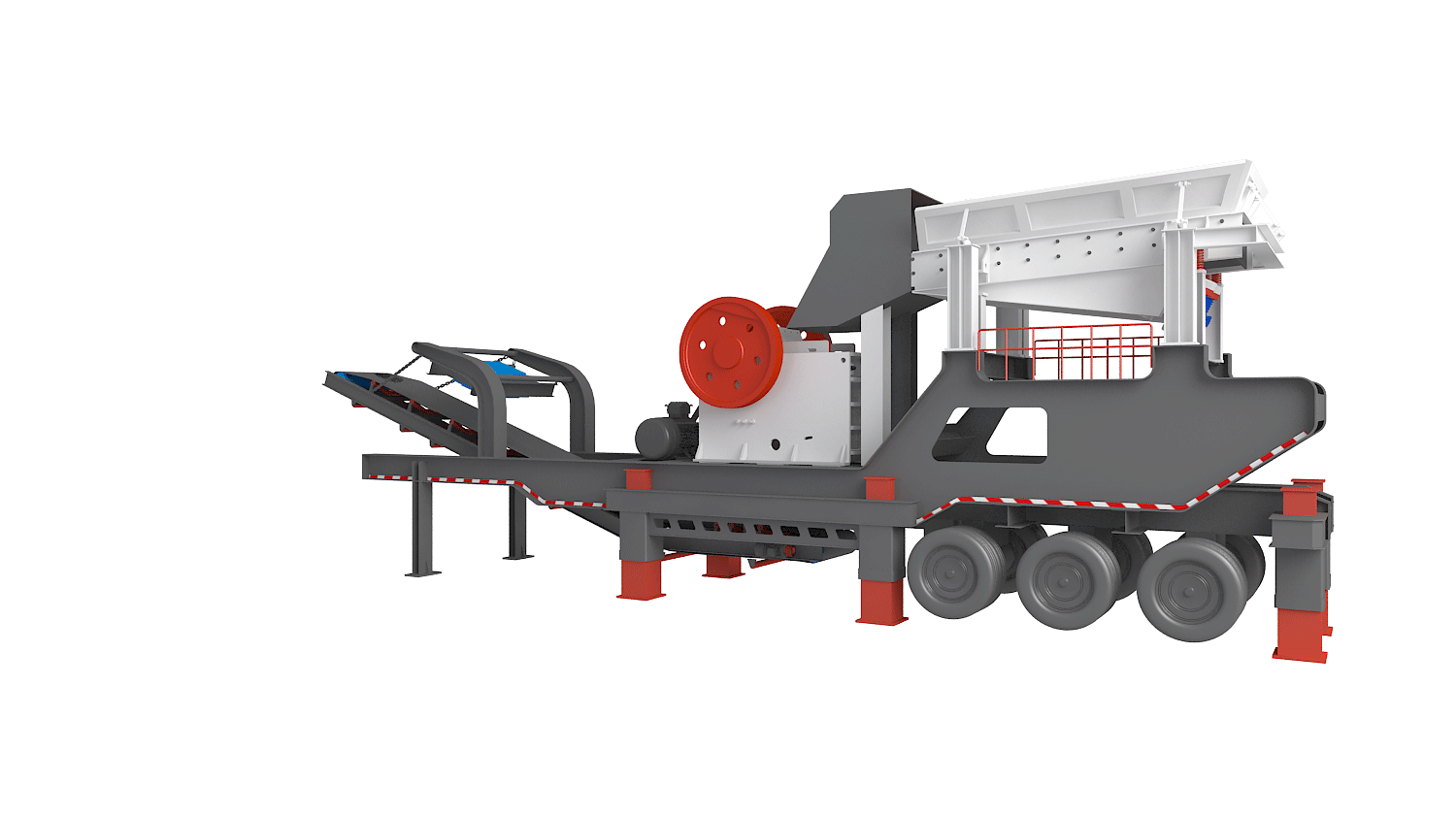

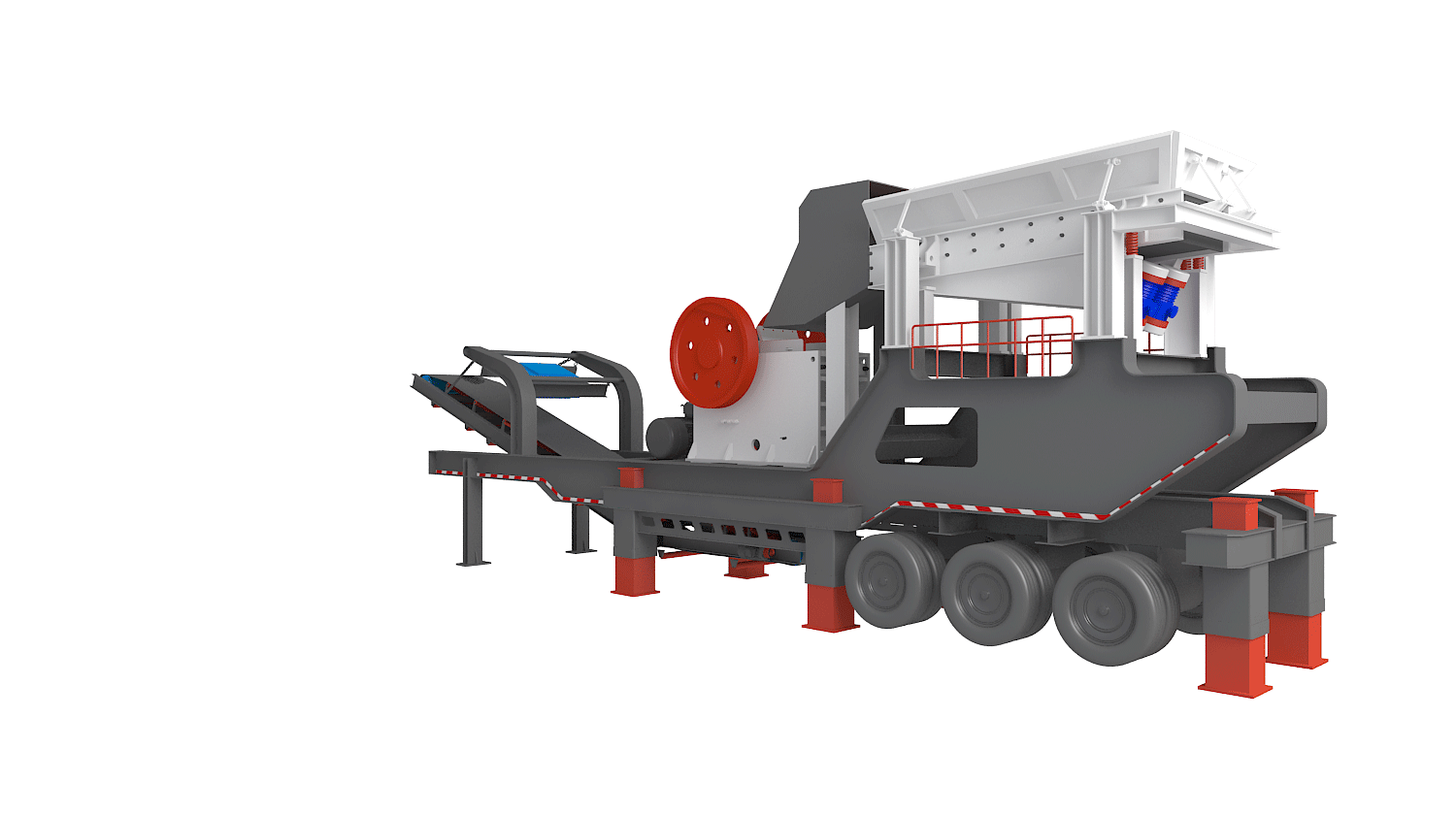

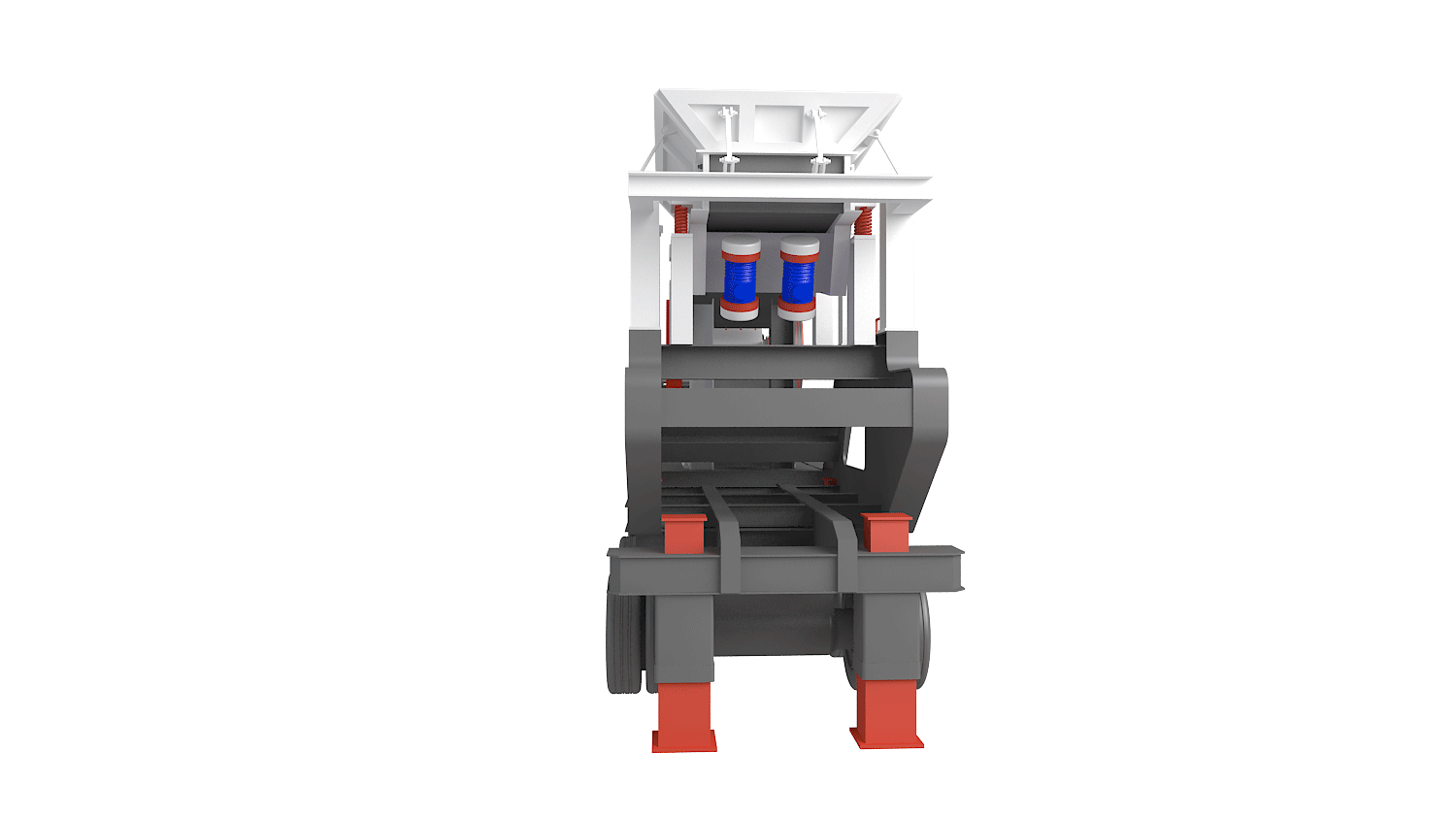

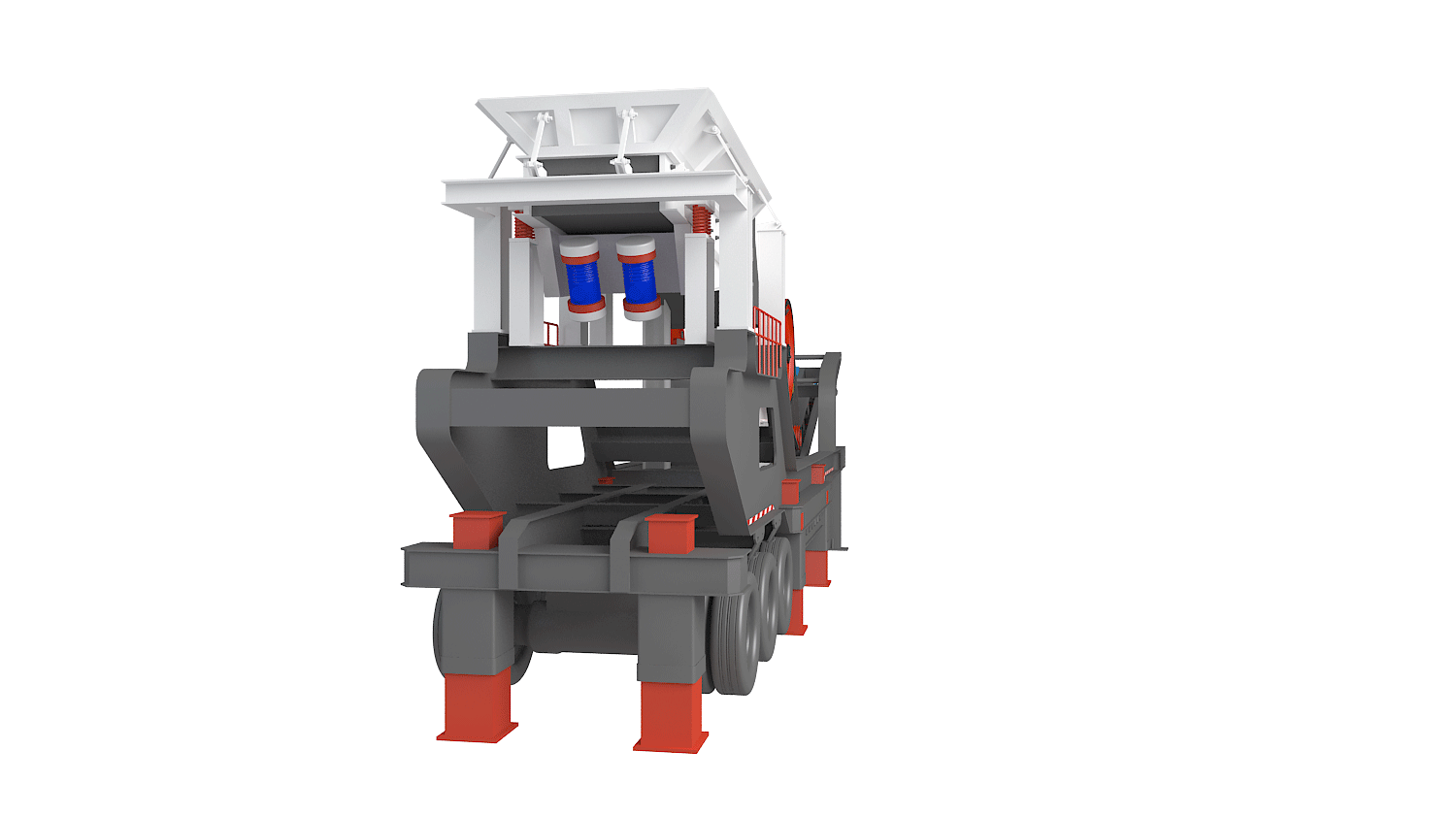

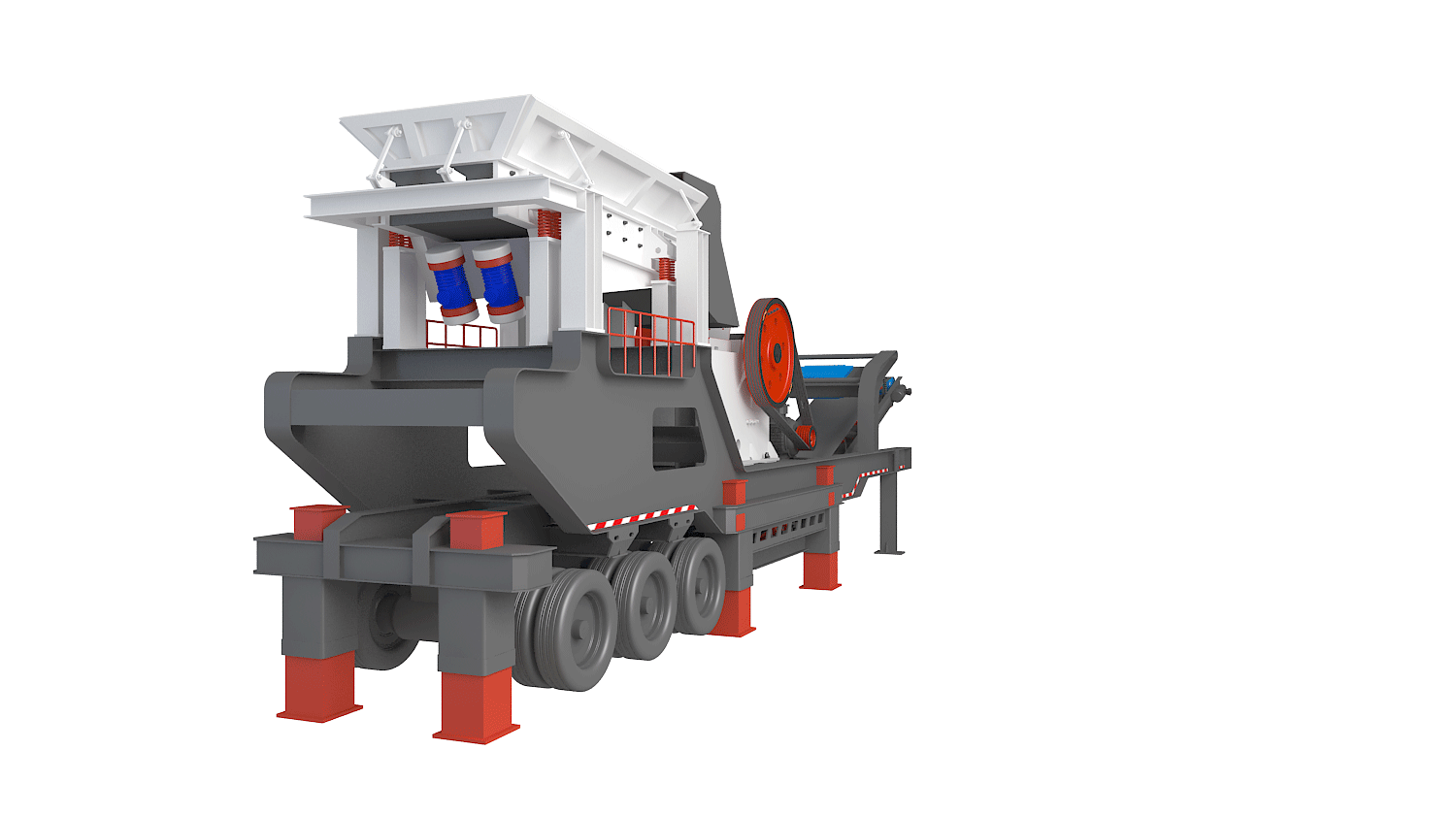

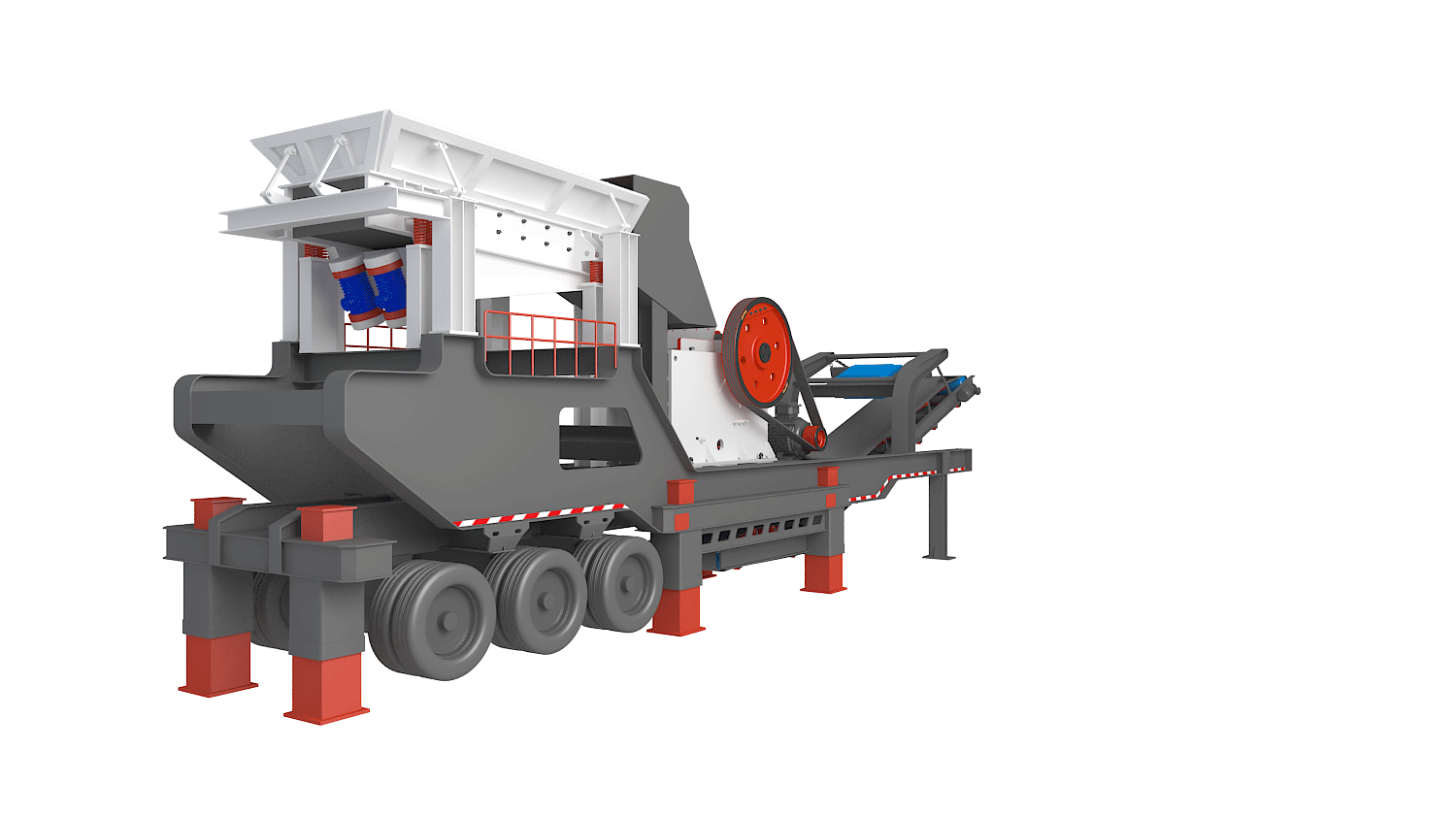

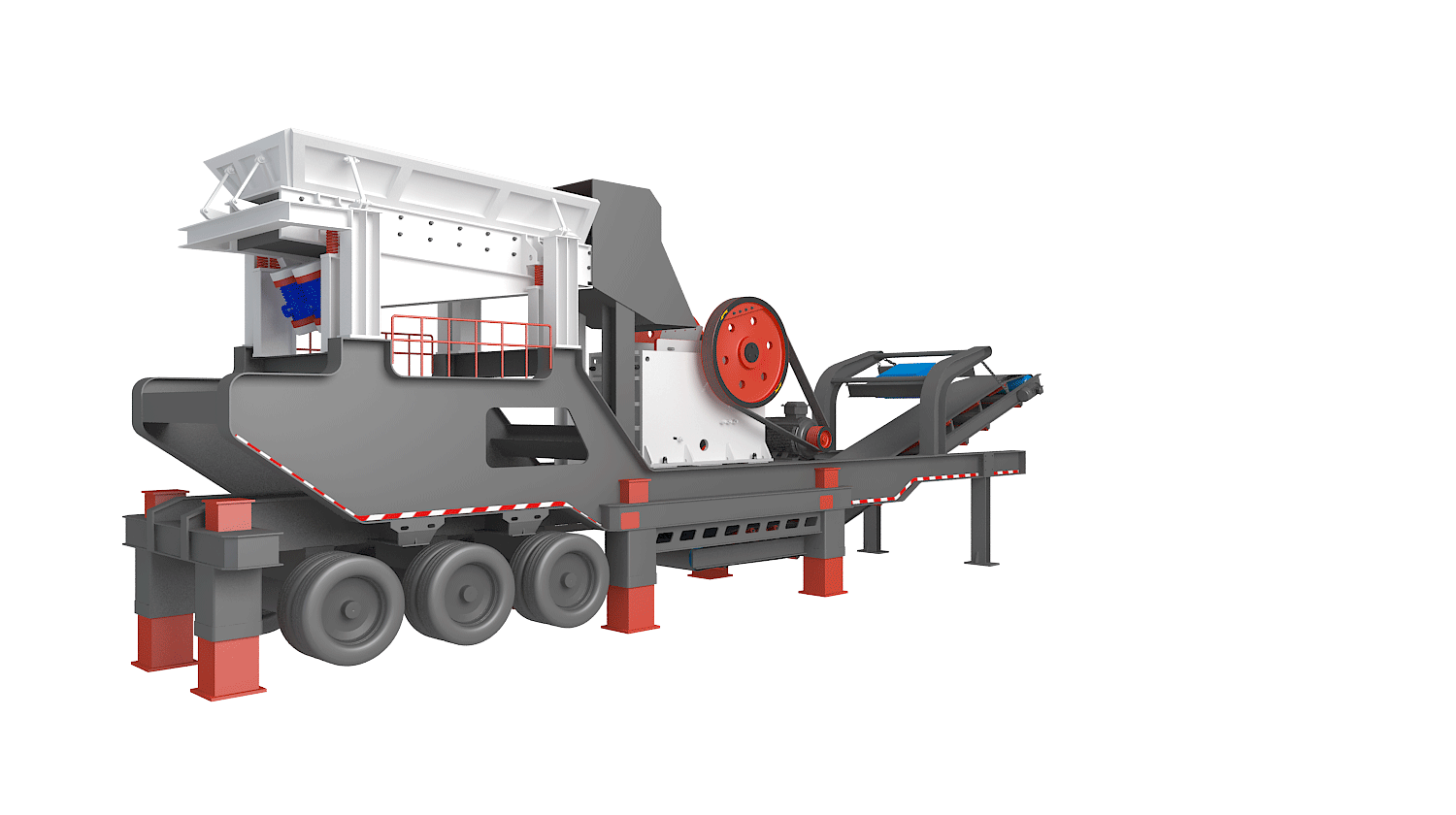

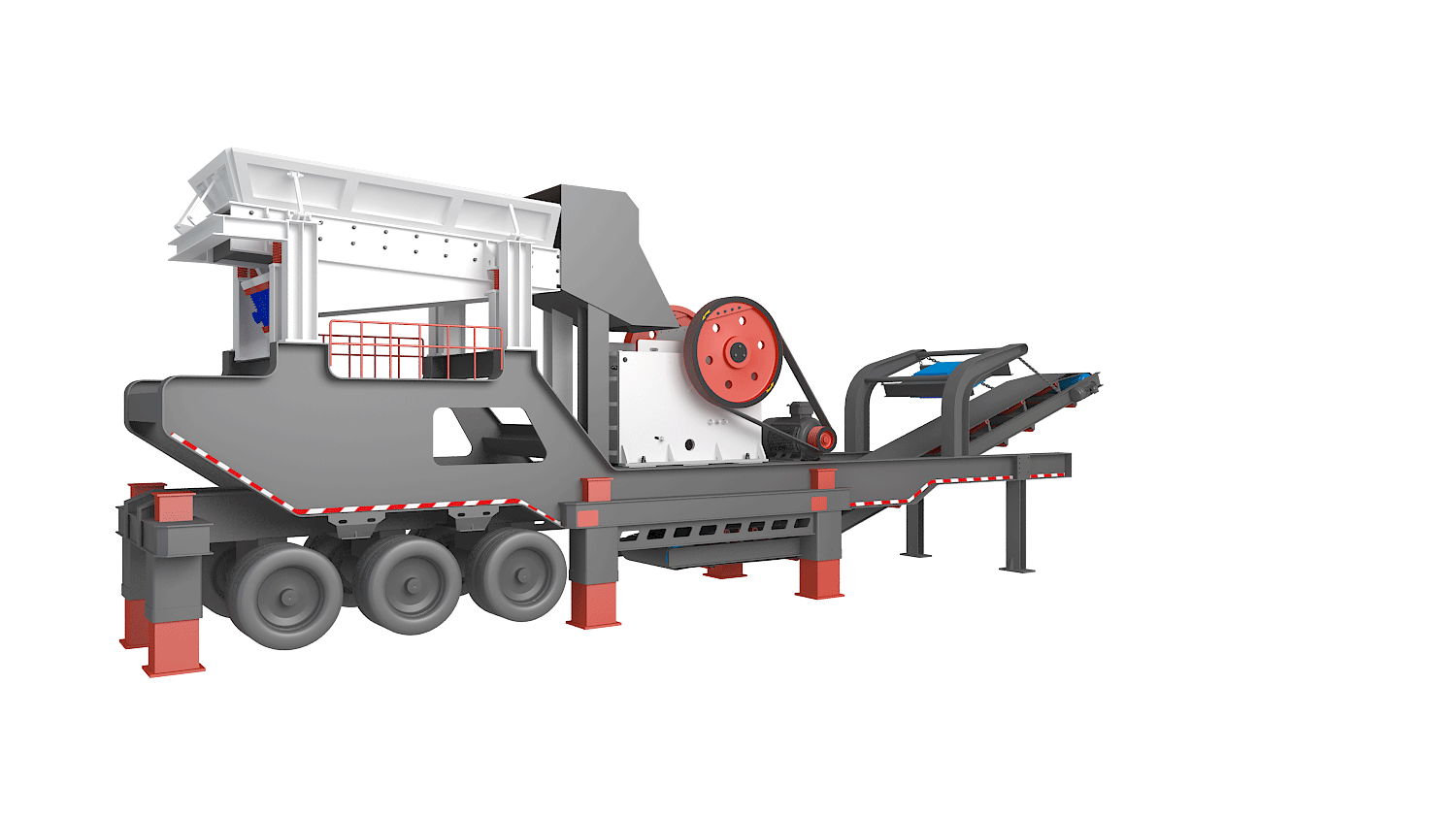

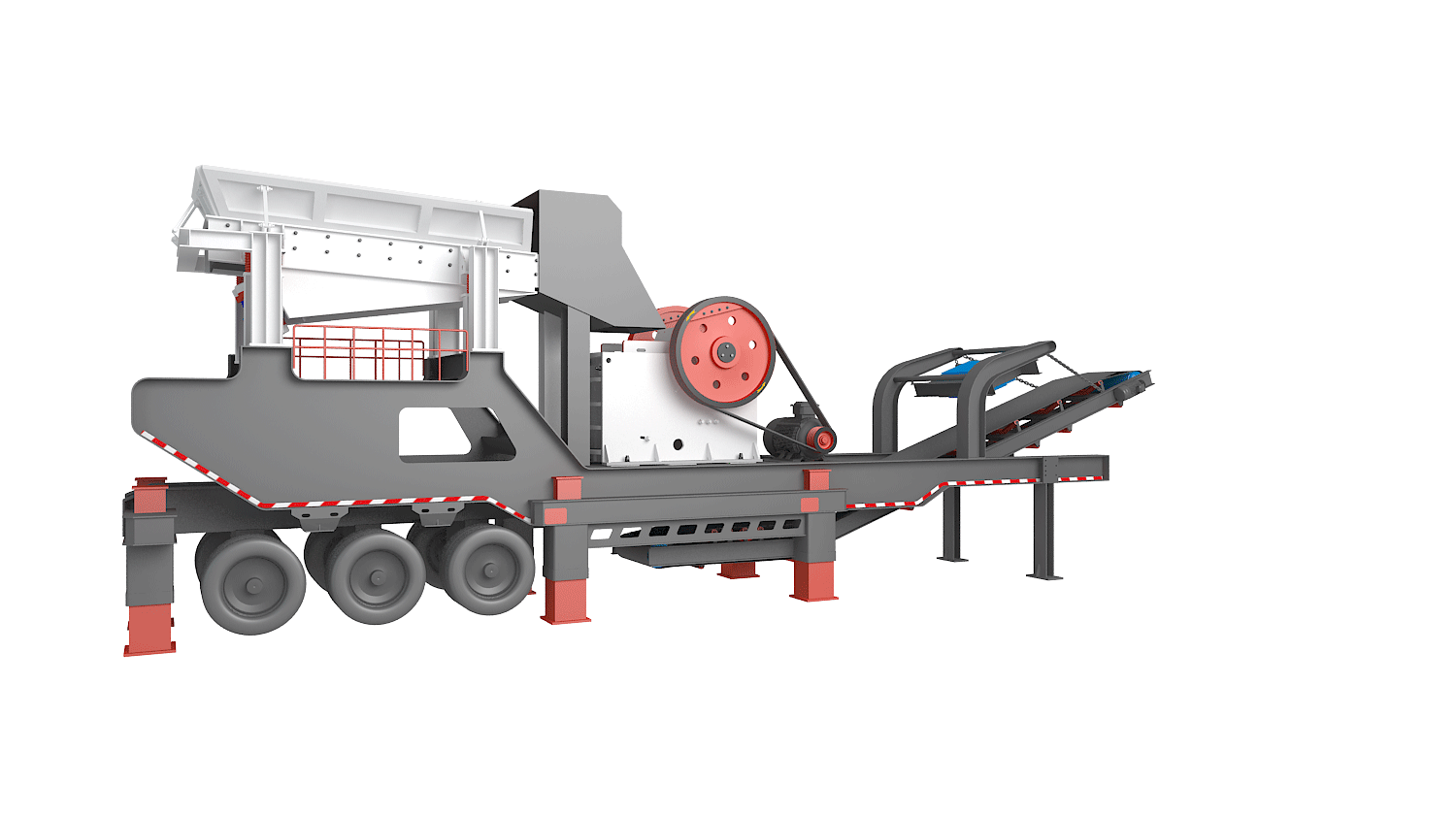

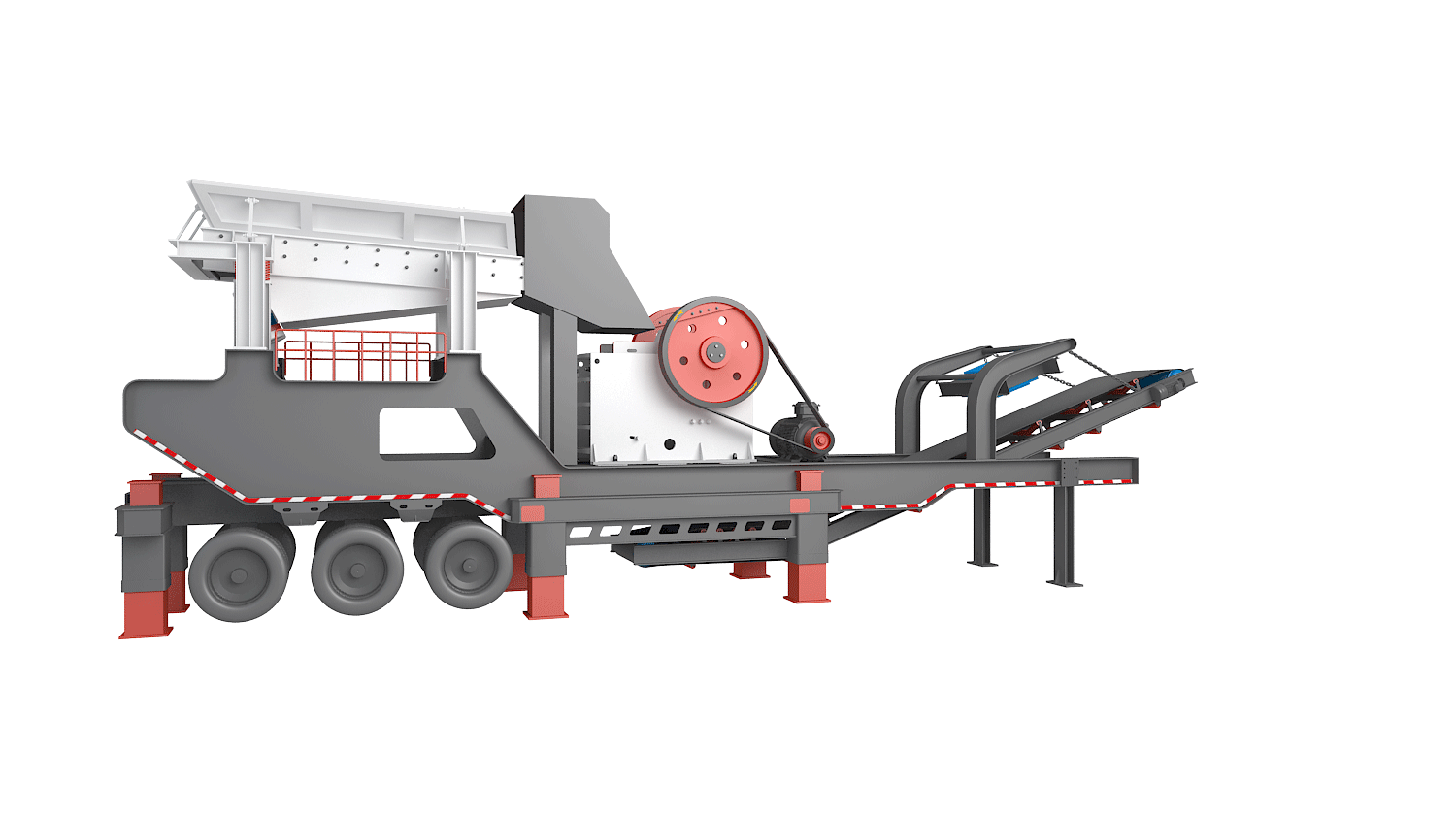

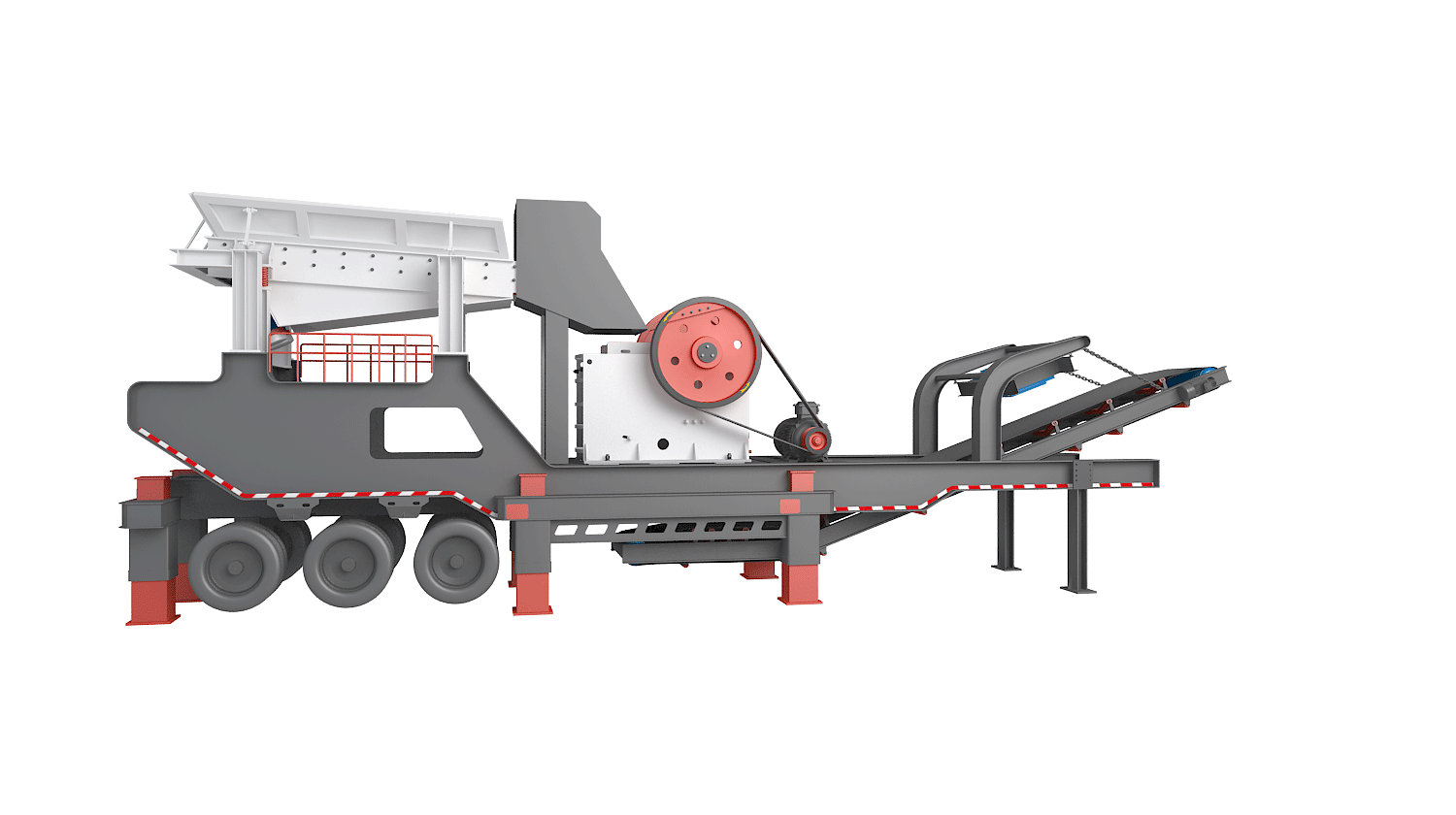

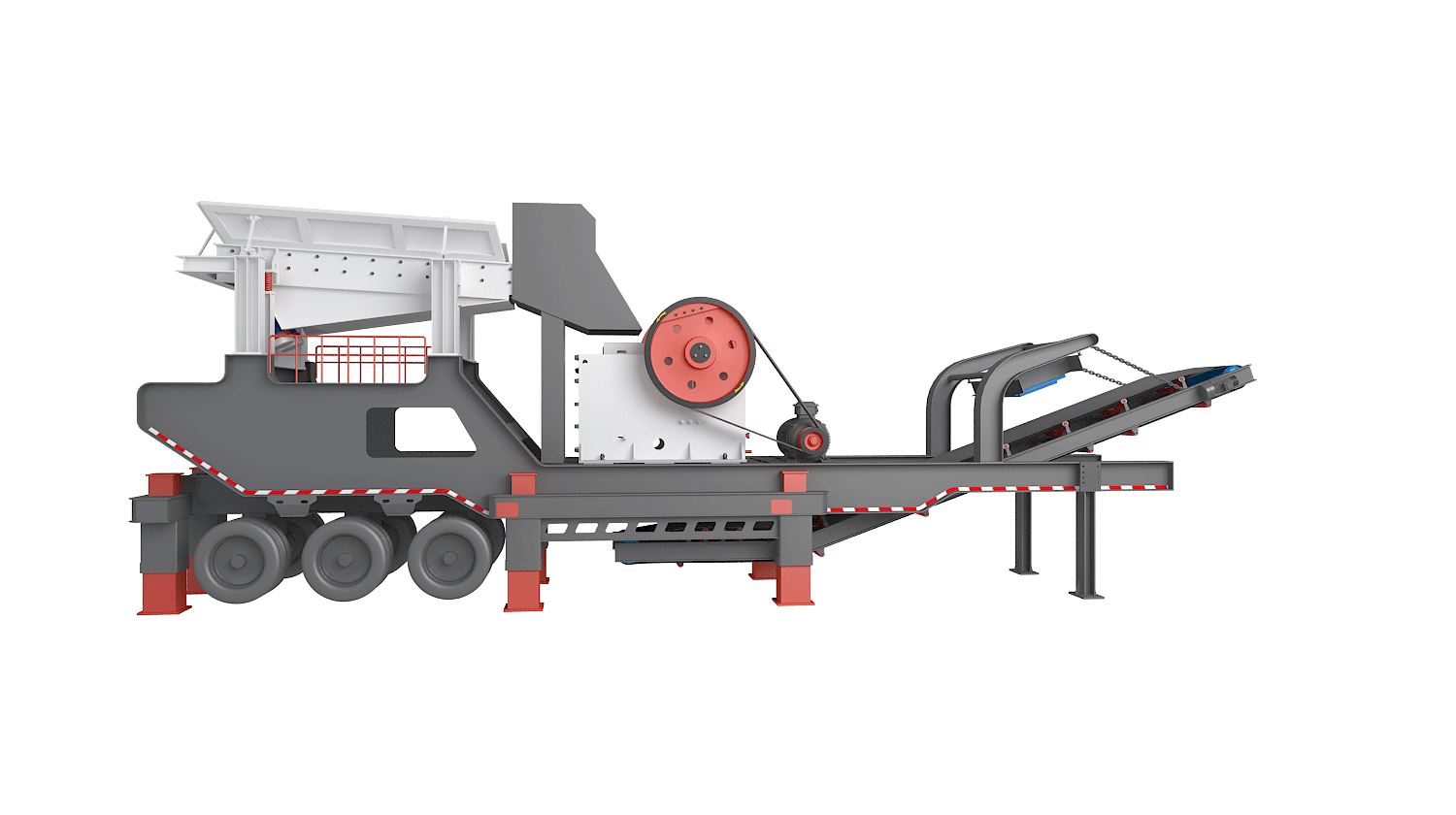

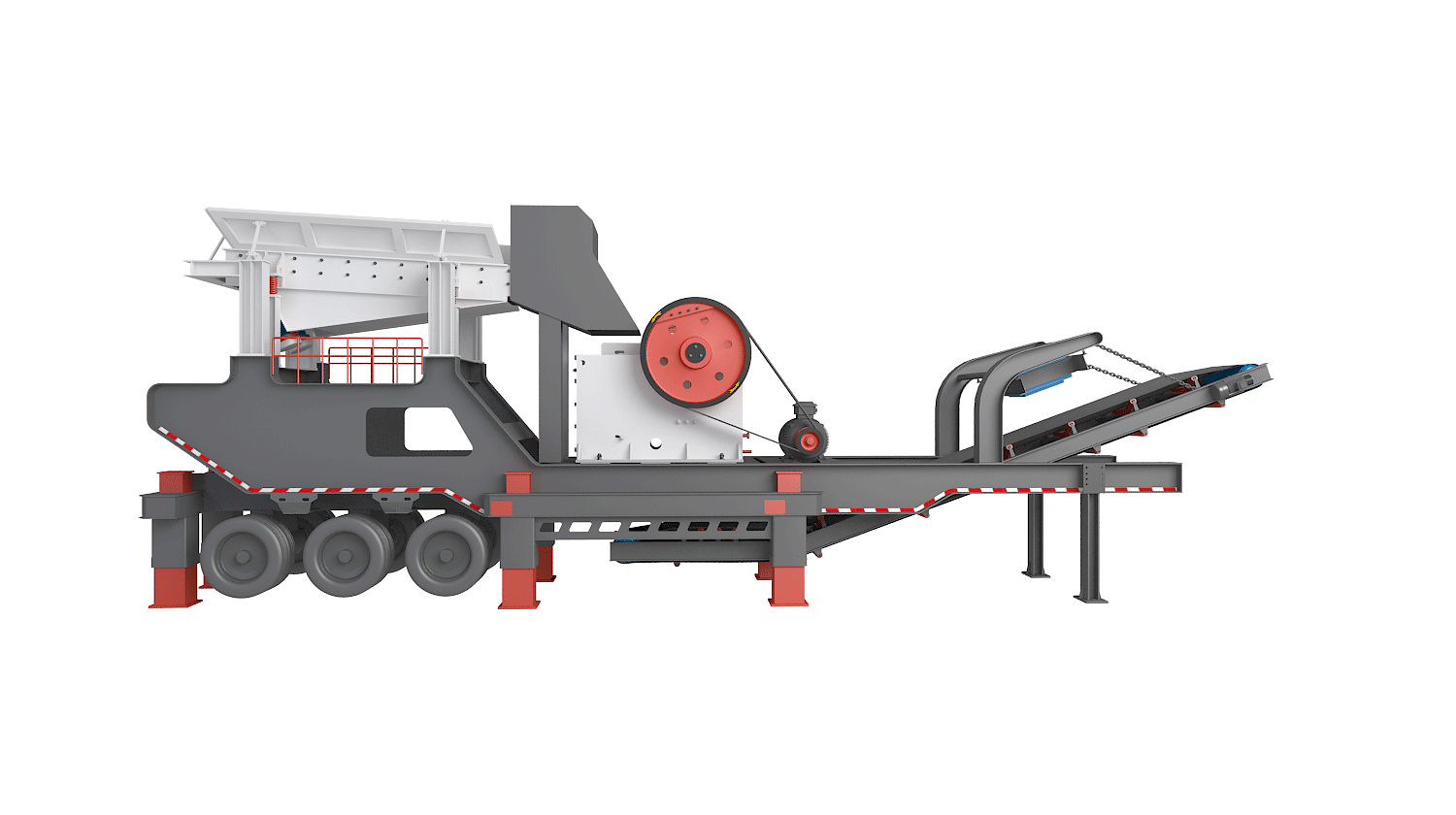

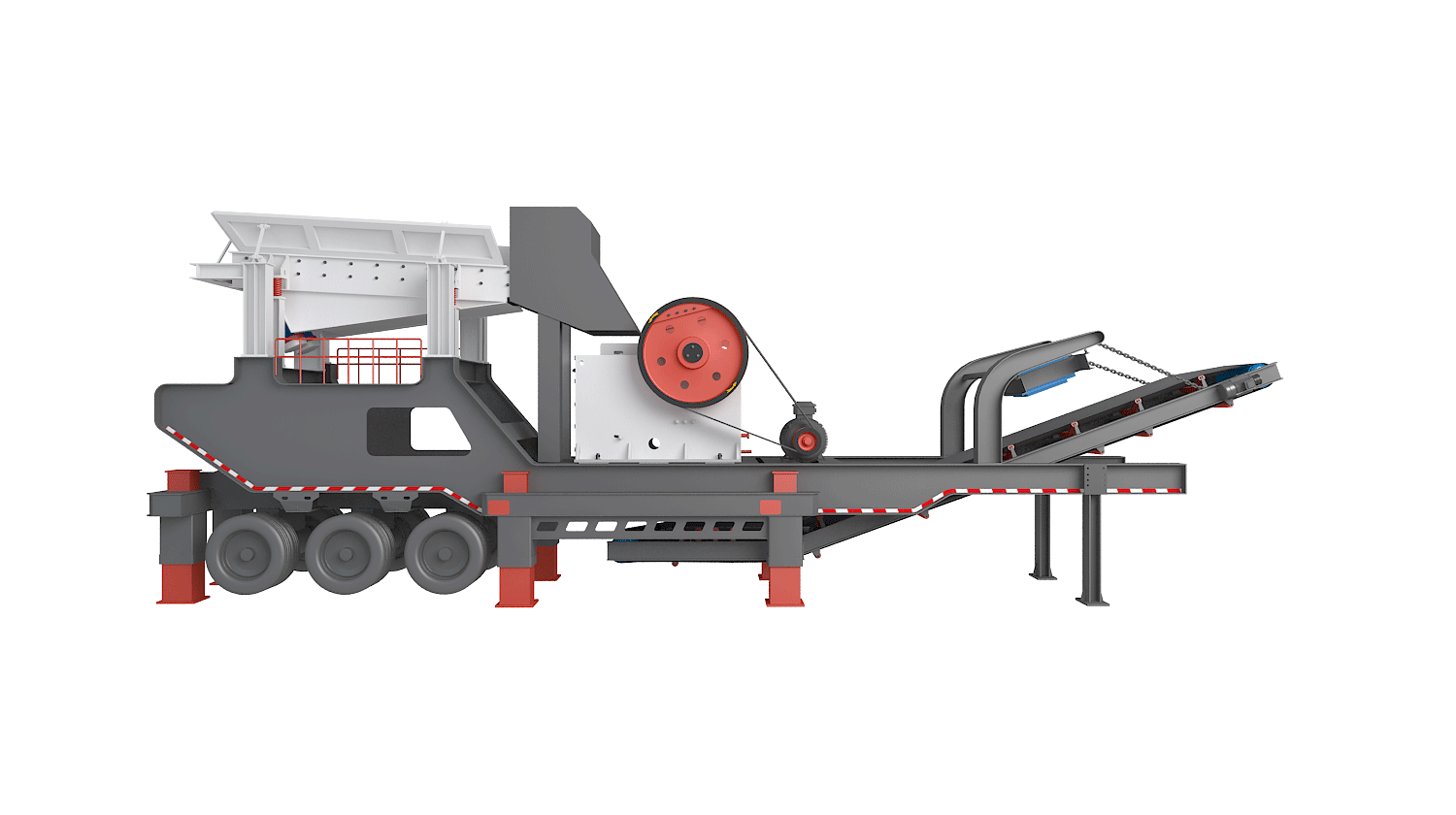

| KPEV69-1 | ZGC1038 | PEV600×900 | ≤500 | 100-180 | ≤100-220 | 13560×2890×4930 |

| KPEV75-1 | ZGC1238 | PEV750×1060 | ≤630 | 100-300 | ≤120-330 | 15340×2920×5370 |

| Standard model | Matching equipment | Feed size (mm) |

Capacity (t/h) |

Complete station capacity (t/h) |

Overall size (mm) |

|

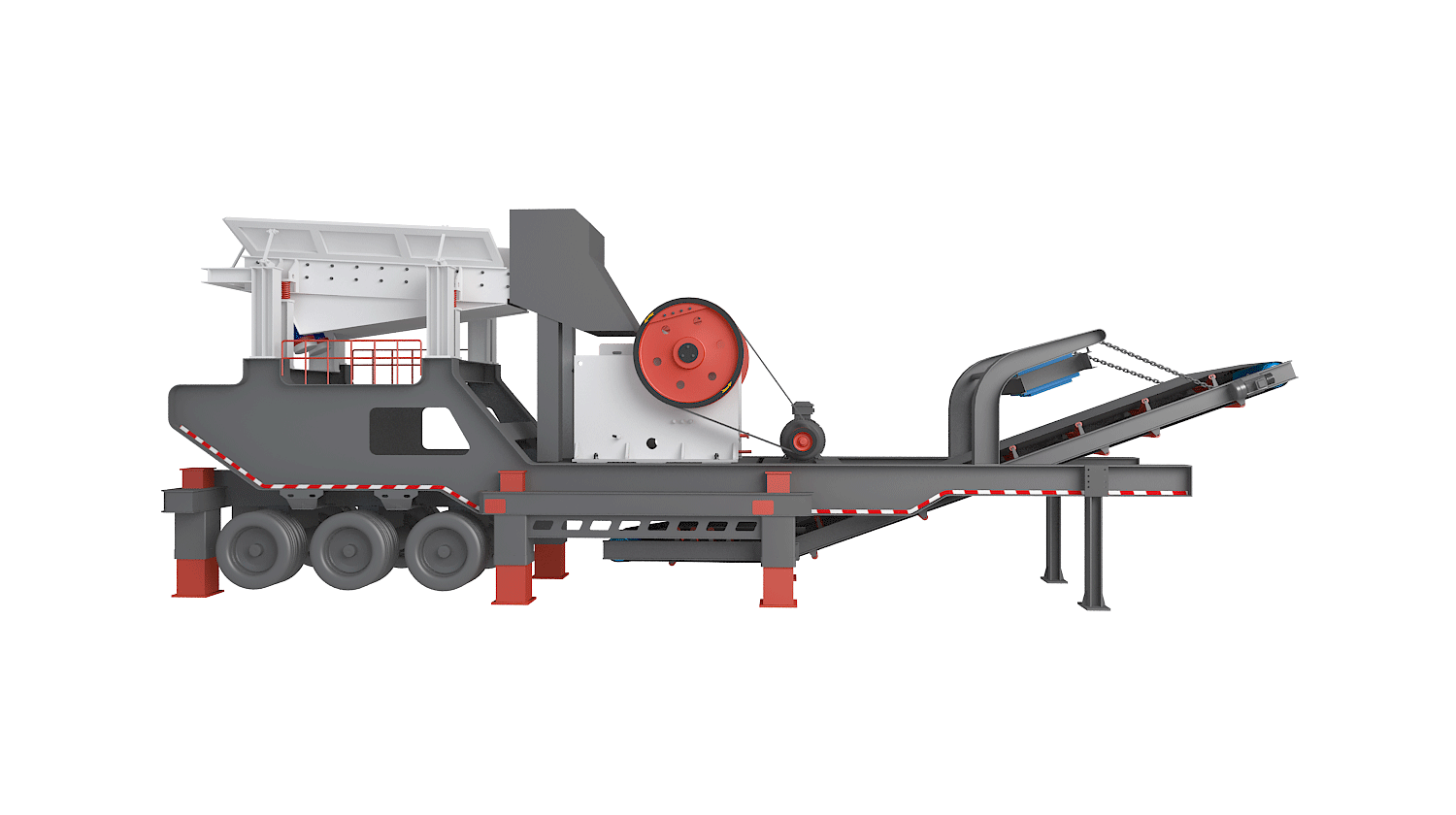

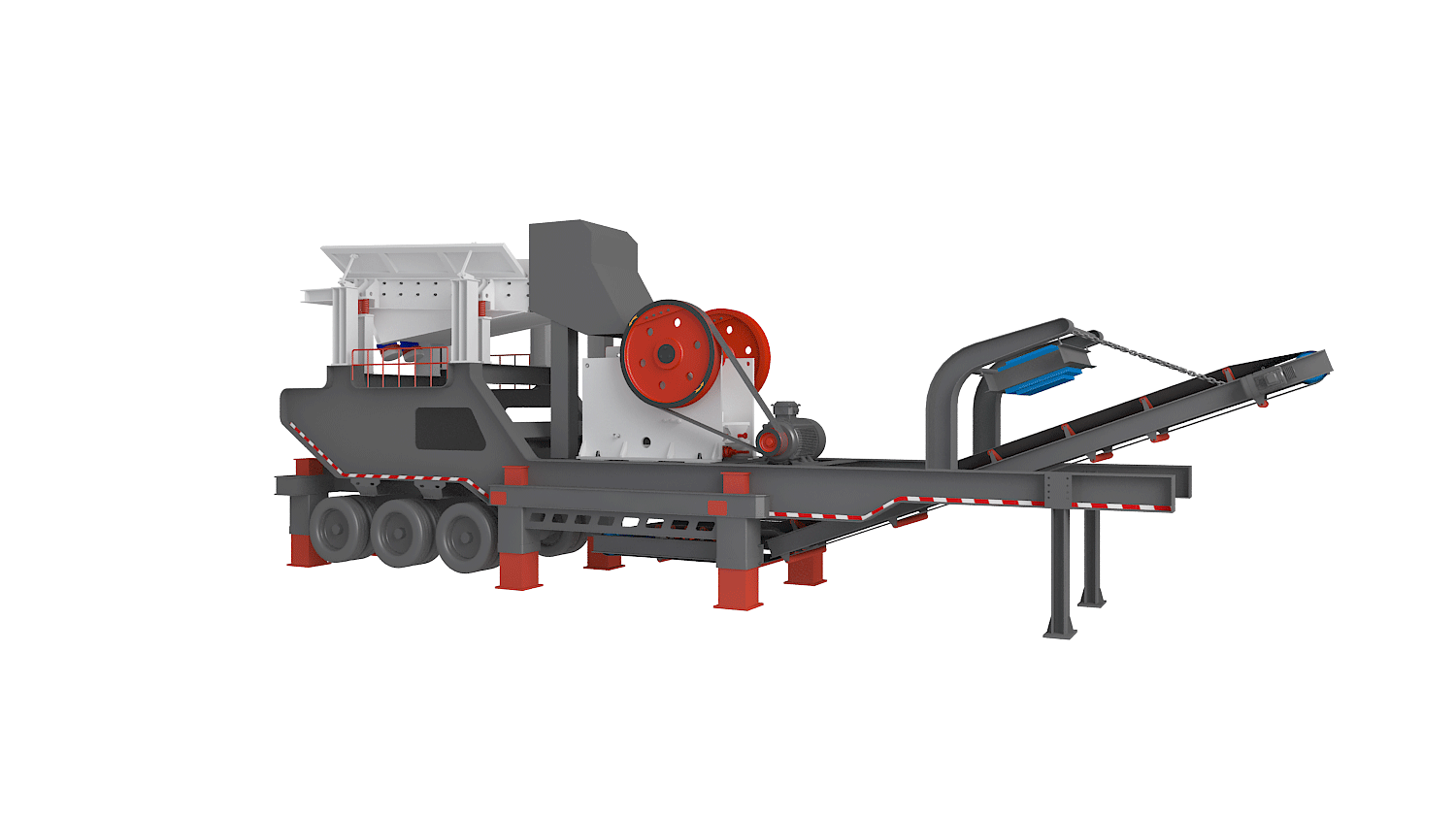

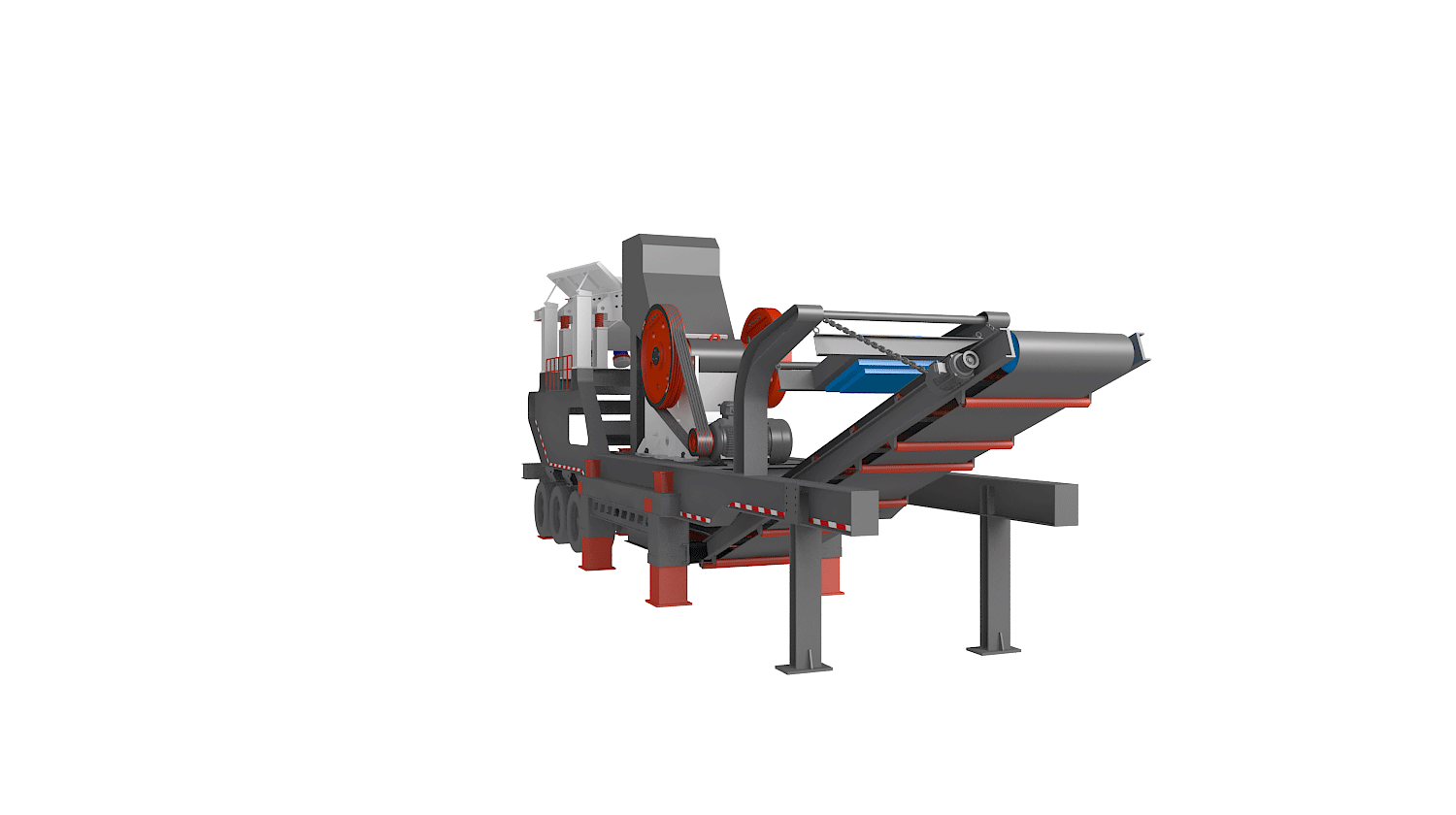

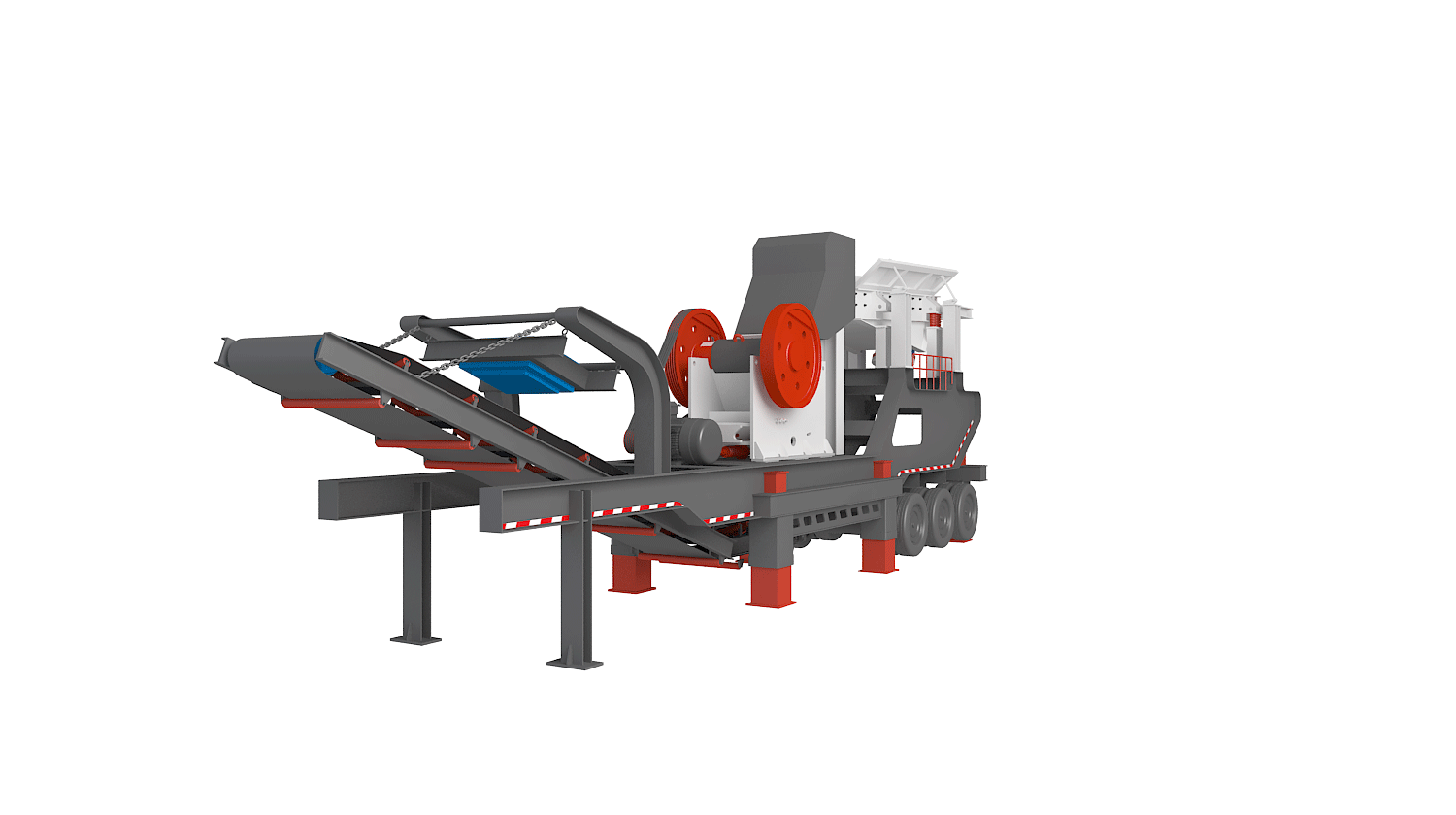

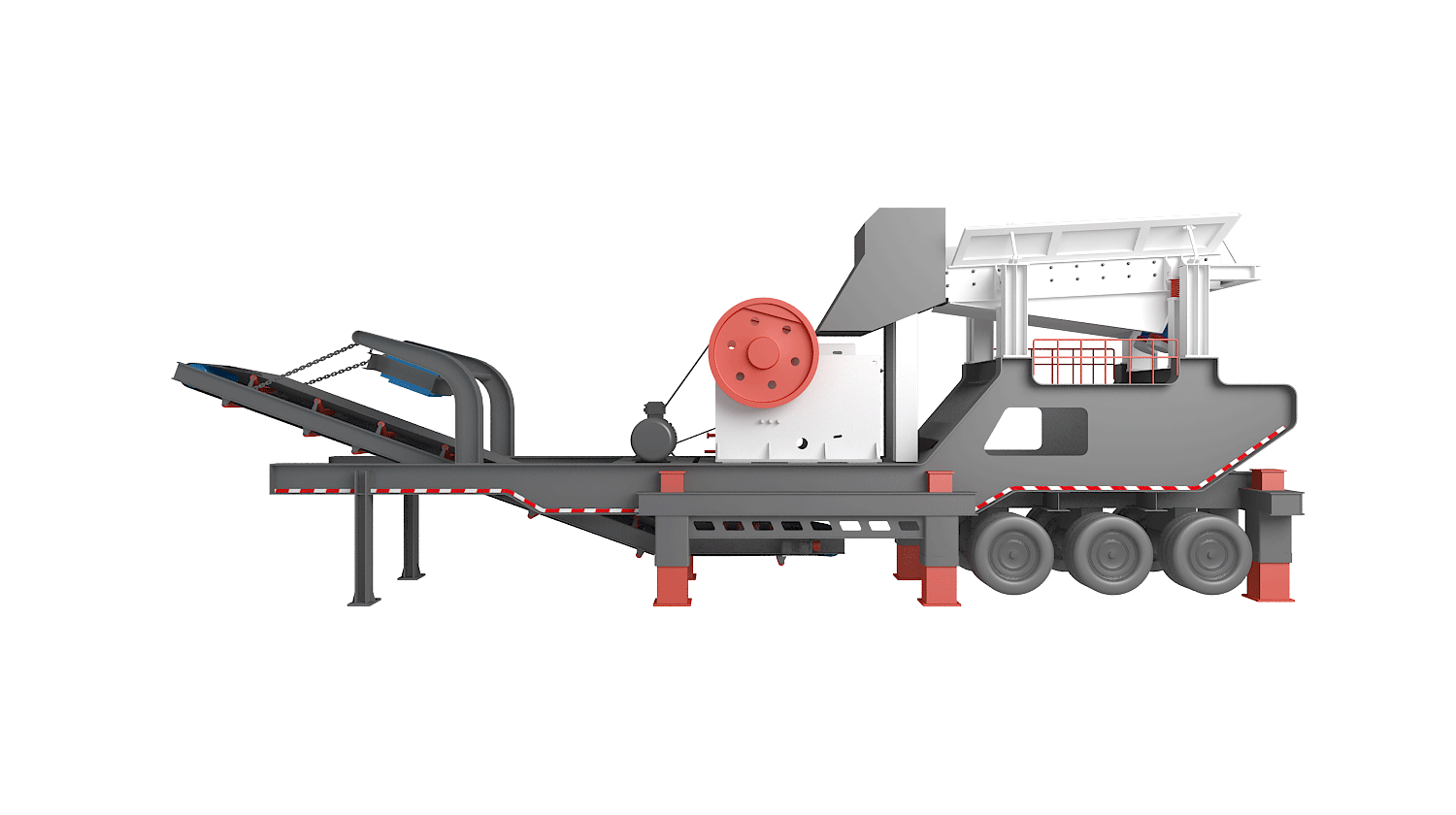

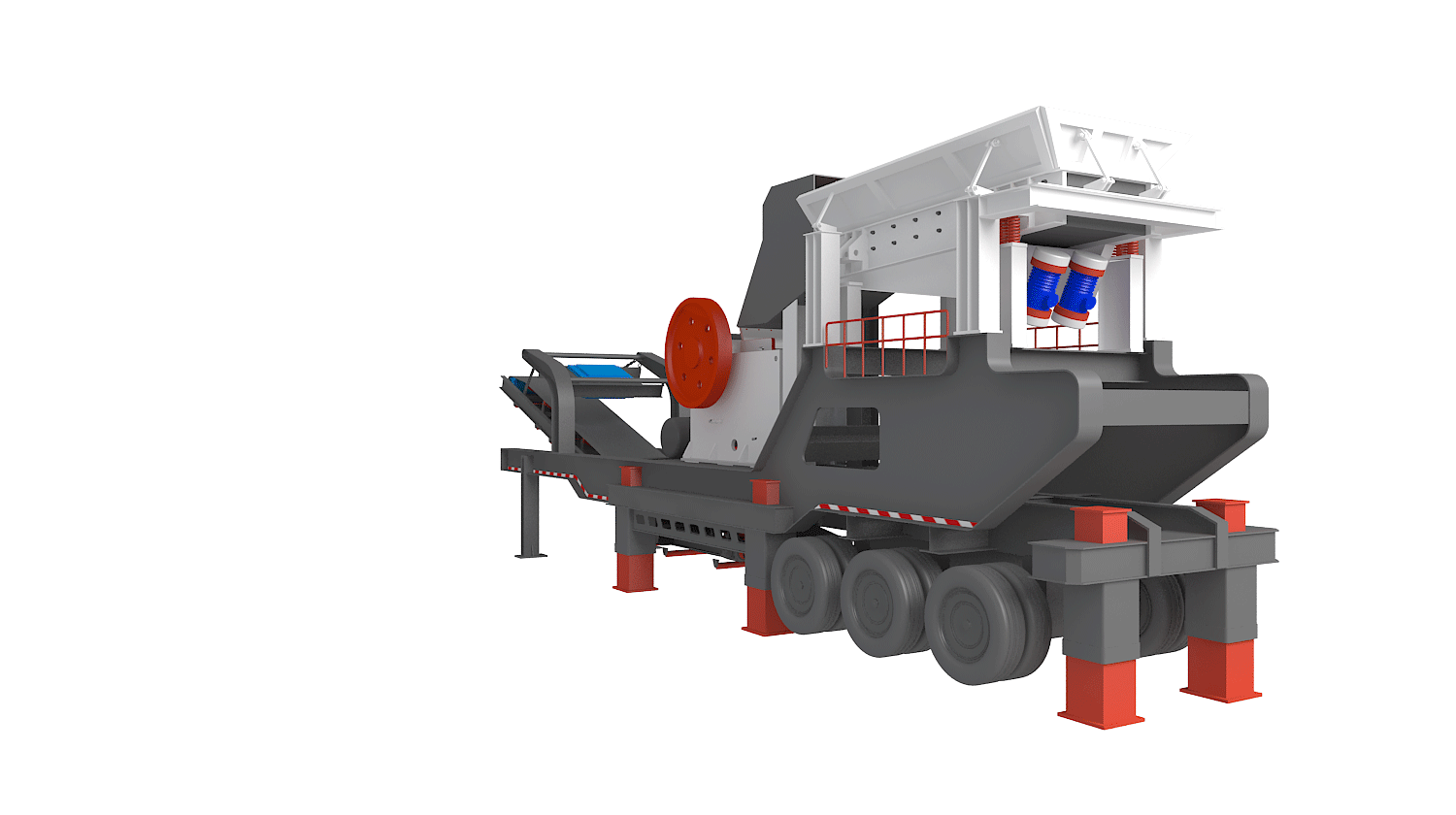

| KHP200 | HP200 | 3YK2160 | 70-190 | - | ≤70-220 | 14640×2920×6470 |

| KHP300 | HP300 | 3YK2470 | 80-200 | - | ≤120-330 | 14790×3050×6660 |

| Standard model | Matching equipment | Feed size (mm) |

Capacity (t/h) |

Complete station capacity (t/h) |

Overall size (mm) |

|

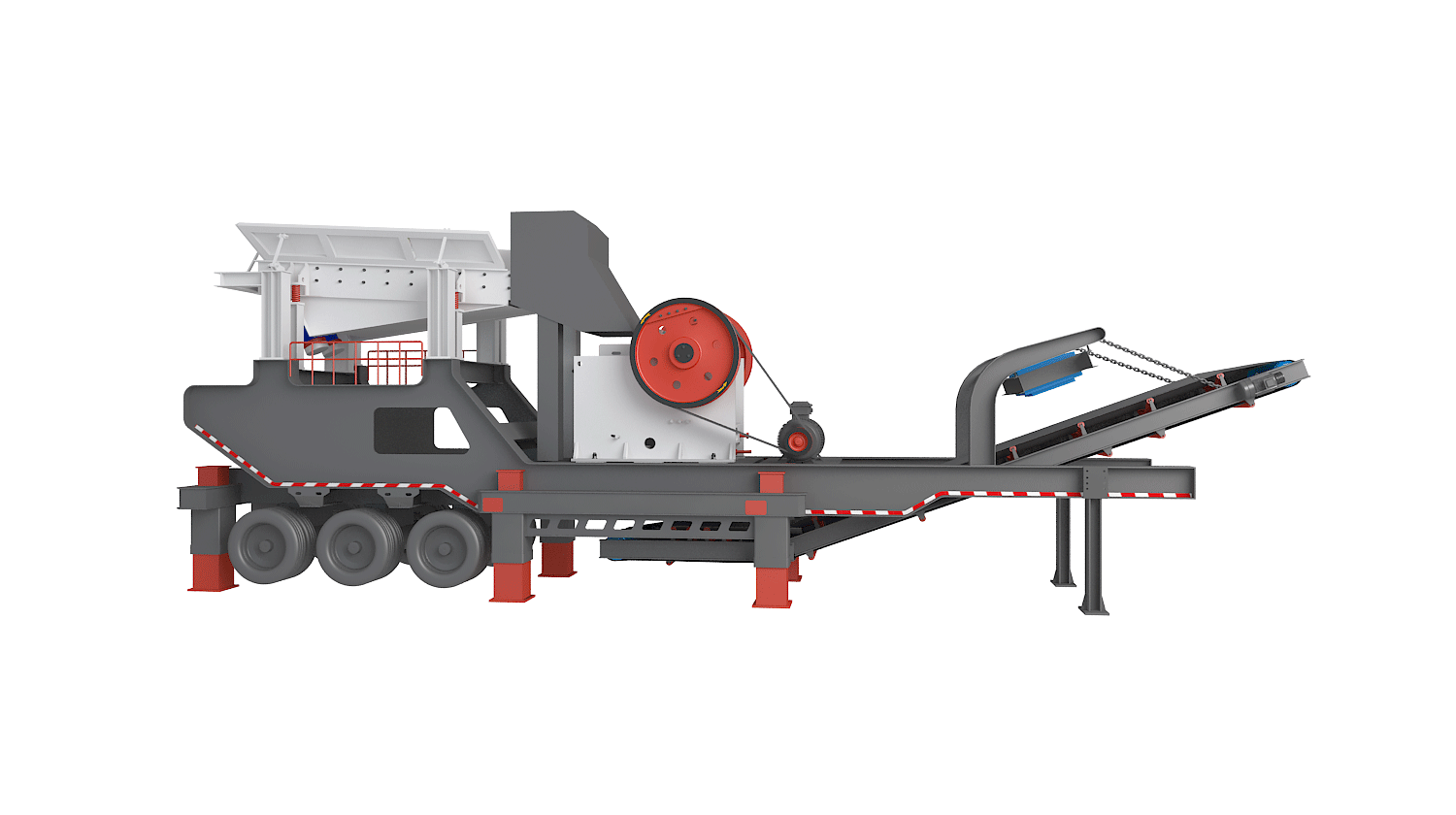

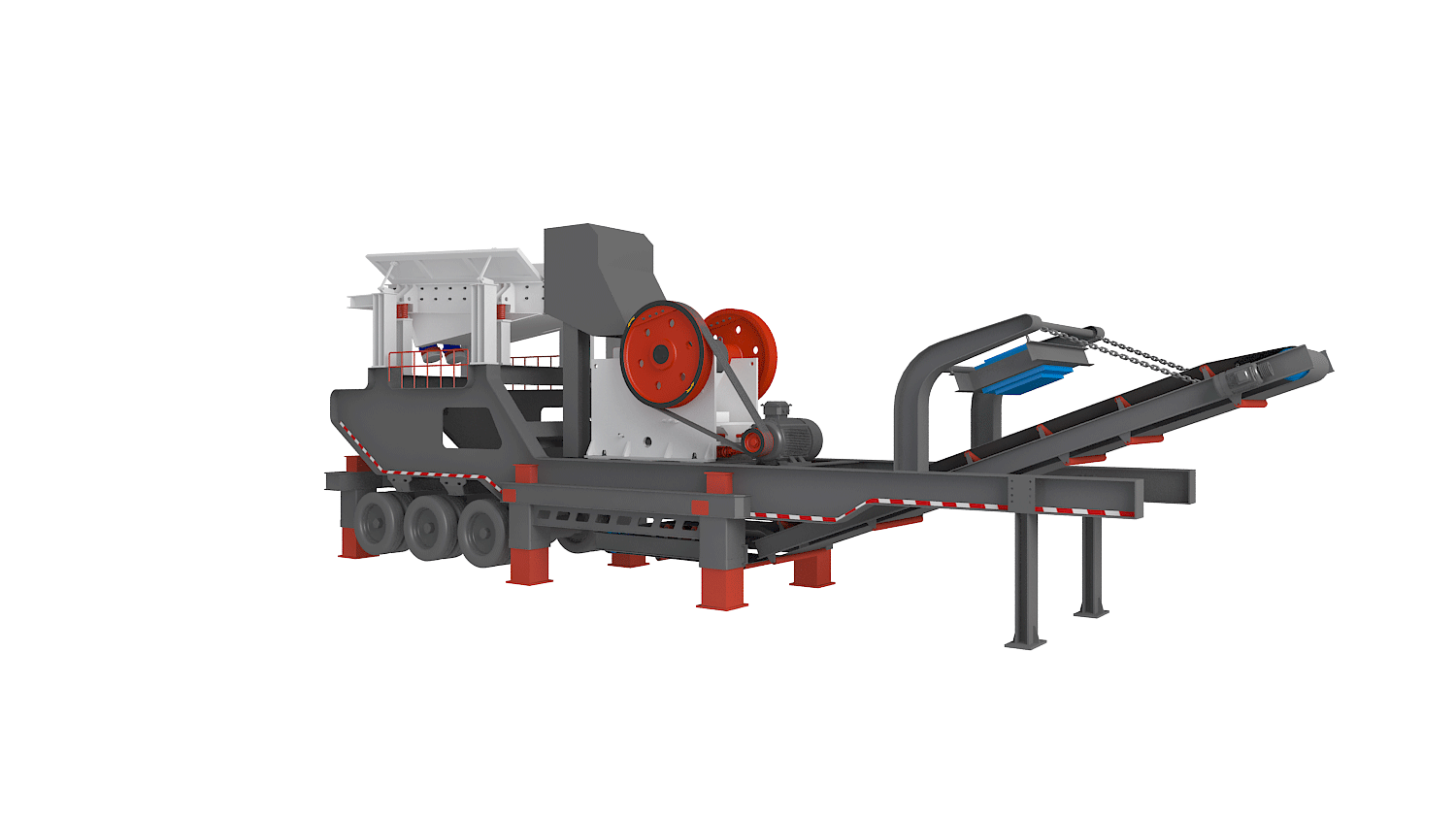

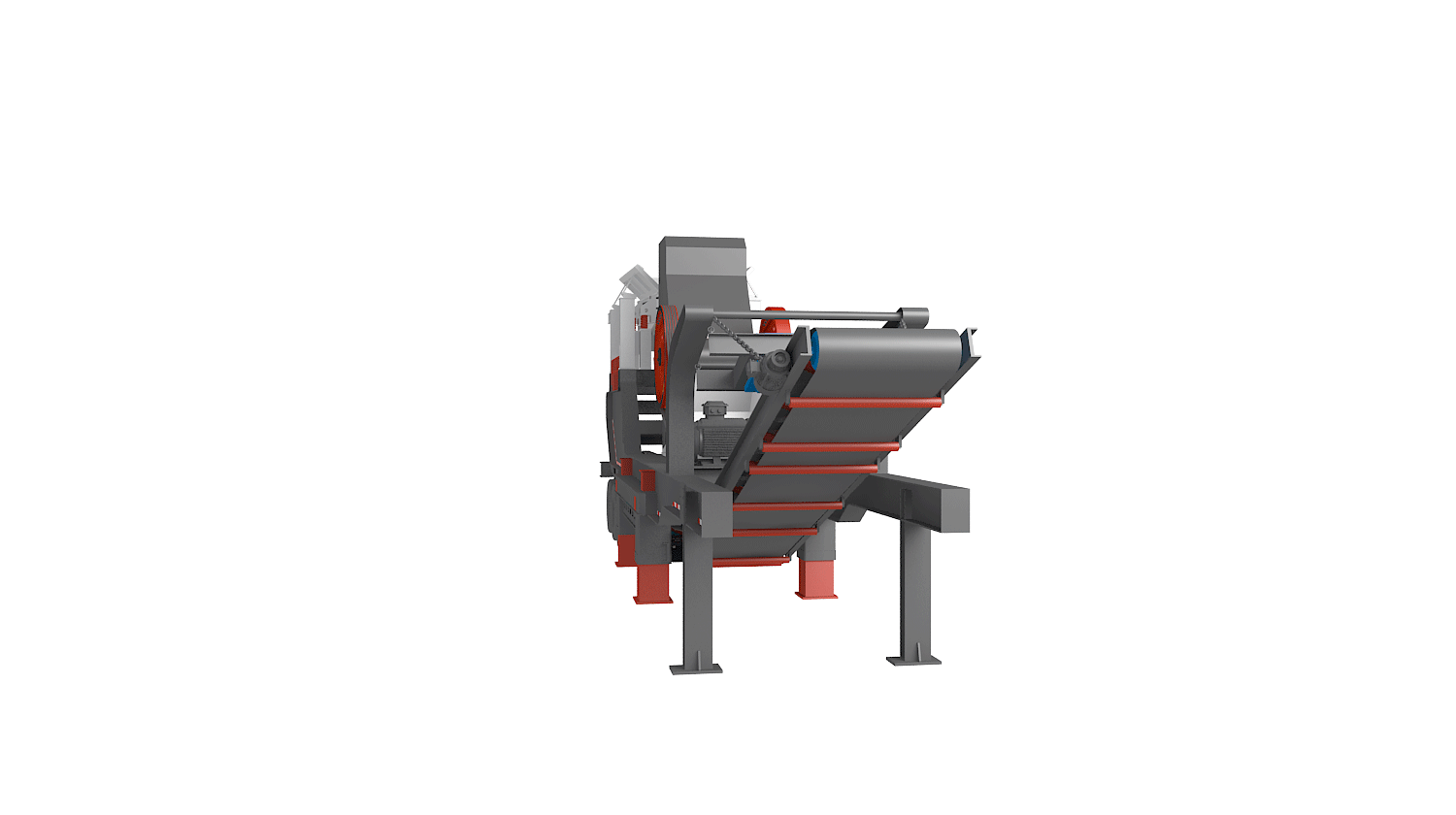

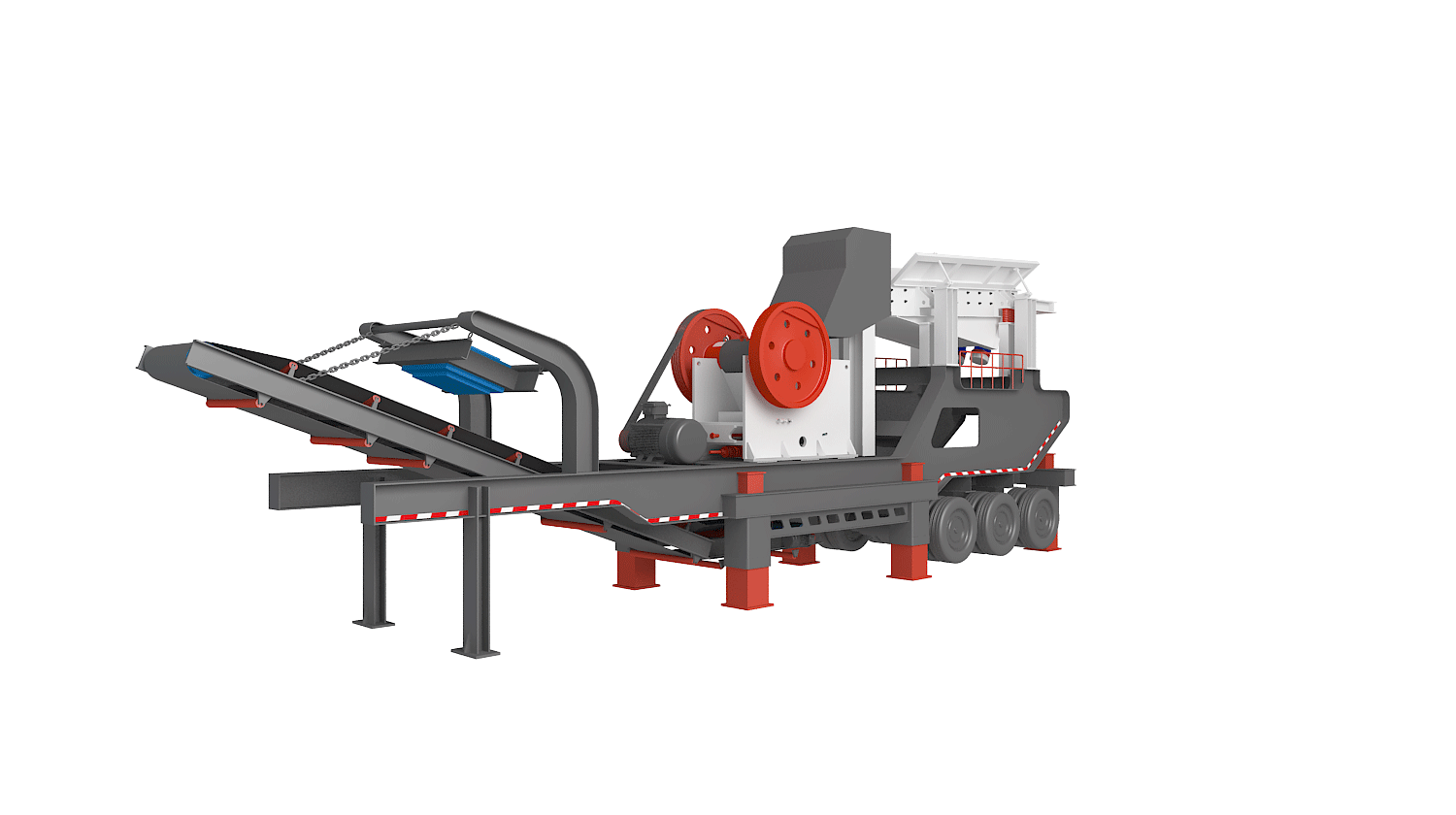

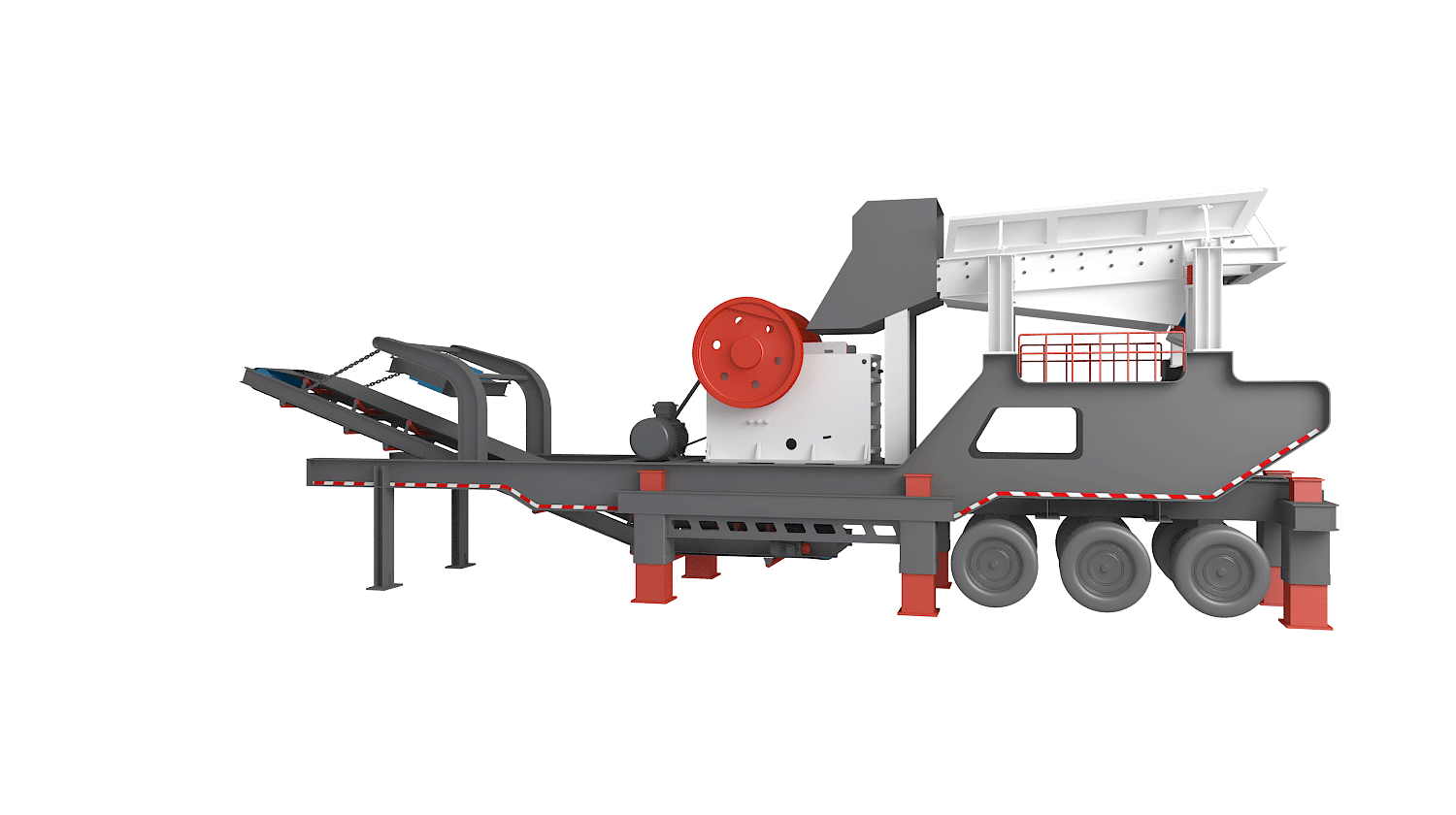

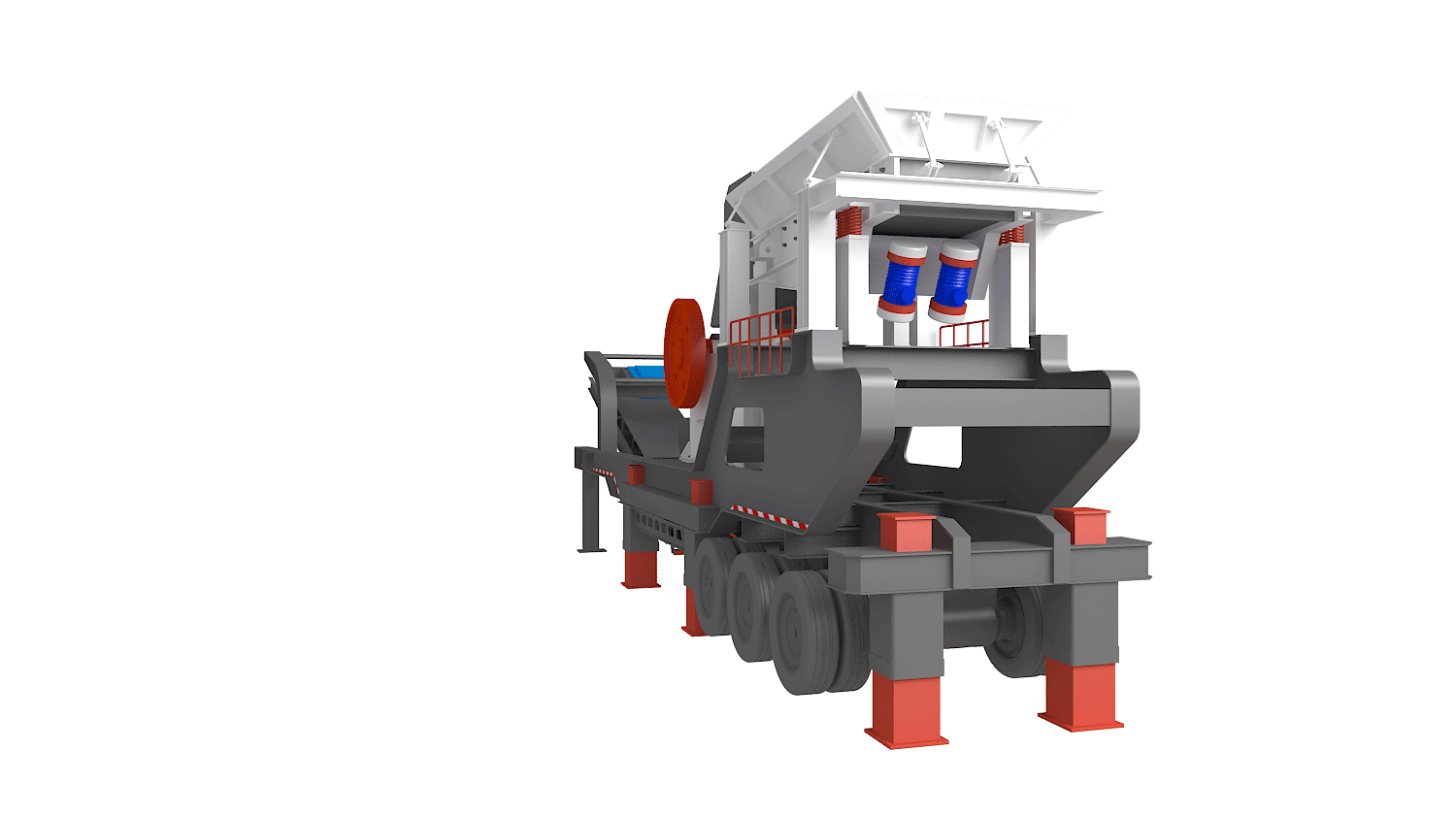

| VSI-9532 | VSI9532 | 2YK2470 | ≤40 | 150-220 | ≤180-250 | 14970×2920×7595 |

| VSI-8522 | VSI8522 | 2YK2160 | ≤40 | 100-120 | ≤100-150 | 14500×2800×7200 |